Multi-layer cavity device with liftable shielding plates

A technology for lifting baffles and cavities, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problem of turbulent flow in the wafer, and achieve the effects of rapid response, low price and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

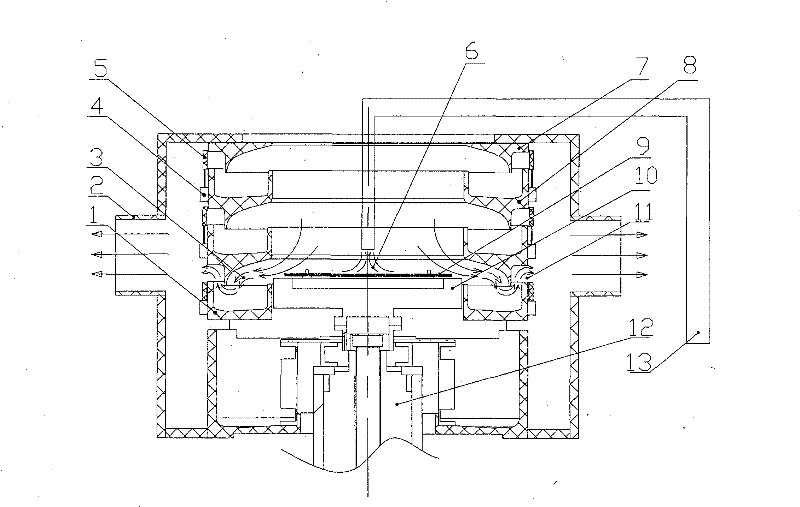

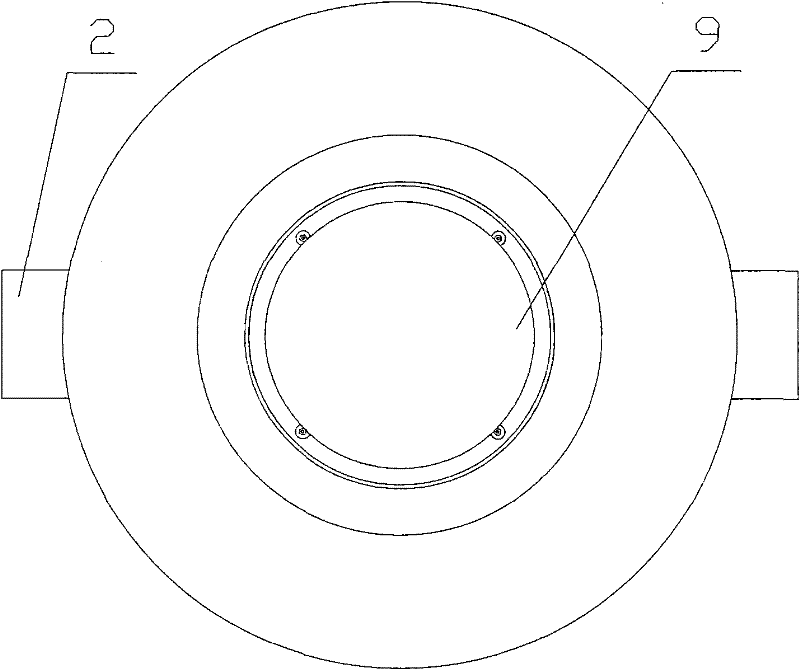

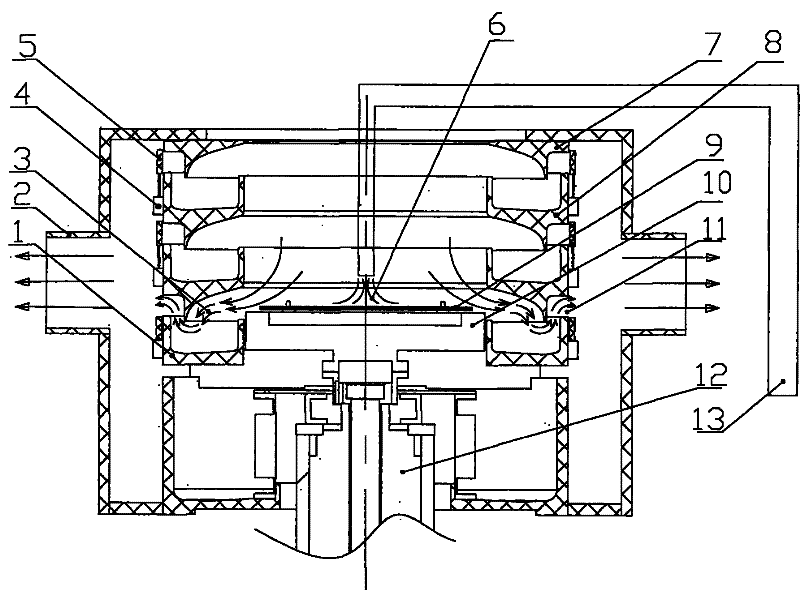

[0018] Such as Figure 1-2 As shown, the multi-layer cavity device with liftable baffles of the present invention mainly includes: the bottom layer of the cavity 1, the exhaust pipe 2, the air flow direction 3, the telescopic cylinder 4, the annular windshield 5, the chemical liquid 6, the cavity The upper layer 7, the middle layer of the cavity 8, the wafer 9, the wafer holder 10, the air outlet 11, the motor 12, the chemical liquid arm 13, etc., the specific structure is as follows:

[0019] The cavity upper layer 7, the cavity middle layer 8, and the cavity bottom layer 1 are arranged up and down to form a multilayer cavity with a stacked structure. The cavity middle layer 8 can be at least one layer, and the number of layers can be freely increased or decreased according to the process requirements. An annular windshield 5 and a telescopic cylinder 4 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com