Heat radiation frame for mounting of battery pack

A heat dissipation rack and battery pack technology, which is applied to battery pack parts, secondary batteries, circuits, etc., can solve the problems of rapid heat dissipation of the battery, poor heat dissipation structure, and poor performance, so as to solve the difficulty of installation and maintenance and improve industrialization horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

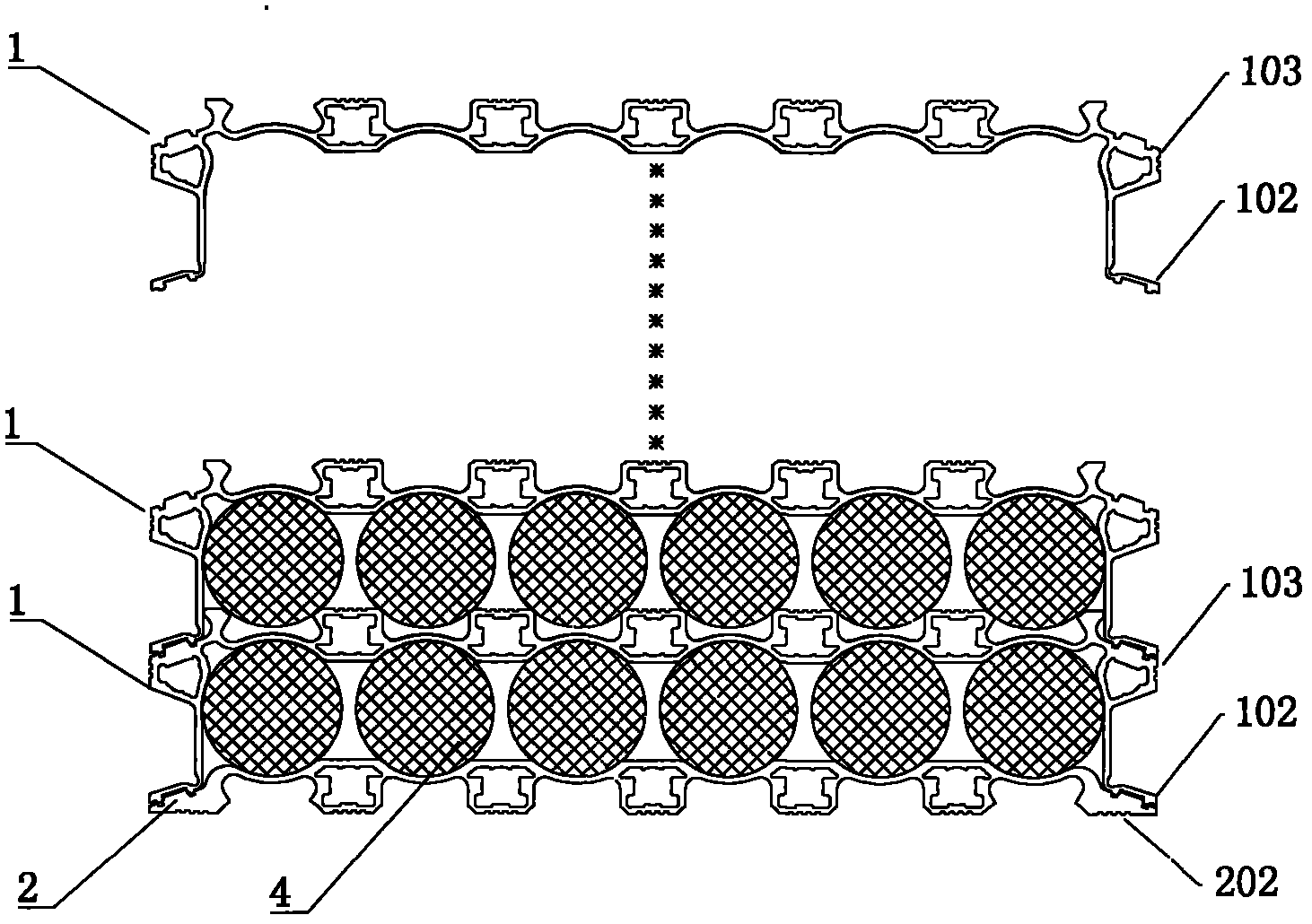

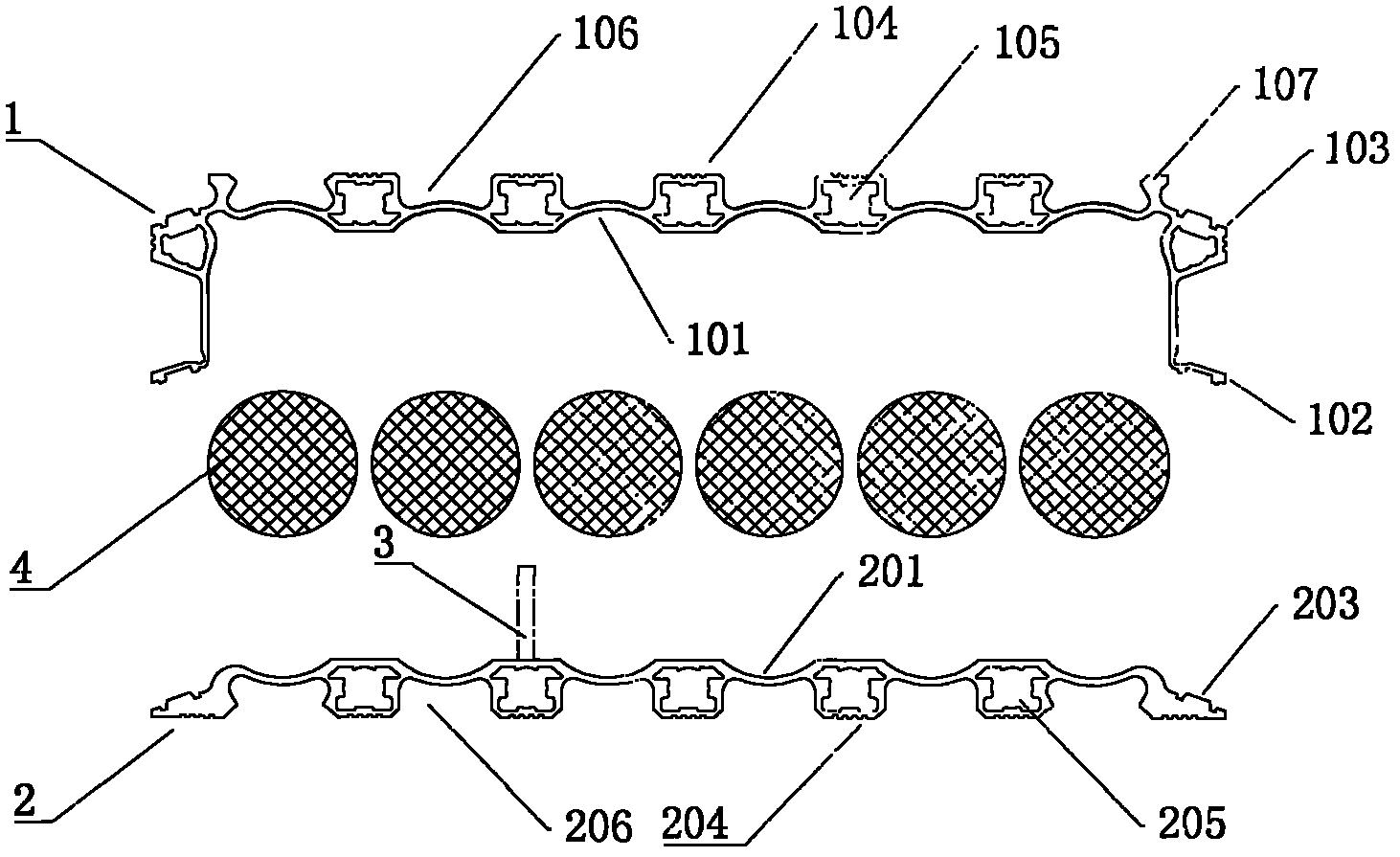

[0020] Such as figure 1 , 2 As shown, a heat sink for installing a battery pack includes a plurality of battery support frames 1 and a baffle plate 2 that can be arbitrarily matched.

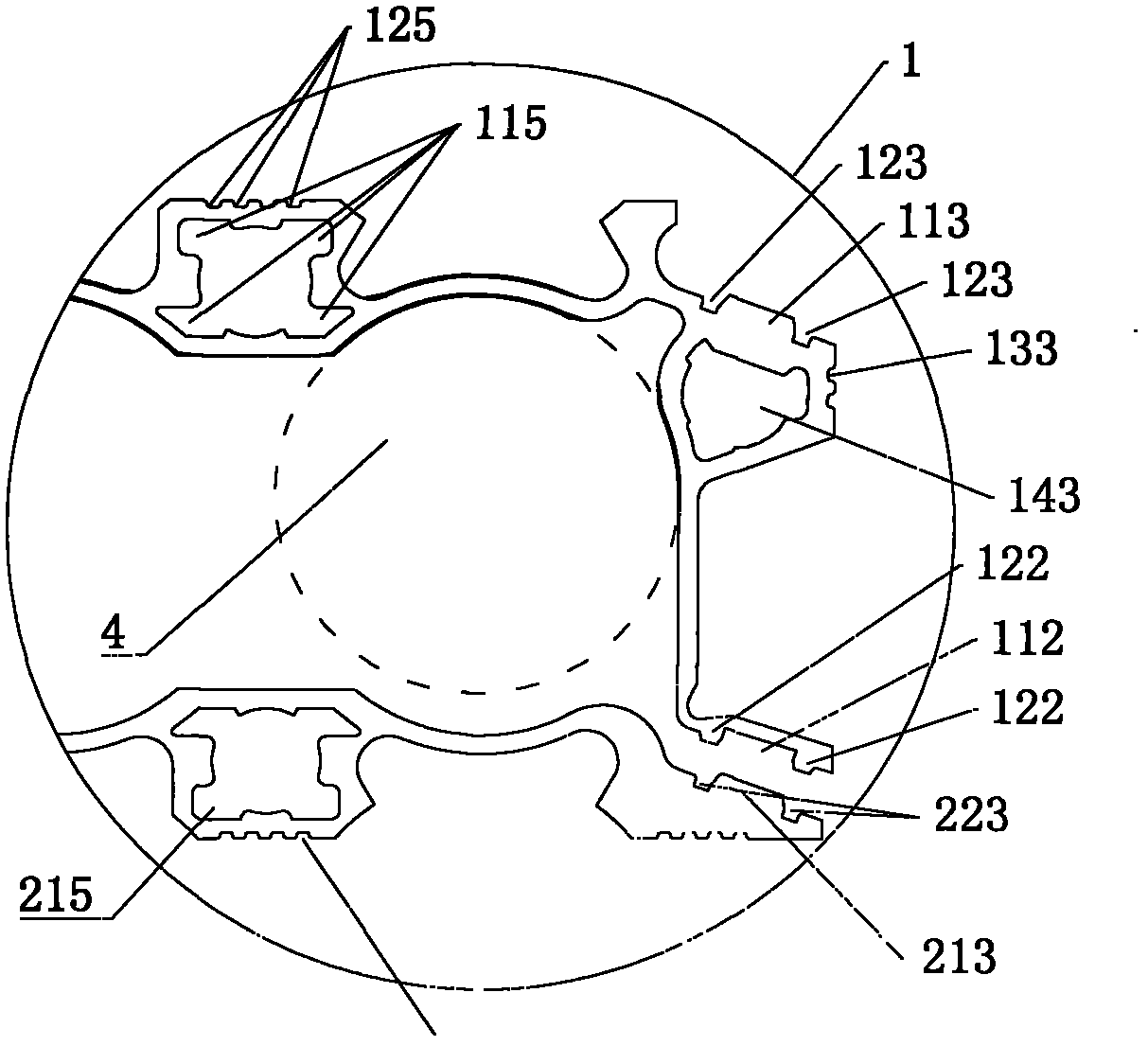

[0021] Wherein the lower end of the battery support frame 1 is open, in order to facilitate the open lower end both sides are provided with a horizontal extension 102, the horizontal extension is provided with corresponding horizontal bosses 103 on both sides of the upper end, and the upper surface of the horizontal boss 103 is formed There is a horizontal extension corresponding to the horizontal extension 102 at its lower end, so that multiple battery support frames 1 can be stacked vertically, and the horizontal extension 102 at the lower end of the lower end is in contact with the upper surface of the horizontal boss 103 at the upper end of the adjacent support frame 1. The aftertouches are bolted together to form a series of battery packs.

[0022] The inner wall of the battery supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com