Cutting method and apparatus

A technology for cutting rings and cups, which is applied in the direction of shearing devices, pipe cutting devices, metal processing equipment, etc., to achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

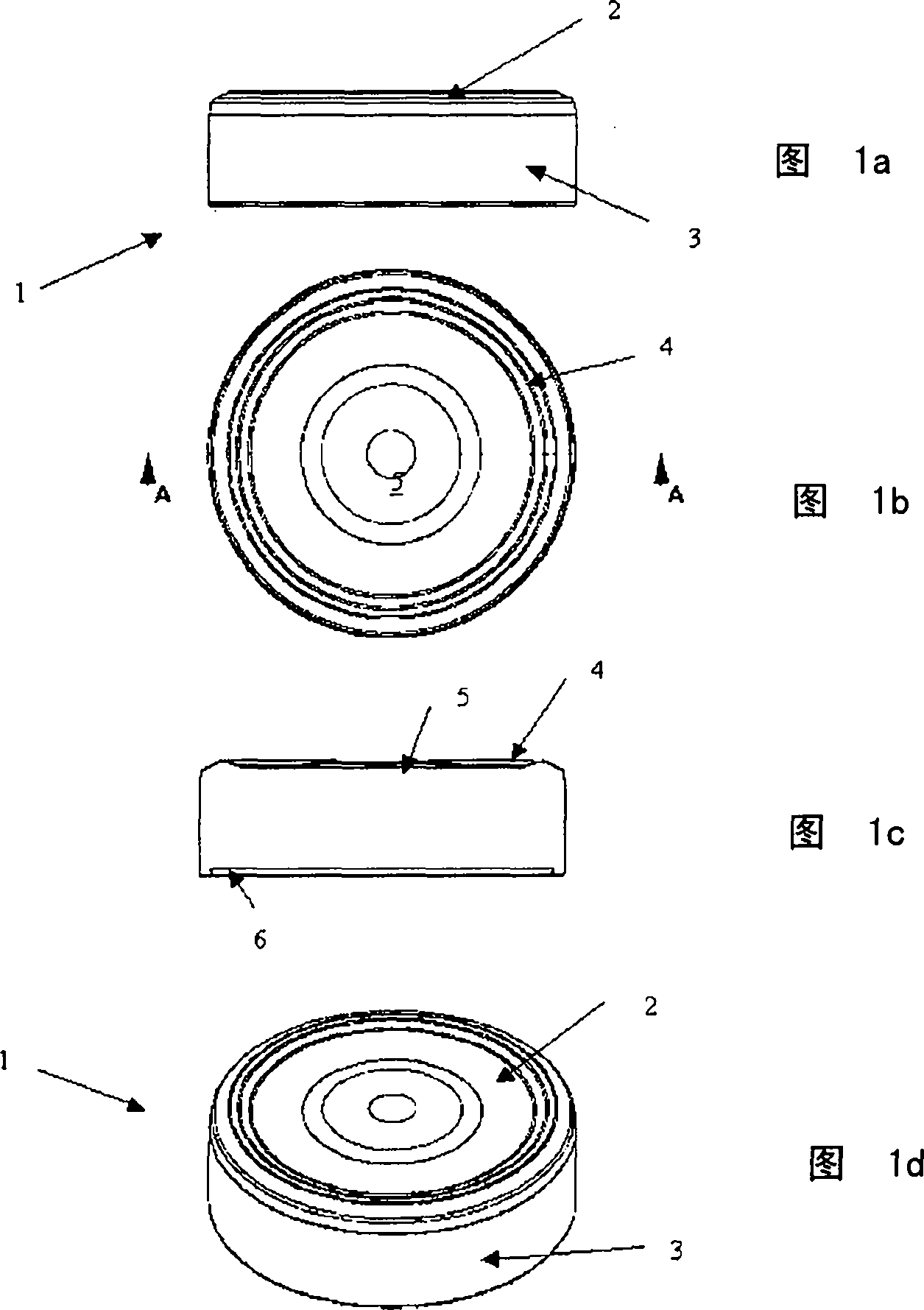

[0059] Figure 1a to Figure 1d A cup 1 is shown comprising an end 2 and an integrally formed side wall 3 . The end 2 is formed into a bead 4 and a center plate 5 during the cup forming process (see Figure 1b and Figure 1c Section through line A-A). The side wall 3 terminates in an inward curl 6 which is best seen in Figure C.

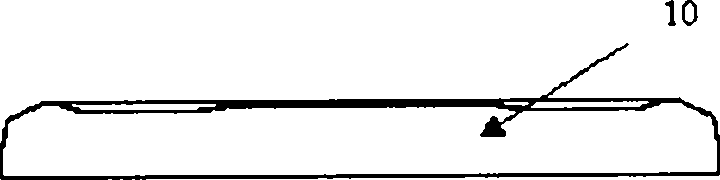

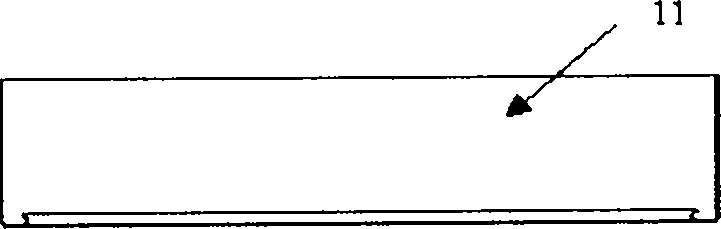

[0060] Figure 2 shows a cut end piece 10 from a single stage process ( Figure 2a ) and cut ring 11 ( Figure 2b ). exist Figure 2c and 2d Their respective cutting edges 12 and 13 are shown in .

[0061] The two-stage option of Figures 3 and 4 first forms a score 15 in the side wall 3 towards the end 2 with a total internal angle 16 of about 60° (degrees) between half and three quarters of the wall thickness. "V" shaped cutout. when Figure 4a When the end piece 2 is divided from the side wall (ring) 3, a flare is formed inwardly through the dividing edges 17 and 18.

[0062] exist Figure 5a and Figure 5b A manual cutting or scoring d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com