Mount

A technology of mounting frame and frame body, which is applied in the direction of machine platform/support, supporting machine, mechanical equipment, etc. It can solve the problems affecting the balance of impeller blades, reducing the service life of fans, shaft and bearing wear, etc., to reduce vibration and noise, Effect of prolonging service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

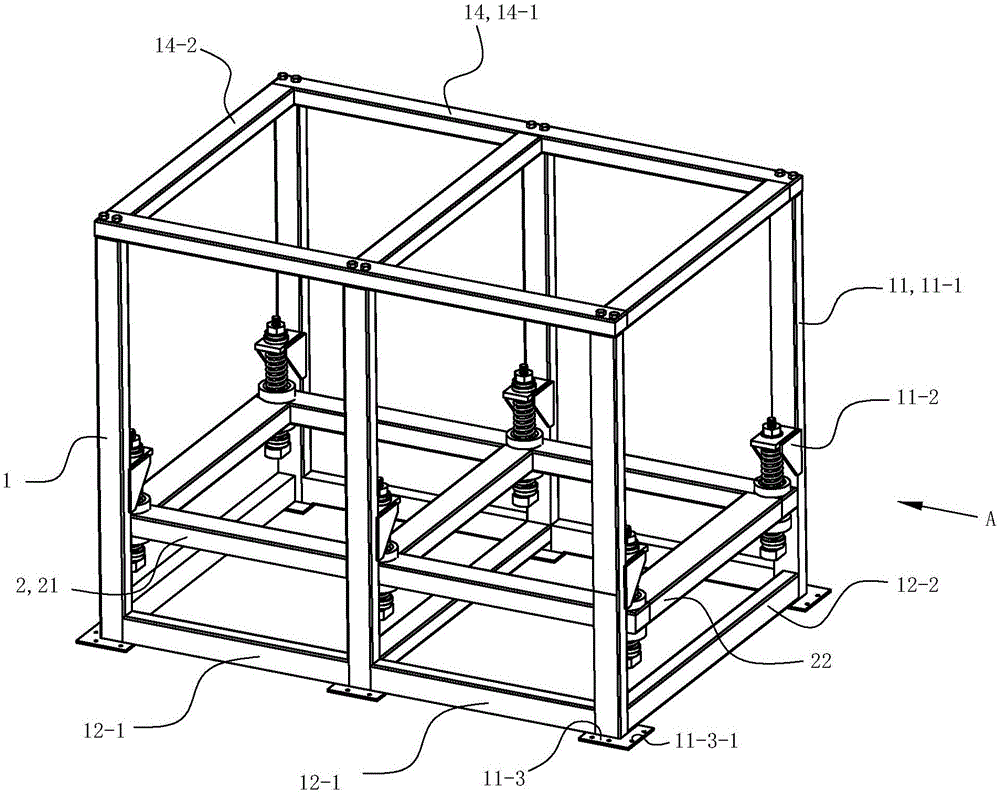

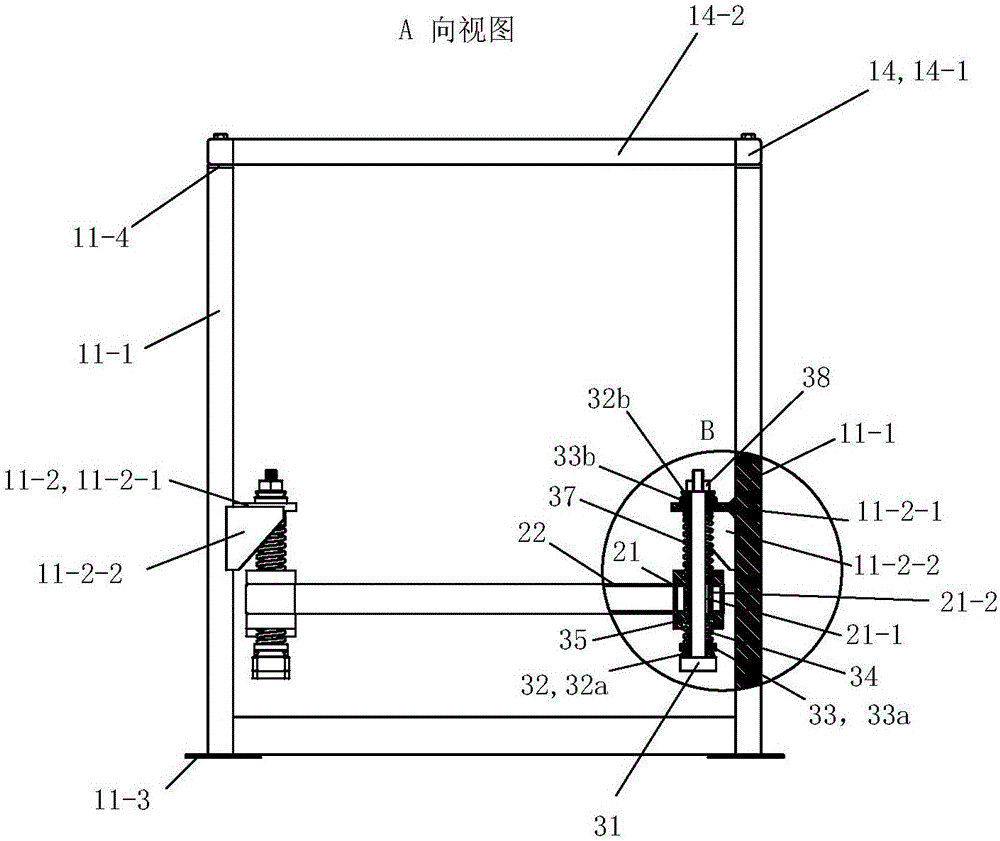

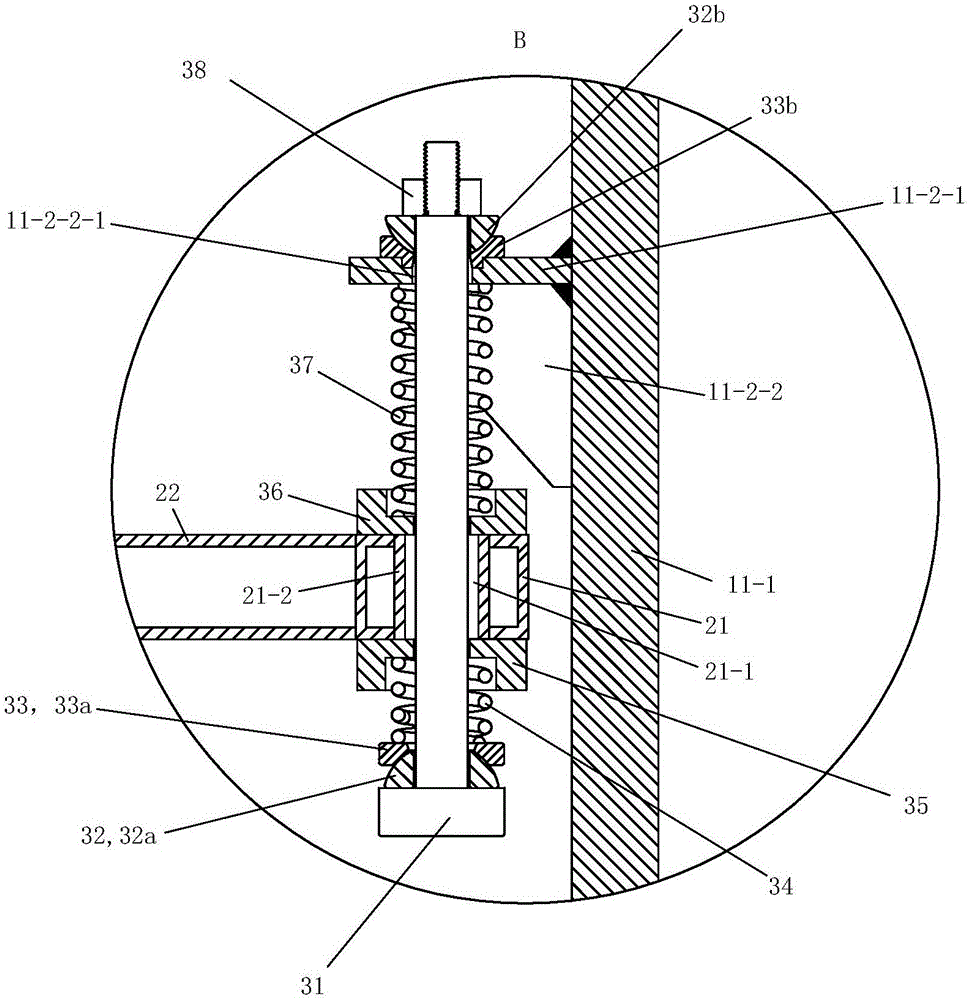

[0024] See figure 1 , The installation frame of the present invention includes a main frame body 1 , a hanger 2 and a connection assembly 3 .

[0025] See figure 1 , figure 2 and Figure 4 , the main frame body 1 includes a column assembly 11 , a connecting beam assembly 12 and an upper connecting frame 14 .

[0026] See figure 1 , figure 2 and Figure 4 , the column assembly 11 has 3 to 8 groups, the present embodiment is 6 groups, and the 6 groups of column assemblies 11 all include a column 11-1, a connecting frame 11-2, a lower fixing plate 11-3 and an upper connecting plate 11-4 . Column 11-1 is a square tube or I-beam or channel steel, and the present embodiment is a steel square tube. Each column 11-1 of the column assembly 11 is arranged vertically by its axis, and the projections of each column 11-1 are connected successively to form a regular polygon or a rectangle. That is, each upright column 11 - 1 is located at the midpoint of the four legs of an imagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com