Method for manufacturing chinaware with optical performance of jadeite

A technology of optical properties and manufacturing methods, which is applied in the field of ceramics manufacturing, can solve the problems of not meeting the requirements of daily utensils and home decorations, not having the ornamental characteristics of jade, and the high cost of synthetic jade, so as to achieve high ornamental value and low cost. The effect of low and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

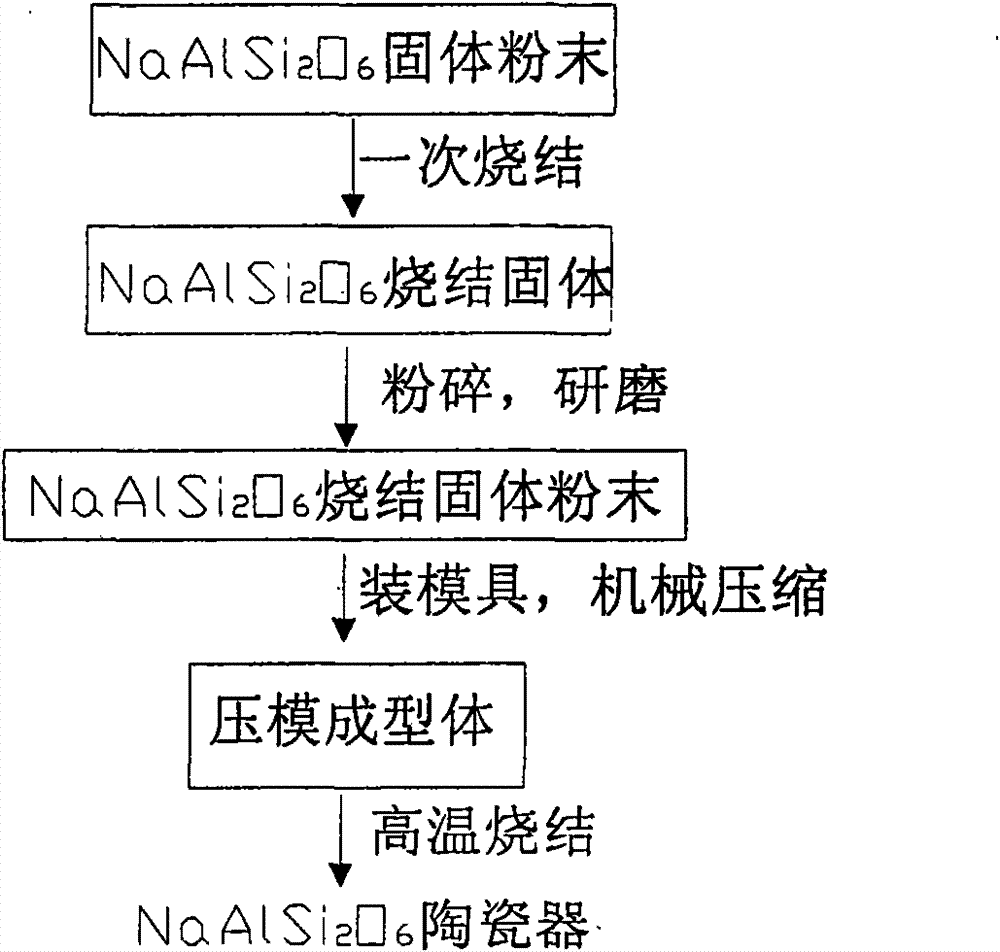

[0021] 1. Sodium aluminum disilicate solid powder primary sintering

[0022] Take 120-300 mesh sodium aluminum disilicate solid powder, put it into a high-temperature resistant vessel, then transfer the high-temperature resistant vessel containing the solid sodium aluminum disilicate powder to a high-temperature furnace, and sinter at 750°C for 96 hours, naturally After cooling, a sintered solid was obtained, and after crushing and grinding, 80 mesh sodium aluminum disilicate (NaAlSi 2 o 6 ) of sintered solid powder, the apparent density of the sintered solid powder is 1.20g / cm 3 .

[0023] 2. Compression molding of sodium aluminum disilicate sintered solid powder

[0024] Take 80 mesh sodium aluminum disilicate sintered solid powder and put it into the mold, compress the solid sodium aluminum disilicate powder through 50Mpa mechanical pressure to form a compression molded body with specific structural characteristics. After demolding, the compression mold is obtained Form...

Embodiment 2

[0028] 1. Sodium aluminum disilicate solid powder primary sintering

[0029] Take 120-300 mesh sodium aluminum disilicate solid powder, put it into a high-temperature-resistant vessel, then transfer the high-temperature-resistant vessel containing the sodium aluminum disilicate solid powder to a high-temperature furnace, and sinter it at 1150°C for 12 hours. After cooling, the primary sintered raw material is obtained, and after crushing and grinding, 180-mesh sodium aluminum disilicate (NaAlSi 2 o 6 ), the apparent density of the sintered solid powder is 1.53g / cm 3 .

[0030] 2. Compression molding of sodium aluminum disilicate sintered solid powder

[0031] Take 180-mesh sodium aluminum disilicate sintered solid powder and put it into the mold, and compress the solid sodium aluminum disilicate powder through 2000Mpa mechanical pressure to form a compression molded body with specific structural characteristics. After demolding, the compression mold is obtained Formed body...

Embodiment 3

[0035] 1. Sodium aluminum disilicate solid powder primary sintering

[0036] Take 120-300 mesh sodium aluminum disilicate solid powder, put it into a high-temperature-resistant container, then transfer the high-temperature resistant container containing the sodium aluminum disilicate solid powder to a high-temperature furnace, and sinter at 920°C for 48 hours. After cooling, the primary sintered raw material is obtained, and after crushing and grinding, 300 mesh sodium aluminum disilicate (NaAlSi 2 o 6 ) of sintered solid powder, the apparent density of the sintered solid powder is 1.65g / cm 3 .

[0037] 2. Compression molding of sodium aluminum disilicate sintered solid powder

[0038] Take 300 mesh sodium aluminum disilicate sintered solid powder and put it into the mold, and compress the solid sodium aluminum disilicate powder through 1000Mpa mechanical pressure to form a compression molded body with specific structural characteristics. After demoulding, the compression m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com