High-density interconnection printed circuit board treatment technology and treatment equipment

A printed circuit board, high-density interconnection technology, used in lighting and heating equipment, smoke removal, dryers, etc., can solve the problems of reducing cleaning effect, complicated cleaning process, increasing cleaning cost, etc., to improve cleaning effect, Guaranteed cleaning effect and reduced cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

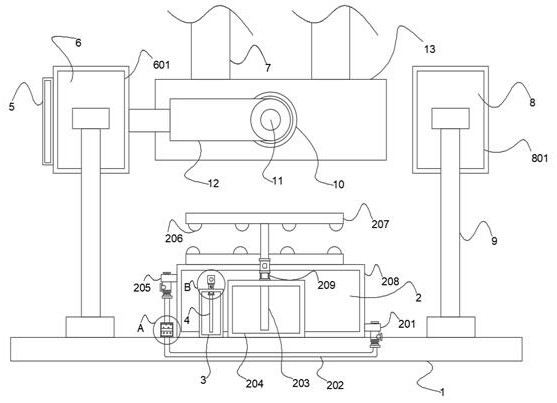

[0028] See Figure 1-6 ,

[0029] Located on top of the base 1 and the cleaning apparatus 2 are both fixedly connected with a support column 9, to facilitate fixing the dust removing device 6 and the drying unit 8, the back support plate 13 is fixedly connected with a fixing plate 15, bottom plate 15 is fixed to the fixed driving connection motor 14, the drive output of the motor 14 is fixedly connected with a rotary shaft penetrating the support plate 13 is 11, the driving motor 14 provides power to drive shaft 11 is rotated, the front support plate 13 defines the through-hole wall 13 front through hole, the support plate defines the welded fixing sleeve 11 provided in the outer wall of the shaft bearing 10, the bearing mounting plate 10 while ensuring the support shaft 11 is rotated 13 does not rotate, both ends of the outer wall of the rotary shaft 11 are fixed sleeve 12 is provided with an electric push rod, the push rod 12 remote from the electric One end of the rotary shaft 1...

Embodiment 2

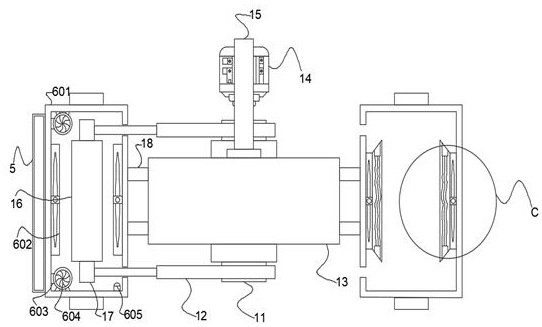

[0031] See Figure 1-6 ,

[0032] Top of the base 1 and the support post 2 located on the left side of the cleaning means 9 are fixedly connected to the back of the dust removing device 6, the dust removing device 6 comprises a dust box 601 and the purge tank 5, the purge gas to facilitate the discharge of vacuum blower 604, the gas discharged into the air to avoid , the pollution of the environment, the inner wall of the left and right inner walls of dust bins 601 are fixedly connected with the first blower 602, the blower 602 generates a first wind blown off dust on the surface of the printed circuit board, the front and the rear inner wall of the inner wall 601 of the dust box are 604 fixedly connected with a suction fan, the inlet end of the suction fan 604 creates a suction, gas in the vicinity of the tank 601 is sucked into the dust suction fan 604, the discharge end of suction fan 604 are fixedly connected with the tank 601 through dust an exhaust pipe 603, exhaust pipe 603 ...

Embodiment 3

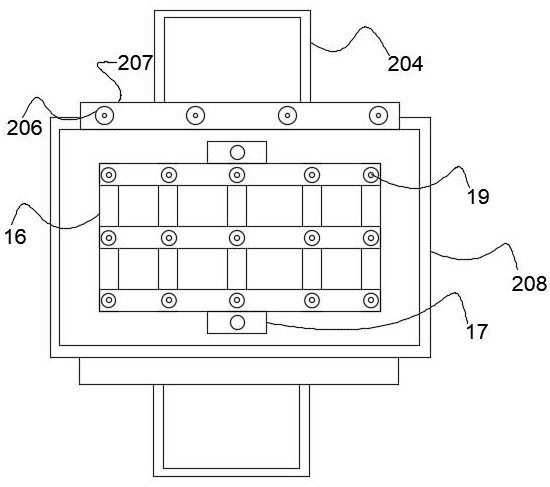

[0034] See Figure 1-6 A high density interconnect printed circuit board processing technology and processing device, comprising a base 1 and the support plate 13, a top of the base 13 and located at the position immediately below the support plate is provided with a cleaning apparatus 2 for cleaning printed circuit boards, cleaning apparatus 2 comprises a base 1 fixed to the top of the cleaning tank 208, washing tank 208 store the cleaning liquid, the bottom of the cleaning tank 208 is fixed to the right side is connected to the first water pump 201, water pump 201 outlet end of the first sleeve provided with a first a pipe 202, a first outlet pipe 202 is provided with a second end sleeve fixed to the top left side of the pump 208 of the cleaning tank 205, the first pump 201, a first pipe 202, a second washing tank 208 and the pump 205 form a loop, to facilitate circulating the cleaning liquid, cleaning liquid flows using a printed circuit board is cleaned to improve the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com