Flight dropper

A descender and overrunning clutch technology, applied in life-saving equipment, building rescue, etc., can solve problems such as difficulty in rewinding ropes, affecting reuse, affecting safety and lifesaving, and achieves an effect that is conducive to safety and lifesaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

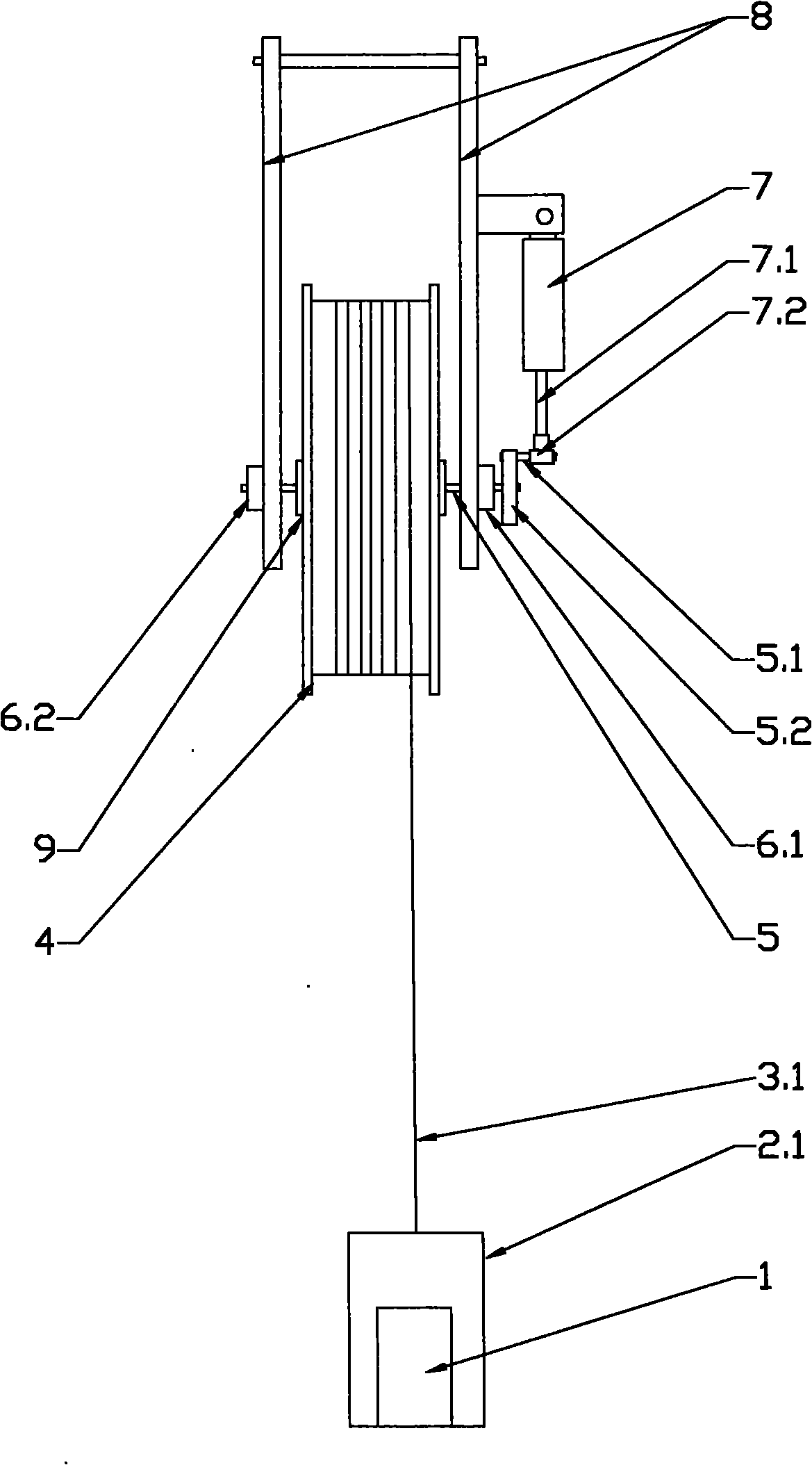

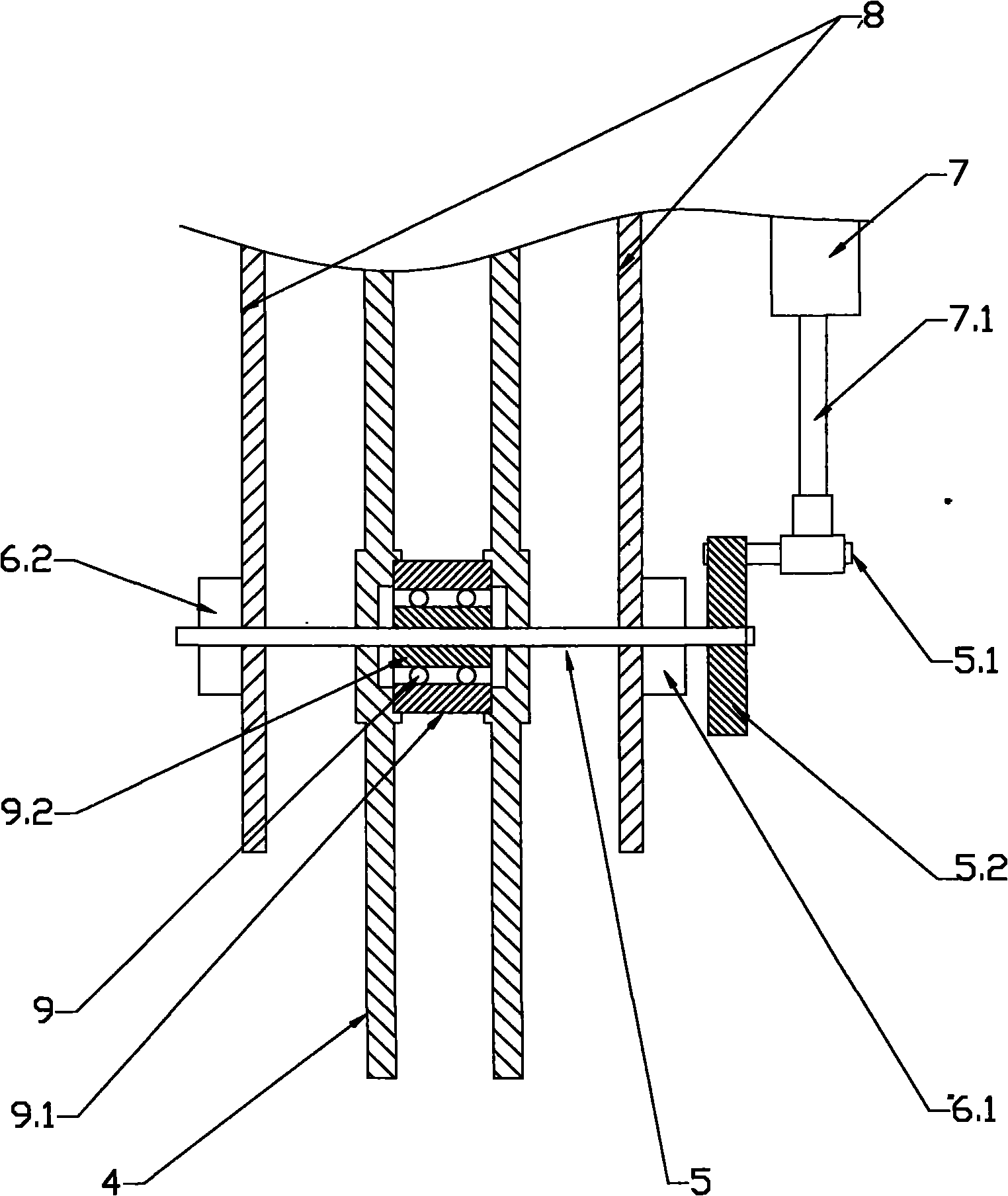

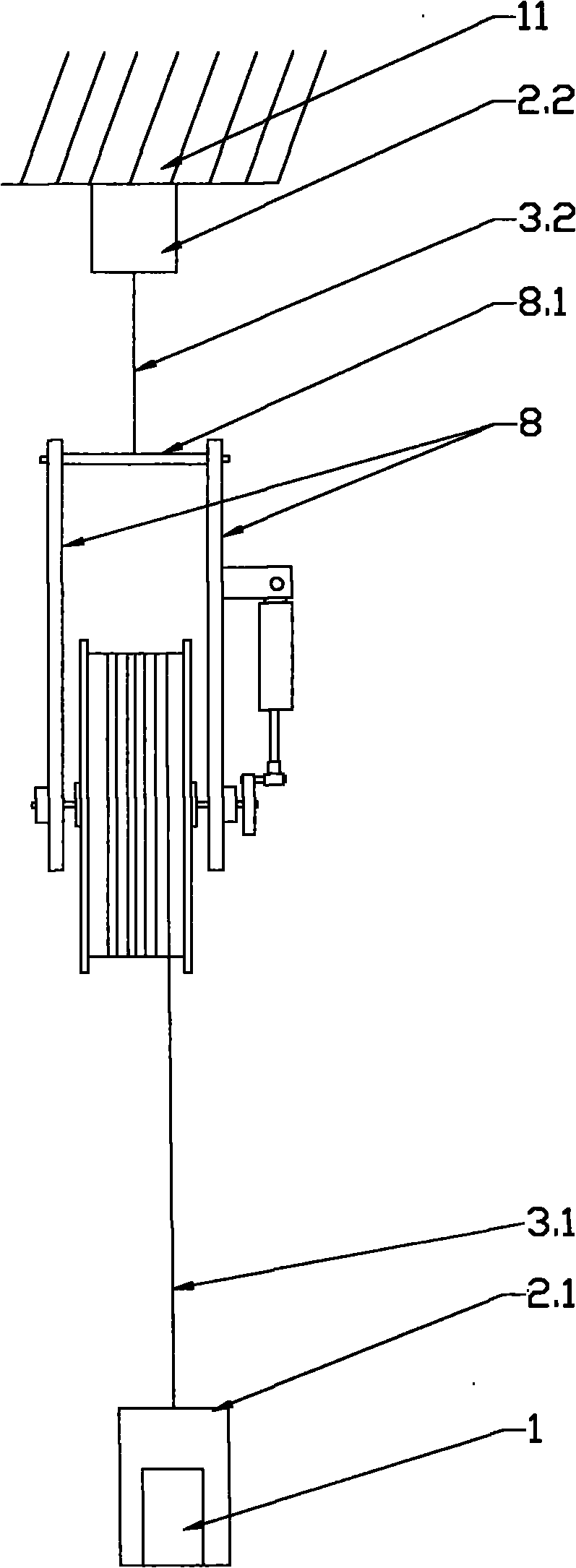

[0018] figure 1 , figure 2 It is a structural schematic diagram of the first embodiment of the present invention; figure 1 is a schematic diagram of the structure, figure 2 It is the schematic diagram of the partially enlarged structure, in figure 1 As shown in , the gravity part 1 is carried by the carrier 2.1, the carrier 2.1 is connected and fixed with the rope 3.1, the rope 3.1 is fixed and wound on the rope coil 4, the rope coil 4 is indirectly installed on the rotating shaft 5, and the rotating shaft 5 passes through Axle bases 6.1 and 6.2 are installed on the support 8, a rotating part 5.2 is installed on the rotating shaft 5, a crankshaft 5.1 is installed on the rotating part 5.2, and the piston rod 7.1 of the piston 7 is connected with the crankshaft 5.1 through the rod end connector 7.2. figure 2 Shown in, the feature of this embodiment is that the rope reel 4 is installed on the rotating shaft 5 through an overrunning clutch 9, the outer ring 9.1 of the overru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com