Shoe-shaped one-step extrusion, ironing and shaping process and special equipment thereof

An ironing and shoe-shaping technology, applied in shoe lasts, applications, footwear, etc., can solve the problems of restricting the grade of leather shoes, discontinuous deformation of upper materials, and low labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

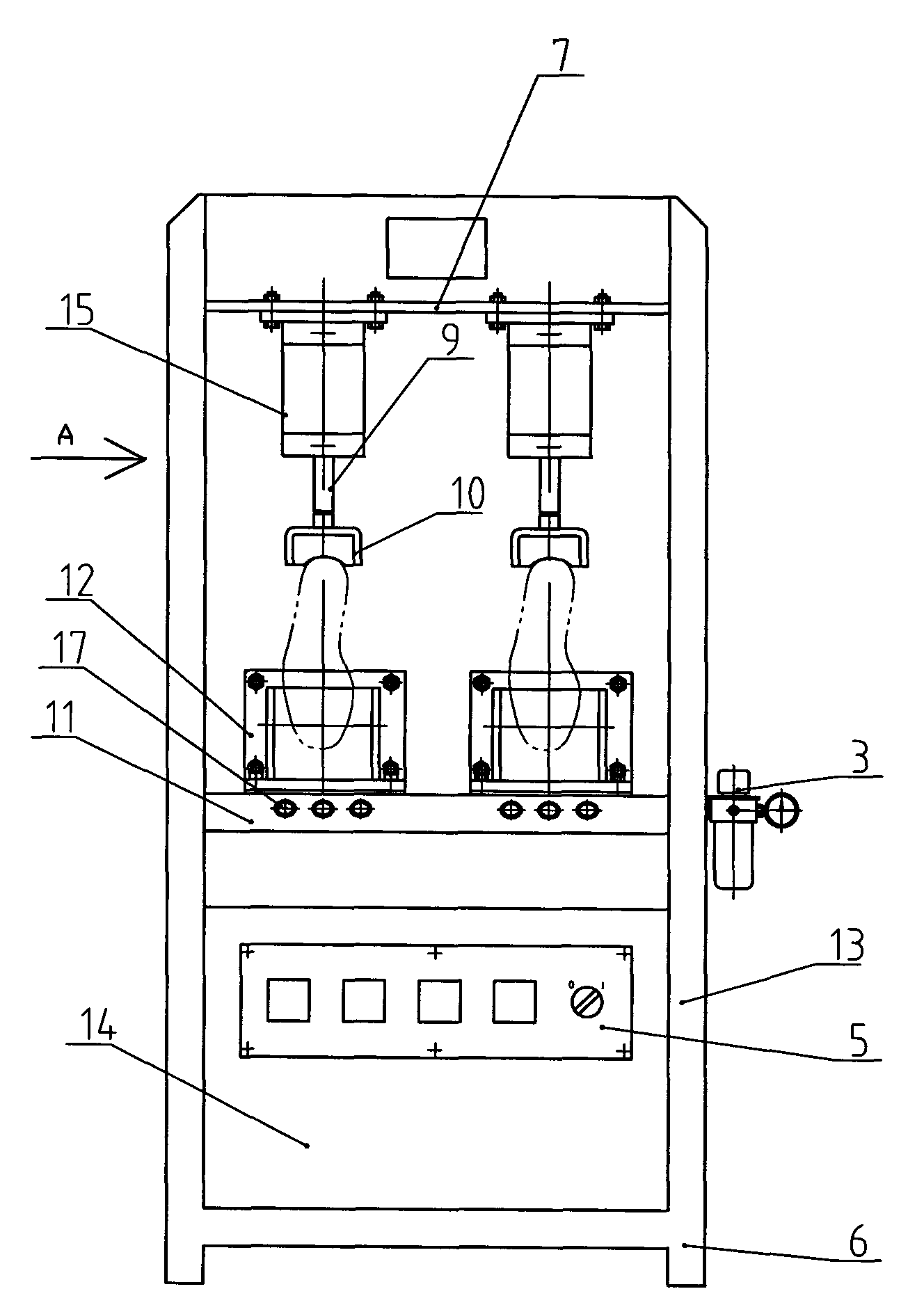

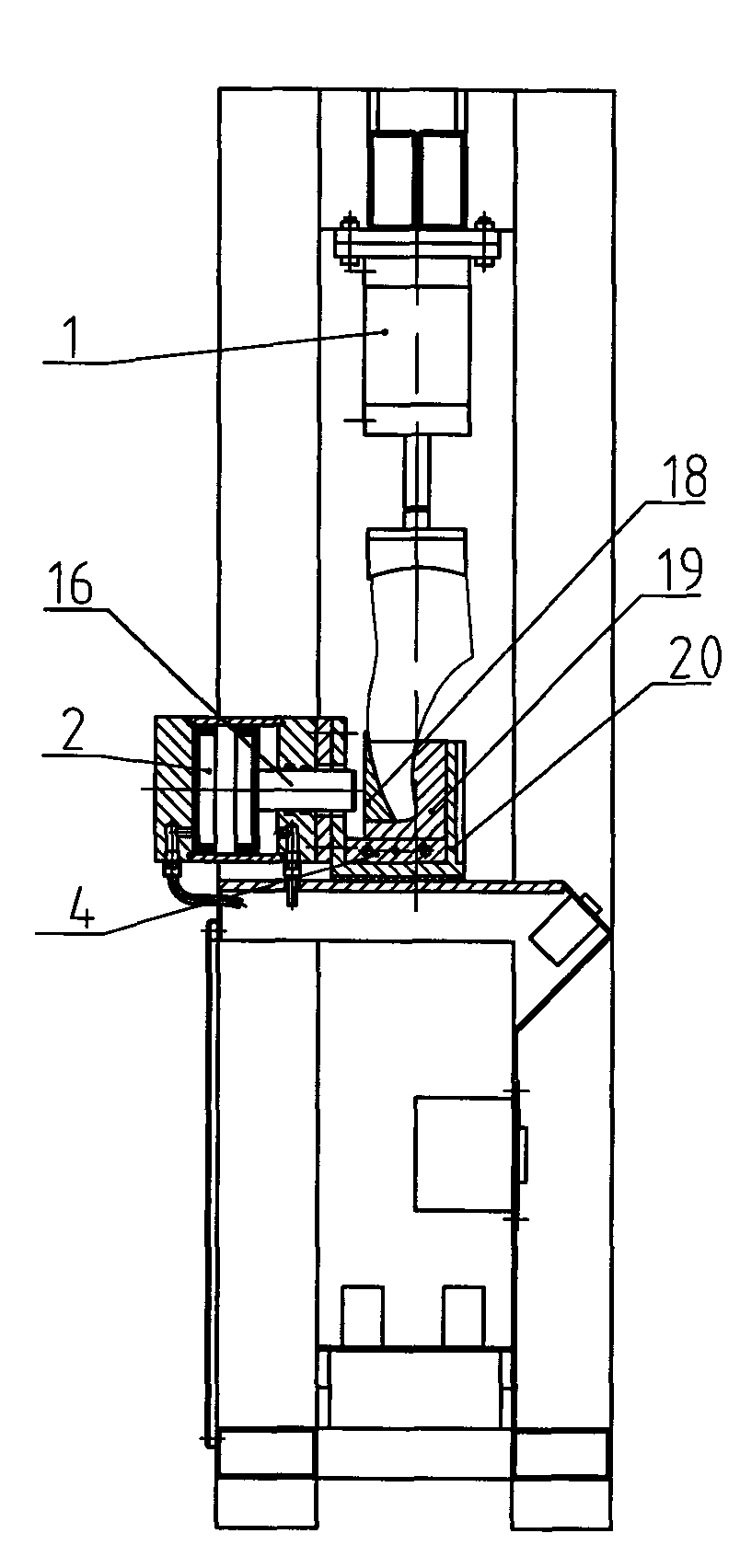

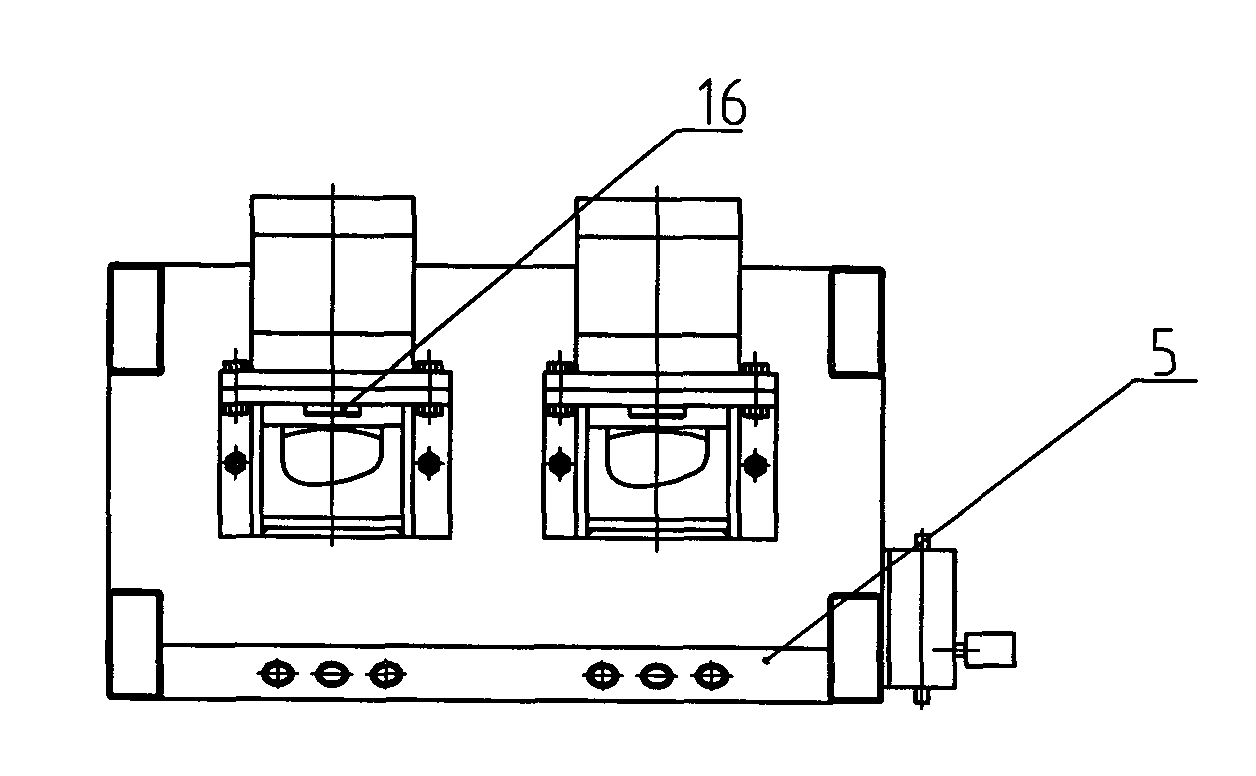

[0027] Embodiment 1: A kind of one-time extrusion ironing shaping process of shoe shape, comprises the following steps:

[0028] a. Use computer scanning technology to collect shoe last data, and then use computer engraving machine to carve the shoe last mold cavity, put the semi-finished shoe cover on the shoe last, and then put the shoe last head down into the shoe last mold;

[0029] b. Start the vertical piston cylinder and the horizontal piston cylinder of the extrusion ironing shaping machine once, and start the mold heating device of the extrusion ironing shaping machine at the same time to heat, extrude and iron the upper surface and inner lining materials. When the upper material is genuine leather, the temperature is controlled at 100°C to 125°C and kept warm for 5s;

[0030] c. Start the extrusion ironing and shaping machine once, the shoe last mold is opened, the piston cylinder returns to its original position, and the shoes are taken out.

Embodiment 2

[0031] Example 2: A process for one-time extrusion and ironing of shoe shapes. When the material of the semi-finished shoe upper is genuine leather, the temperature in step b is controlled at 115°C-122°C, and the temperature is kept for 8s. Other steps are the same as in Example 1.

Embodiment 3

[0032] Embodiment 3: One-time extrusion and ironing shaping process for shoe shape. When the upper material of the semi-finished product is genuine leather, the step b is kept warm for 8 seconds, and the other steps are the same as in embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com