Extrusion molding adjustable type sealing device

A sealing device and extrusion molding technology, applied in the direction of adjustable connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of high precision requirements, high cost, complex process, etc., and achieve high precision, easy operation, The effect of flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

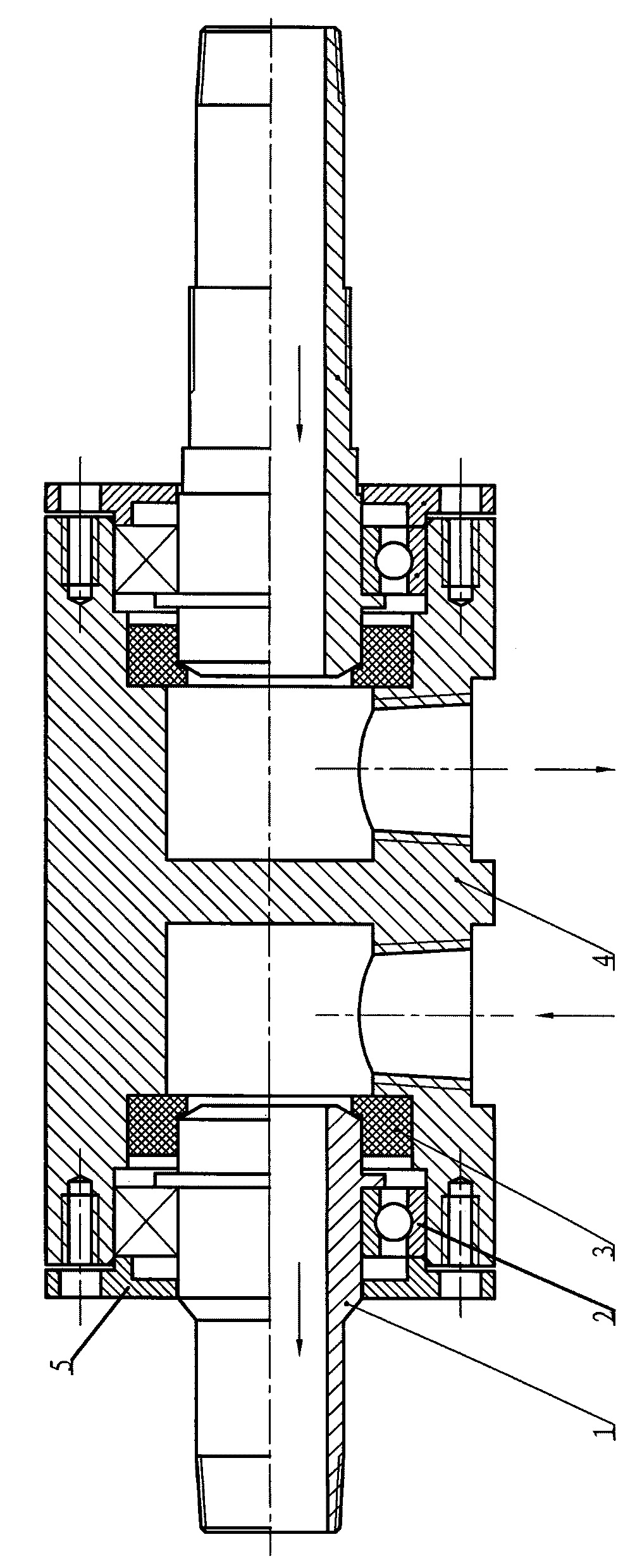

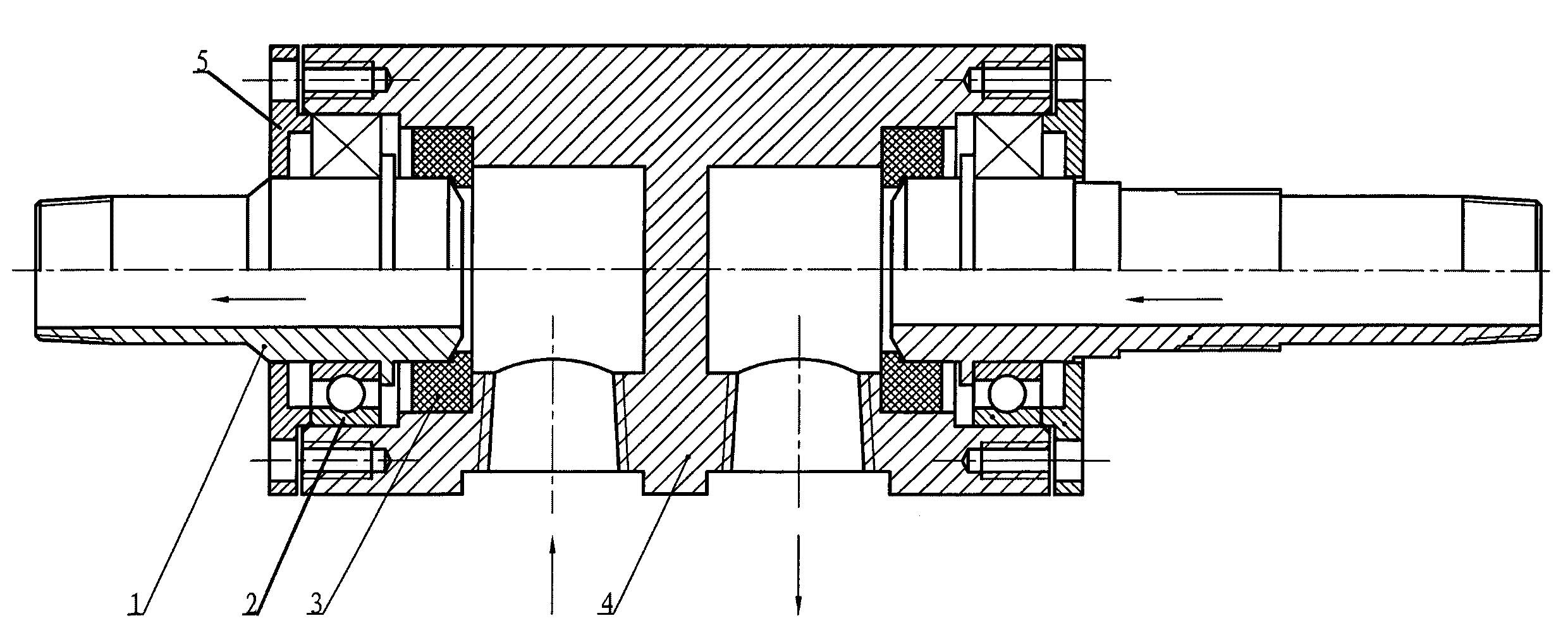

[0010] An extrusion-molded adjustable sealing device, as shown in the attached drawings, is provided with a fluid core tube bearing seat at the end of the seat body 4 with an interface, and a flexible and resistant bearing seat is installed on the step at the inner end of the fluid core tube bearing seat. The sealing ring 3 made of abrasive material is fitted in the bearing hole of the fluid core tube bearing seat through the rolling bearing 2 installed on the fluid core tube 1 through the inner shoulder. To adjust the gap, the cylindrical surface on the inner side of the fluid core tube 1 and the conical surface at the inner end are matched with the sealing surface formed by the sealing ring 3 by extrusion. The outer ring of the rolling bearing 2 is matched, and an adjustment gap is set between the inner end face of the bearing transparent cover 5 and the outer end face of the fluid core tube bearing seat. The fluid core tube 1 is a rotating part, and the base body 4 is a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com