Cloth rolling, automatic compacting and tail automatic fixing device for garment processing

An automatic compaction and cloth technology, applied in the field of clothing, can solve the problems of easy to get dirty, and the cloth is easy to be eroded by moisture in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

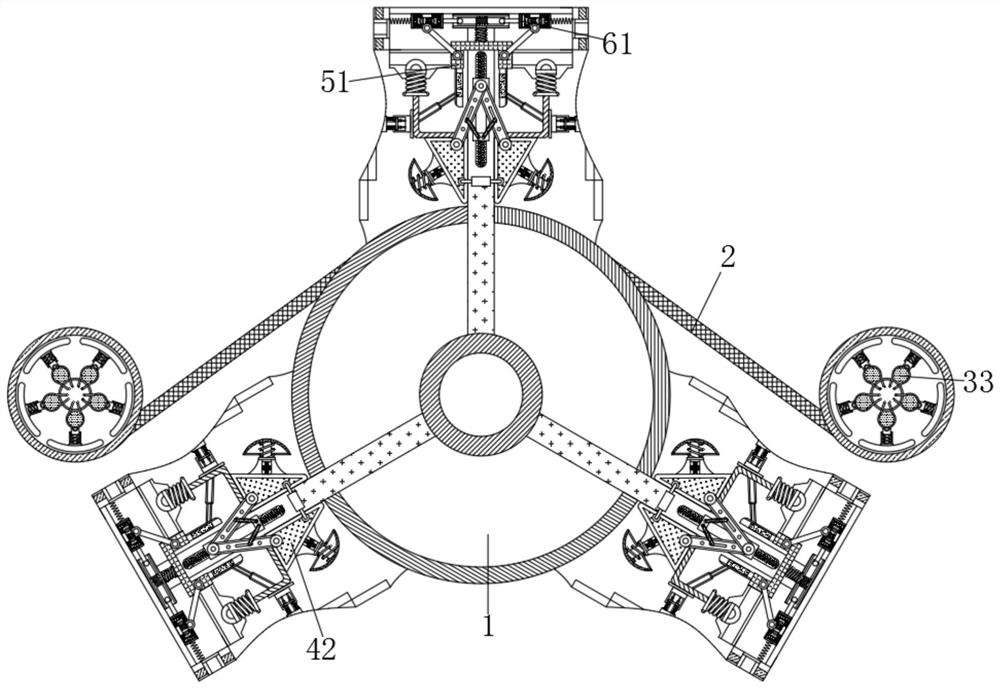

[0022] see image 3 , a device for automatically rewinding and compacting cloth for garment processing and automatically fixing the tail, comprising a cloth roller 1, the surface of the cloth roller 1 is movably connected with a cloth 2, the surface of the cloth 2 is movably connected with a trigger mechanism 3, and the surface of the cloth 2 is A pressure applying mechanism 4 is movably connected, and a conversion mechanism 5 is movably connected to the surface of the pressure exerting mechanism 4 , and a transmission mechanism 6 is movably connected to the surface of the conversion mechanism 5 .

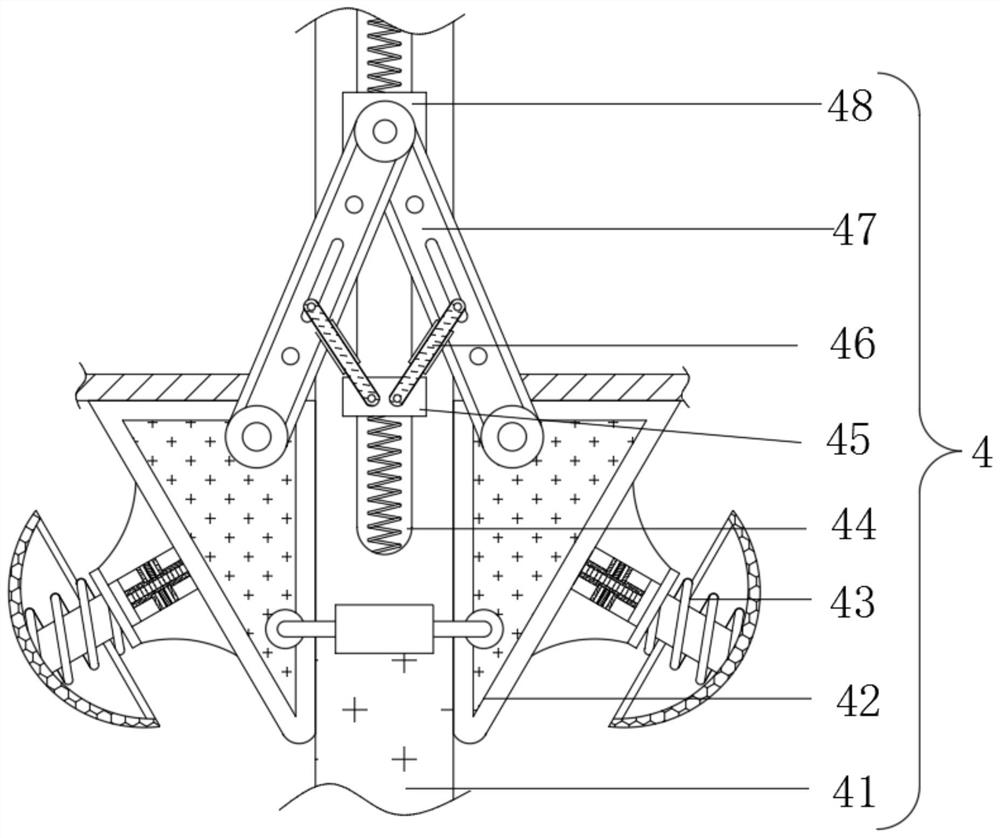

[0023] The inside of the pressing mechanism 4 includes a fixed mount 41, a swash plate 42, a fixed block 43, a chute 44, a first slide block 45, a stop rod 46, a connecting rod 47, a second slide block 48, and one end of the fixed mount 41 Fixedly connected at the center of the cloth roller 1, the surface of the fixed frame 41 is provided with a chute 44, the inclined plate 42 is m...

Embodiment 2

[0026] see image 3 and Figure 4 , a device for automatically rewinding and compacting cloth for garment processing and automatically fixing the tail, comprising a cloth roller 1, the surface of the cloth roller 1 is movably connected with a cloth 2, the surface of the cloth 2 is movably connected with a trigger mechanism 3, and the surface of the cloth 2 is A pressure applying mechanism 4 is movably connected, and a conversion mechanism 5 is movably connected to the surface of the pressure exerting mechanism 4 , and a transmission mechanism 6 is movably connected to the surface of the conversion mechanism 5 .

[0027] The inside of the pressing mechanism 4 includes a fixed mount 41, a swash plate 42, a fixed block 43, a chute 44, a first slide block 45, a stop rod 46, a connecting rod 47, a second slide block 48, and one end of the fixed mount 41 Fixedly connected at the center of the cloth roller 1, the surface of the fixed frame 41 is provided with a chute 44, the incline...

Embodiment 3

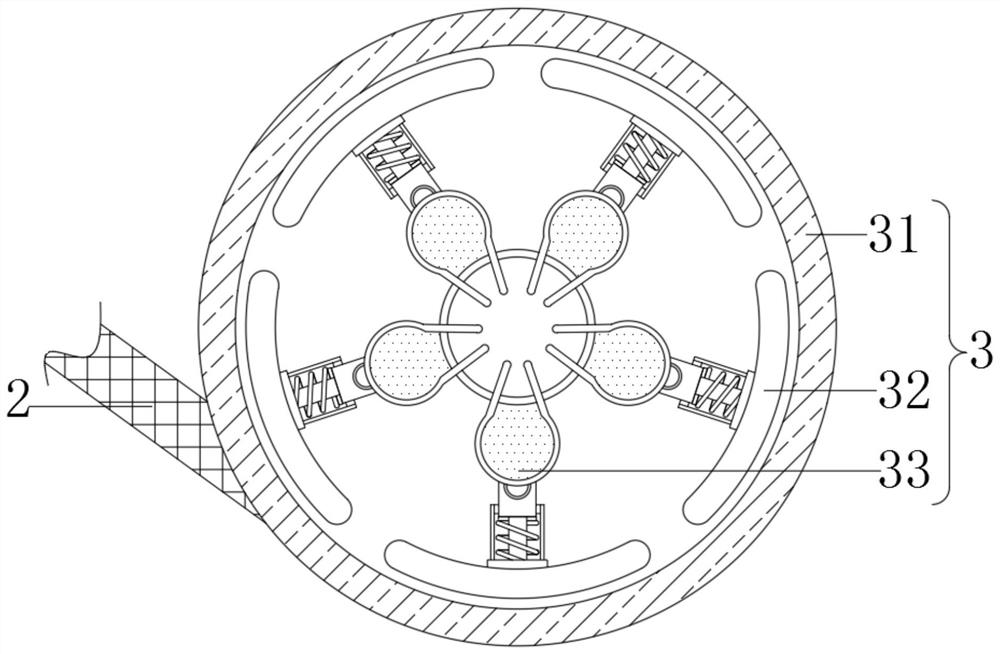

[0030] see Figure 1-5 , a device for automatically rewinding and compacting cloth for garment processing and automatically fixing the tail, comprising a cloth roller 1, the surface of the cloth roller 1 is movably connected with a cloth 2, the surface of the cloth 2 is movably connected with a trigger mechanism 3, and the trigger mechanism 3 The interior includes a guide roller 31, a pressure plate 32, and a piezoresistor 33. The piezoresistor 33 is fixedly connected to the axis of the guide roller 31, the pressure plate 32 is movably connected to the surface of the pressure plate 32, and the surface of the fabric 2 is movably connected with a pressure-applying mechanism. 4.

[0031] The inside of the pressing mechanism 4 includes a fixed mount 41, a swash plate 42, a fixed block 43, a chute 44, a first slide block 45, a stop rod 46, a connecting rod 47, a second slide block 48, and one end of the fixed mount 41 Fixedly connected at the center of the cloth roller 1, the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com