A device and method for cleaning and drying sheet metal parts

A sheet metal part, drying technology, applied in the directions of drying gas arrangement, cleaning method and utensils, cleaning method using liquid, etc., can solve the problems of wasting time and complicated operation, and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

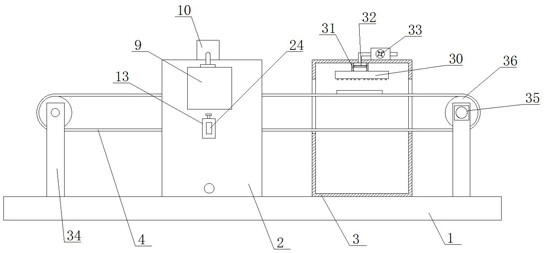

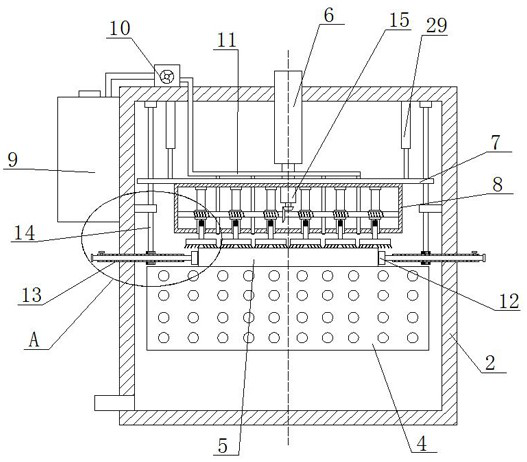

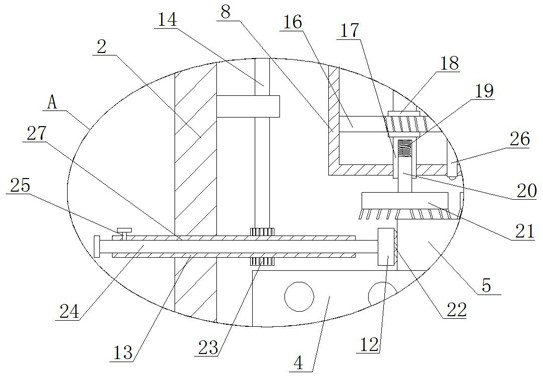

Embodiment 1

[0037] refer to Figure 1-5, a device for cleaning and drying sheet metal parts, comprising a bottom plate 1, a transmission mechanism, a cleaning box 2 and a drying box 3, the cleaning box 2 and the drying box 3 are fixedly arranged on the top of the bottom plate 1, the cleaning box 2 and the drying box 3 There are through holes on both sides, the transmission mechanism is movably connected with the through holes, a sheet metal part 5 is placed on the transmission mechanism, a drying mechanism is arranged inside the drying box 3, and a lifting motor 6 is fixedly connected to the inner wall of the top of the cleaning box 2. , the output shaft of the lifting motor 6 is fixedly connected with a welding plate 7, the bottom of the welding plate 7 is fixedly connected with a scrubbing mechanism, and the top inner wall of the cleaning box 2 is rotated and installed with two threaded rods 14, and the two threaded rods 14 are all welded to each other. The plates 7 are threaded, and bo...

Embodiment 2

[0053] refer to Figure 1-5 , a device for cleaning and drying sheet metal parts, comprising a bottom plate 1, a transmission mechanism, a cleaning box 2 and a drying box 3, the cleaning box 2 and the drying box 3 are fixedly arranged on the top of the bottom plate 1, the cleaning box 2 and the drying box 3 There are through holes on both sides of the body, and the transmission mechanism is flexibly connected with the through holes. Sheet metal parts 5 are placed on the transmission mechanism. Motor 6, the output shaft of lifting motor 6 is fixedly connected with welding plate 7 by screws, and the bottom of welding plate 7 is fixedly connected with brushing mechanism by screws, and two threaded rods 14 are installed on the top inner wall of cleaning box 2, two The threaded rods 14 are all threadedly connected with the welding plate 7, and both sides of the cleaning box 2 are slidingly connected with clamping mechanisms, and the two threaded rods 14 are respectively adapted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com