Nut slider type angle adjustment mechanism

An angle-adjusting, slider-type technology, applied in the direction of electrical components, antennas, etc., can solve problems such as difficult to design angle adjustment mechanisms and small spaces, and achieve the effects of small and compact overall size, reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The words "upper", "lower", "left", "right" etc. used in the following to describe the orientation are based on the orientation shown in the drawings for the convenience of explanation. In the actual device, these Orientation may vary due to how the unit is positioned.

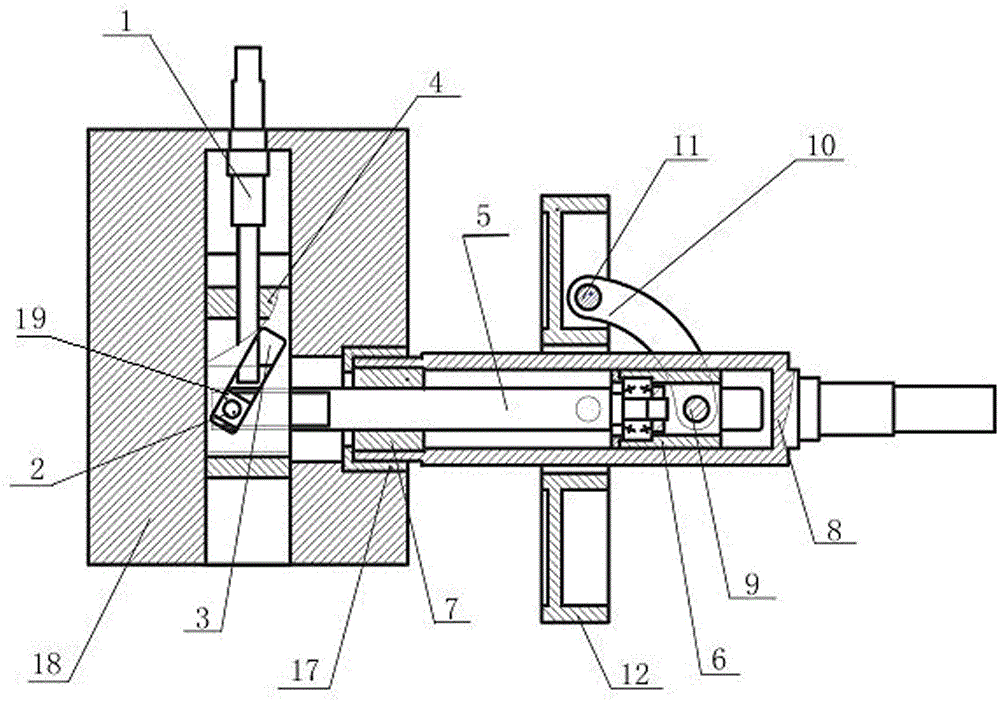

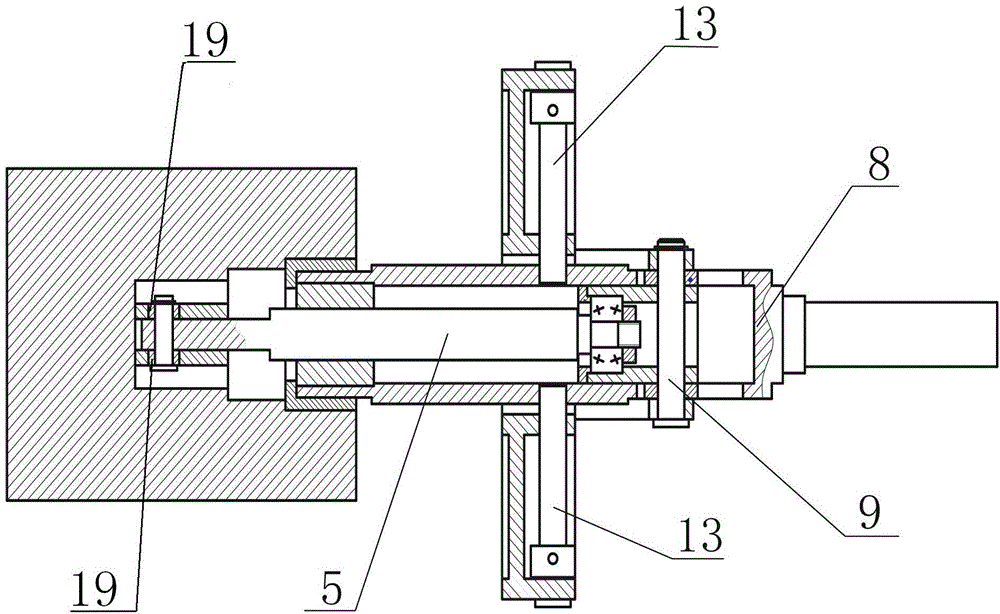

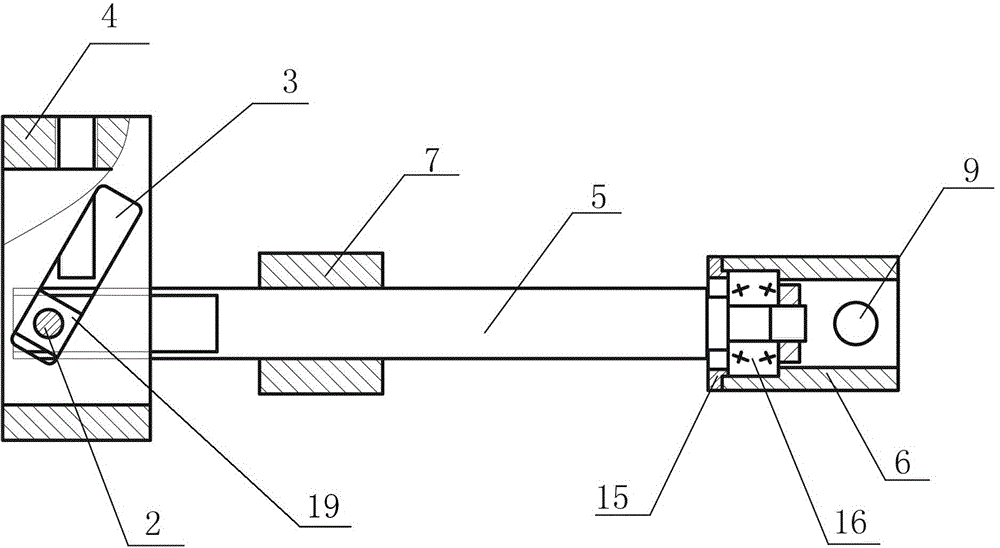

[0020] The structure description of the preferred embodiment of the nut-slider type angle adjustment mechanism of the present invention will be described below with reference to the accompanying drawings. Accompanying drawing shows the nut slider type angle adjustment mechanism of the present invention, wherein the body 18 is fixed, the input screw 1 is screwed with the moving nut 4, and the moving nut 4 can only move up and down in the body 18. The mobile nut 4 is seen as a zigzag from the cross-section, and an oblique chute 3 is respectively opened on its both sides. The two direction-changing sliders 19 are respectively embedded in the inclined chute 3 of the moving nut 4 , respectively forming a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com