Ultrasonic transducer

A transducer and ultrasonic technology, applied in the direction of the fluid using vibration, can solve the problems of uneven ultrasonic effect, narrow operating frequency bandwidth, weak ultrasonic effect, etc., to avoid energy loss, wide operating frequency bandwidth, and avoid electric shock hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

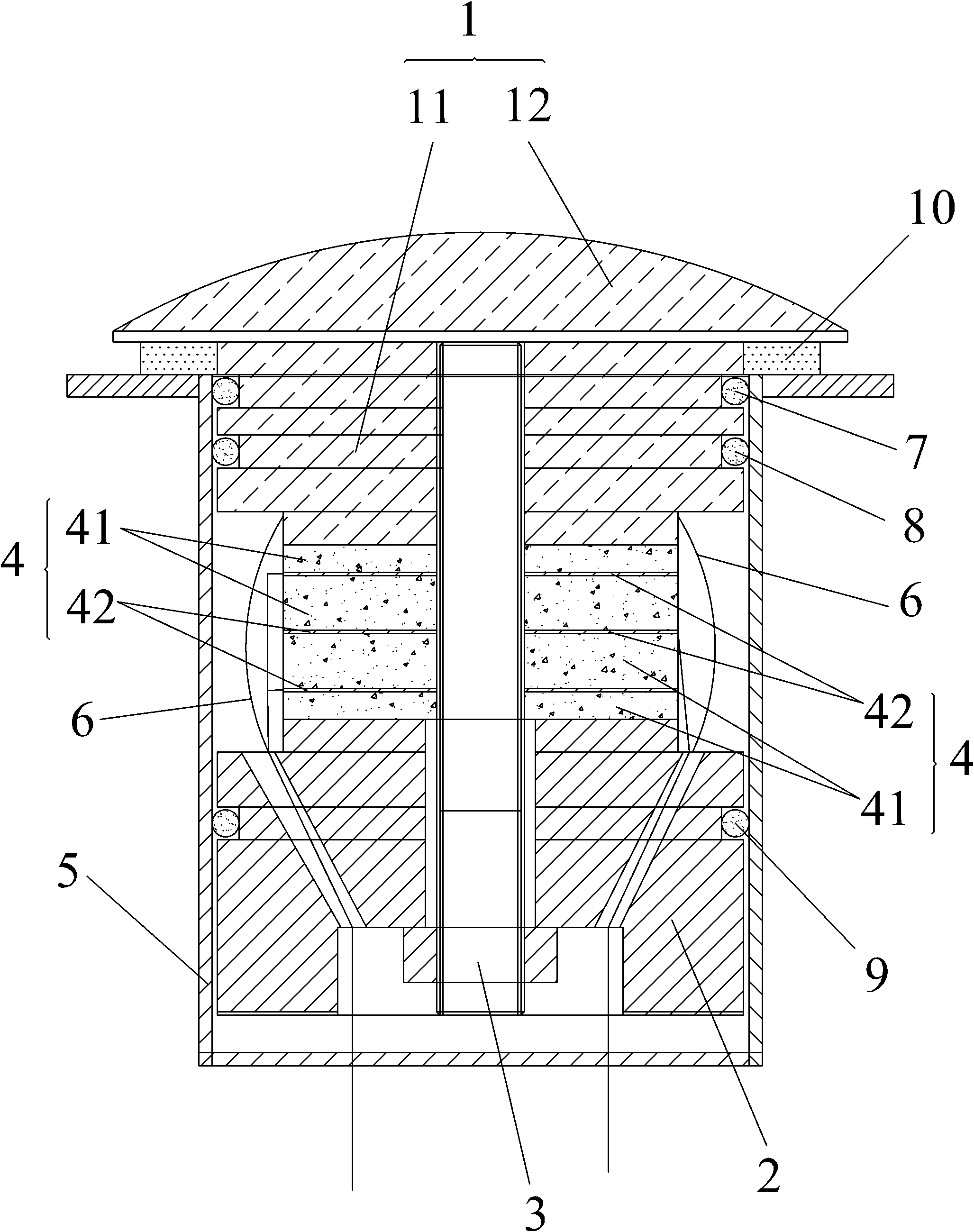

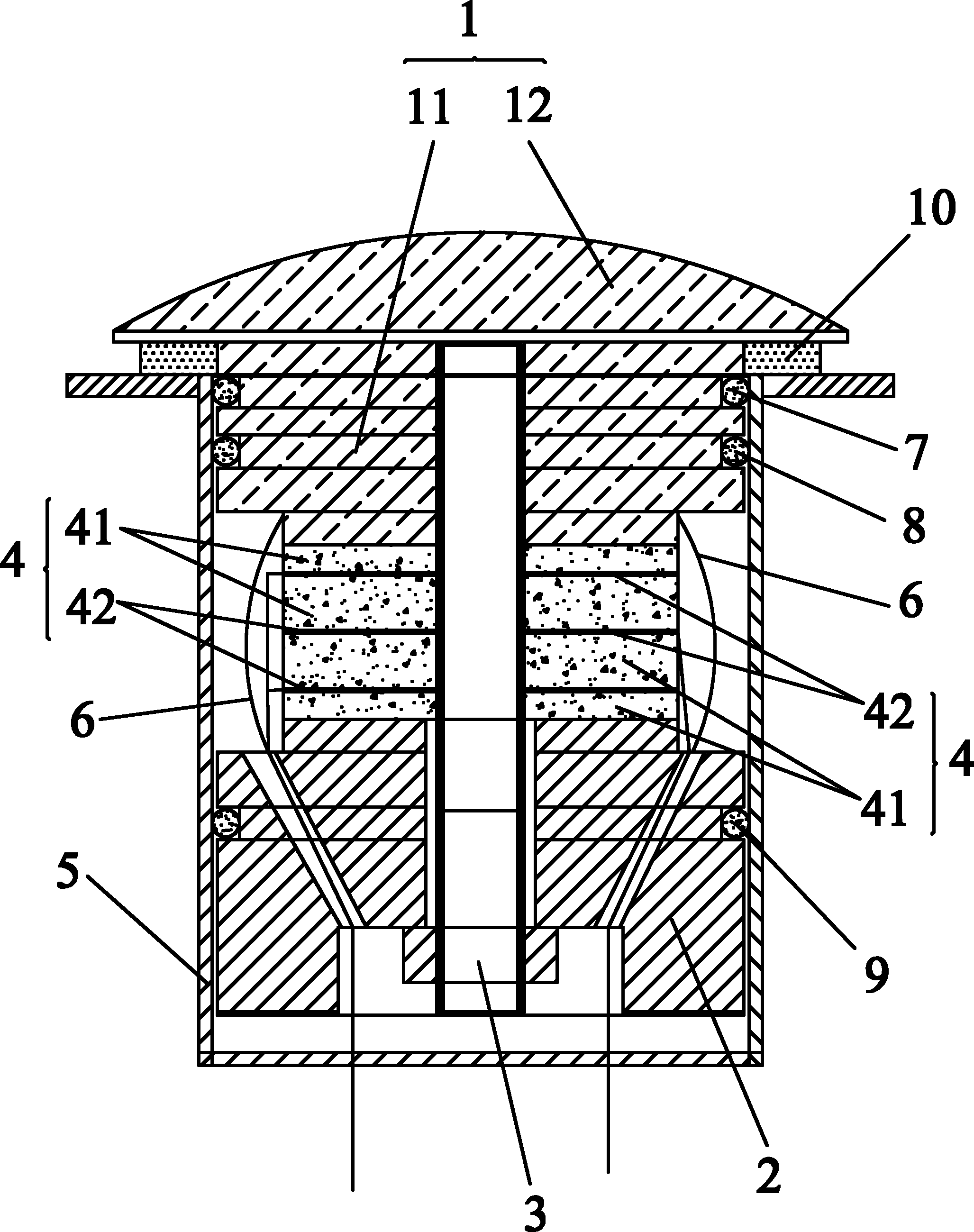

[0008] figure 1 The ultrasonic transducer shown in the present invention includes: a transmitting head 1 , a rear mass block 2 , a bolt 3 , a piezoelectric element 4 and a housing 5 .

[0009] Wherein, the emitter 1 includes a working part 12 whose top surface is a spherical convex surface and a connecting part 11 protruding from the middle part of the bottom surface of the working part 12 and extending into the housing 5, and the connecting part 11 of the emitting head 1 is arranged inside the housing 5 , the working part 12 of the launch head 1 protrudes from the top of the housing 5 . The back-end mass 2 is arranged at the bottom of the housing 5 , and the piezoelectric element 4 is fixed between the emitter head 1 and the back-end mass 2 by bolts 3 , and the bolts 3 are fixed on the connecting portion 11 .

[0010] The piezoelectric element 4 includes at least two piezoelectric ceramic sheets 41 and a non-polar electrode sheet 42 arranged between two adjacent piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com