Paying-off system and method

A technology for pay-off pulleys and wires, applied in the directions of overhead lines/cable equipment, cable railways, motor vehicles, etc., can solve the problems of insufficiency, waste of resources, stretching equipment, and too many traction rope wires, etc., so as to improve the lack of traction, Improve the effect of waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

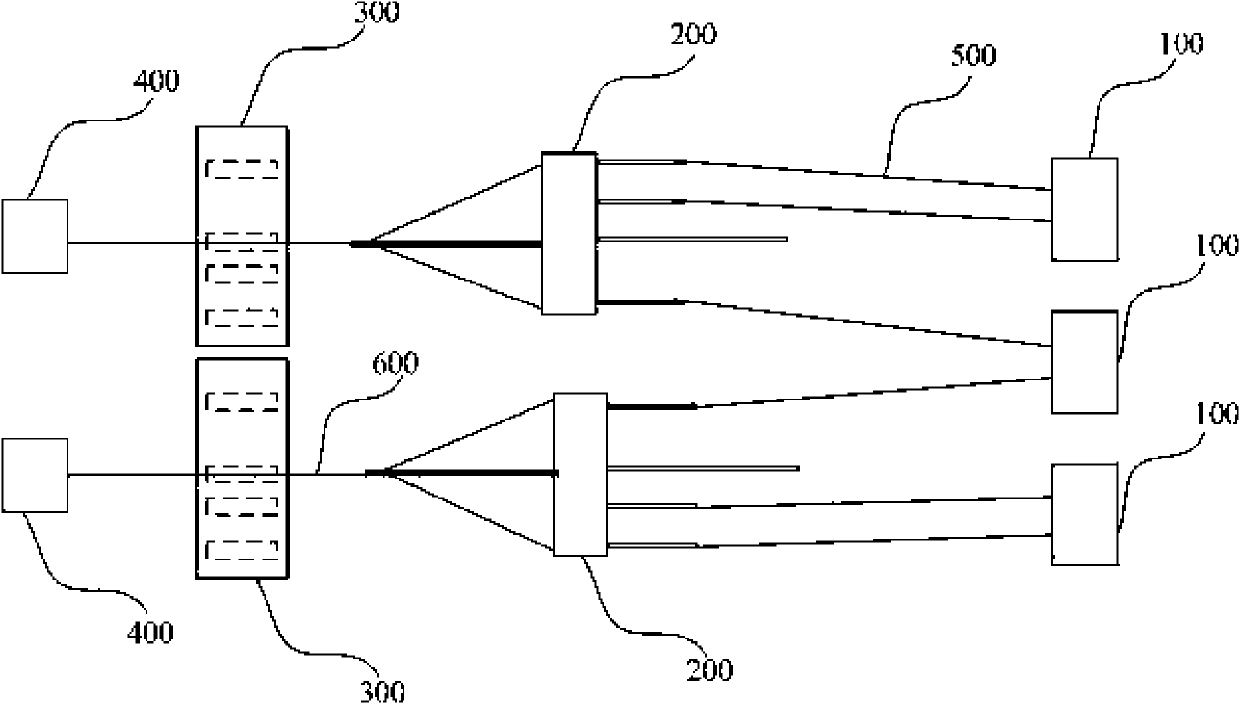

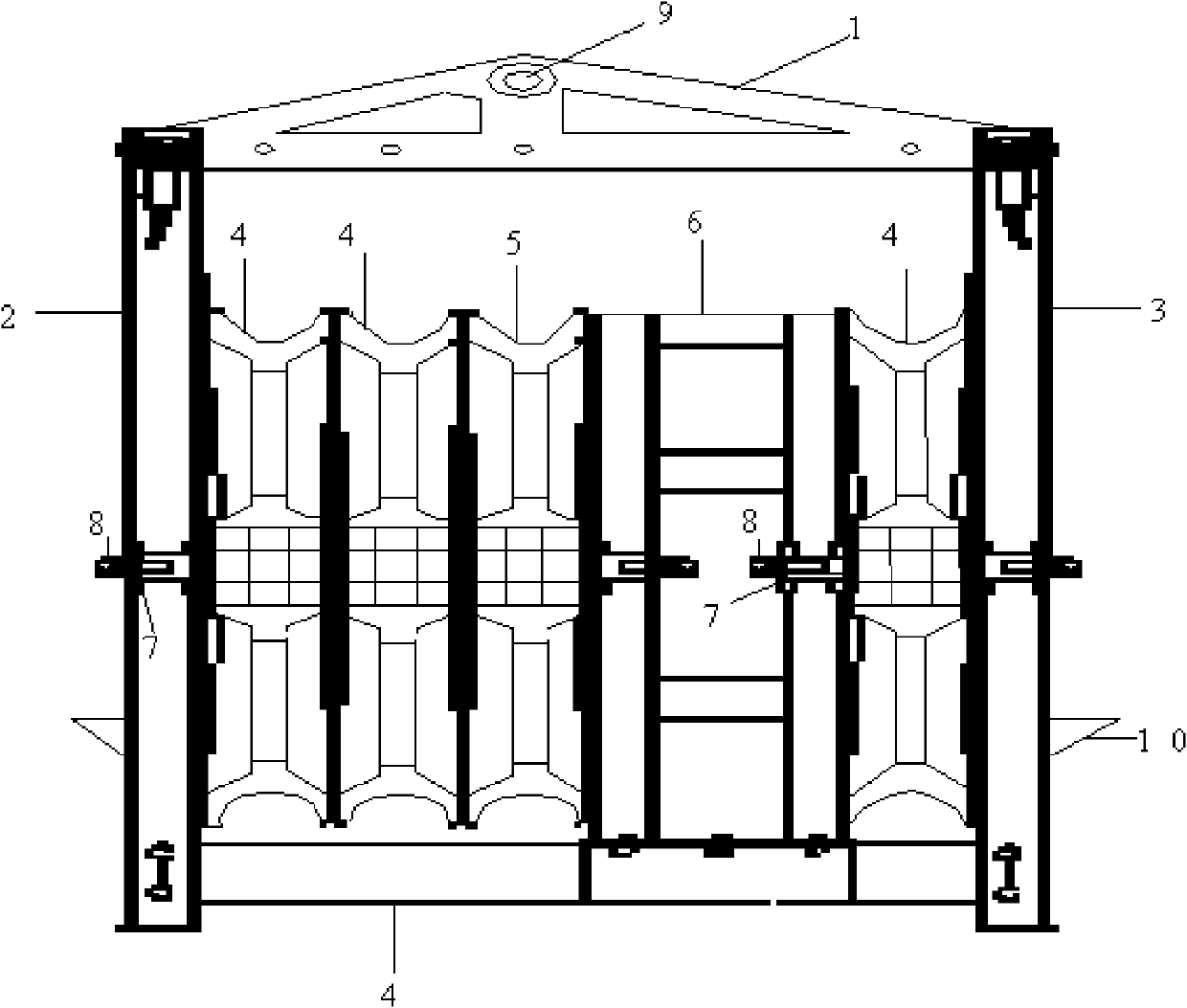

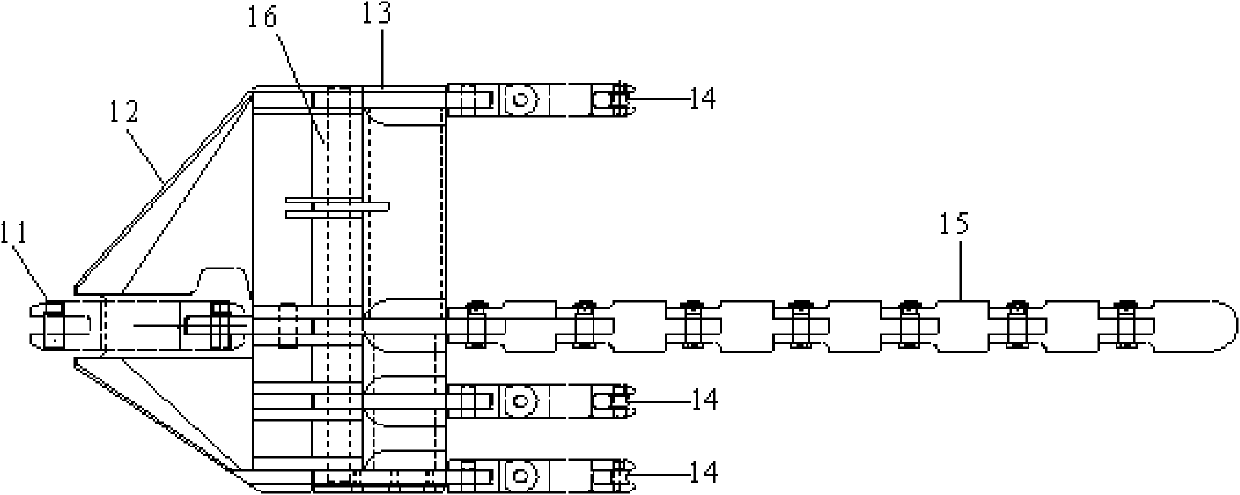

[0022] The purpose, functions and advantages of the present invention will be further described with reference to the accompanying drawings in conjunction with the embodiments.

[0023] The pay-off system provided by the embodiment of the present invention may include at least one tractor as the main traction device, at least two tension machines and at least one pay-off tackle. The traction machine pulls the three conductors laid out by the two tension machines through a traction rope laid out by it through the three lead pulleys of the pay-off block. Such as figure 1 As shown, a pay-off system of 2×"one pull 3" can be formed. The 2×"one pull 3" pay-off system may include two tractors 400, two pay-off tackles 300 and three tension machines 100.

[0024] During setting-out construction, two tractors 400 (such as 25 tons) are set as the main traction equipment in the traction field, three second-line tension machines 100 are set in the Zhang stand, and two sets of mutually in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com