Improved coal sliding tube anti-blocking structure

An improved technology for sliding coal pipes, applied in the field of circulating fluidized bed boiler equipment, can solve problems such as coal blocking, furnace shutdown, and inability to start transportation, so as to reduce investment and maintenance costs, solve the problem of coal blocking, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

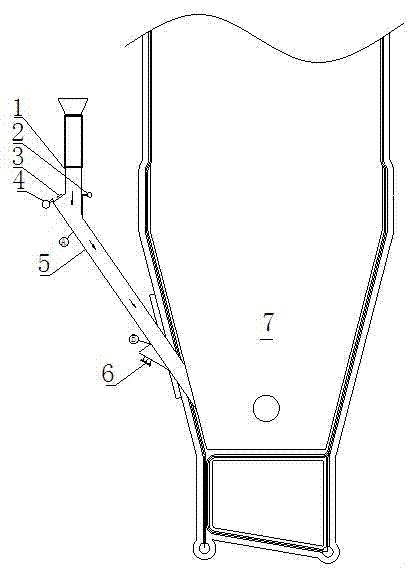

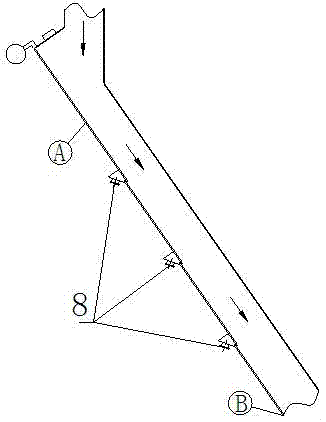

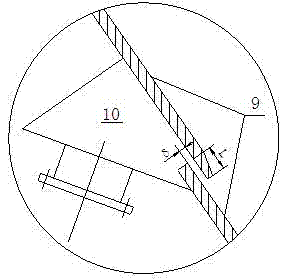

[0020] An improved anti-blocking structure for coal-sliding pipes, such as figure 2 As shown, the coal-sliding pipe 1 can be roughly divided into two sections according to its shape, that is, a vertical section and an inclined section 5. The cross section of the inclined section is square, and the joints of the vertical section and the inclined section 5 are respectively provided with coal conveying air ports 4 on the left and right. With the auxiliary coal delivery air interface 2, the bottom of the inclined section 5 and the junction of the furnace 7 are provided with a coal broadcasting air interface 6, and the inclined section 5 and the vertical section junction are provided with a fire sight glass 3. The emphasis of the present invention is that according to The length of the coal-sliding pipe 1, the bottom plate of the coal-sliding pipe 1 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com