Method for preparing and preventing plug of wide-span case beam rear tension method prestress pore passage

A post-tensioning and prestressing technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of difficult penetration of steel strands, damage of pipe walls, holes formed in iron sheets, etc., and achieve simple construction, earthquake resistance and anti-corrosion Good fatigue performance and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

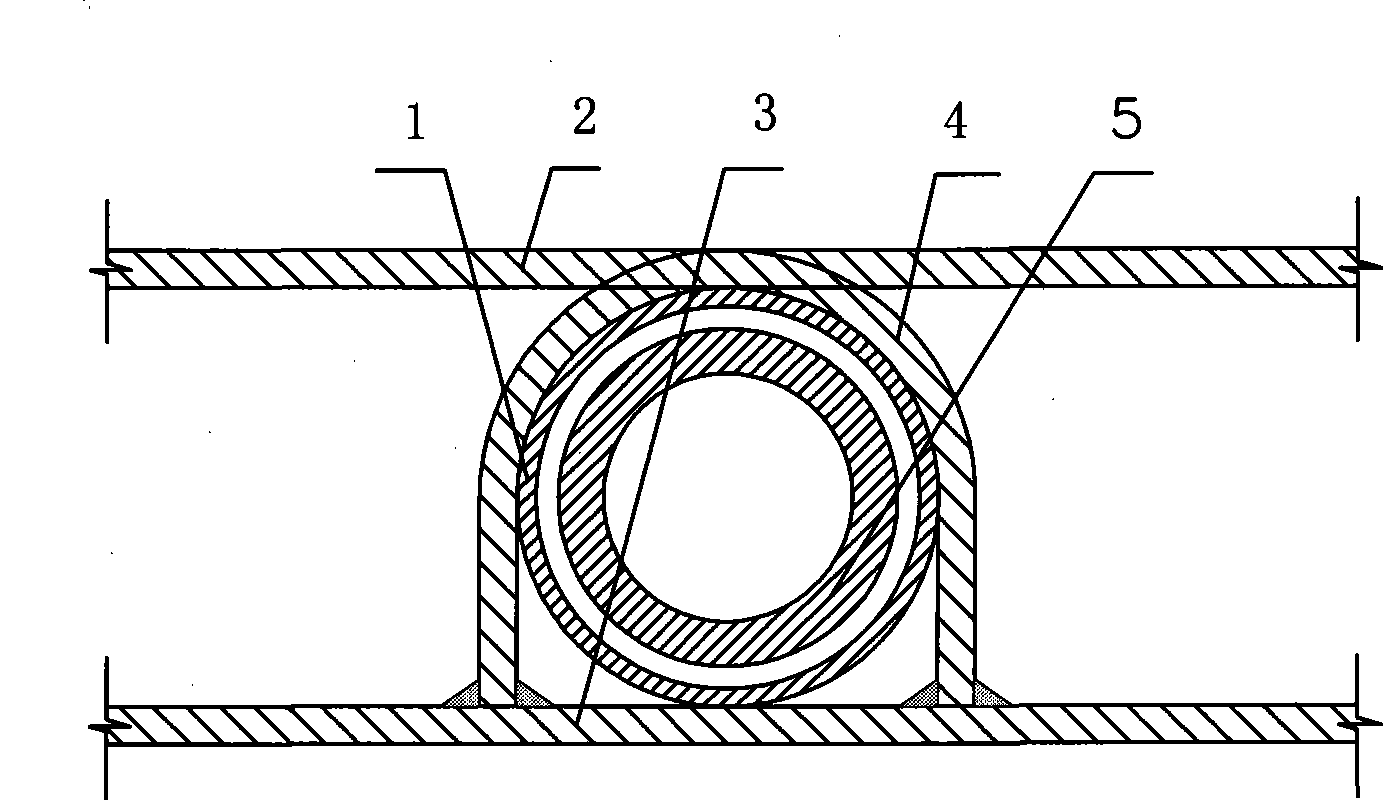

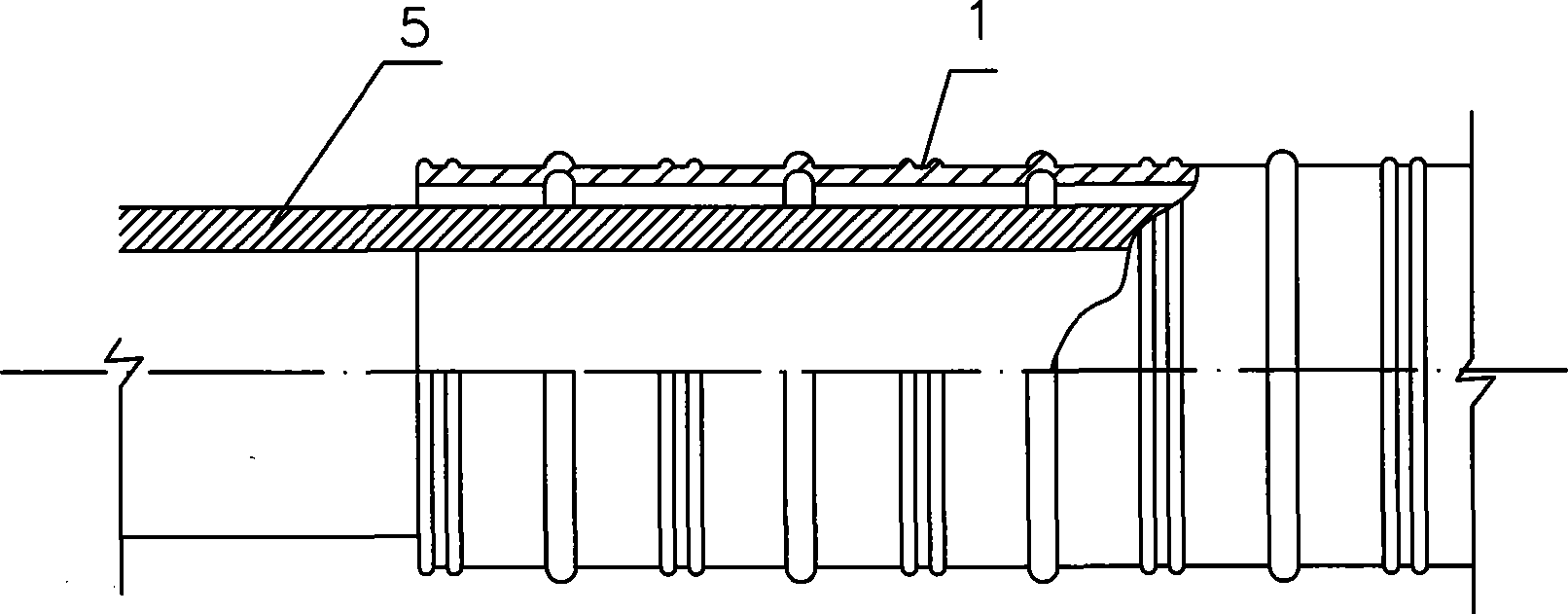

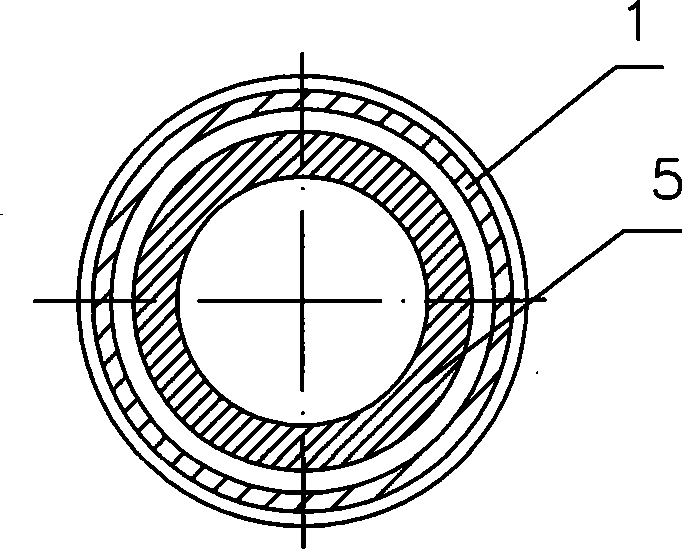

[0021] A. The round plastic corrugated pipe 1 is used as the tunnel pipe, in which the plastic corrugated pipe 1 is made of high-density polyethylene (HDPE) or polypropylene (PP) resin as the main material, extruded at high temperature, and then the two tubes are connected by an outer sleeve. The middle joints of the plastic bellows 1 are connected, the lining is prohibited, and the seal is intact;

[0022] B. Use "U" or "#" type steel bars to make the upper steel frame 2, the lower steel frame 3 and the steel positioning frame 4 between the upper steel frame 2 and the lower steel frame 3, and fix the plastic bellows 1 on The steel bars are positioned within the framework 4 and positioned, and the distance between the positioning grids meets the national norms and design requirements;

[0023] C. Pouring concrete on the plastic bellows 1, the upper steel frame 2, the lower steel frame 3 and the steel frame 4;

[0024] D. After the final setting of the concrete, the post-tensi...

Embodiment 2

[0026] A. The round plastic corrugated pipe 1 is used as the channel pipe, wherein the plastic corrugated pipe 1 is made of high-density polyethylene (HDPE) or polypropylene (PP) resin and extruded at high temperature, and then the two plastic corrugated pipes are sealed by an outer sleeve. The intermediate joints of the bellows 1 are connected, the lining is prohibited, and the seal is intact;

[0027] B. Use "U" or "#" type steel bars to make the upper steel frame 2, the lower steel frame 3 and the steel positioning frame 4 between the upper steel frame 2 and the lower steel frame 3, and fix the plastic bellows 1 on The steel bars are positioned within the framework 4 and positioned, and the distance between the positioning grids meets the national norms and design requirements;

[0028] C. Manually insert the anti-blocking plastic mandrel 5 into the plastic corrugated pipe 1, which can prevent the pipe from being blocked when pouring concrete, and check before the anti-bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com