Composite material boot

A composite material and sleeve technology, applied in the field of anti-skid shoes, can solve the problems of poor anti-skid performance, can only be used on hard ground, and inconvenient to use.

Inactive Publication Date: 2011-04-13

吴永刚

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The invention mainly aims at the problems of inconvenient use, poor anti-skid performance and can only be used on hard ground in the existing anti-skid shoes, and provides a composite material boot which is easy to use, reliable in anti-skid performance and suitable for various ground conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

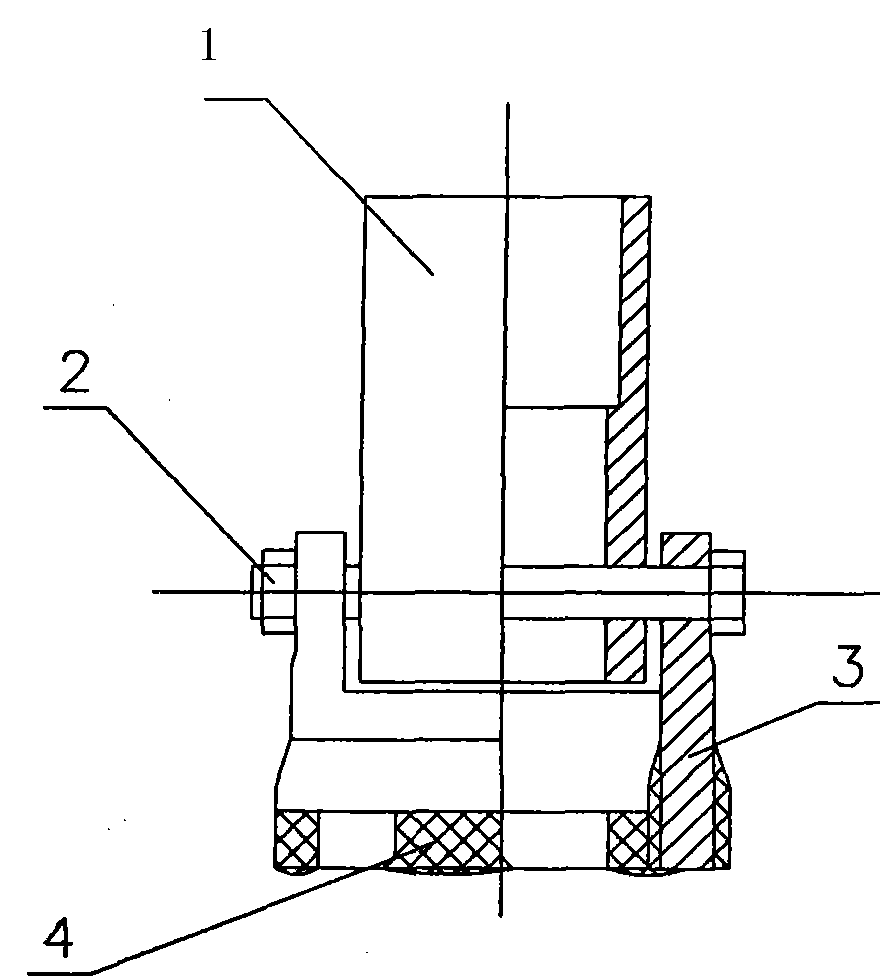

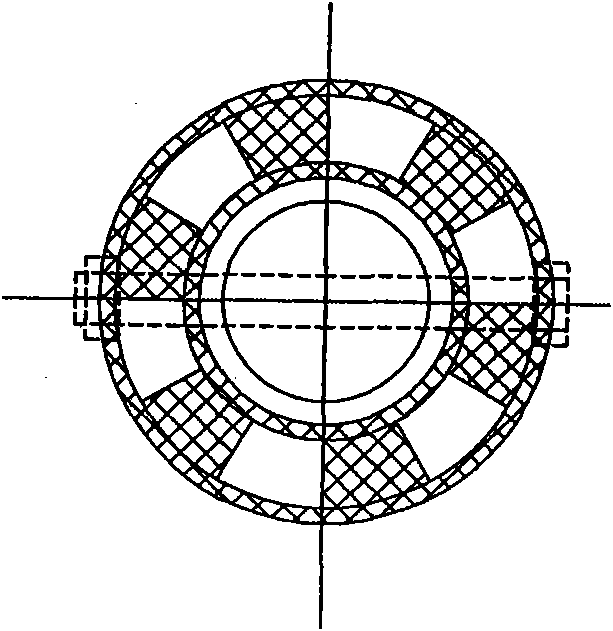

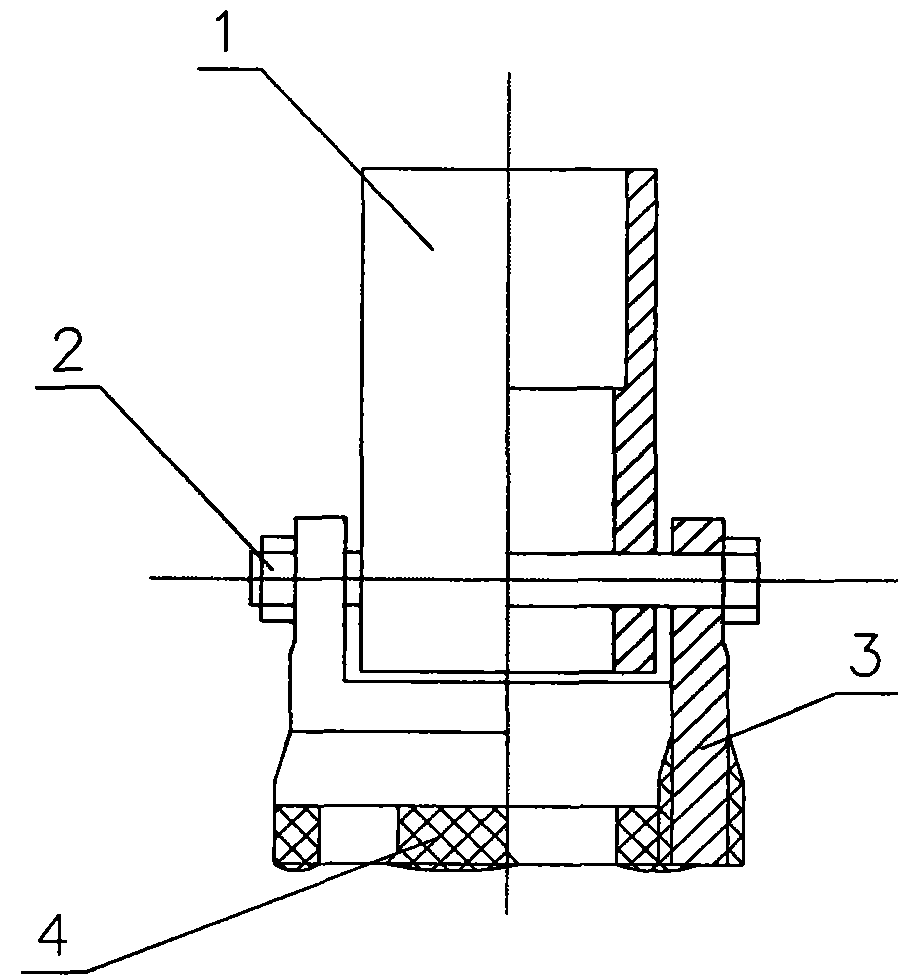

[0008] figure 1 with figure 2 As shown, a composite material boot includes a casing 1, a pin 2 and a hoe 3, the casing 1 and the hoe 3, the casing and the hoe are hinged by the pin 2, the hoe 3 is tubular, and the hoe The bottom of the hoe is evenly distributed with anti-skid teeth; hard rubber or polyester materials are filled in the female grooves of the teeth, and the bottom plane of the ground hoe is protruded.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of anti-skidding shoes, in particular to a composite material boot. According to the invention, problems that the existing anti-skidding shoes are not convenient for use, have poor anti-skidding property and are only used on a hard floor are solved. The technical scheme is as follows: the composite boot comprises a casing pipe, a pin roll and a ground hoe, wherein the casing pipe and the ground hoe are hinged through the pin roll; the ground hoe is in a tubular shape; anti-skidding teeth are evenly distributed at the bottom of the ground hoe; and a hard rubber or polyresin material is filled in female grooves of the anti-skidding teeth and the anti-skidding teeth is protruded at the bottom surface of the ground hoe is protruded. The composite material boot is convenient for use, has reliable anti-skidding property and is suitable for various ground conditions.

Description

technical field [0001] The invention belongs to the technical field of anti-skid shoes, and in particular relates to a composite material anti-skid boot. Background technique [0002] At present, there are two main ways to increase the anti-slip function on the feet of moving objects. One is to wrap or stuff the bottom of the feet with anti-slip materials; the other method uses mostly rubber or other materials with strong elasticity. Material, this kind of material has poor wear resistance, is easy to age, and has a short service life; the second method is to use the spikes to generate greater pressure when they are in contact with the ground, so as to achieve the purpose of anti-skid by increasing friction. The ground is more destructive, and secondly, when used on soft ground, it is often too deep into the ground, it is laborious to pull out, it is inconvenient to use, and there is less contact surface with the ground, and the anti-skid performance is not reliable when use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47B91/00

Inventor 吴永刚

Owner 吴永刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com