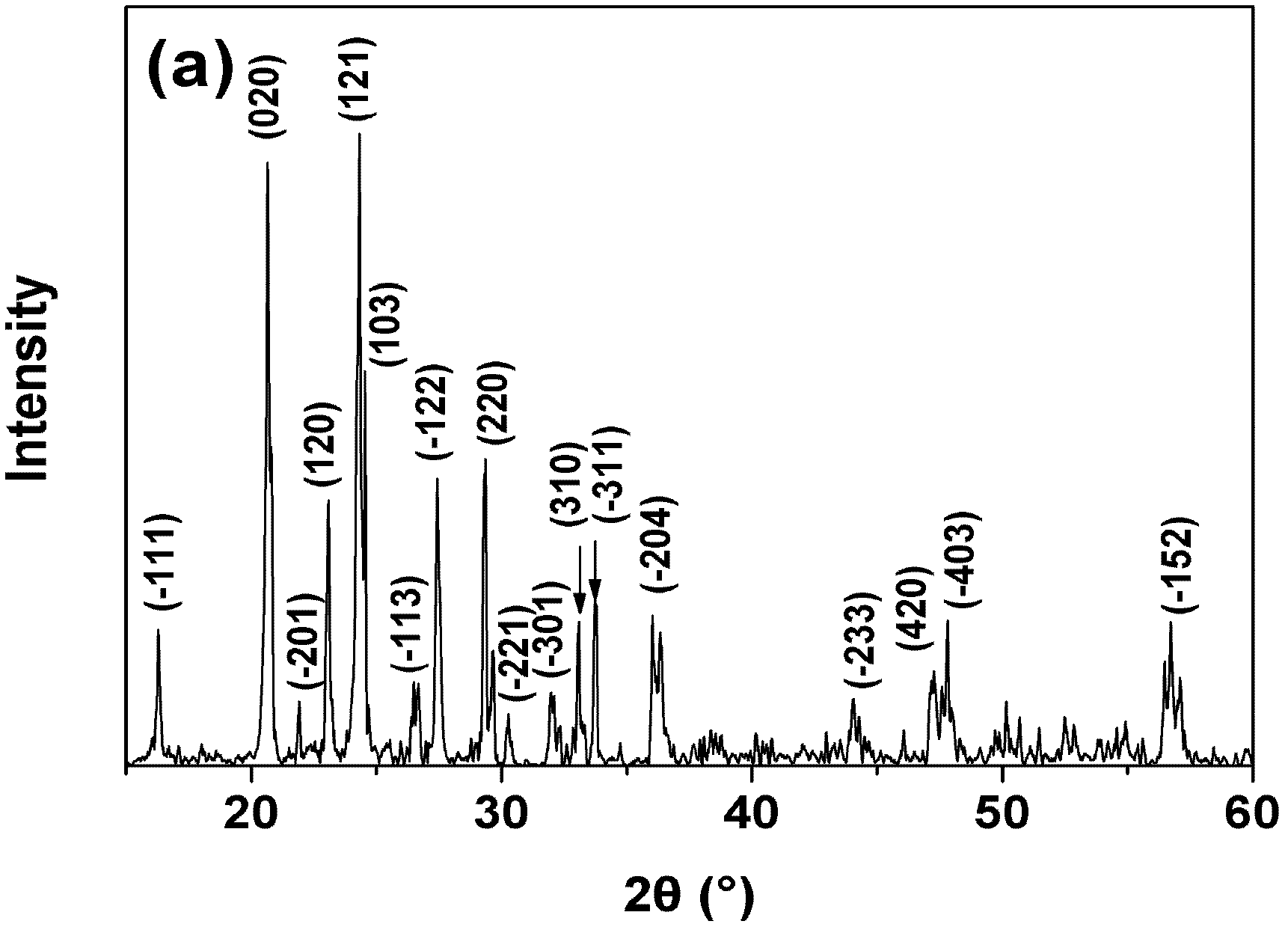

Method for preparing monoclinic lithium vanadium phosphate

A technology of vanadium lithium monoclinic phosphate and phosphoric acid, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of complex sol-gel process, large material particle size, and long calcination time, etc., and achieve large-scale production , small particle size, fast synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing lithium vanadium monoclinic phosphate, comprising the following steps:

[0022] a. Lithium hydroxide (LiOH·H 2 O), ammonium metavanadate (NH 4 VO 3 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and oxalic acid (H 2 C 2 o 4 2H 2 O) Dissolved in 350ml deionized water under mechanical stirring to form solution I, wherein calculated according to the amount of substance, n Li :n V :n PO4 3- =3.0:2:3, n V :n 草酸 =1:3;

[0023] b. Dissolve 1 g of citric acid in 50 mL of deionized water under ultrasonic dispersion to obtain solution II;

[0024] c. In a water bath at 70°C, under vigorous stirring, slowly add solution II to solution I dropwise to obtain solution III;

[0025] d. React the solution III obtained in step c in a water bath at 70°C for 3 hours to obtain solution IV;

[0026] e. Dissolve the acrylamide monomer and N,N'-methylenebisacrylamide crosslinking agent in solution IV under stirring, then raise the temperature of the w...

Embodiment 2

[0030] A method for preparing lithium vanadium monoclinic phosphate, comprising the following steps:

[0031] a. Lithium acetate (CH 3 COOLi·2H 2 O), ammonium metavanadate (NH 4 VO 3 ), phosphoric acid (H 3 PO 4 ) and oxalic acid (H 2 C 2 o 4 2H 2 O) Dissolved in 350ml deionized water under mechanical stirring to form solution I, wherein calculated according to the amount of substance, n Li :n V :n PO4 3- =3.05:2:3, n V :n 草酸 =1:3.5;

[0032] b. Dissolve 1 g of glycine in 70 mL of deionized water under ultrasonic dispersion conditions to obtain solution II;

[0033] c. In a water bath at 70°C, under vigorous stirring, slowly add solution II to solution I dropwise to obtain solution III;

[0034] d. React the solution III obtained in step c in a water bath at 70°C for 3 hours to obtain solution IV;

[0035] e. Dissolve the acrylamide monomer and N,N'-methylenebisacrylamide crosslinking agent in solution IV under stirring, then raise the temperature of the water...

Embodiment 3

[0039] A method for preparing lithium vanadium monoclinic phosphate, comprising the following steps:

[0040] a. Lithium acetate (CH 3 COOLi·2H 2 O), vanadium pentoxide (V 2 o 5 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and oxalic acid (H 2 C 2 o 4 2H 2 O) Dissolved in 400ml deionized water under mechanical stirring to form solution I, wherein calculated according to the amount of substance, n Li :n V :n PO4 3- =3.1:2:3,n V :n 草酸 =1:4;

[0041] b. Dissolve 1.5g of glycine in 70mL of deionized water under the condition of ultrasonic dispersion to obtain solution II;

[0042] c. In a water bath at 75°C, under vigorous stirring, slowly add solution II to solution I dropwise to obtain solution III;

[0043] d. React solution III obtained in step c in a water bath at 75°C for 2 hours to obtain solution IV;

[0044] e. Dissolve the acrylamide monomer and N,N'-methylenebisacrylamide crosslinking agent in solution IV under stirring, then raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com