Tool special for detaching isolating switch double-layer sleeved elastic pin

A technology for isolating switches and special tools, which is applied in the field of special tools for dismantling elastic pins in double-layer sets of isolating switches. It can solve the problems of long operation process and low maintenance efficiency, and achieve the effects of reasonable structure, improved work efficiency, and reduced frequent replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

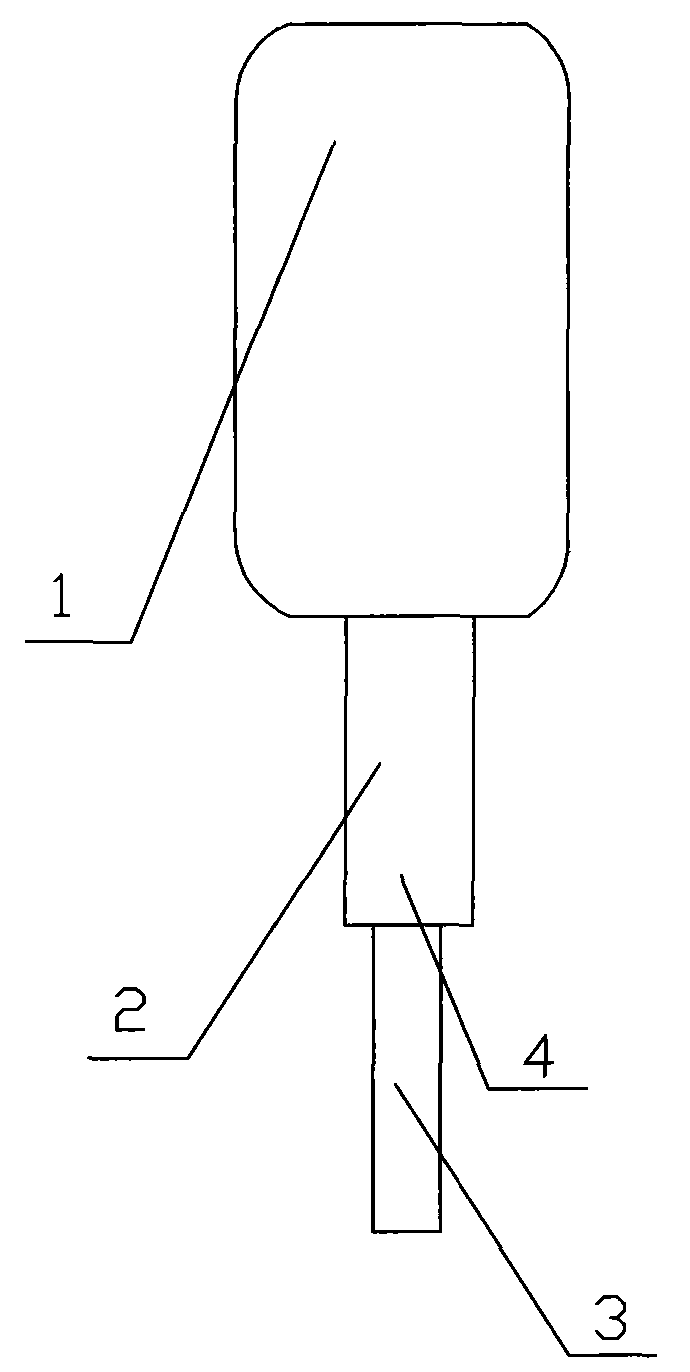

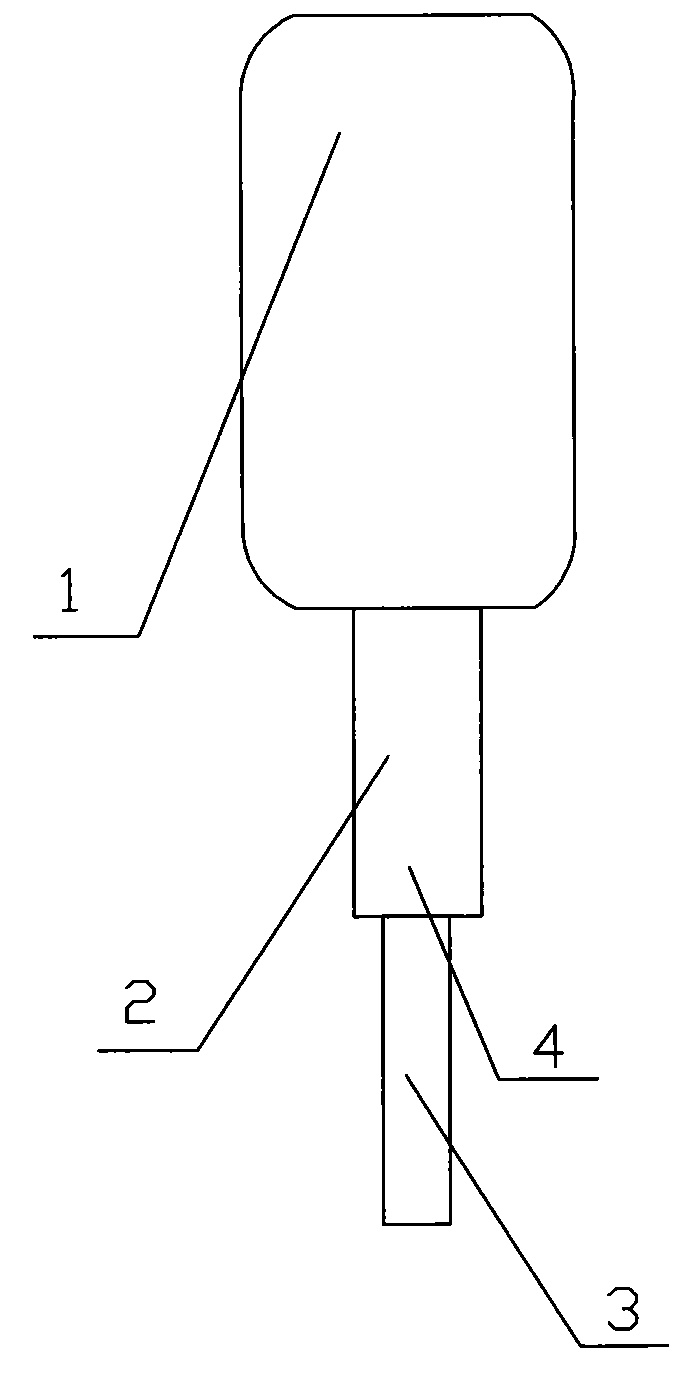

[0010] Such as figure 1 Shown: a special tool for removing elastic pins in double-layer sets of isolating switches, including a handle 1 and a punch 4, and the punch 4 is connected to the handle 1.

[0011] The punch 4 includes an inner pin punch 3 and an outer pin punch 2, and the inner pin punch 3 and the outer pin punch 2 are connected.

[0012] Both the inner pin punch 3 and the outer pin punch 2 are cylinders.

[0013] Because the diameter of the inner pin punch 3 is consistent with the diameter of the inner layer pin, the inner pin punch 3 can enter the inside of the outer pin, the diameter of the outer pin punch 2 is consistent with the diameter of the outer pin, and the outer pin punch 2 can enter the round hole of the workpiece. Therefore, the present invention uses , the internal pin punch 3 is in contact with the internal pin of the isolating switch double-layered elastic pin. Under the hammering of the hammering tool, the internal pin punch 3 punches out the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com