EMI controlled integral HID reflector lamp

An integral, reflector technology, applied in the direction of reflectors, gas discharge lamps, discharge lamps, etc., can solve problems such as electrical safety hindering general use by consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

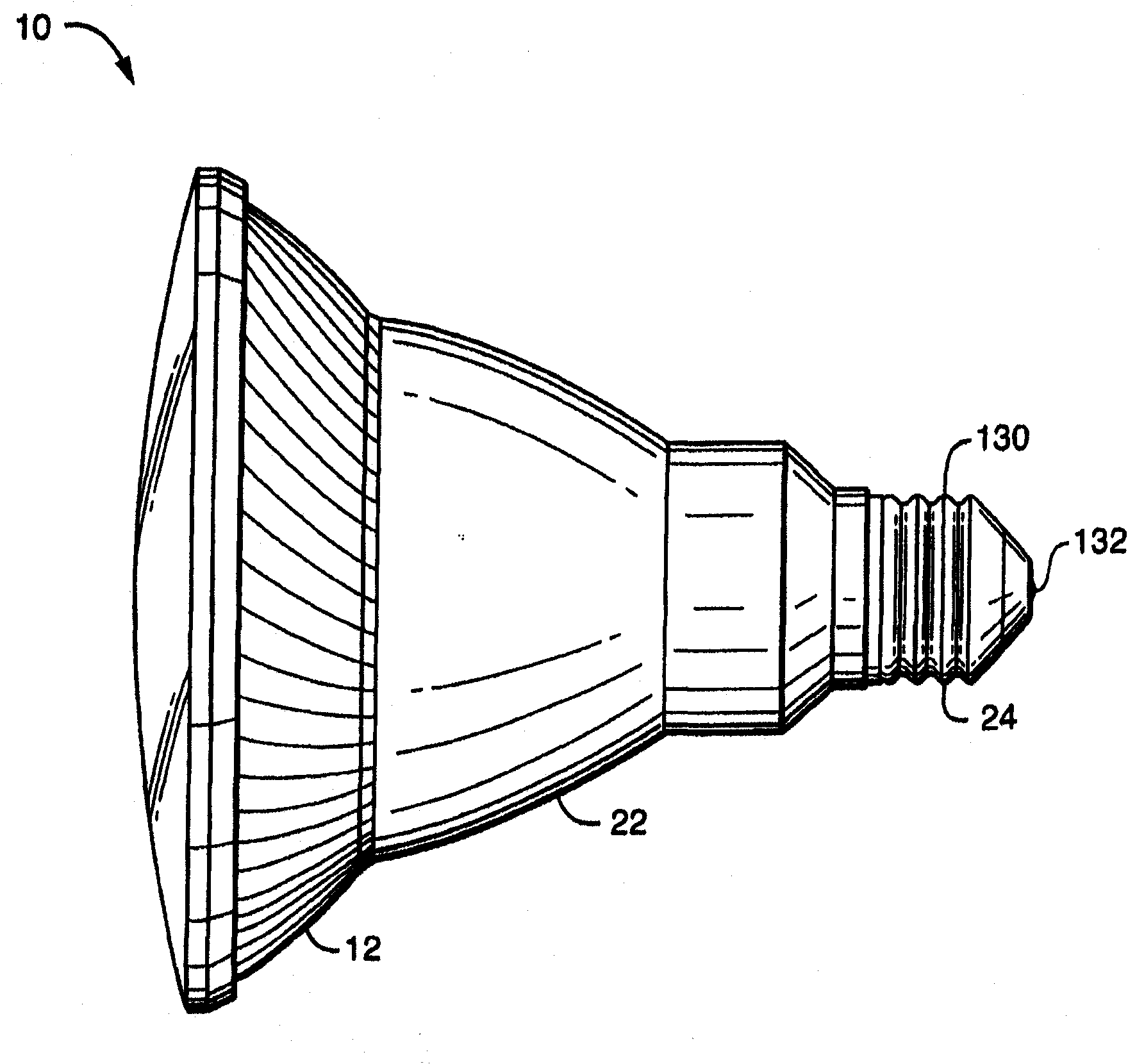

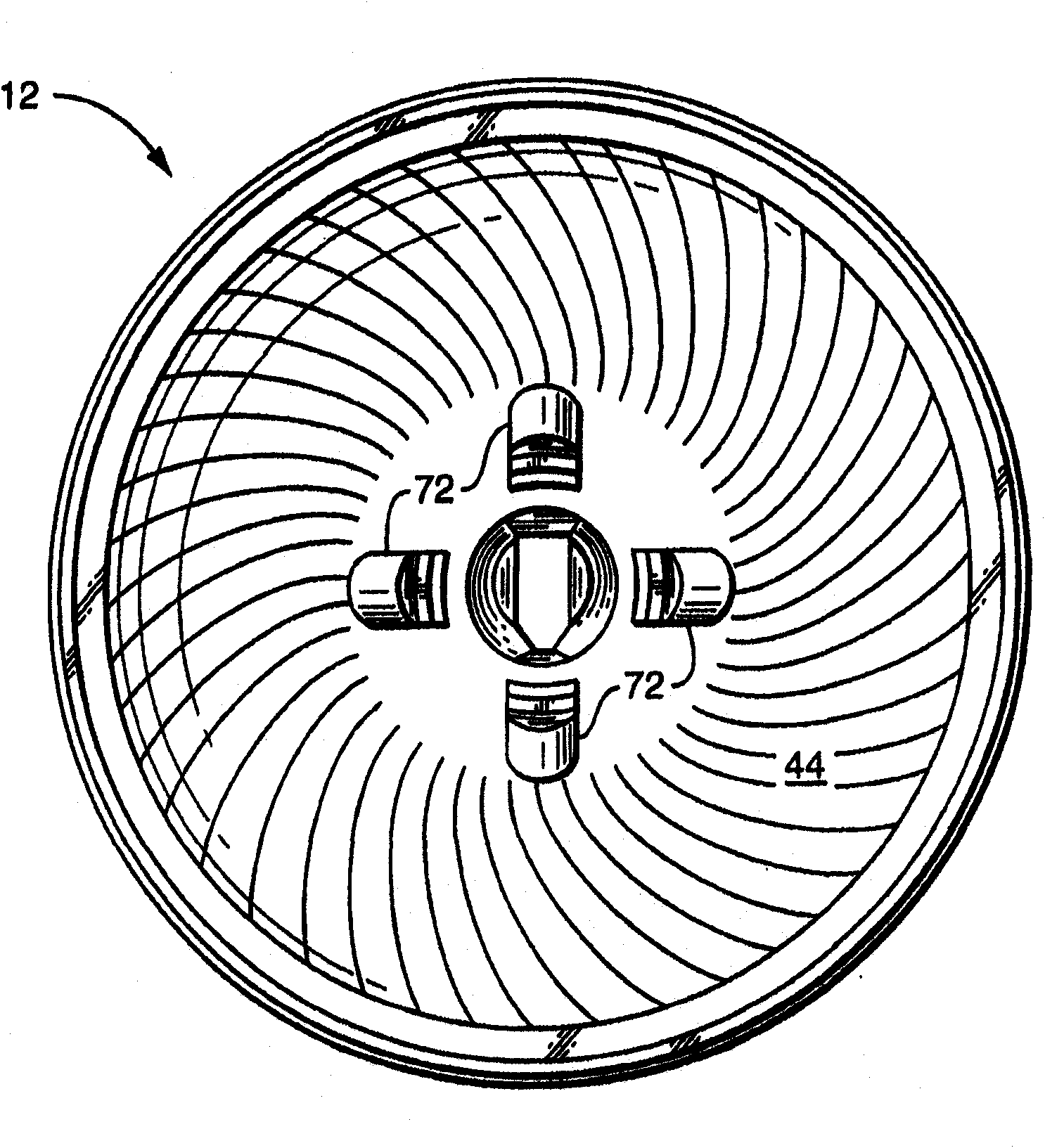

[0016] figure 1 A side perspective view of a preferred embodiment of the HID reflector lamp 10 is shown. HID reflector lamp assembly 10 is made of reflector 12 , lamp housing 14 , internal components such as inner cover 16 , circuit board 18 , heat sink 20 , outer cover 22 and threaded base 24 . A front cover lens may also be used to close the front end of the reflector 12 .

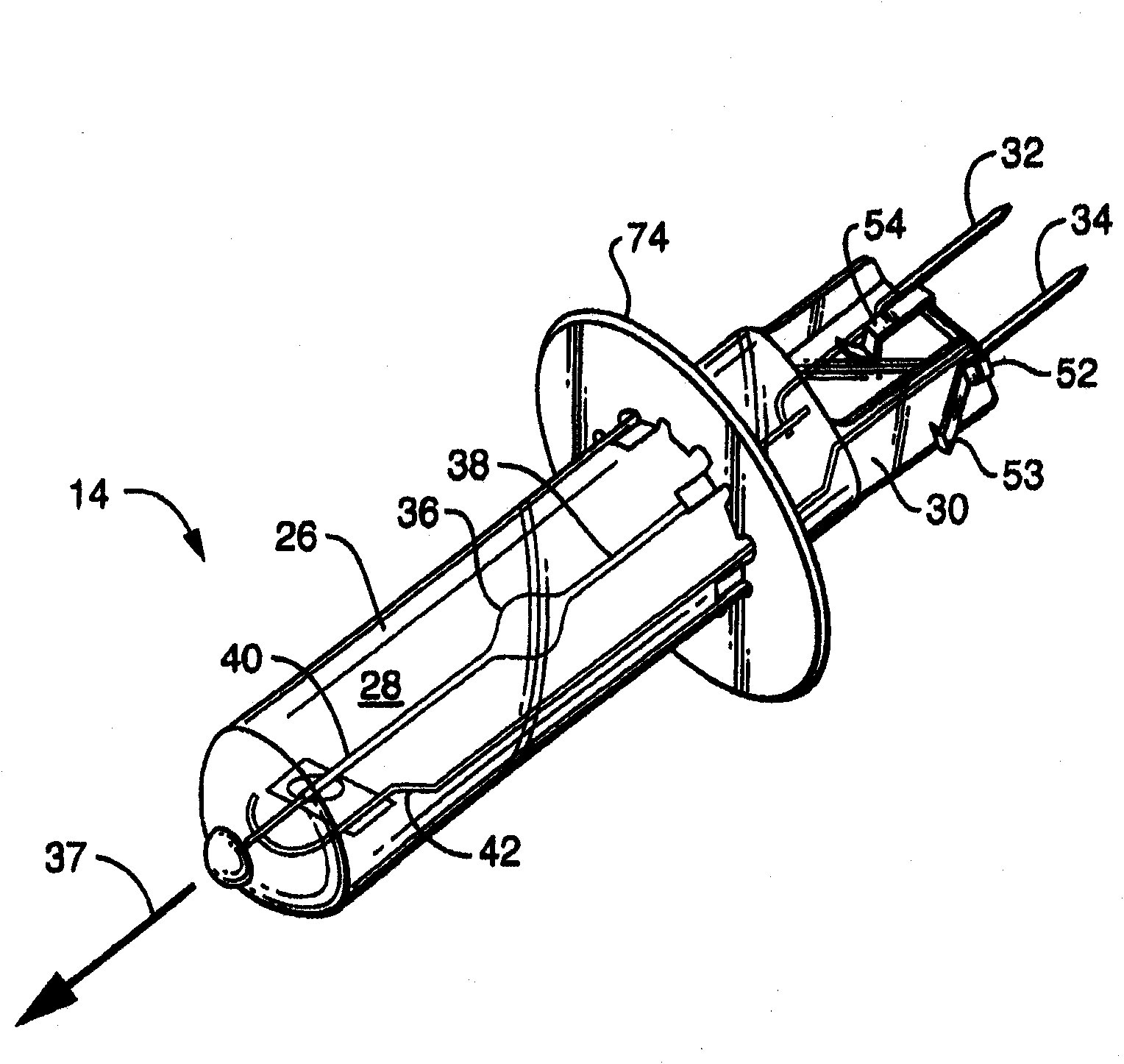

[0017] figure 2 A side perspective view of a preferred embodiment of the assembly of the integral HID light capsule 14, support ring 74, and contact clip 52 is shown. The HID capsule 14 has a wall 26 defining an enclosed space 28 , and a sealed end 30 with at least two electrical connections, a first lead 32 and a second lead 34 . The preferred capsule 14 is a tubular lamp capsule with press-fit sealed ends 30 . The preferred lamp housing 14 includes ceramic lamps 36 such as Power Balls, but any similar small ceramic or quartz HID lamp configuration would also be suitable for use in the present HID ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap