Apparatus and method for detecting damage to a machine

A kind of equipment and machine technology, applied in the direction of machine/structural component testing, instruments, measuring devices, etc., can solve problems such as structural damage and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

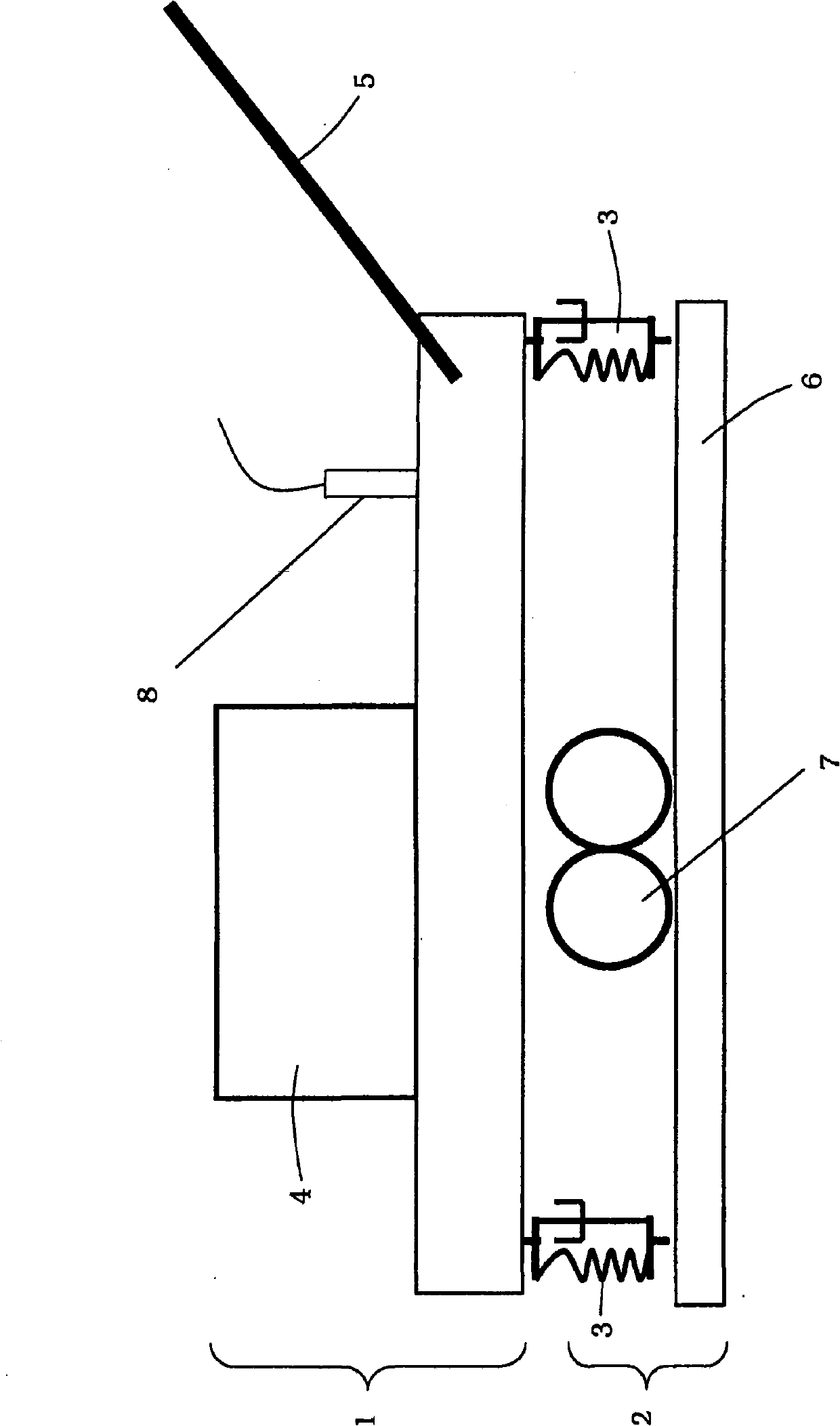

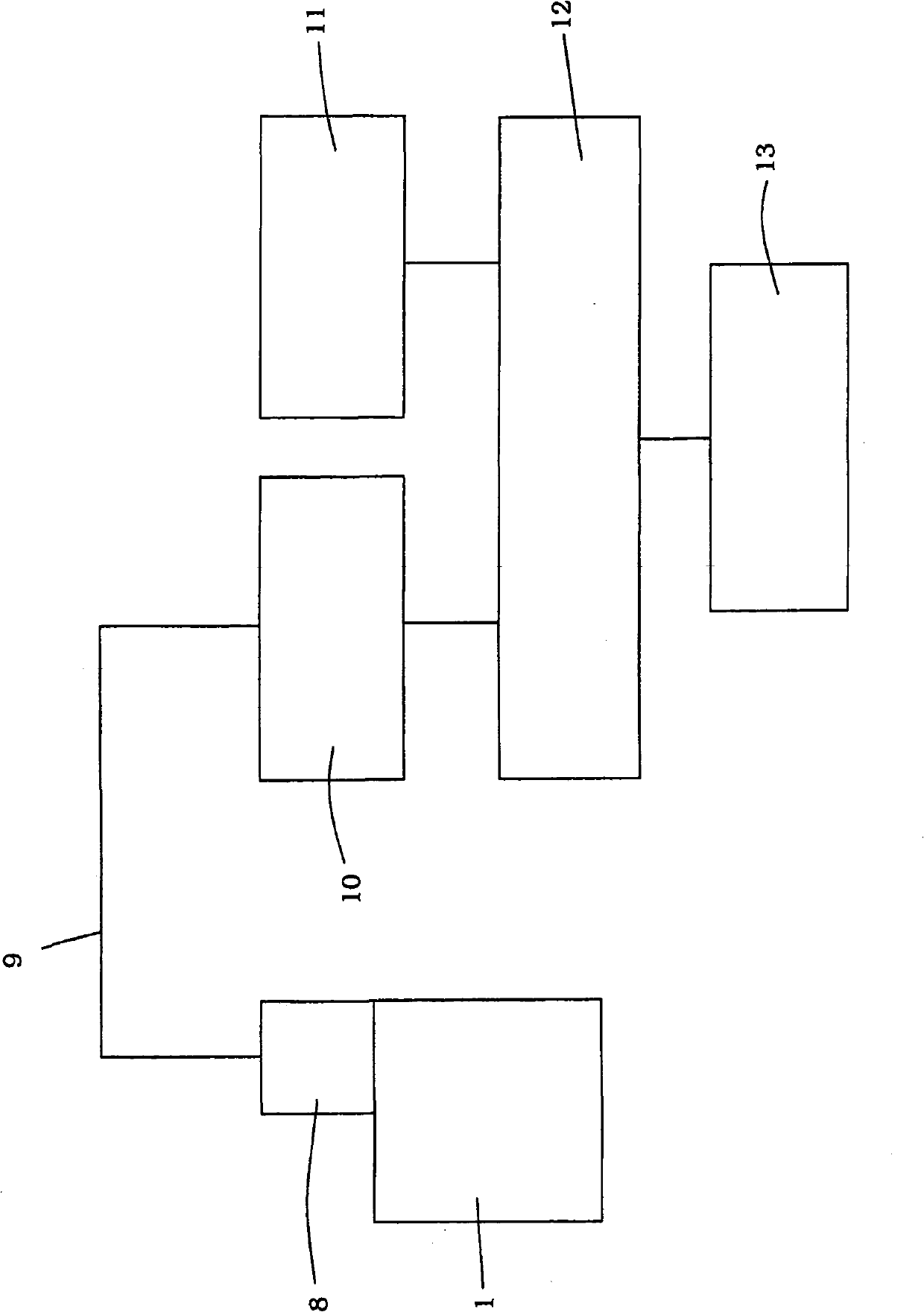

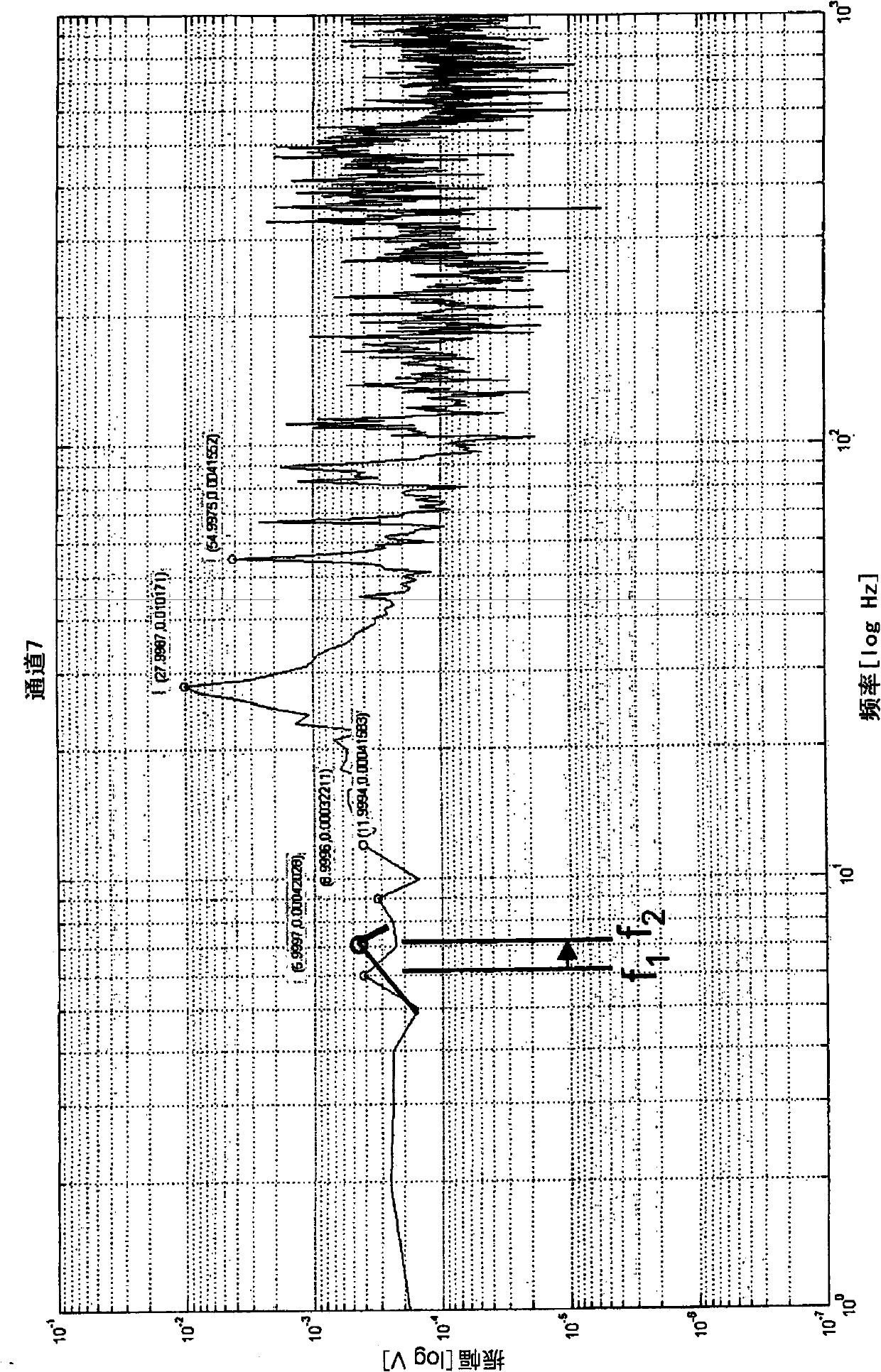

[0045] figure 1 A machine in the form of a construction machine is shown, in this case a vibrating plate. However the device according to the invention may be used in many other types of machines, including construction machines, for timely diagnosis of damage to mechanical parts.

[0046] The vibrating plate has an upper block 1 which is coupled to a lower block 2 via a spring-damping element 3 so that the two blocks can move relative to each other. The upper block 1 comprises a drive motor 4 and a drawbar 5 by which the vibrating plate can be manually guided by the operator. The lower block 2 has a soil contact plate 6 for compacting the soil and a vibration exciter 7 which strikes the soil contact plate 6 and is driven by the drive motor 4 . The vibration exciter 7 may for example consist of two unbalanced shafts which rotate in opposite directions in operative cooperation and generate directional vibrations. However, other excitation possibilities are also known.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com