Two-way controllable ratchet clutch transmission device

A clutch transmission and ratchet technology, which is applied in the directions of gear transmission, transmission, one-way clutch, etc., can solve the problems of not being able to have both at the same time, and achieve the effect of small driving displacement, ingenious principle and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

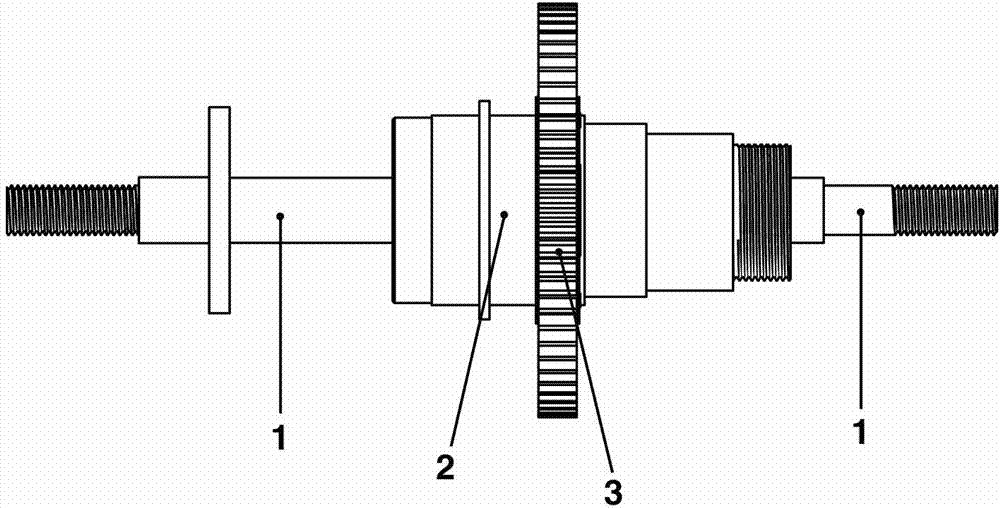

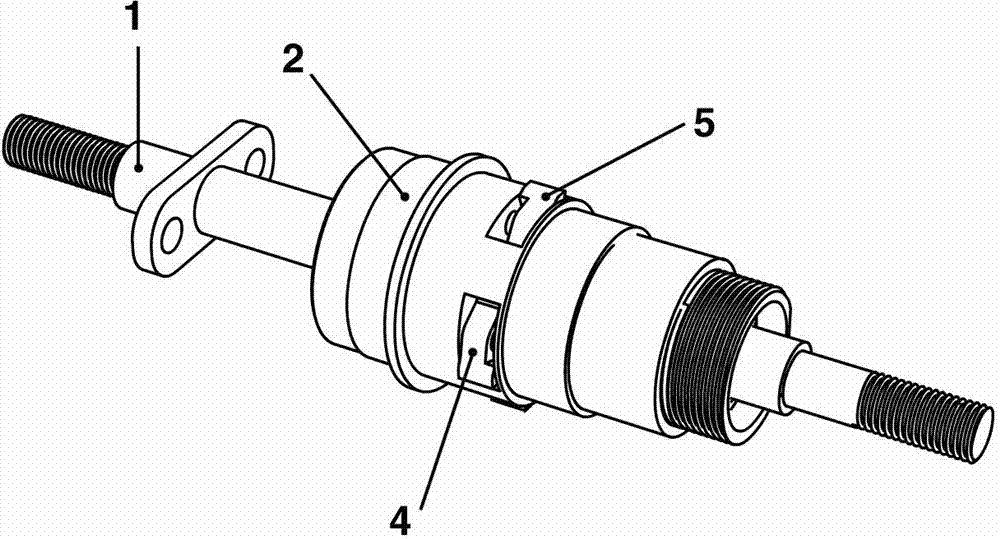

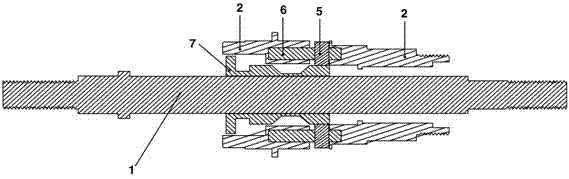

[0031] Example: see figure 1 , figure 2 , image 3 and Figure 4 , a two-way controllable ratchet clutch transmission device, including a fixed shaft 1, the fixed shaft 1 can be used as a load-bearing shaft of a vehicle to support the front tire or rear tire of the vehicle, and its two ends are supported on the flat fork of the vehicle or the frame of the vehicle On the fixed shaft 1, there is an output sleeve 2 (empty sleeve), and the input gear 3 is arranged on the output sleeve 2, and is meshed with the power device (such as an electric motor, engine) through a gear, or a belt drive, or a sprocket The input gear 3 connected to the transmission can drive the output shaft sleeve 2 to rotate, and transmit the output torque of the power device to the output shaft sleeve 2 through the input gear 3, and drive the output shaft sleeve 2 to rotate; when installing, the output shaft sleeve 2 is usually connected with the vehicle The hubs of the front tires or rear tires cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com