Patents

Literature

47results about How to "Guaranteed ironing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

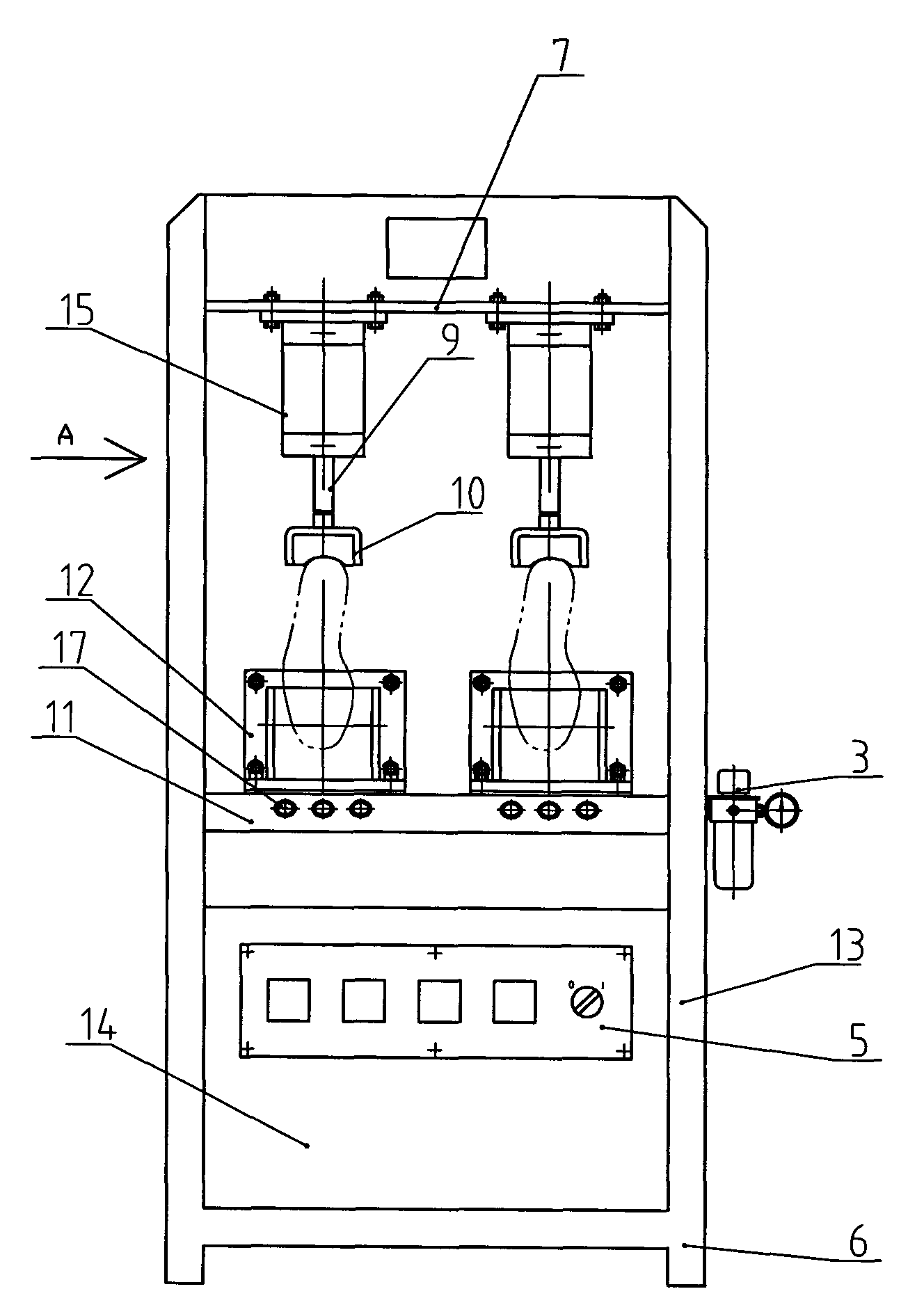

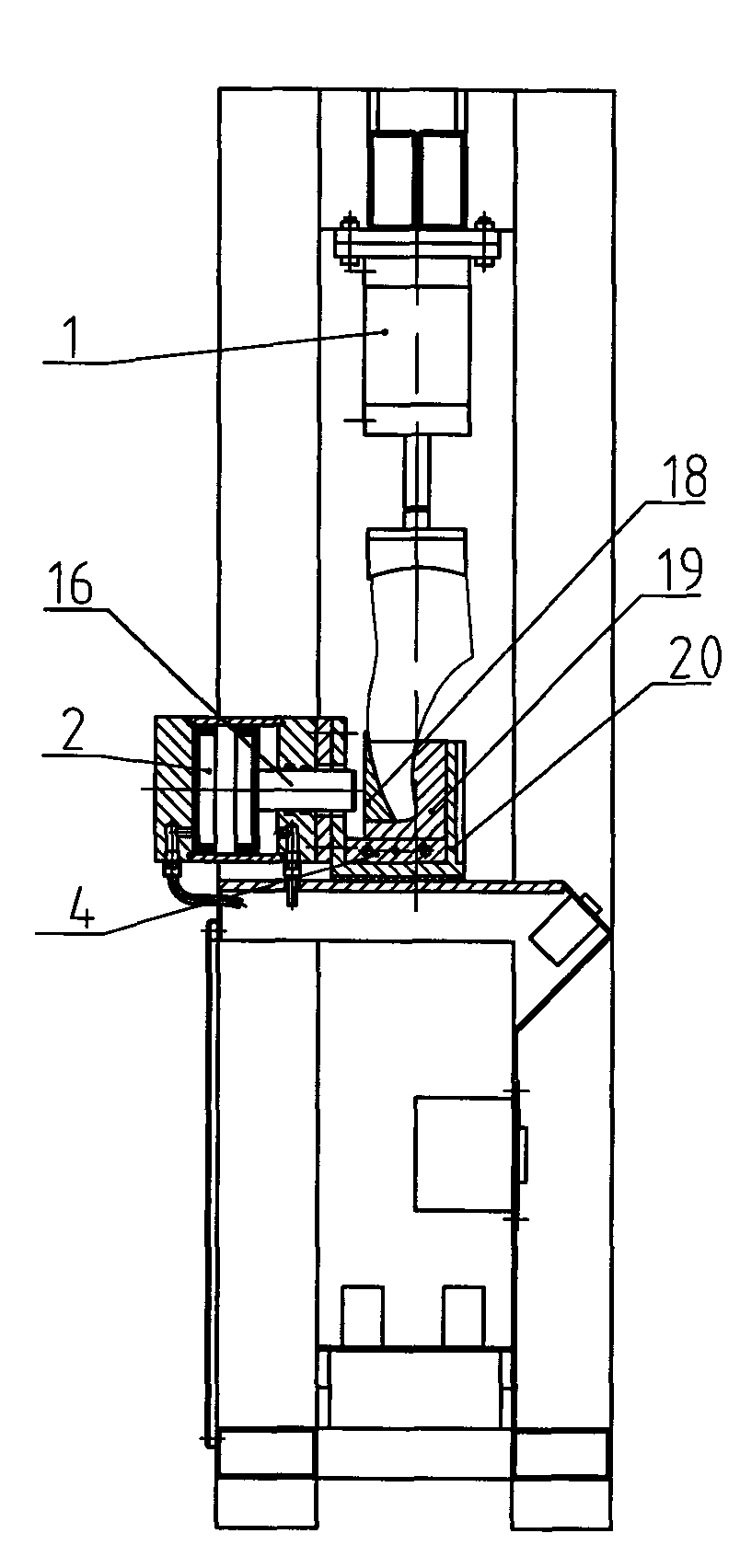

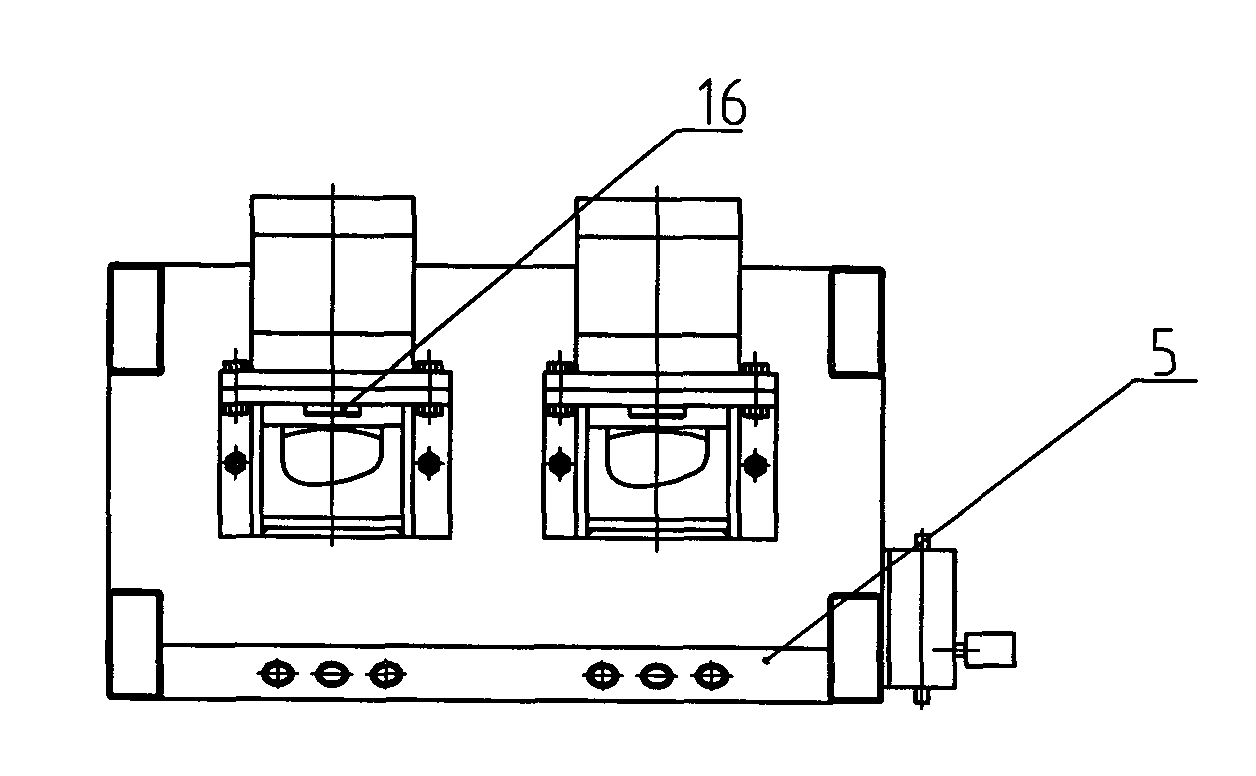

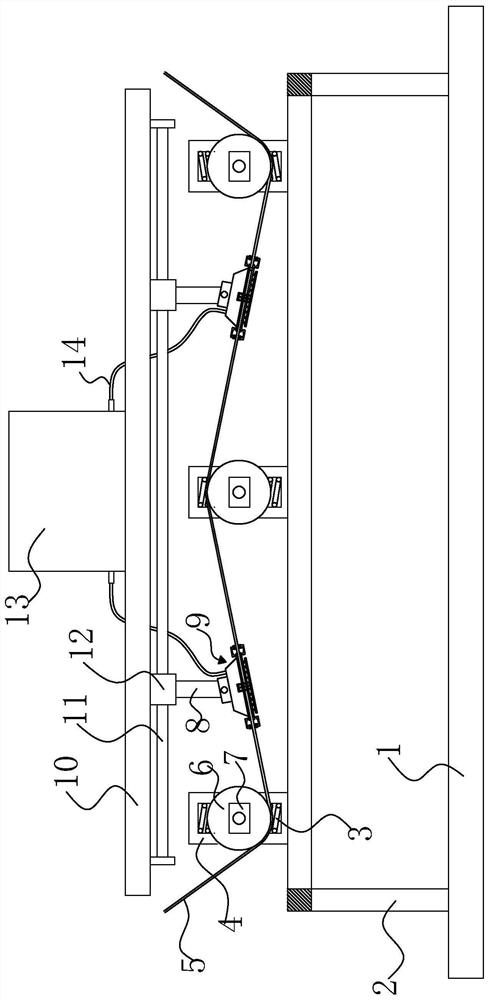

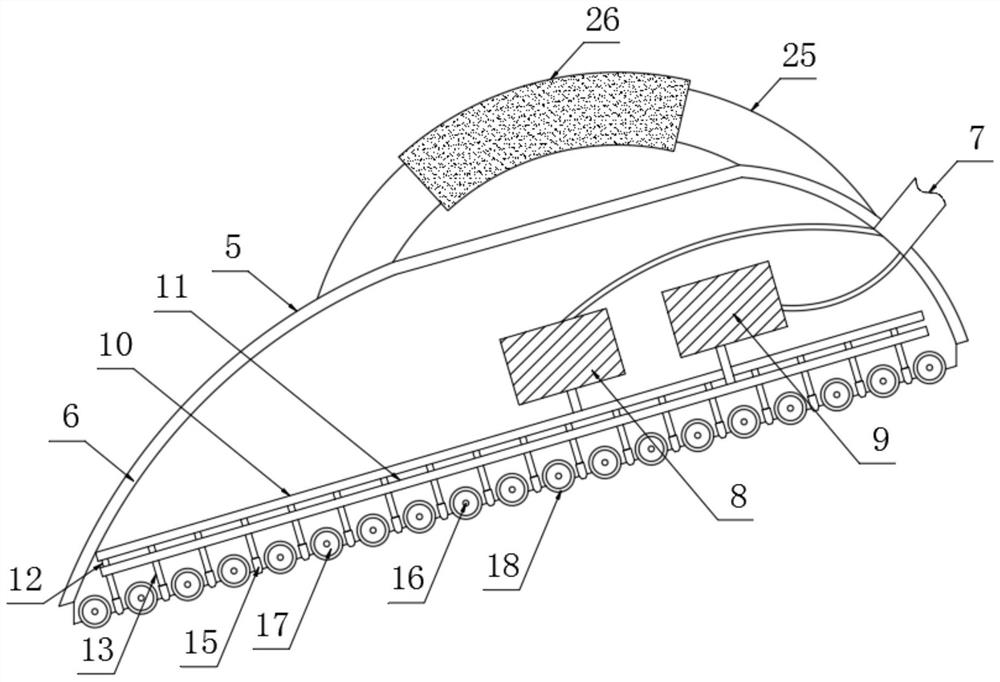

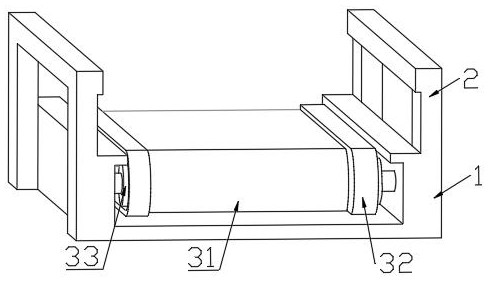

Shoe-shaped one-step extrusion, ironing and shaping process and special equipment thereof

InactiveCN102028340AHarmonious light refraction effectGuaranteed ironing effectLastingShoe sizeWork in process

The invention discloses a shoe-shaped one-step extrusion, ironing and shaping process and special equipment thereof. The shoe-shaped one-step extrusion, ironing and shaping process comprises the following steps of: a, manufacturing a boot tree die, sleeving a semi-finished product shoe to be shaped on the boot tree, and placing the boot tree into the one-step extrusion and ironing boot tree die; b, heating the boot tree die and heating, extruding and ironing an opposite upper face and a lined material of the boot tree, wherein the temperature is controlled to be between 80 and 122 DEG C and the heat is preserved for 3 to 12 seconds; and c, opening the boot tree die and taking out the shoe. According to the technical scheme, the shoe-shaped one-step extrusion, ironing and shaping process and the special equipment thereof have the advantages that: due to the precision consistency of the boot trees with the same shoe size and the uniform consistency of the upper materials, the upper faceis extruded and ironed through the surface of the high-temperature smooth boot tree die, so that the upper and the vamp are attached to the boot tree, materials are redistributed, the internal organization structure of the upper material is improved, the boot tree has the visual effects of a smooth line, a dense and flat upper face and a harmonious upper face photorefractive effect, and the ironing effect of the upper face can be guaranteed.

Owner:JIHUA 3515 LEATHER & SHOES

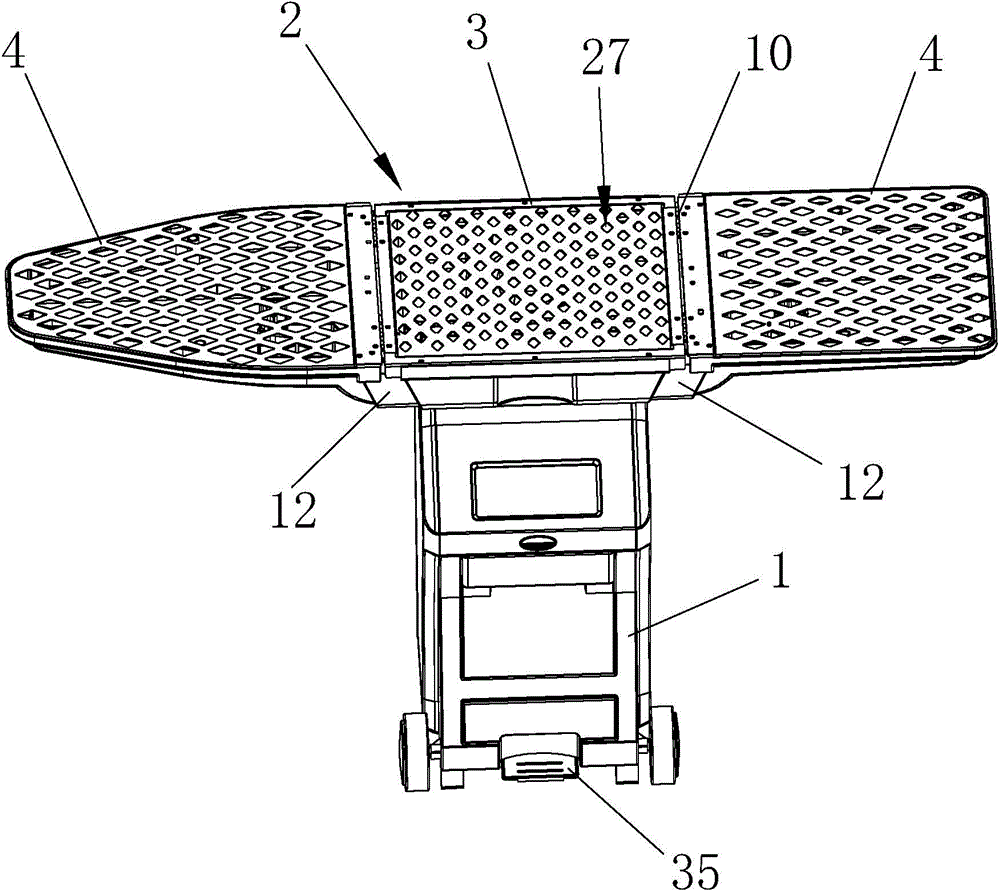

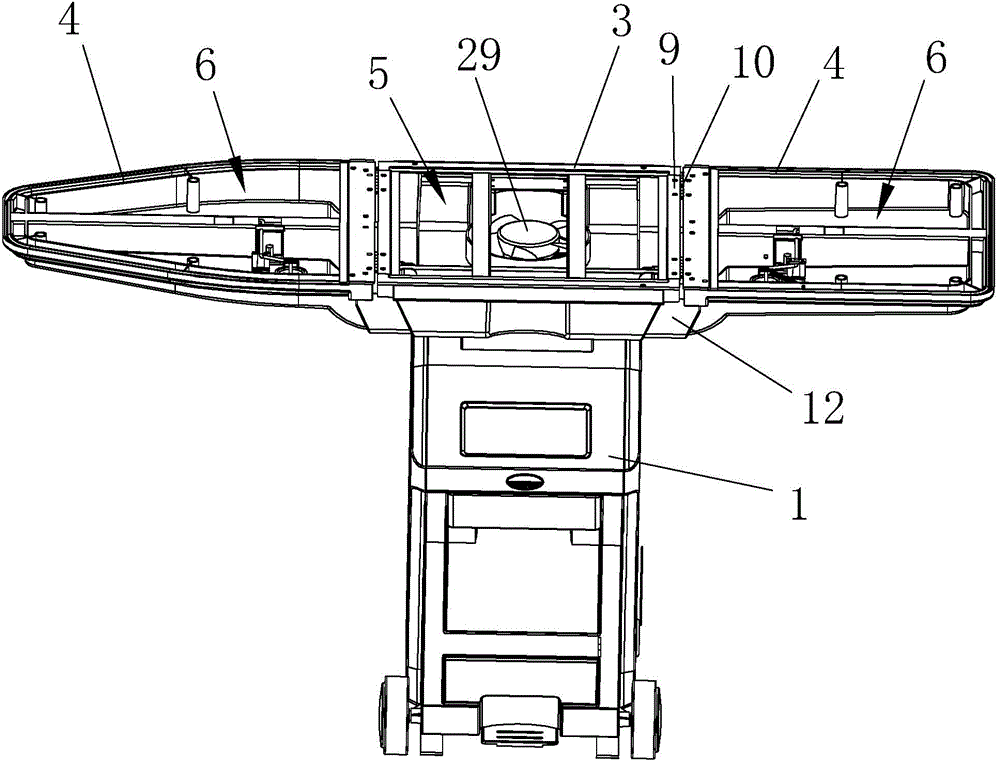

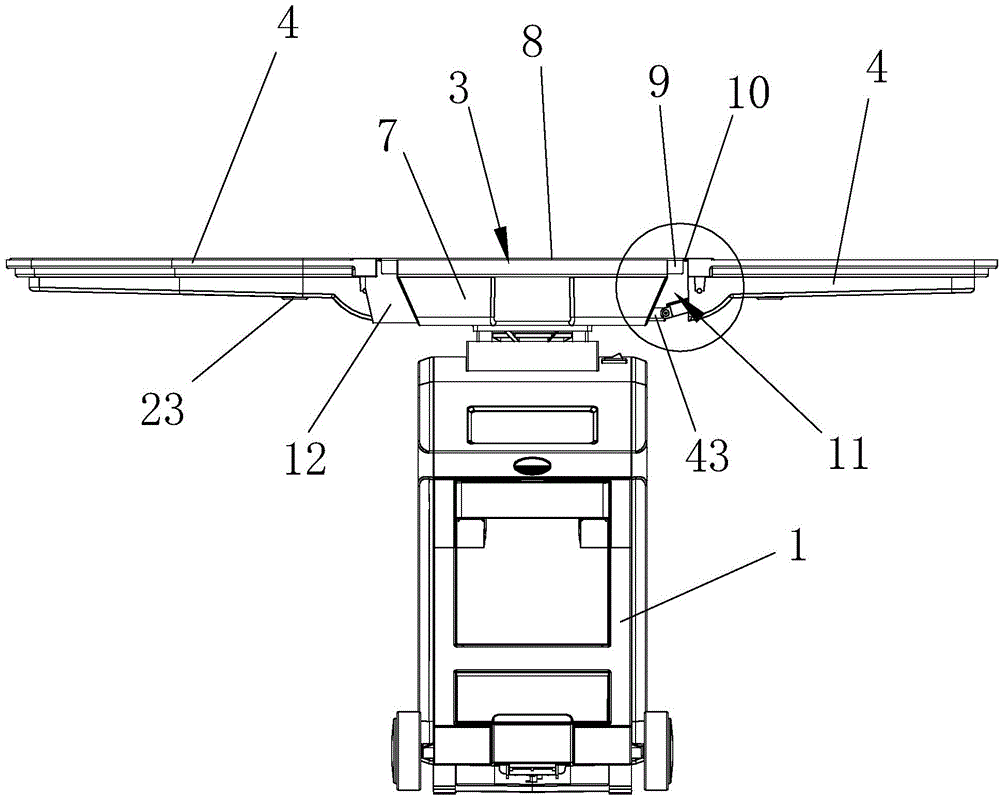

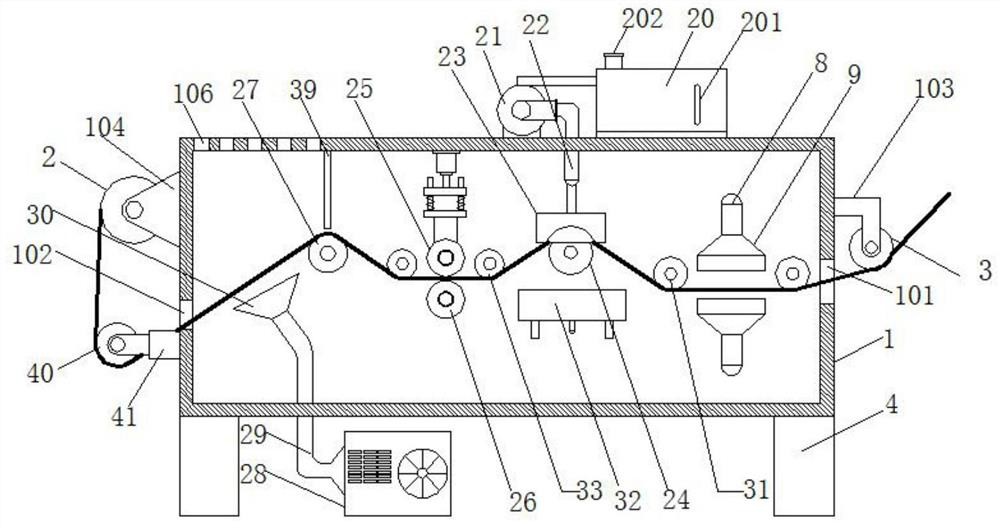

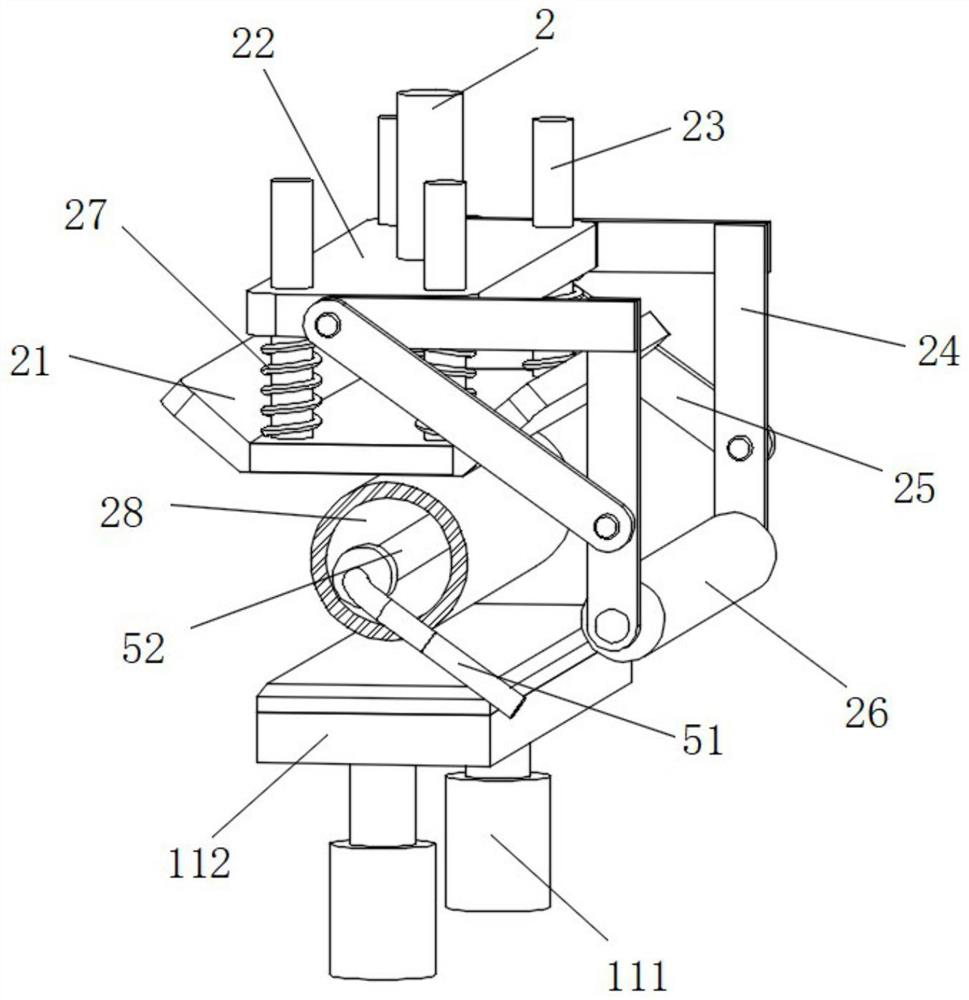

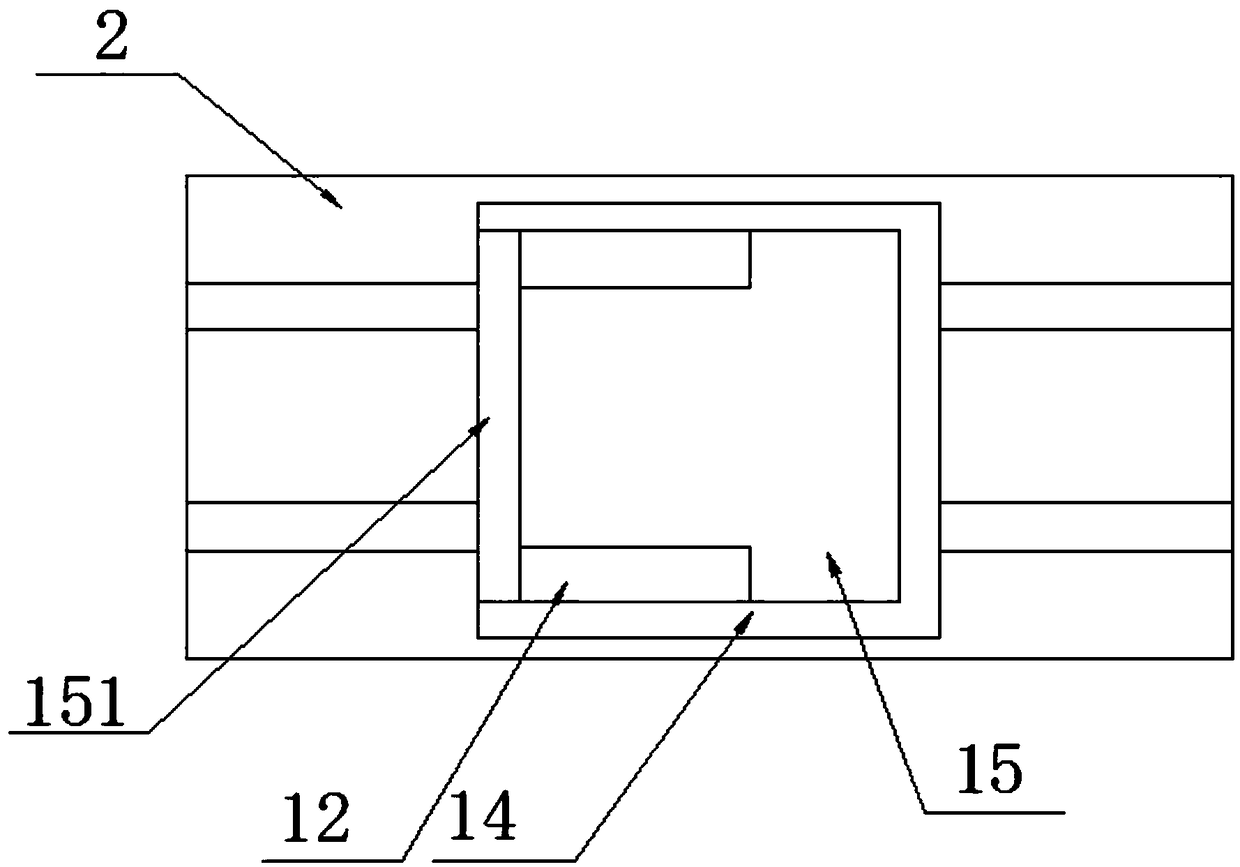

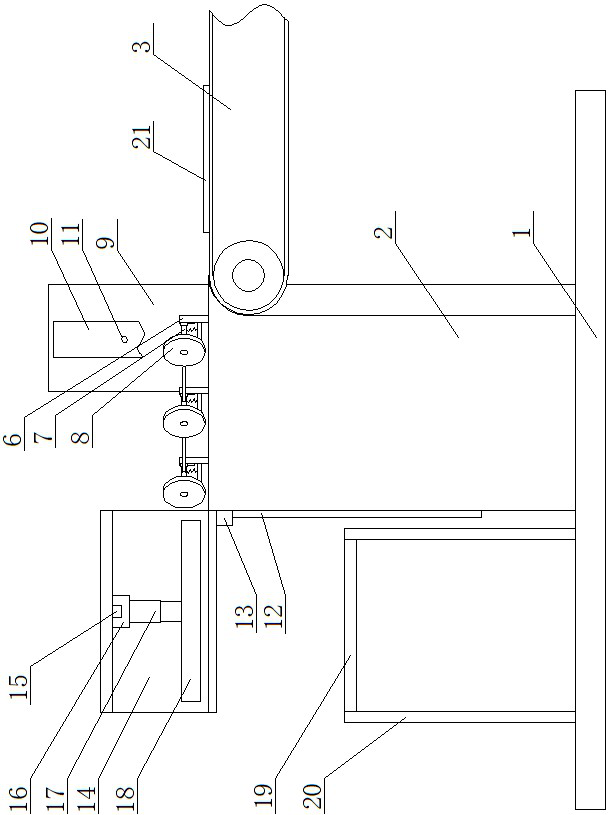

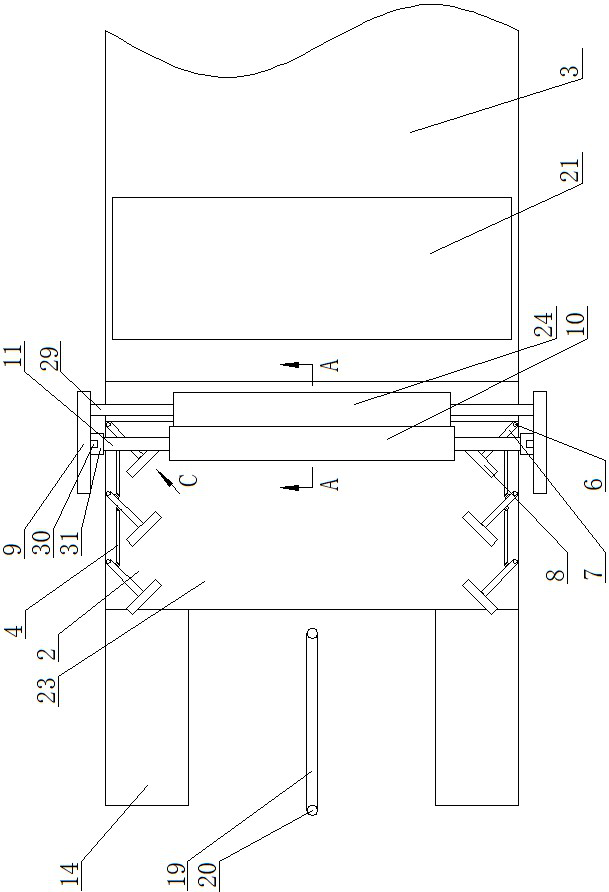

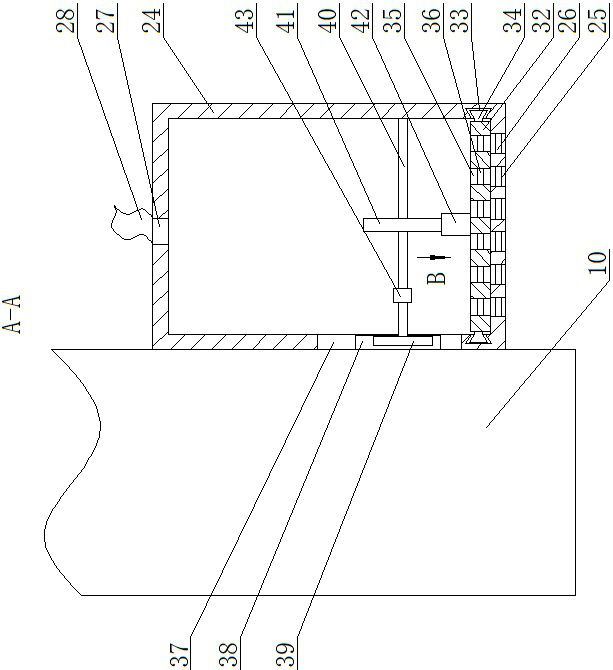

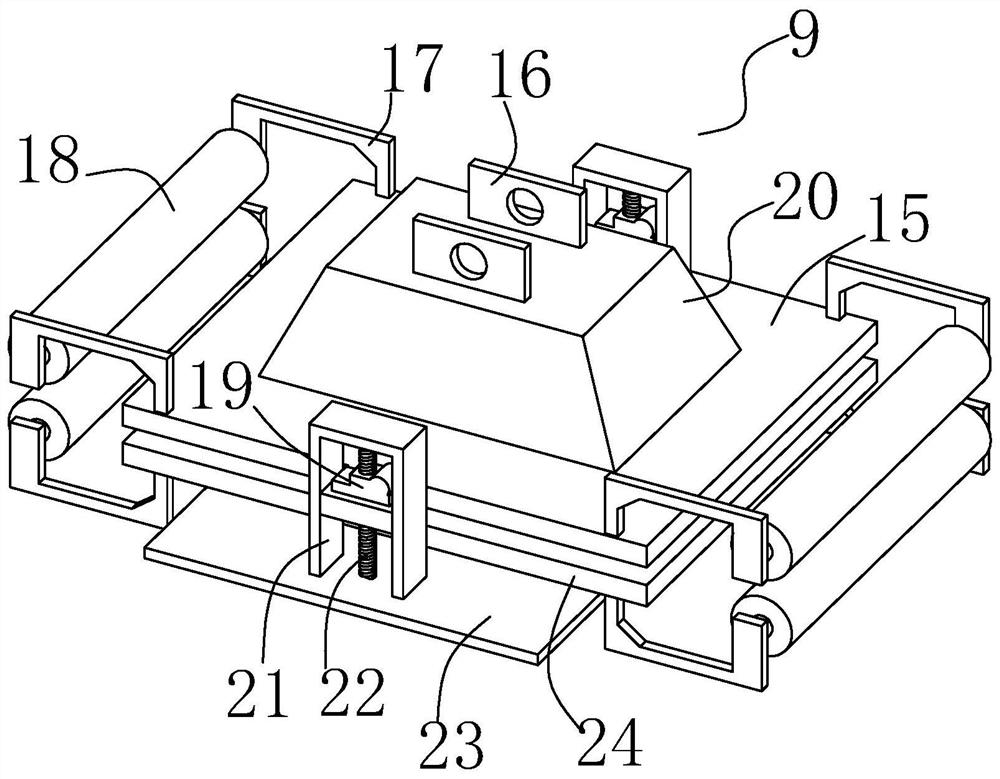

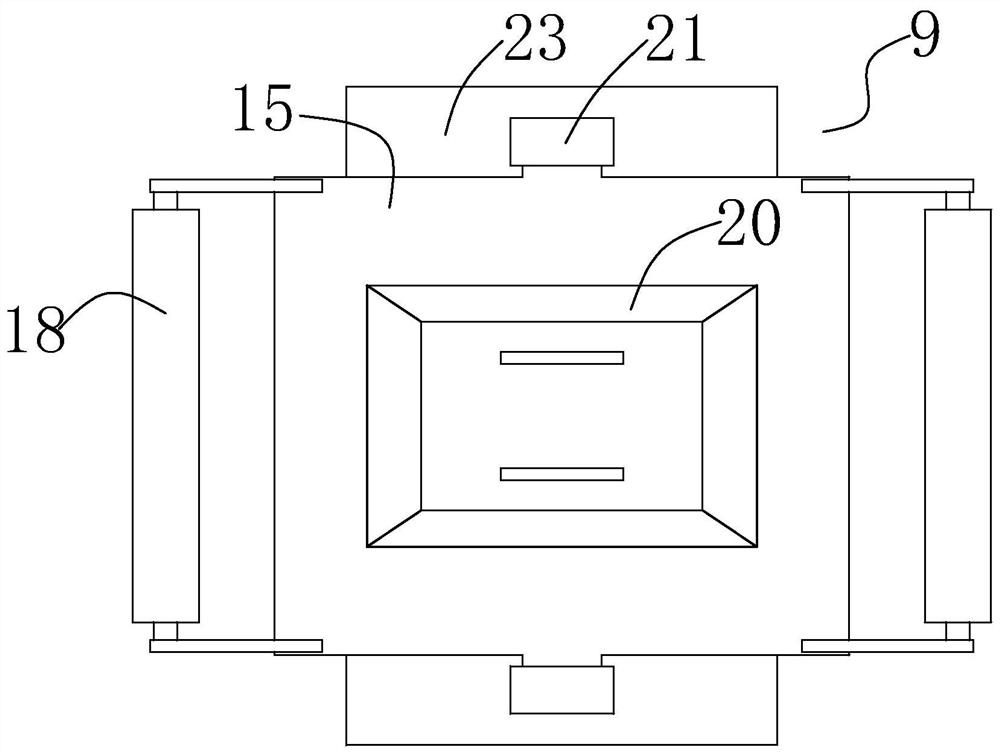

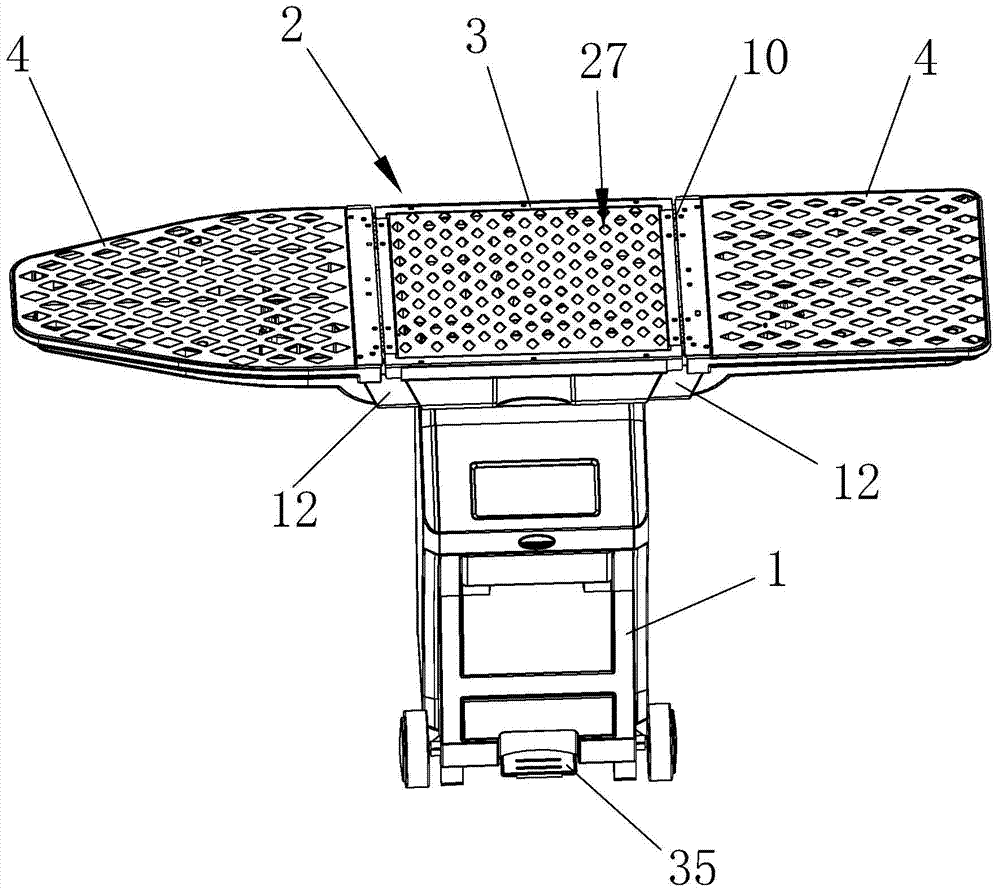

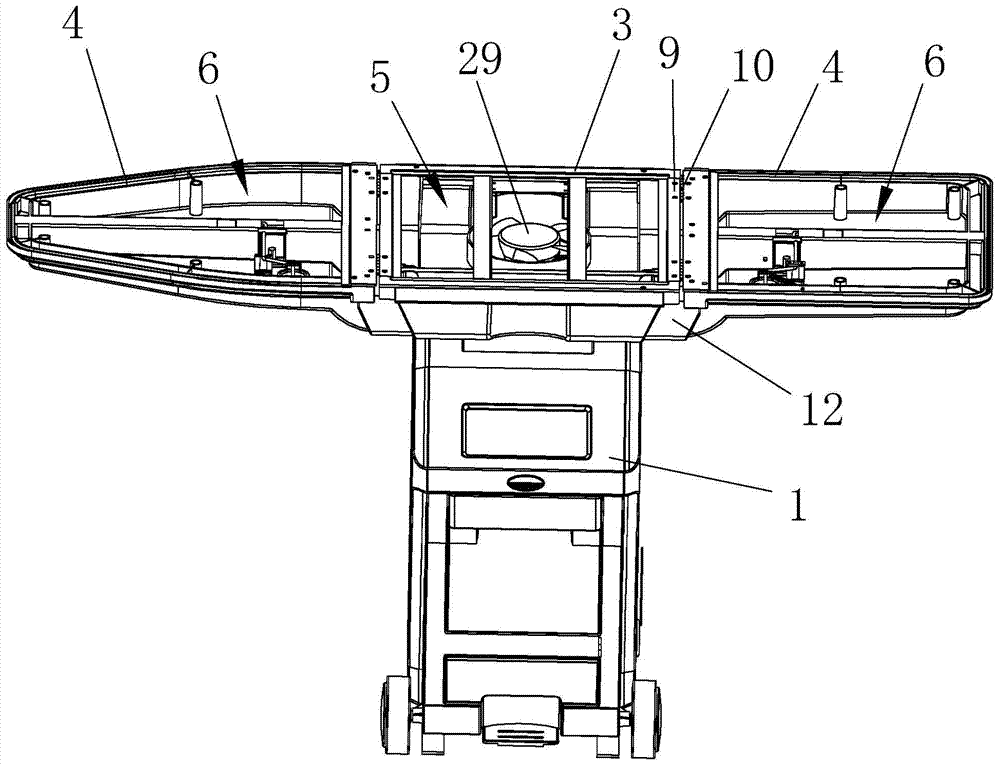

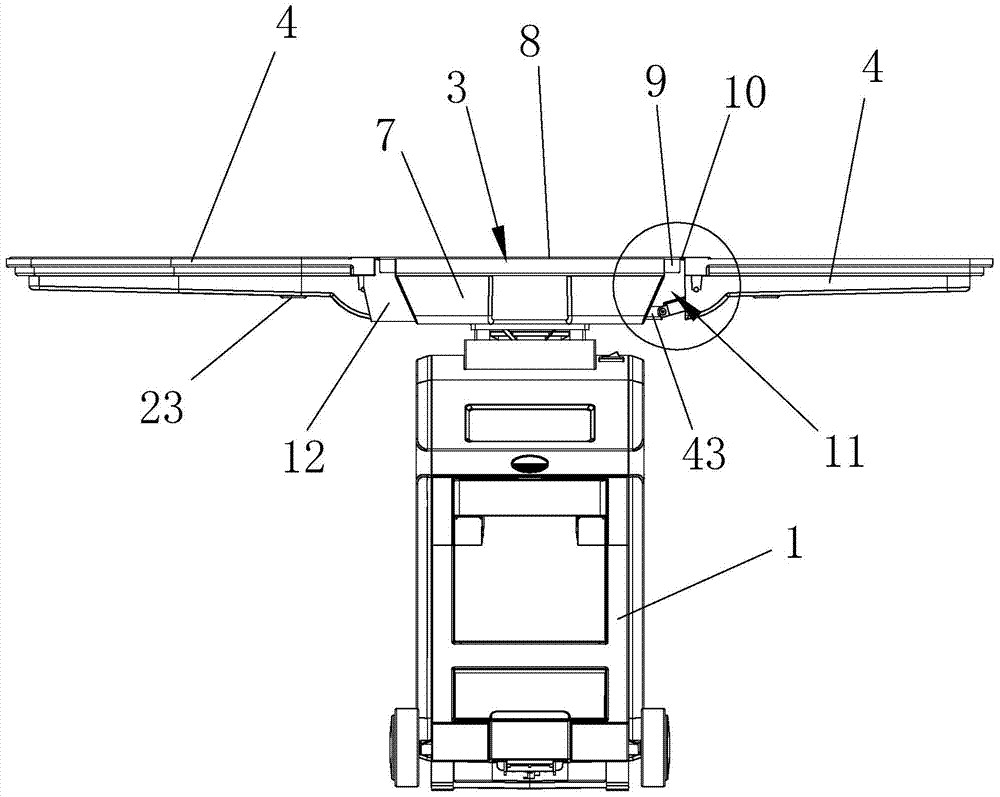

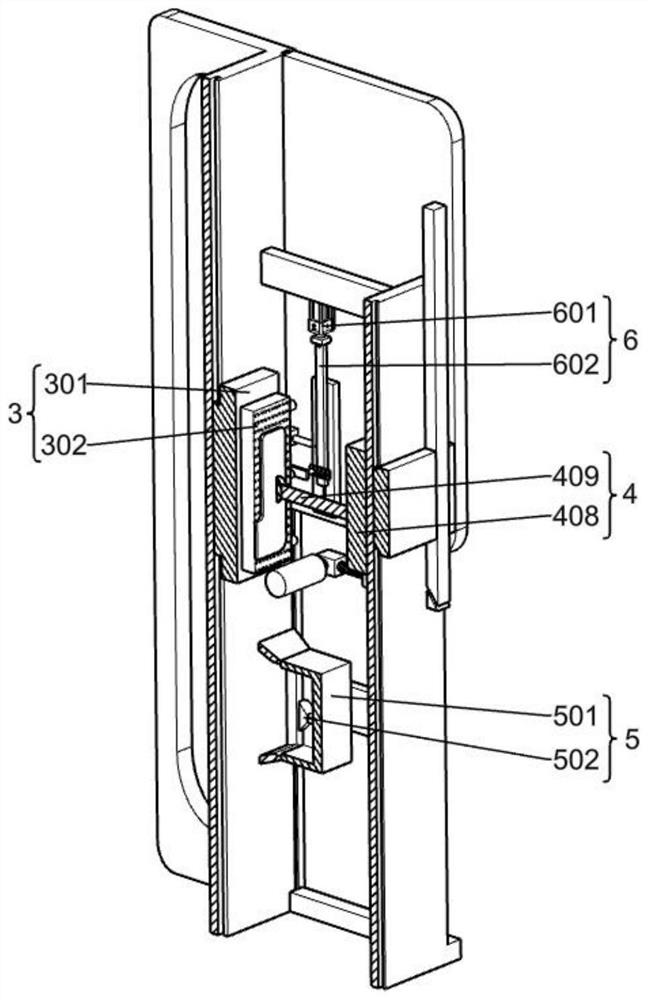

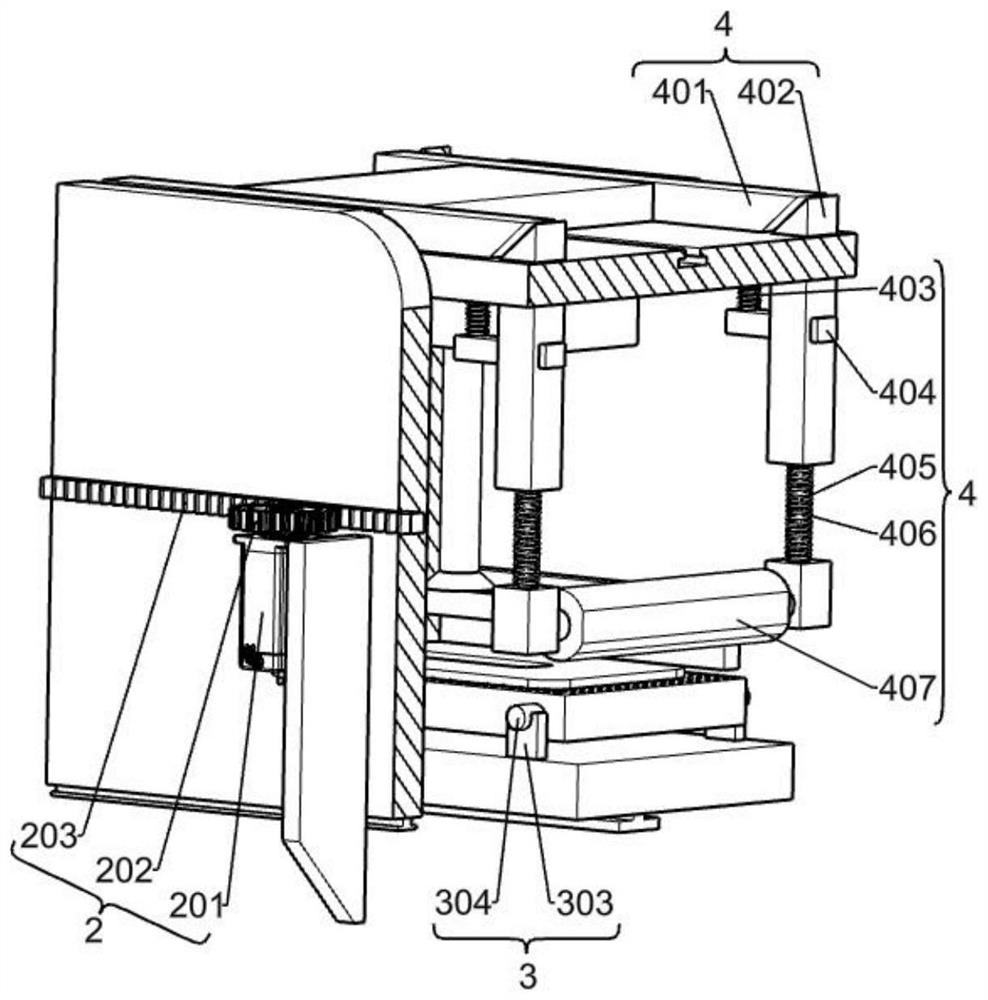

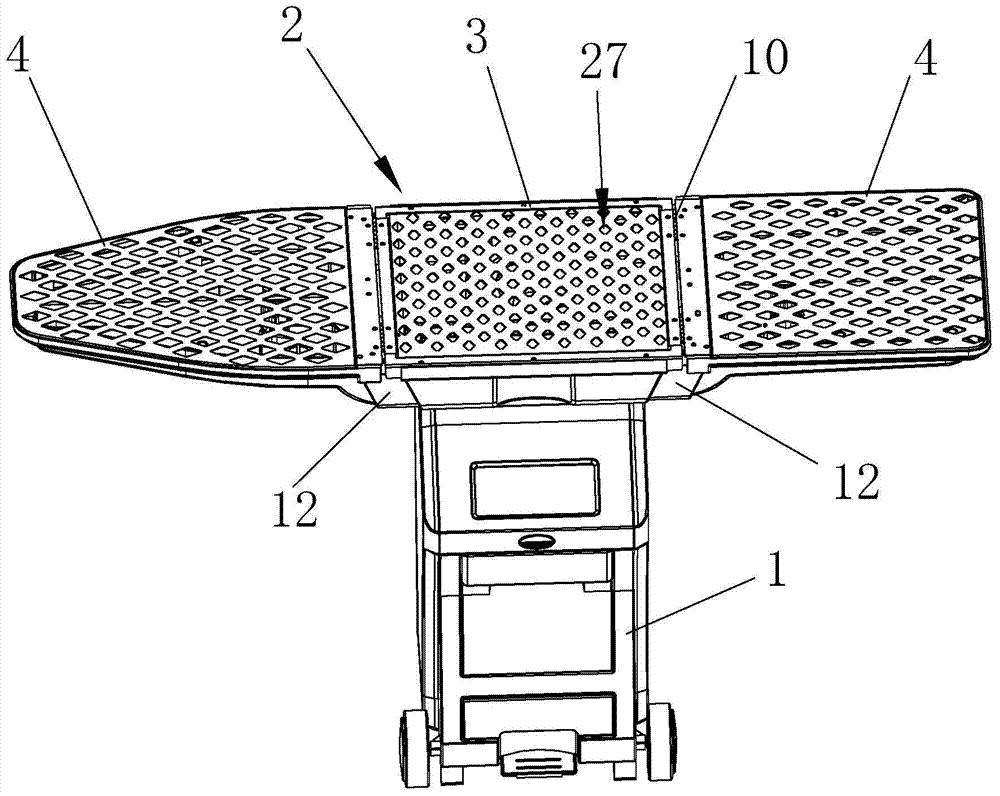

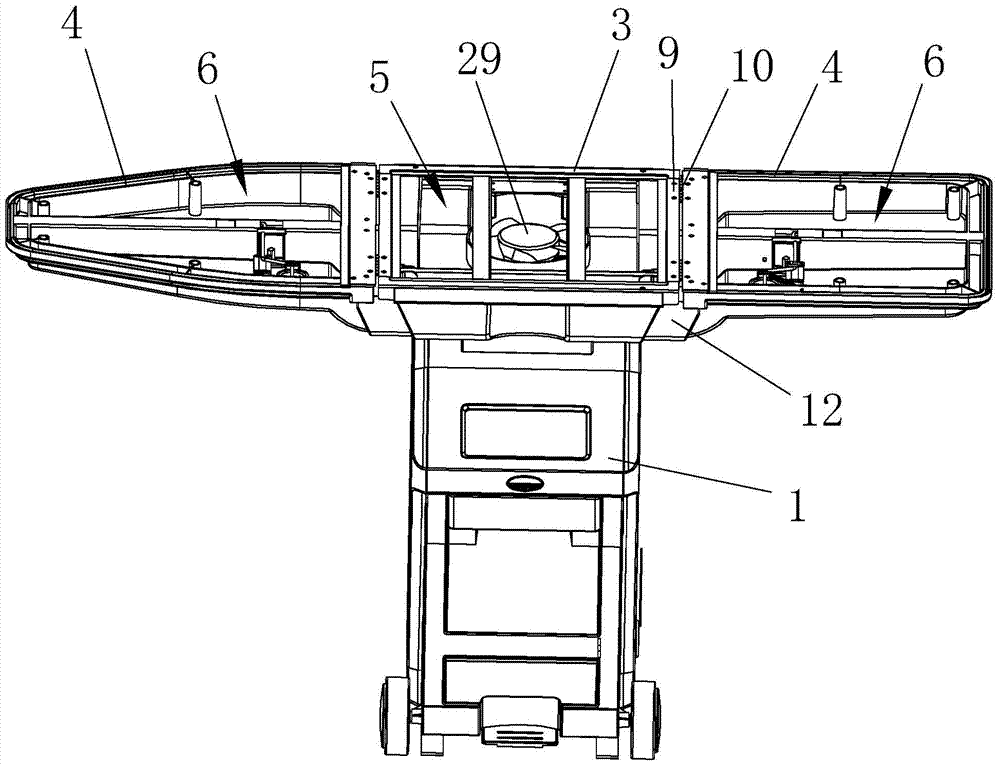

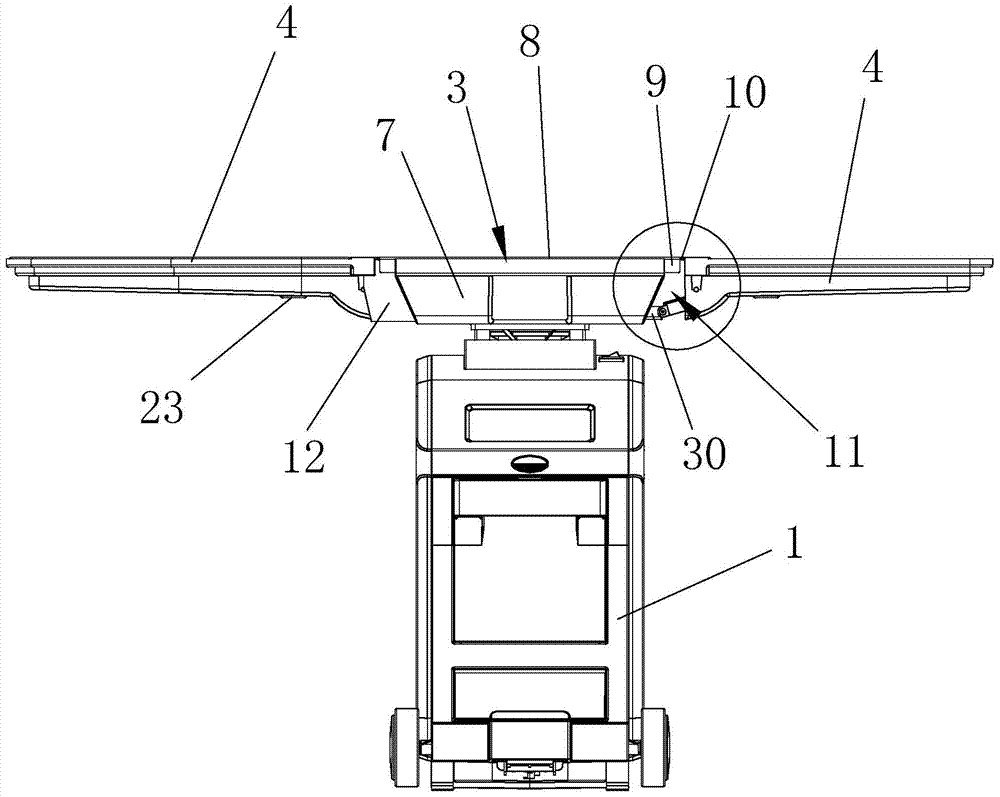

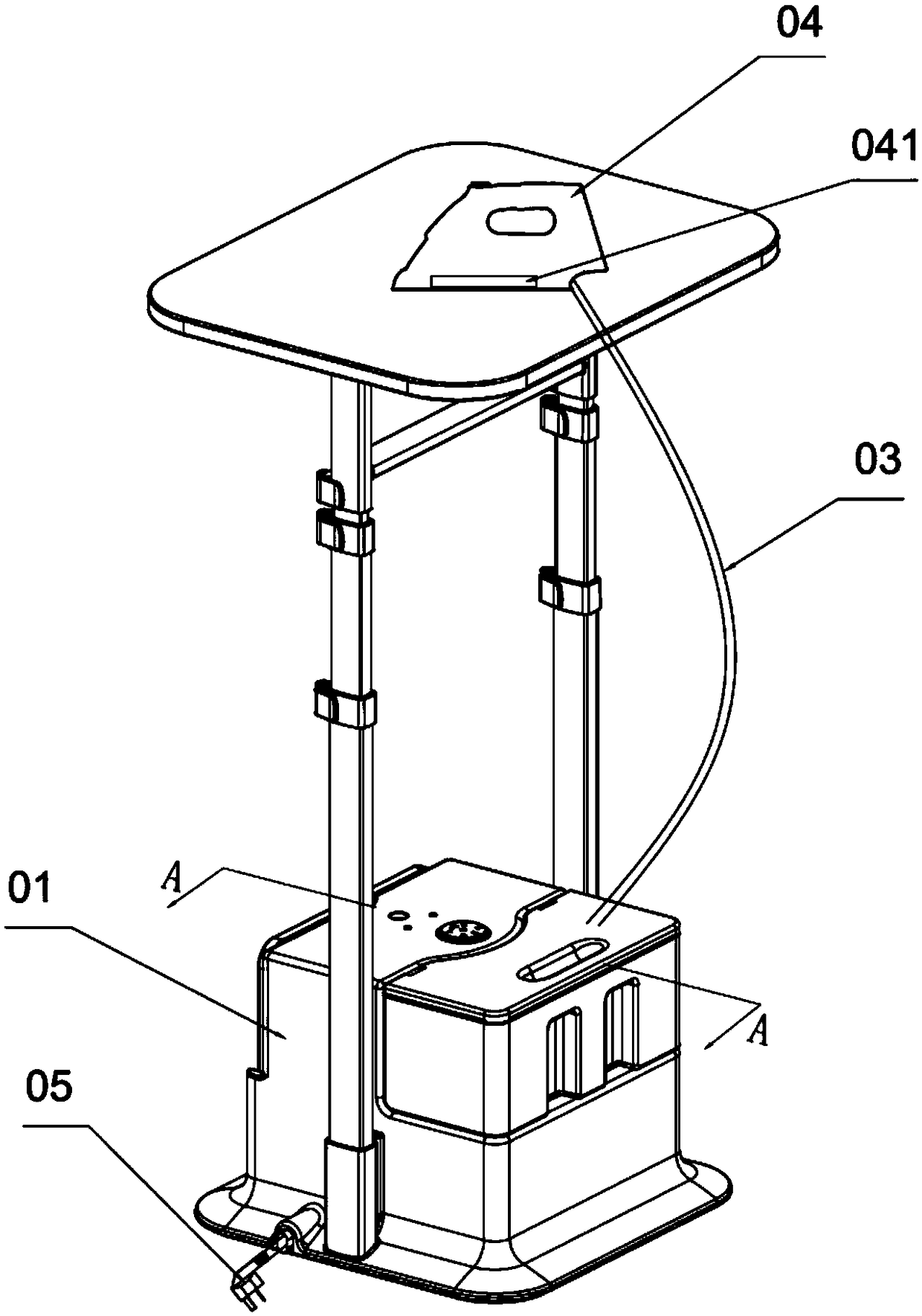

Foldable ironing machine

The invention provides a foldable ironing machine, belongs to the technical field of ironing equipment and solves the problem that existing ironing machines cannot be folded or are inconvenient to fold. The foldable ironing machine comprises a base and an ironing board, wherein the ironing board comprises a main body part and a folding part which comprise a main body inner cavity and a folding inner cavity respectively, the folding part is hinged to the main body part, a folding yielding notch is formed in one side of the hinge direction, and a supporting structure for keeping the unfolding state of the folding part as well as a closing structure for covering the folding yielding notch when the folding part is unfolded are arranged between the folding part and the main body part. The ironing board can be folded through simple operation, and the storage space is reduced. During unfolding, sides and the bottom of the whole cavity of the ironing board are well closed, air and most steam pass in and out of vent holes in the working surface when a fan blows and sucks air, and the ironing effect is guaranteed.

Owner:ZHEJIANG SONGYANG ELECTRIC

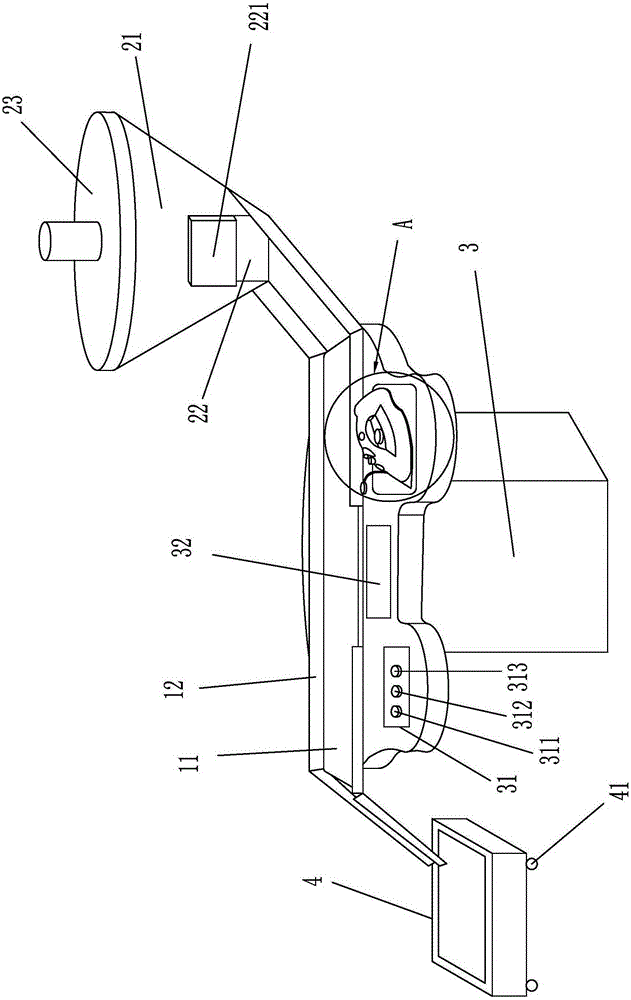

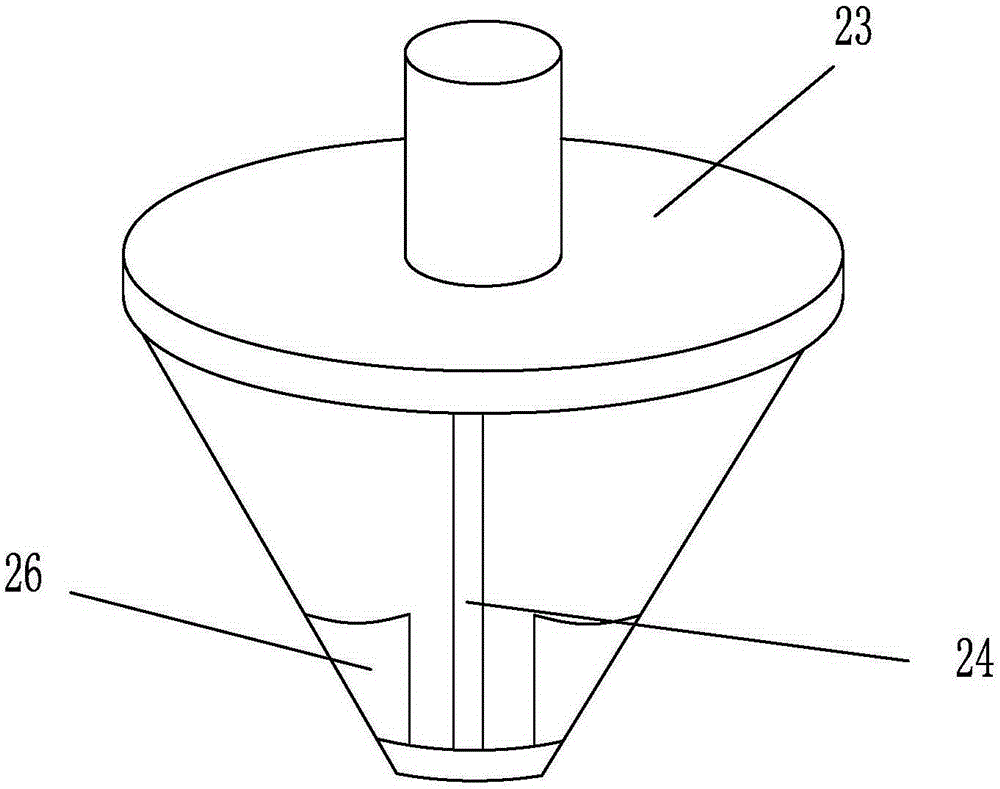

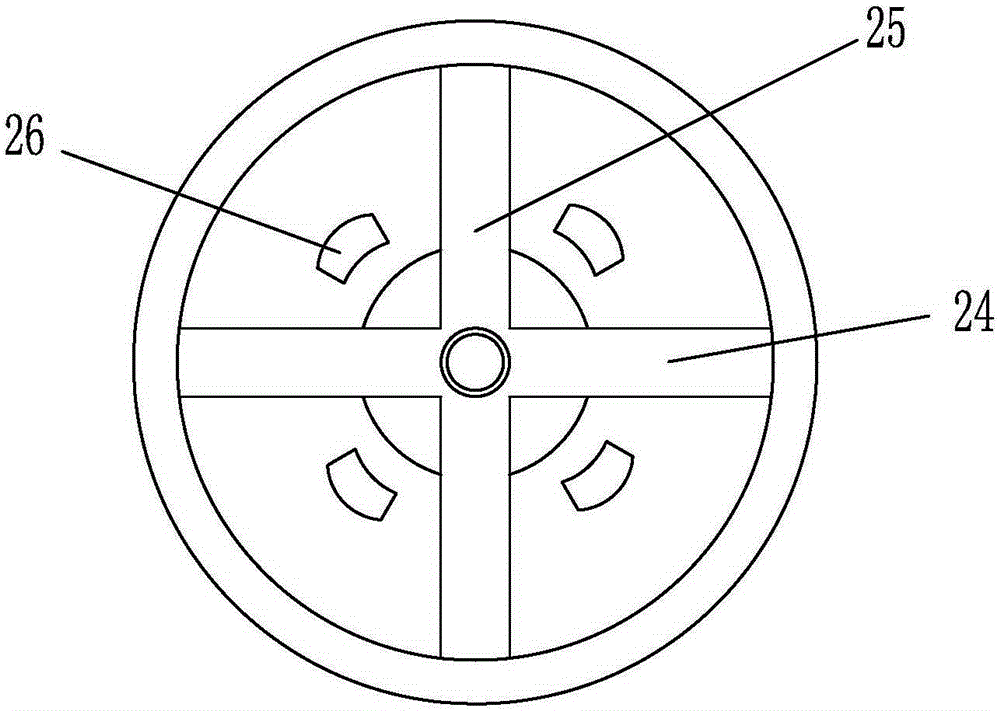

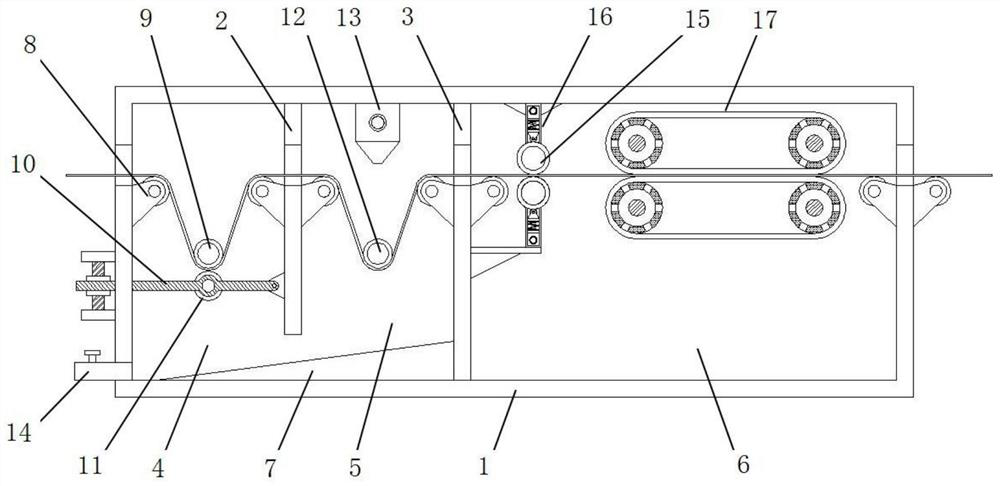

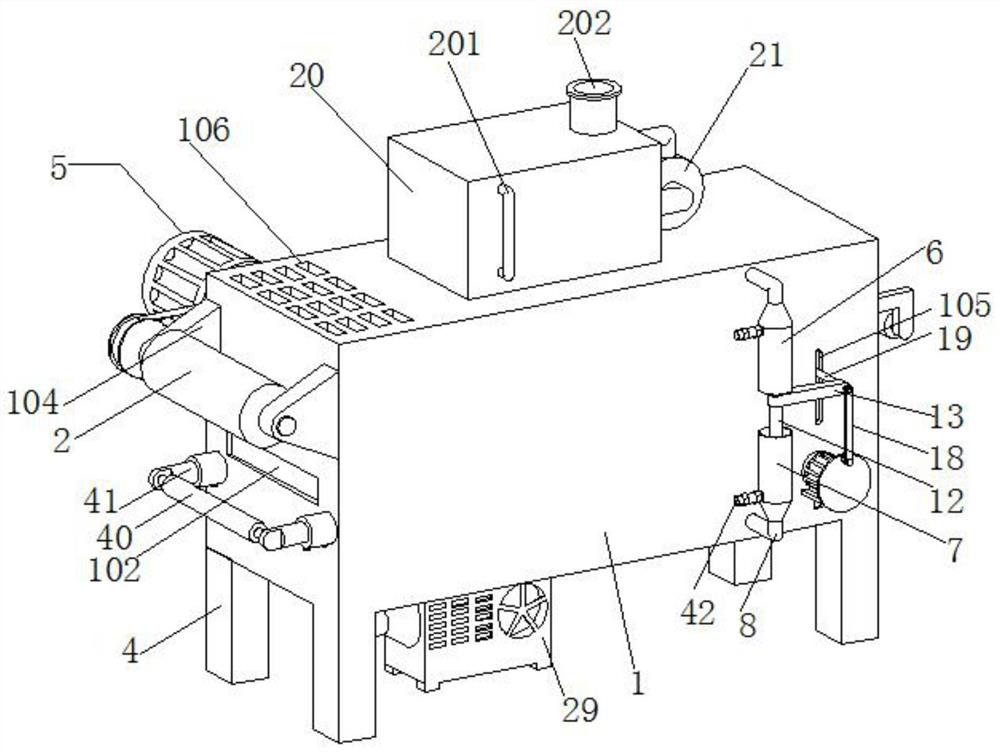

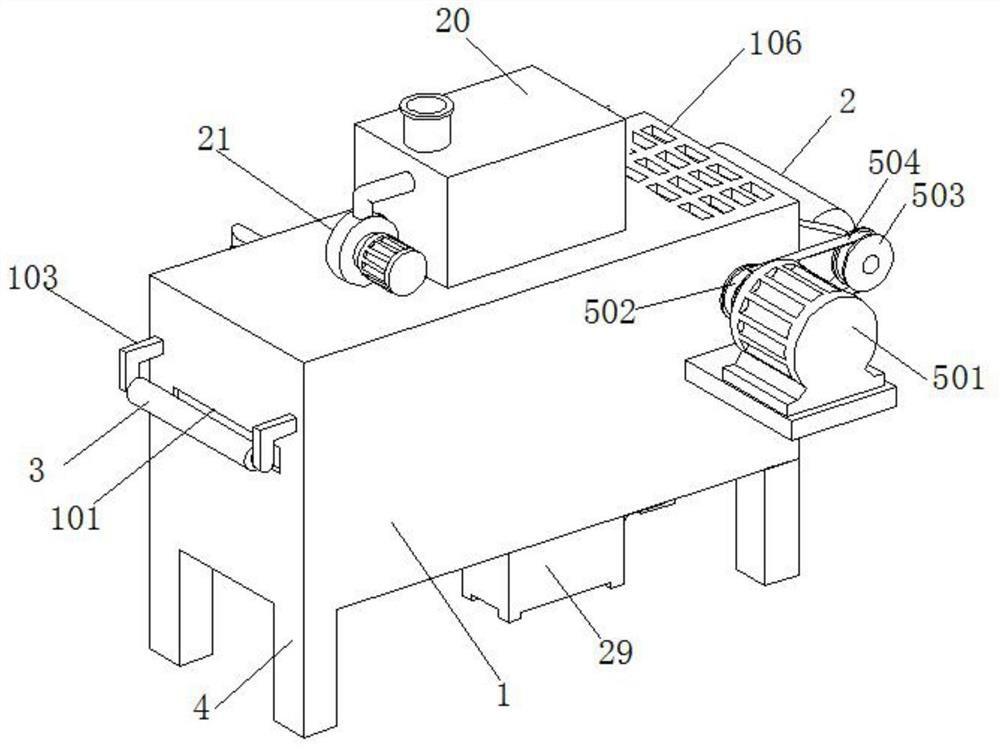

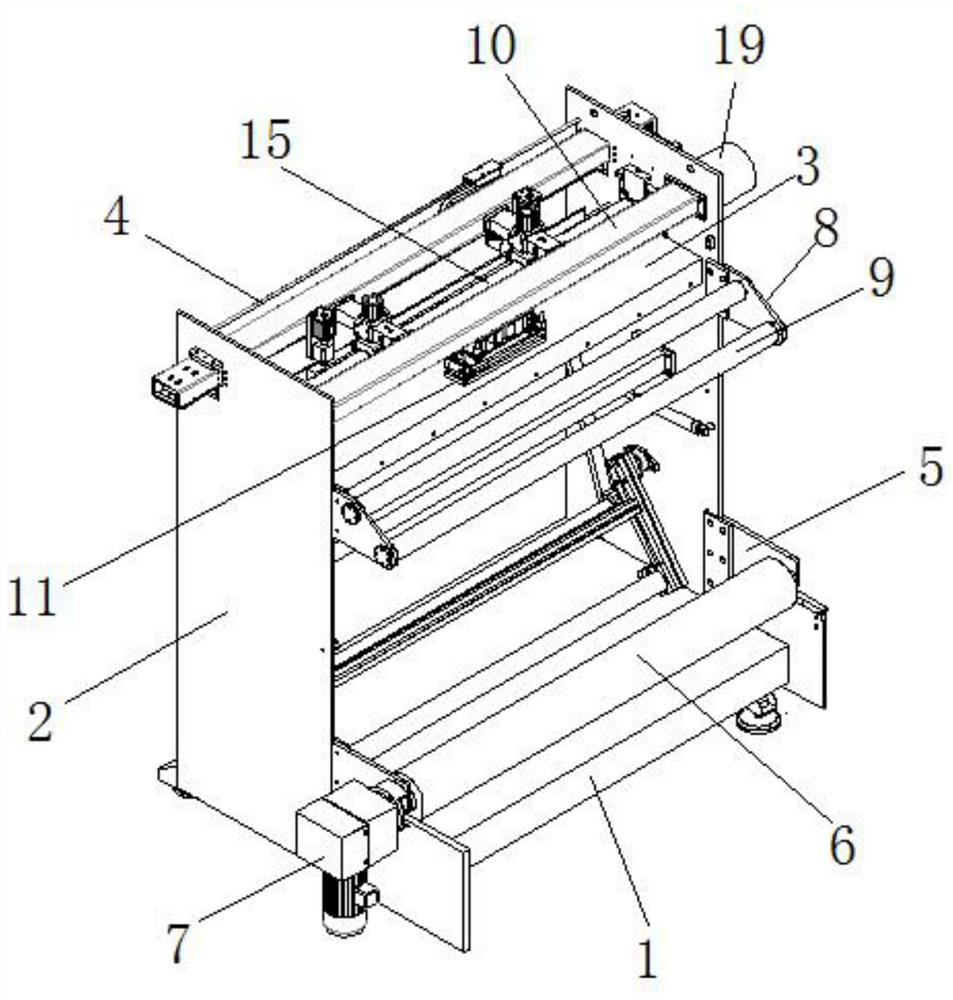

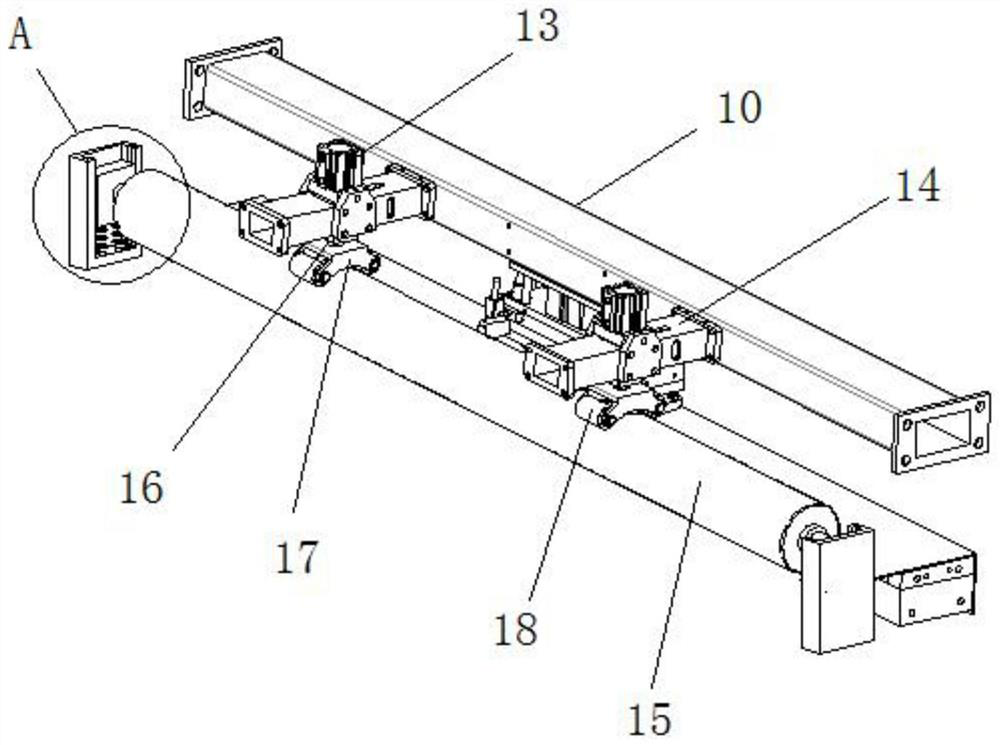

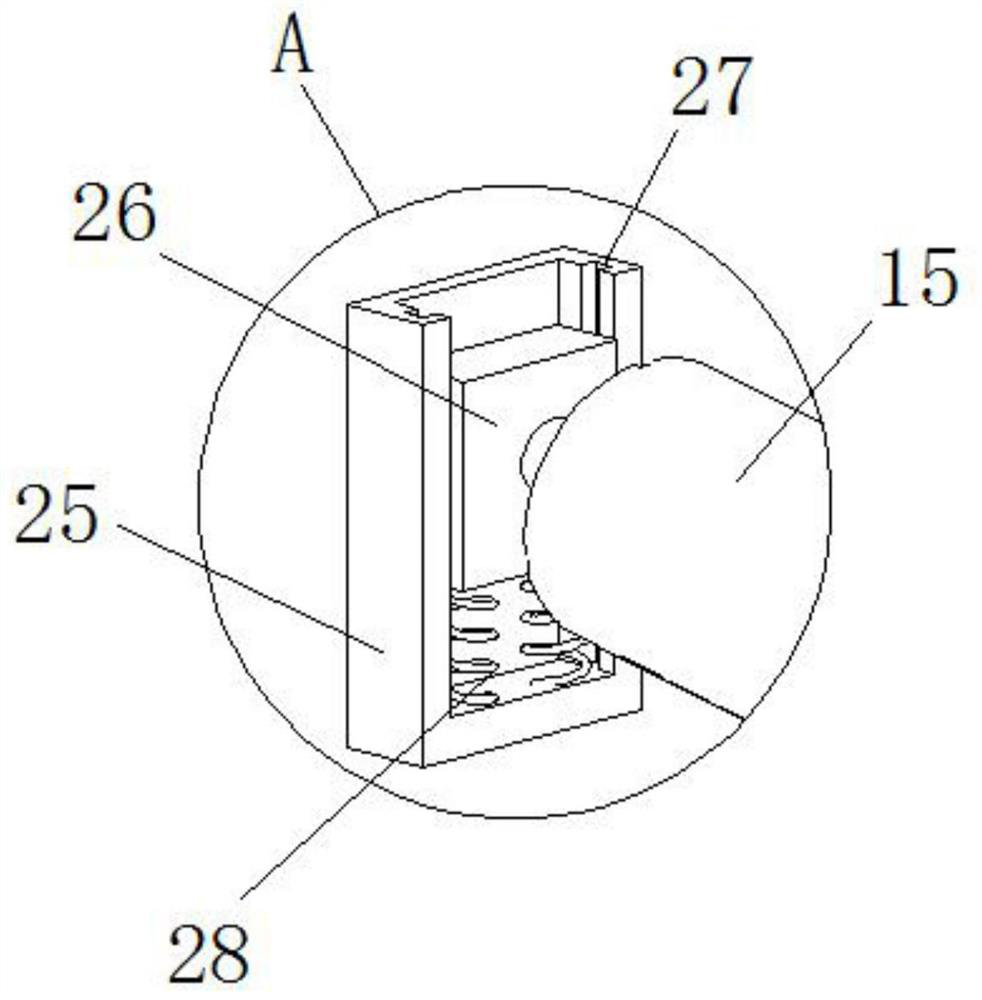

Spinning machine for textile fabric producing and processing and technology of spinning machine

ActiveCN111501169AImprove surface qualityNo wrinklesMechanical cleaningPressure cleaningSpinningDust control

The invention relates to the technical field of textile fabric processing equipment, and particularly discloses a spinning machine for textile fabric producing and processing and a technology of the spinning machine. A machine case, a winding roller and a guiding-in roller are included. Stand bars are arranged at the four corner positions of the lower surface of the machine case. A fabric inlet isformed in the right side face of the machine case. A fabric outlet is formed in the left side face of the machine case. The right side face of the part, located above the fabric inlet, of the machinecase is provided with a first rotation support, and the guiding-in roller is rotationally arranged on the first rotation support. Wind power combined electrostatic precipitation is conducted on the spun formed fabric firstly, then, anti-static liquid is sprayed to the fabric, the fabric obtained after anti-static liquid spraying is subjected to ironing treatment, finally, after an air heater is used for drying the fabric at the front treatment end, rolling is conducted, accordingly, static electricity does not exist on the surface of the prepared textile fabric, meanwhile, the dust on the surface of the textile fabric is effectively removed, wrinkles do not exist on the surface of the ironed textile fabric, the fabric surface quality is greatly improved, and the product market competitiveness is improved.

Owner:浙江兰溪银丰纺织有限公司

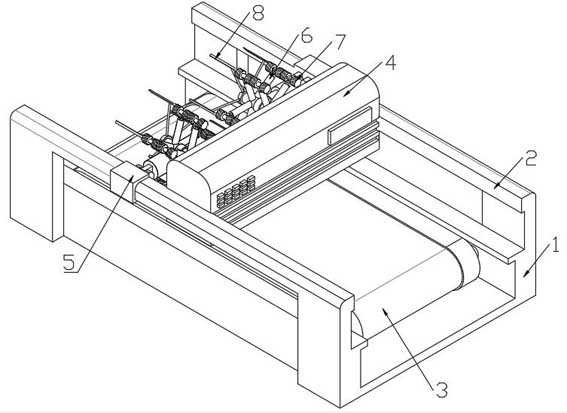

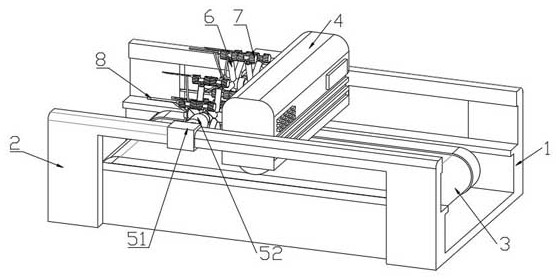

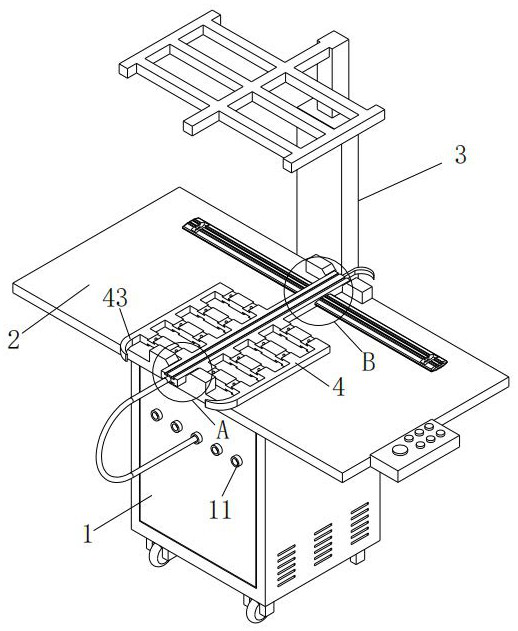

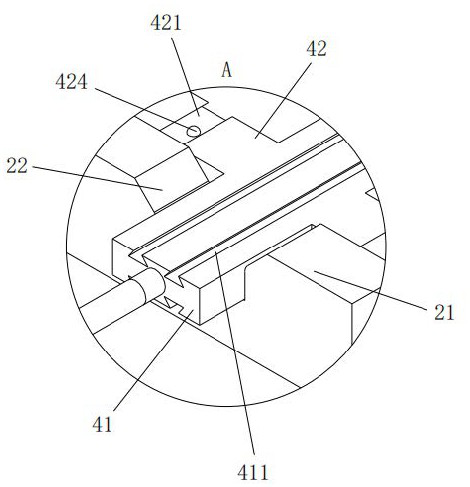

Ironing table device for clothing production

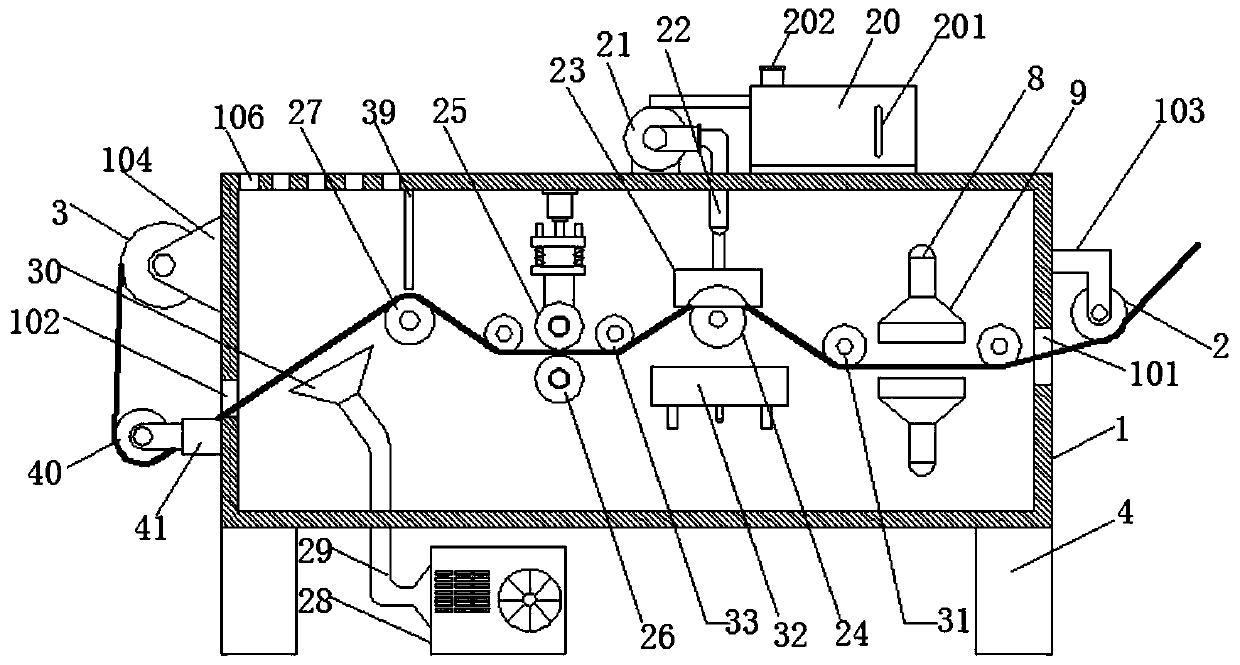

ActiveCN105177962APromote sportsEasy to moveIroning boardsHand ironConveyor beltIndustrial engineering

The invention discloses an ironing table device for clothing production. The ironing table device comprises a conveying mechanism, a working table and an iron. The conveying mechanism and the iron are arranged on the working table. The conveying mechanism comprises a conveyor belt, a conveying shaft and a conveying rack. A feeding barrel is connected to the upper end of the conveying rack and comprises a feeding barrel body, a feeding outlet and a rotating device. The rotating device is arranged in the feeding barrel body and comprises a speed reducing motor, a barrel cover and a partition frame. A control table is arranged at the left end of the working table. An iron storing table is arranged at the right end of the working table. The control table is provided with a control button. The iron is stored on the iron storing table and comprises an iron body, a universal pipe, a magnifying lens and an ironing head. The ironing head is fixed to the lower end of the iron body. An ironing table is arranged between the control table and the iron storing table. The ironing table device is high in practicality, the stability of the ironing table device is improved, the ironing effect is ensured, the whole process is convenient to operate, the ironing effect is obvious, and the working efficiency is improved.

Owner:安徽豹子头服饰股份有限公司

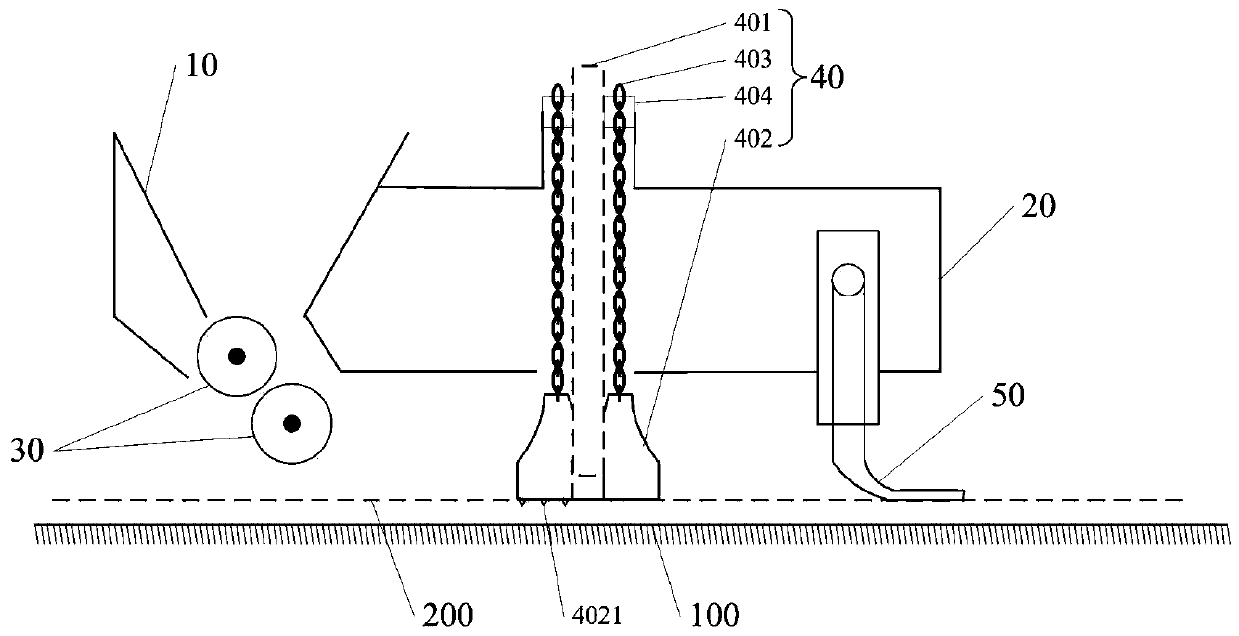

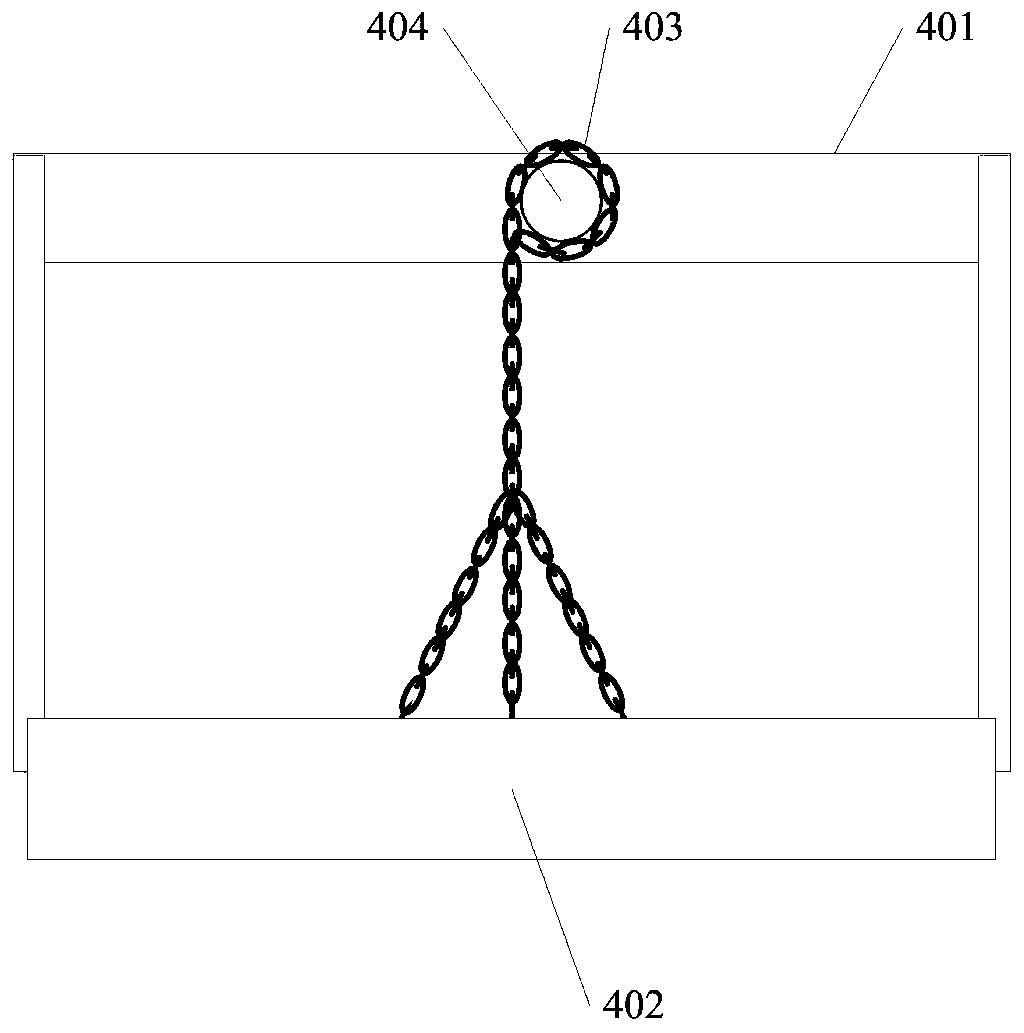

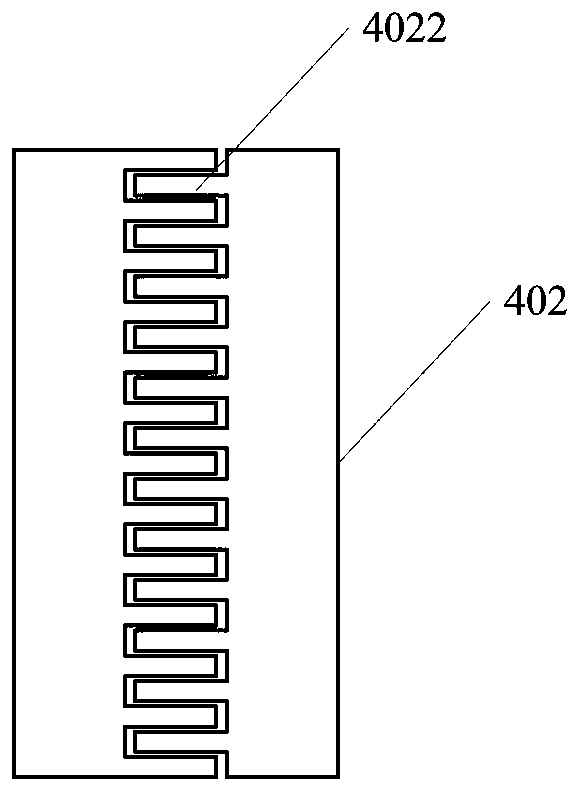

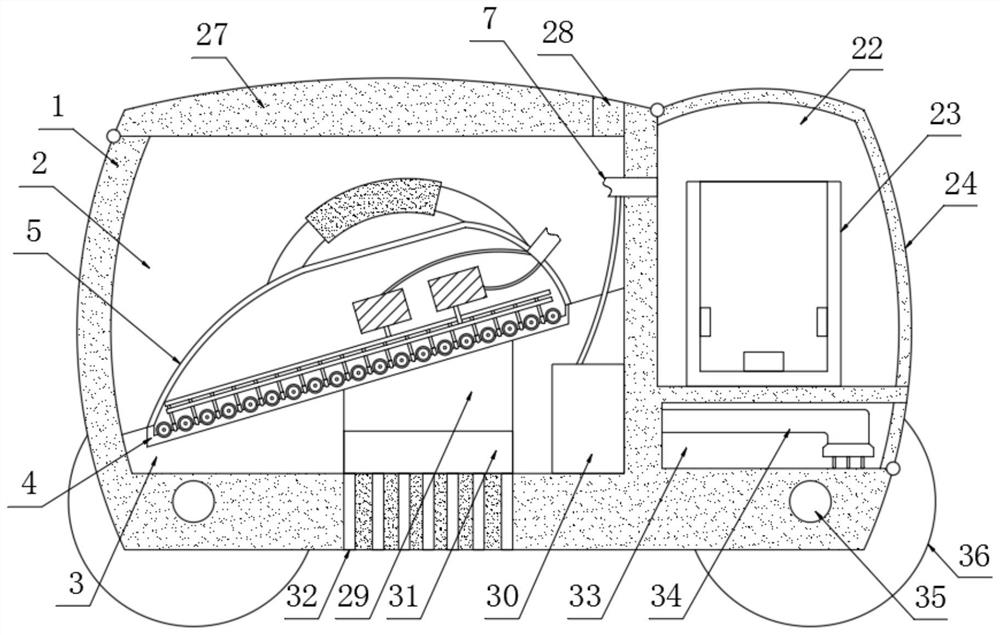

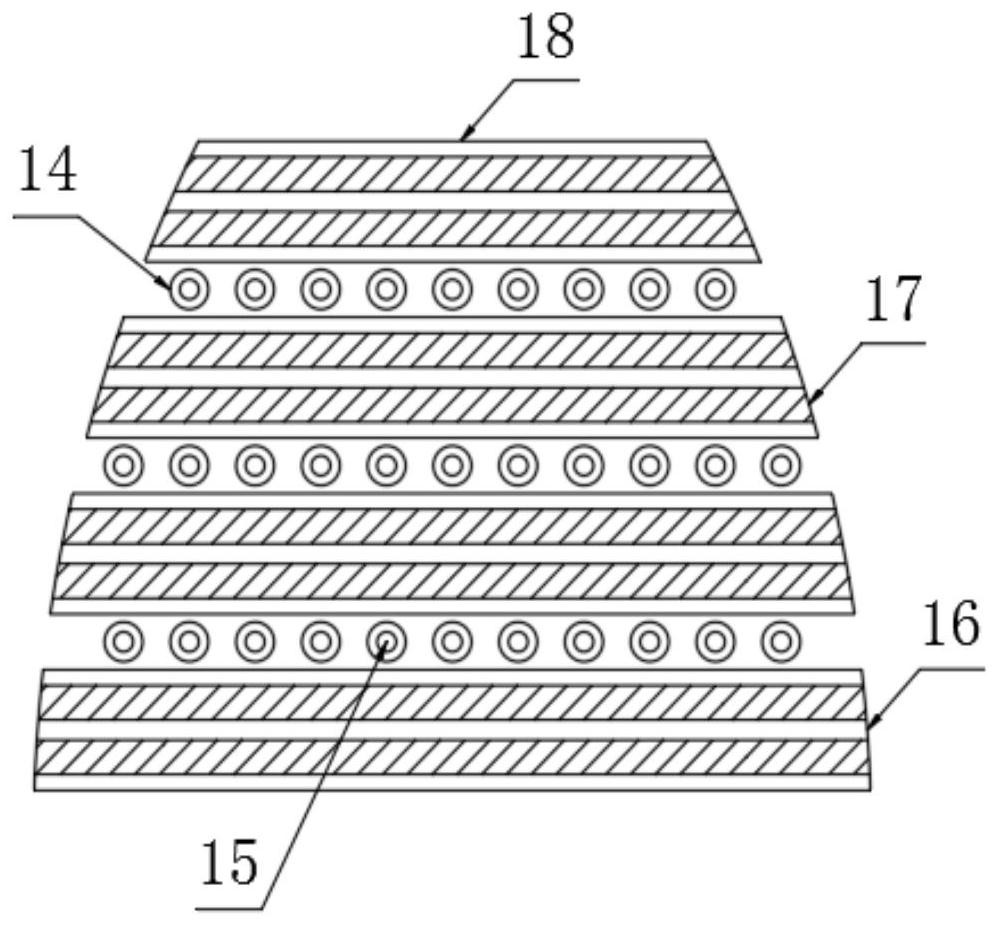

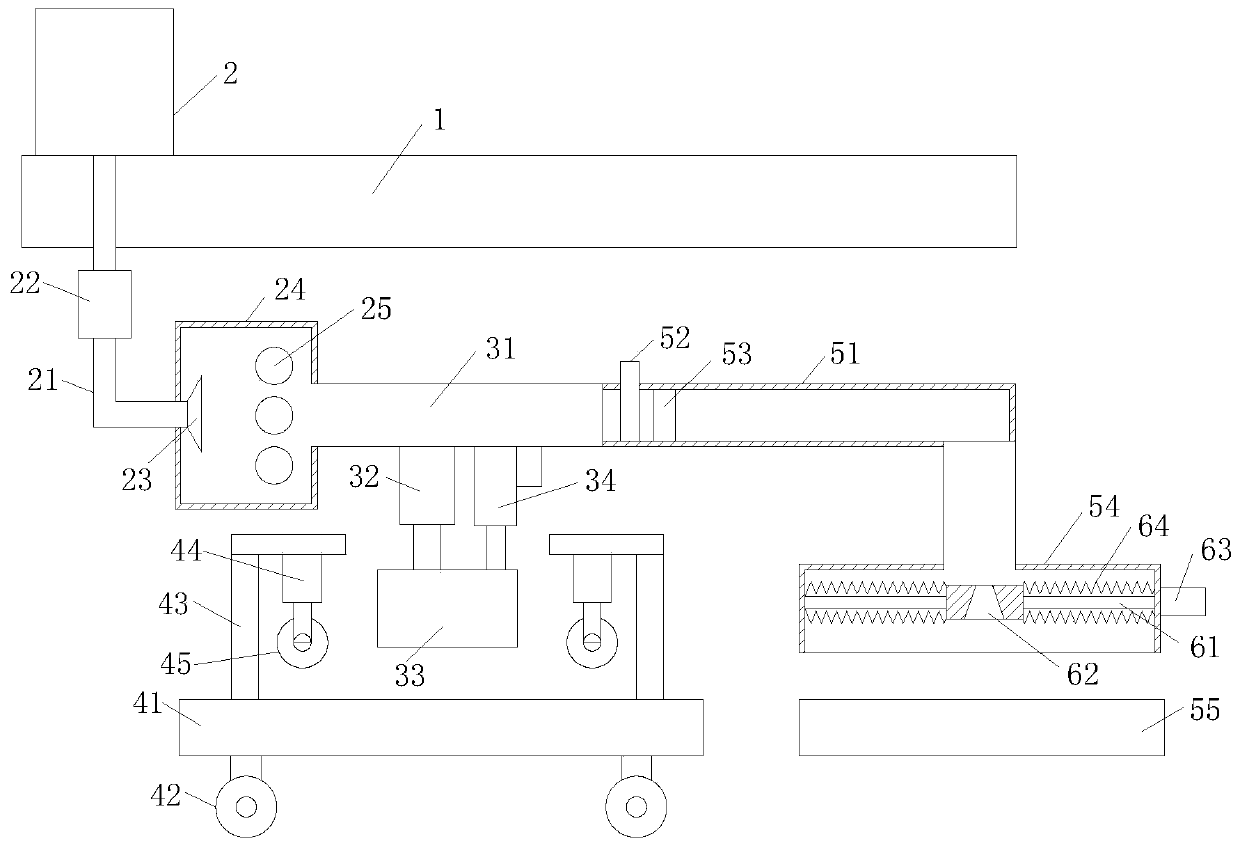

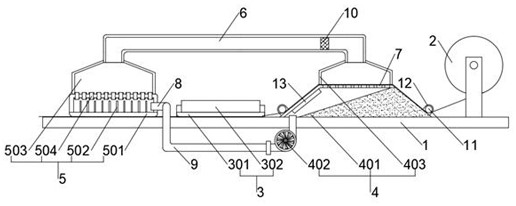

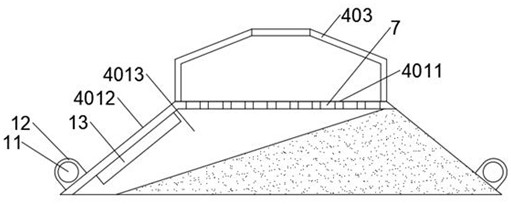

Asphalt paver capable of achieving quick vibrating compaction of roads and bridges

ActiveCN110258266AGuaranteed paving effectReal-time vibration operationRoads maintainenceAsphaltMechanical engineering

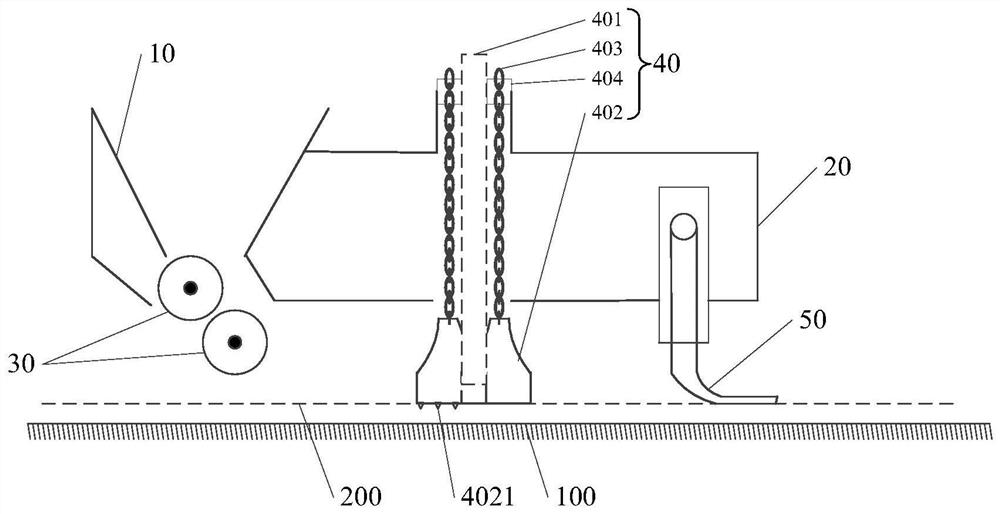

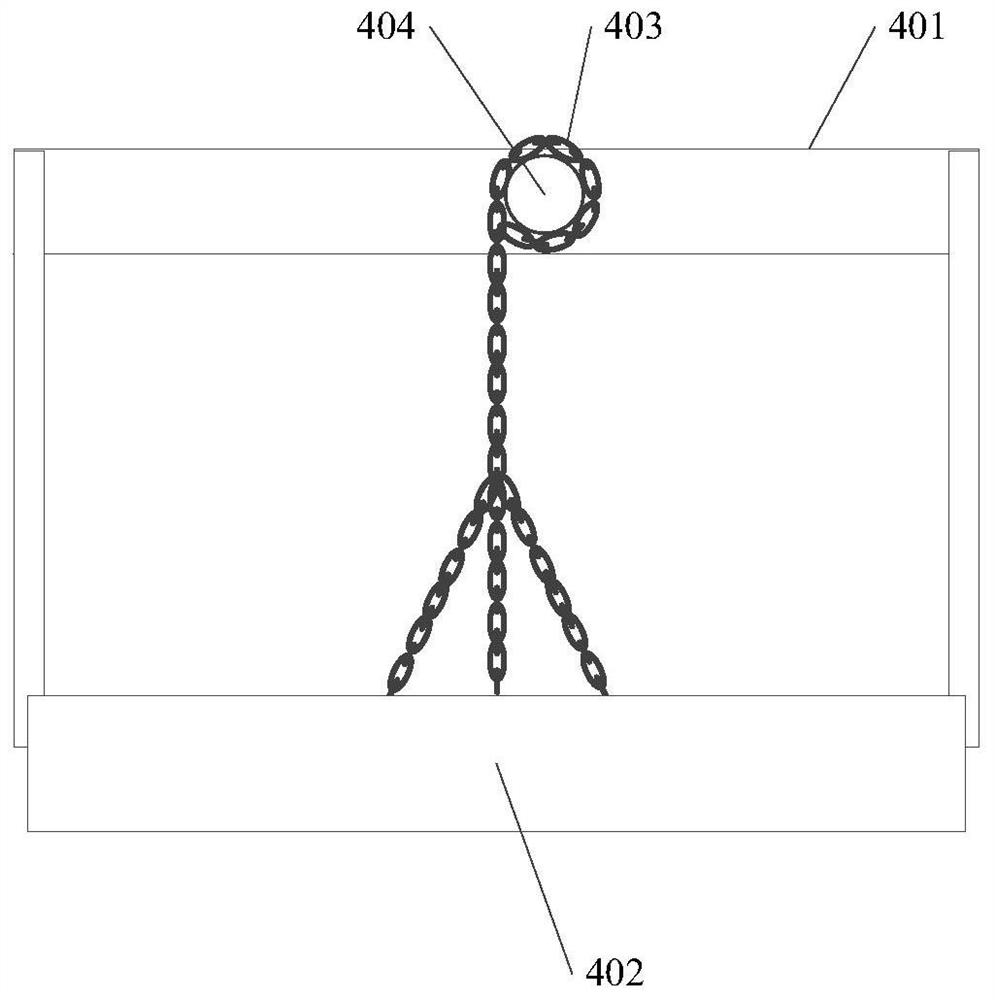

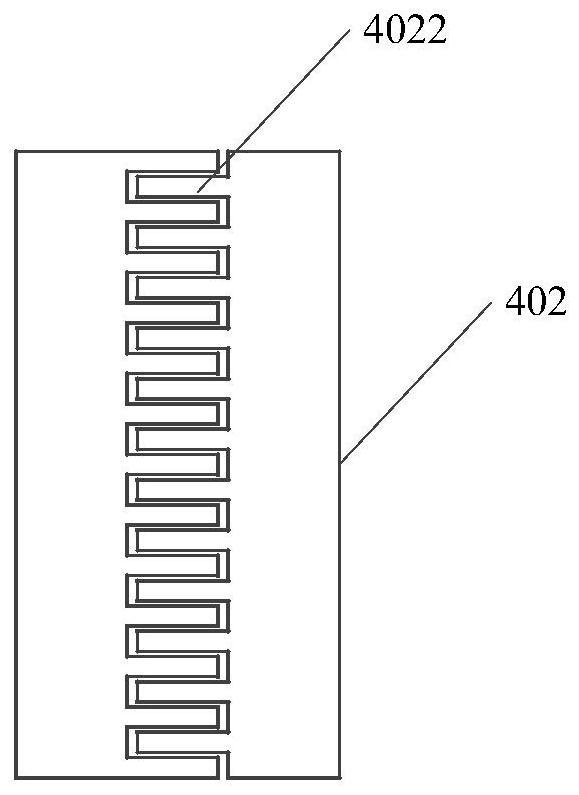

The invention discloses an asphalt paver capable of achieving quick vibrating compaction of roads and bridges. The asphalt paver comprises an asphalt storing box I, a material distributing auger assembly and a vibrating compaction assembly; the asphalt storing box I is arranged at the front end of a machine body of the asphalt paver; the material distributing auger assembly is arranged under an asphalt discharging port I; and the vibrating compaction assembly is arranged behind the material distributing auger assembly and comprises a bracket, a pair of vibrating compaction hammers, a pair of hinges and an ironing plate, the ironing plate is arranged behind the vibrating compaction assembly, and the upper end of the ironing plate is hinged to the back end of the machine body. According to the asphalt paver capable of achieving quick vibrating compaction of the roads and the bridges, the material distributing auger assembly achieves uniform material distributing and can conduct vibrating compaction operation on asphalt in real time, the asphalt paving firmness is improved, and the asphalt paving effect is guaranteed.

Owner:江苏金堰交通工程有限公司

Textile drying device with ironing function and using method

InactiveCN112146410AOverall structure layout scienceSimple processDrying using combination processesDrying gas arrangementsWoven fabricAir knife

The invention discloses a textile drying device with an ironing function and a using method thereof.The textile drying device comprises a drying box, an inner cavity of the drying box is divided intoa draining chamber, a pre-drying chamber and an ironing chamber through a first partition plate and a second partition plate, an upper pressing roller is rotationally supported between two supportingrollers in the draining chamber, a lower pressing roller is rotationally supported in the draining chamber through an adjusting frame assembly, a guide roller is rotationally supported in the pre-drying chamber, and an air knife is fixed to the top wall of the pre-drying chamber; and pretreatment rollers are symmetrically arranged on the front portion of the ironing chamber and abut against a cleaning cylinder assembly, and ironing assemblies are symmetrically arranged on the rear portion of the ironing chamber. The textile drying device is reasonable in structural design, textiles can be sequentially moved into the draining chamber to be drained, moved into the pre-drying chamber to be pre-air-dried, moved to the pretreatment rollers of the ironing chamber to be subjected to impurity removal and flattening and then moved to the ironing assemblies of the ironing chamber to be ironed under the traction effect, ironing is achieved through gathering in the drying process, and subsequent process flow is simplified.

Owner:安徽职业技术学院

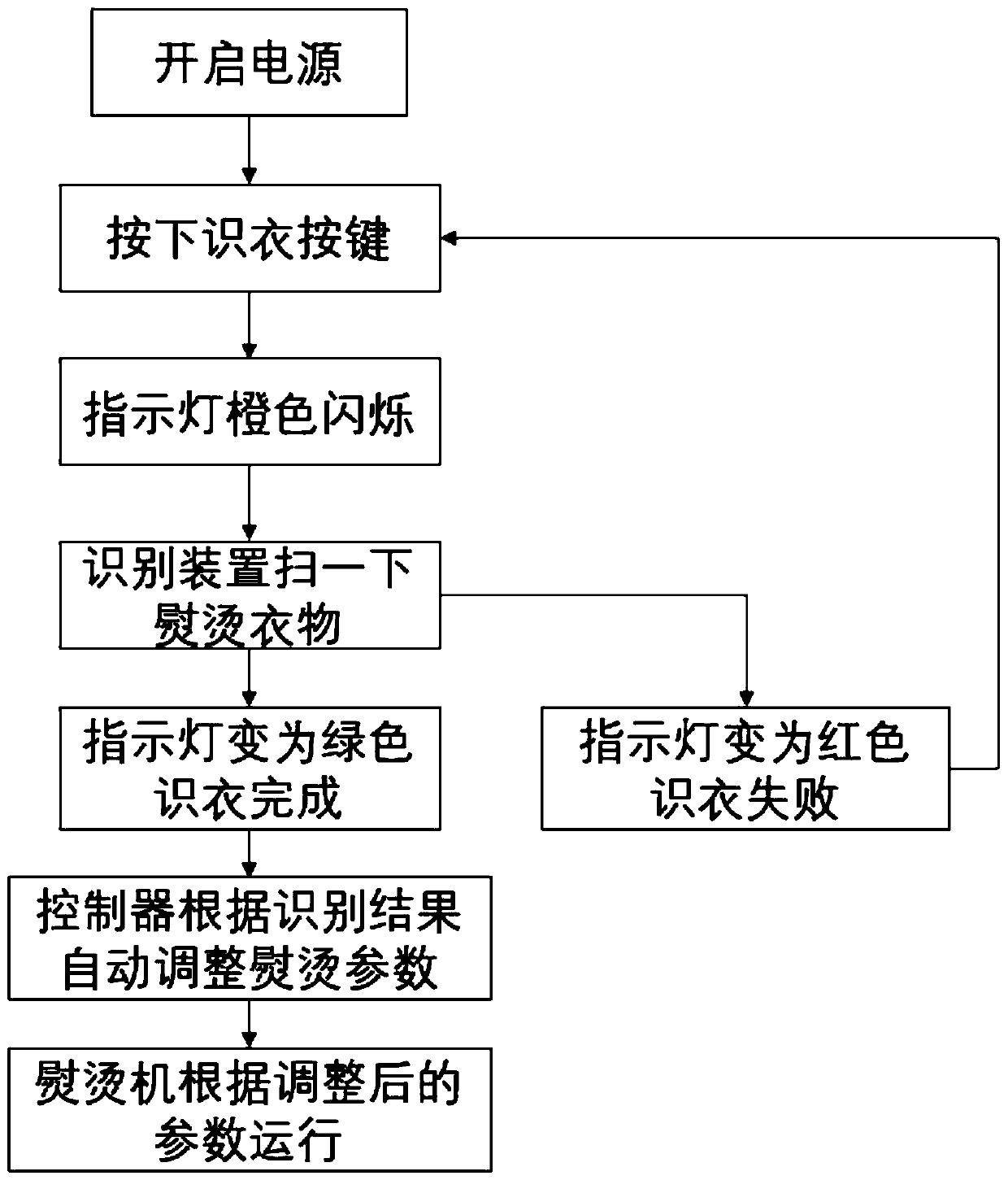

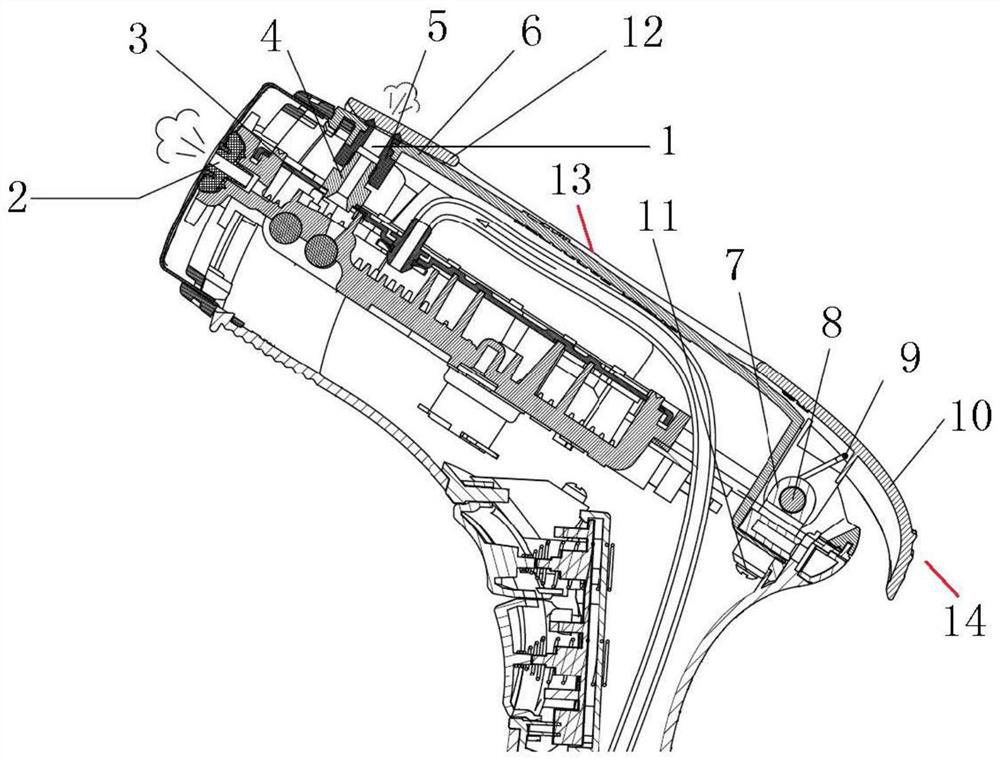

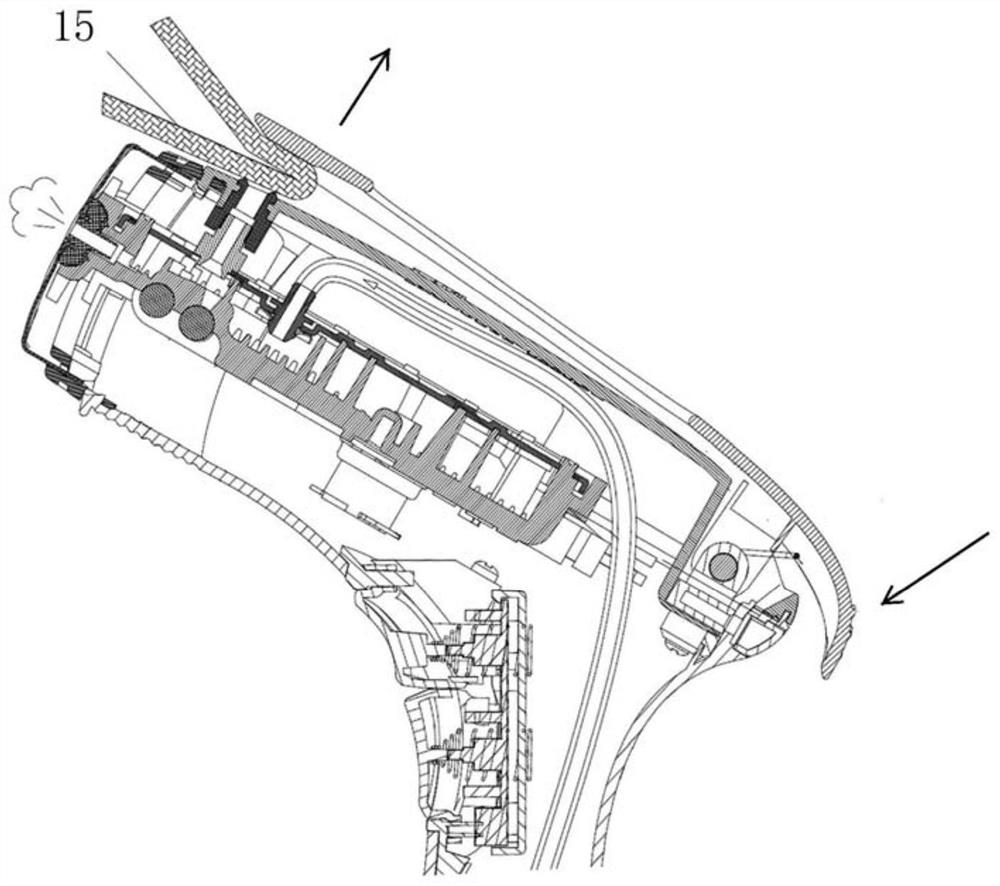

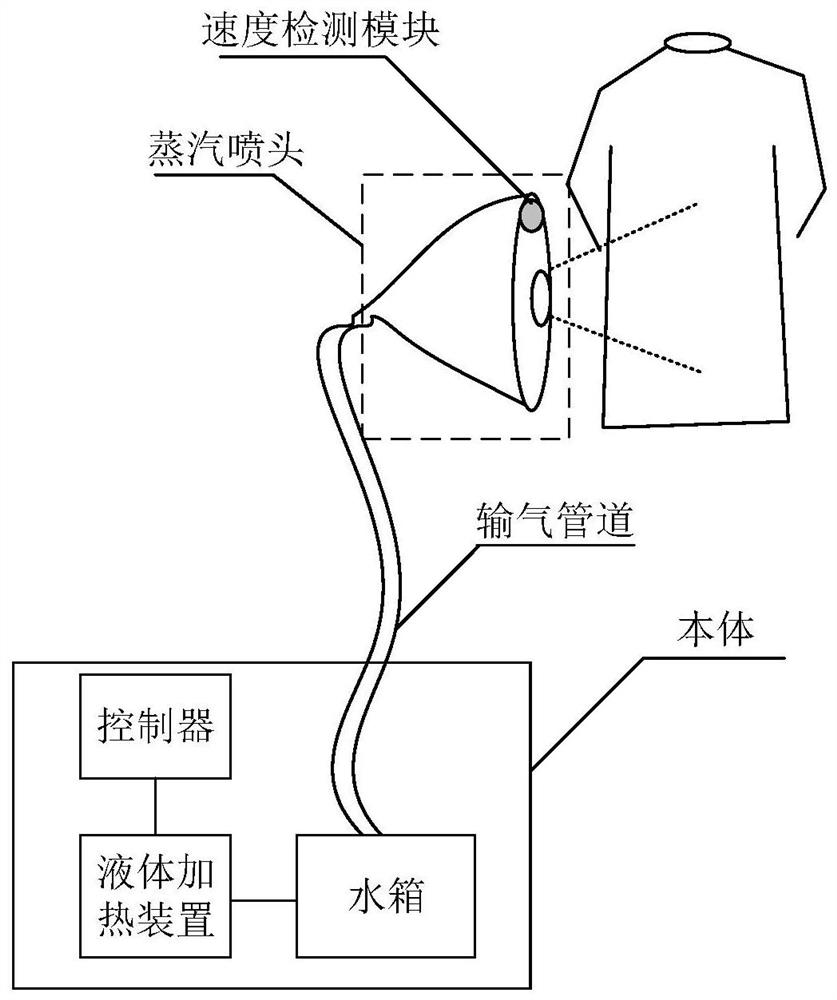

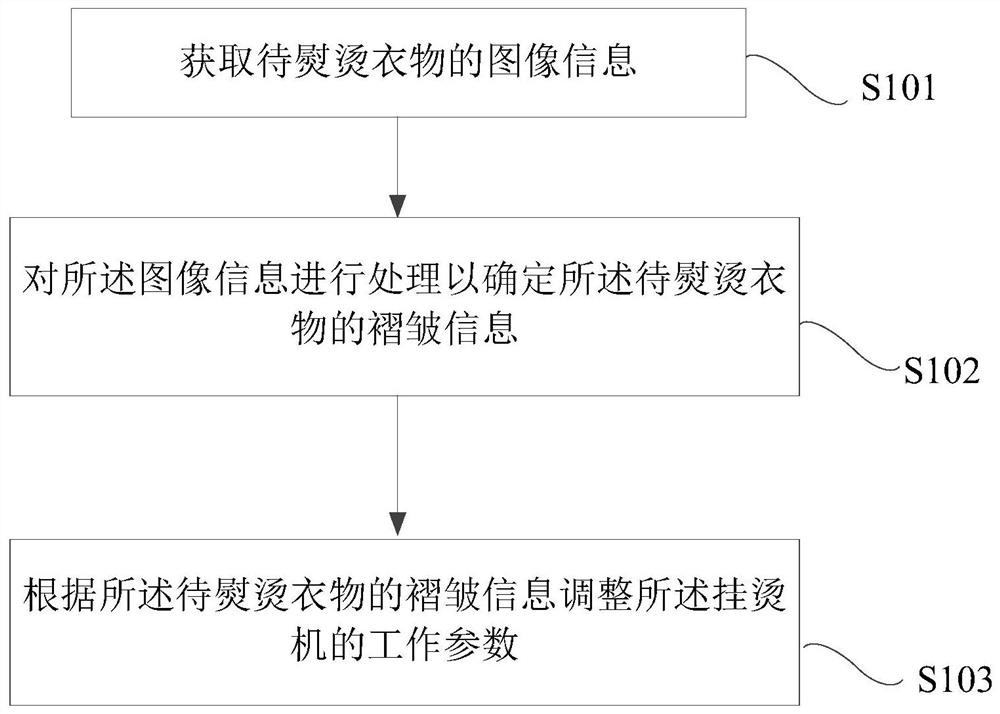

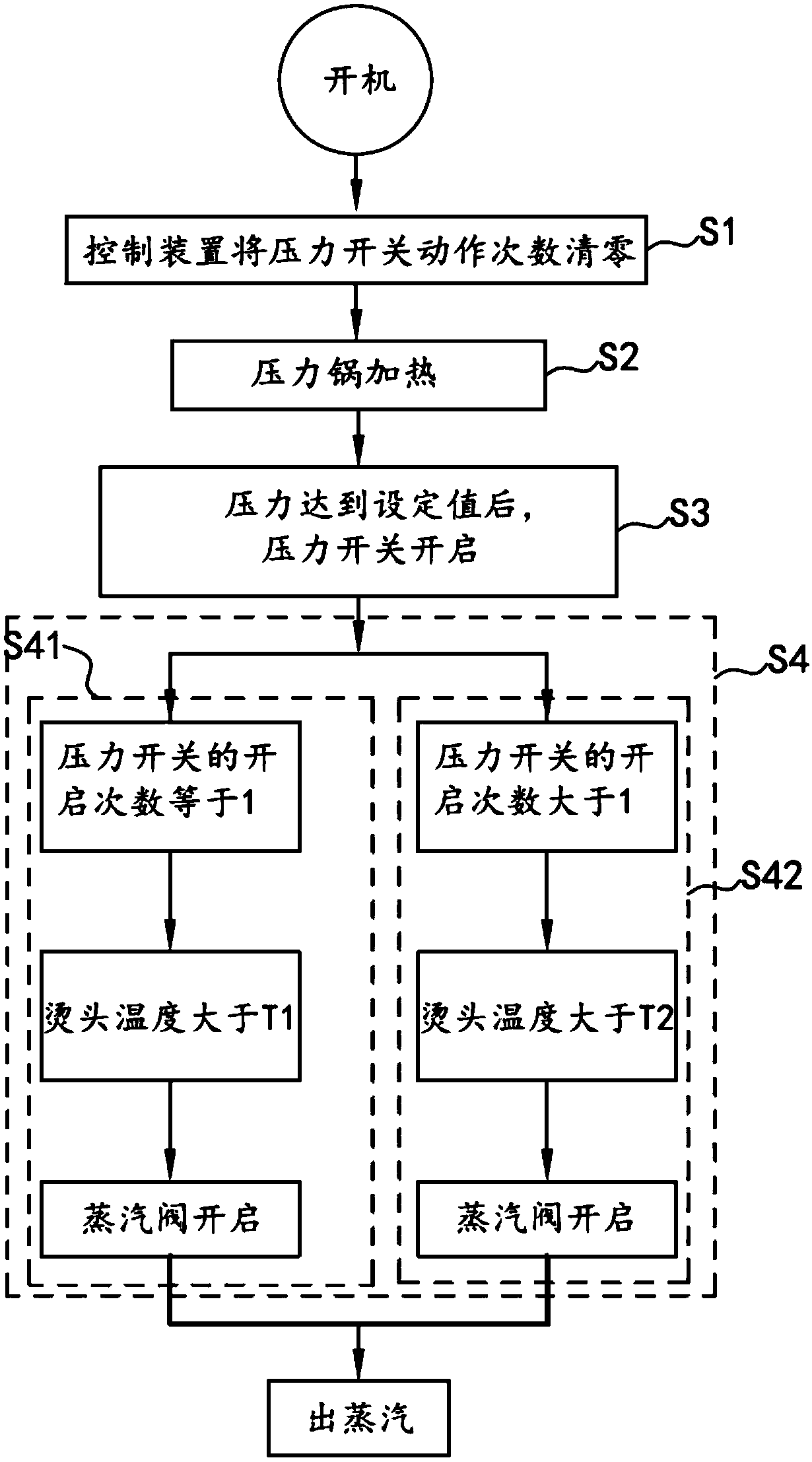

Control method of ironing device and ironing device

ActiveCN111485411AIntelligent fully automatic intelligent ironingGuaranteed ironing effectHand ironIroning apparatusEngineeringMechanical engineering

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

A textile machine for producing and processing textile fabrics and its technology

ActiveCN111501169BImprove surface qualityNo wrinklesMechanical cleaningPressure cleaningDust controlAir blower

The invention relates to the technical field of textile fabric processing equipment, and specifically discloses a textile machine for textile fabric production and processing and its technology; it includes a machine case, a winding roller and a lead-in roller, four corners of the lower surface of the machine case are provided with feet, and the body of the machine case The right side is provided with a fabric inlet, the left side of the cabinet is provided with a fabric outlet, and the first rotating bracket is arranged on the right side of the cabinet above the fabric inlet, and the introduction roller is rotated and arranged on the first rotating bracket; The fabric after spinning is combined with wind force and electrostatic dust removal, and then sprayed with antistatic liquid, and then the fabric sprayed with antistatic liquid is ironed, and finally the fabric at the pre-treatment end is dried by a hot air blower and rolled up. Therefore, there is no static electricity on the surface of the prepared textile fabric, and at the same time, the dust on the surface of the textile fabric can be effectively removed, and there will be no wrinkles on the surface of the textile fabric after ironing, which greatly improves the surface quality of the fabric and improves the market competitiveness of the product .

Owner:浙江兰溪银丰纺织有限公司

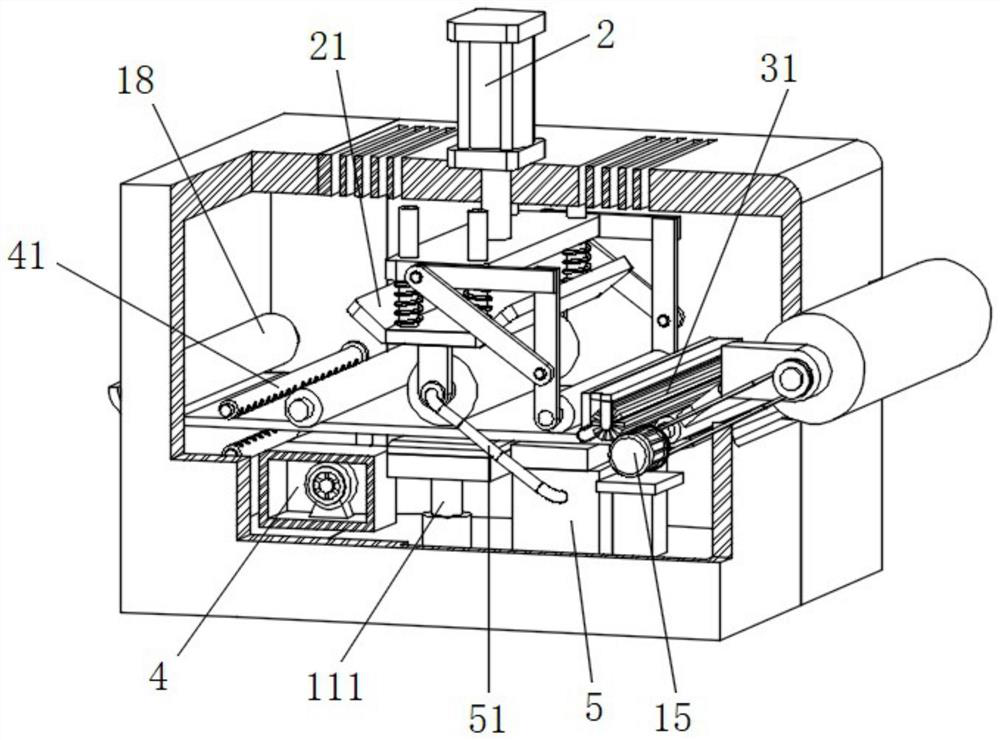

Textile fabric flattening ironing process

PendingCN114737345AImprove flatnessEasy ironingMechanical cleaningPressure cleaningMechanical engineeringPleat

The invention discloses a textile fabric flattening ironing process. The textile fabric flattening ironing process sequentially comprises the following steps that firstly, textile fabric to be ironed is manually conveyed into a machine box through an unwinding roller; dust adhered to the surface of the textile fabric is adsorbed and cleaned through a cleaning roller; the cleaned textile fabric is shaped through an ironing device, the ironed textile fabric is conveyed to a winding roller to be wound, and a finished textile fabric product is obtained; through the cooperative use of the movable plate, the compression roller, the ironing cylinder and the like, the compression roller flattens the conveyed fabric, so that the fabric is flat before being ironed, the smoothness of subsequent ironing is ensured, the fabric is prevented from wrinkling in the conveying process, and the bearing plate moving vertically is elastically matched with the spring, so that the fabric is prevented from being wrinkled. The surface of the fabric can be prevented from being burnt due to too large clamping force in the ironing process, the ironing effect of the textile fabric is effectively guaranteed, and meanwhile the fabric with different thicknesses can be ironed conveniently.

Owner:杭州理和织物整理有限公司

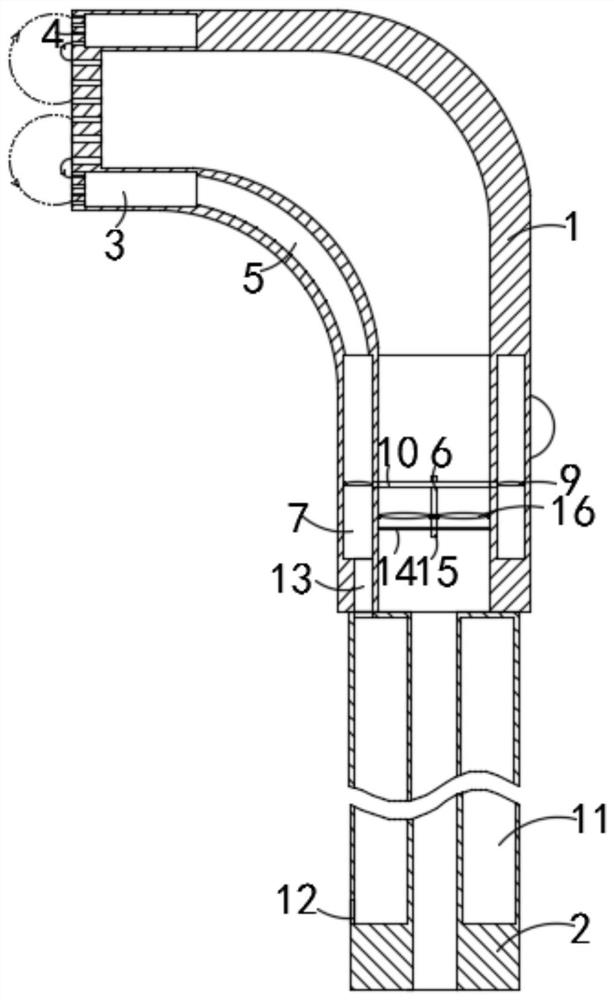

Handheld steam hanging ironing device

PendingCN108252068ASimple structureGuaranteed ironing effectIroning apparatusTextiles and paperEngineering

The invention provides a handheld steam hanging ironing device. The handheld steam hanging ironing device comprises a handle, an ironing plate, a steam conveying pipe and a sealed connecting component, wherein the handle is hollow, the steam conveying pipe penetrates into the handle, and the ironing plate is rotatably arranged at one end of the handle and is rotatably connected with the steam conveying pipe through the sealed connecting component in a sealing manner. The handheld steam hanging ironing device provided by the invention is simple in structure, and the production cost is effectively lowered.

Owner:GUANGDONG BARSETTO ELECTRIC IND CO LTD

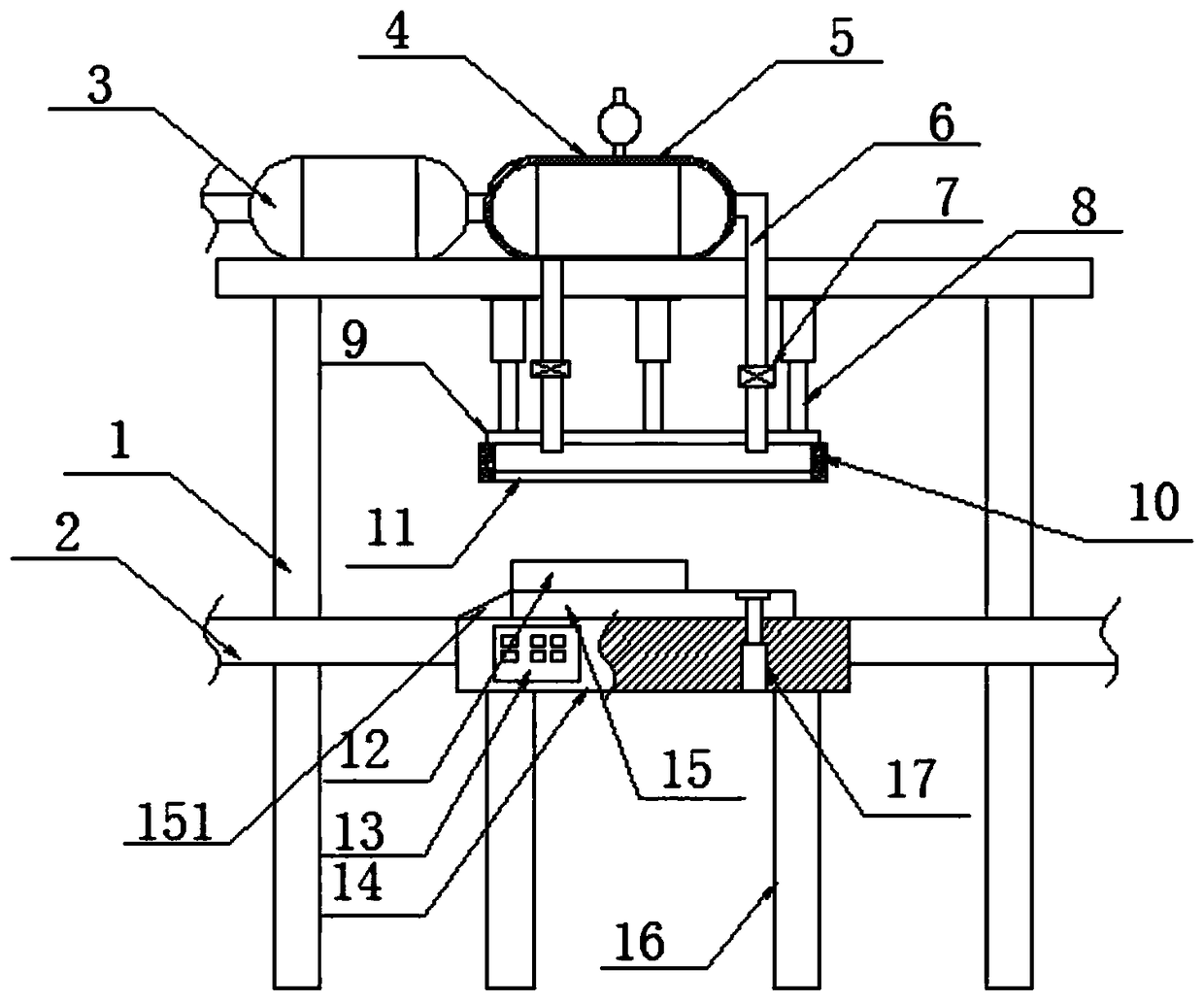

Garment ironing working platform

InactiveCN108797063APrevent leakageEven by forceIroning apparatusTextiles and paperBuffer tankUltimate tensile strength

The invention discloses a garment ironing working platform. The garment ironing working platform comprises a first support and a conveying belt. A gas buffer tank is arranged on the top of the first support, the conveying belt is arranged at the bottom of the first support, one end of the gas buffer tank is connected with a steam tank through a pipeline, a heat insulating layer is arranged on theouter side of the steam tank, the steam tank is provided with a pressure meter, gas conveying pipes are arranged at the two ends of the steam tank, electromagnetic valves are arranged on the gas conveying pipes, multiple first electric push rods are fixedly arranged at the bottom of a top plate of the first support, a push plate is fixedly arranged on the tops of the first electric push rods, thebottom of the push plate is fixedly connected with a transversely-arranged ironing plate, sealing layers are arranged at the two ends of the ironing plate, a second support is arranged on one side ofthe first support, a workbench is arranged on the top of the second support, a containing plate is arranged on the top of the workbench, and baffles are fixedly arranged on the two sides of the containing plate. The device is convenient to operate, high in ironing speed and low in labor intensity.

Owner:东台市天工纺织品有限公司

Multifunctional ironing table device for cloth production

PendingCN111962243AGuaranteed ironing effectEffective pullingTextile treatment by spraying/projectingFabric steaming/decatisingWorkbenchEngineering

The invention discloses a multifunctional ironing table device for cloth production. The multifunctional ironing table device comprises a base, wherein a workbench is fixedly arranged on the top surface of the base; a horizontal conveying belt is arranged on the right side of the workbench; a plurality of first vertical rods are arranged on the top surface of the workbench in a fore-and-aft symmetrical way; horizontally-tilting first rotating shafts are arranged close to the tops on the side faces of the first vertical rods; the other ends of the first rotating shafts are sleeved with electricrollers; vertical electric telescopic rods are fixedly arranged on second electric slide blocks; and strip-shaped second irons are fixedly arranged at the bottoms of the electric telescopic rods. According to the multifunctional ironing table device, cloth can be flattened by stretching while the cloth is driven to move by the electric rollers, so that the ironing effect is ensured. After the cloth is ironed, the cloth can continually keep in a stretching-flattened state through remaining electric rollers, and is shaped after cooling, so that each part of the cloth can be ironed effectively with the second irons after ironing is finished, and the ironed cloth can be placed on a first cross rod automatically.

Owner:HEBEI ACADEMY OF FINE ARTS

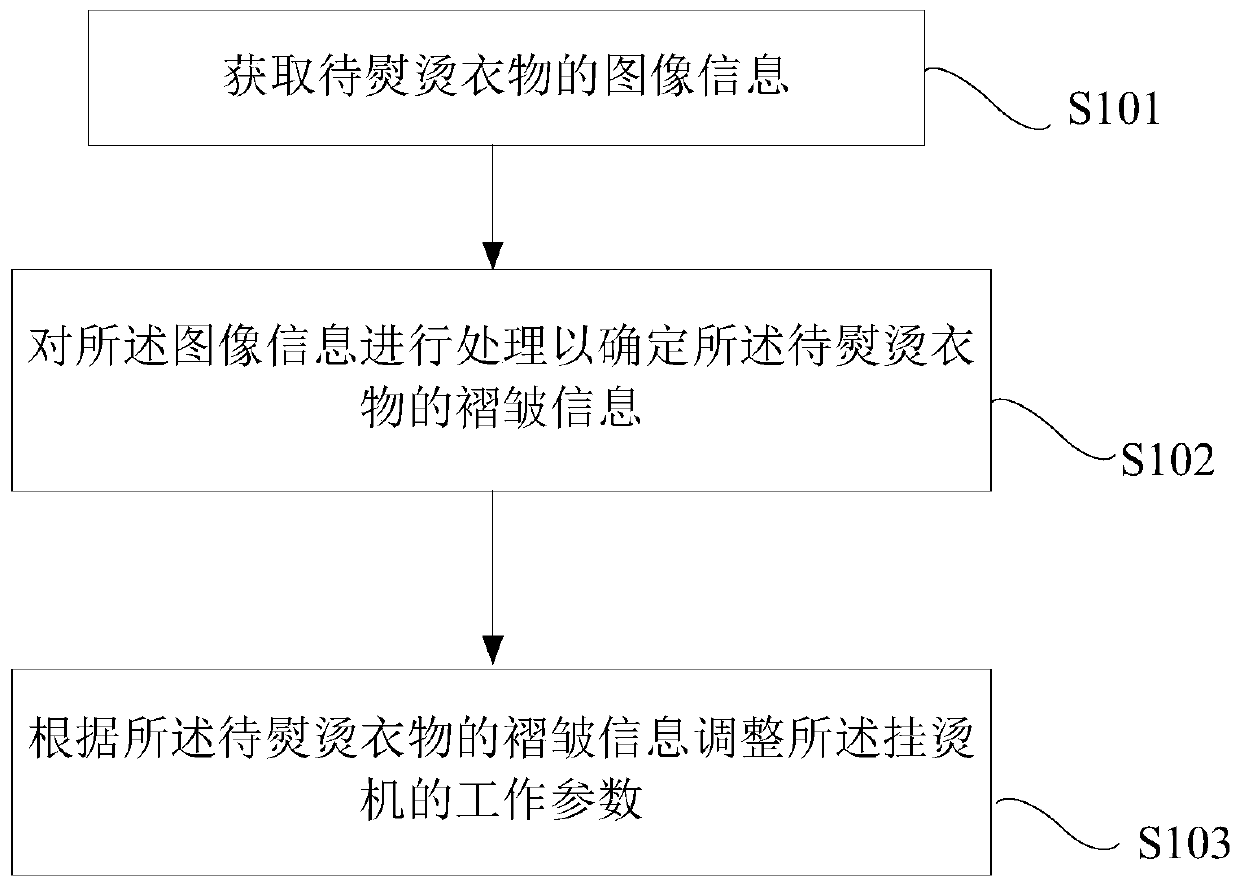

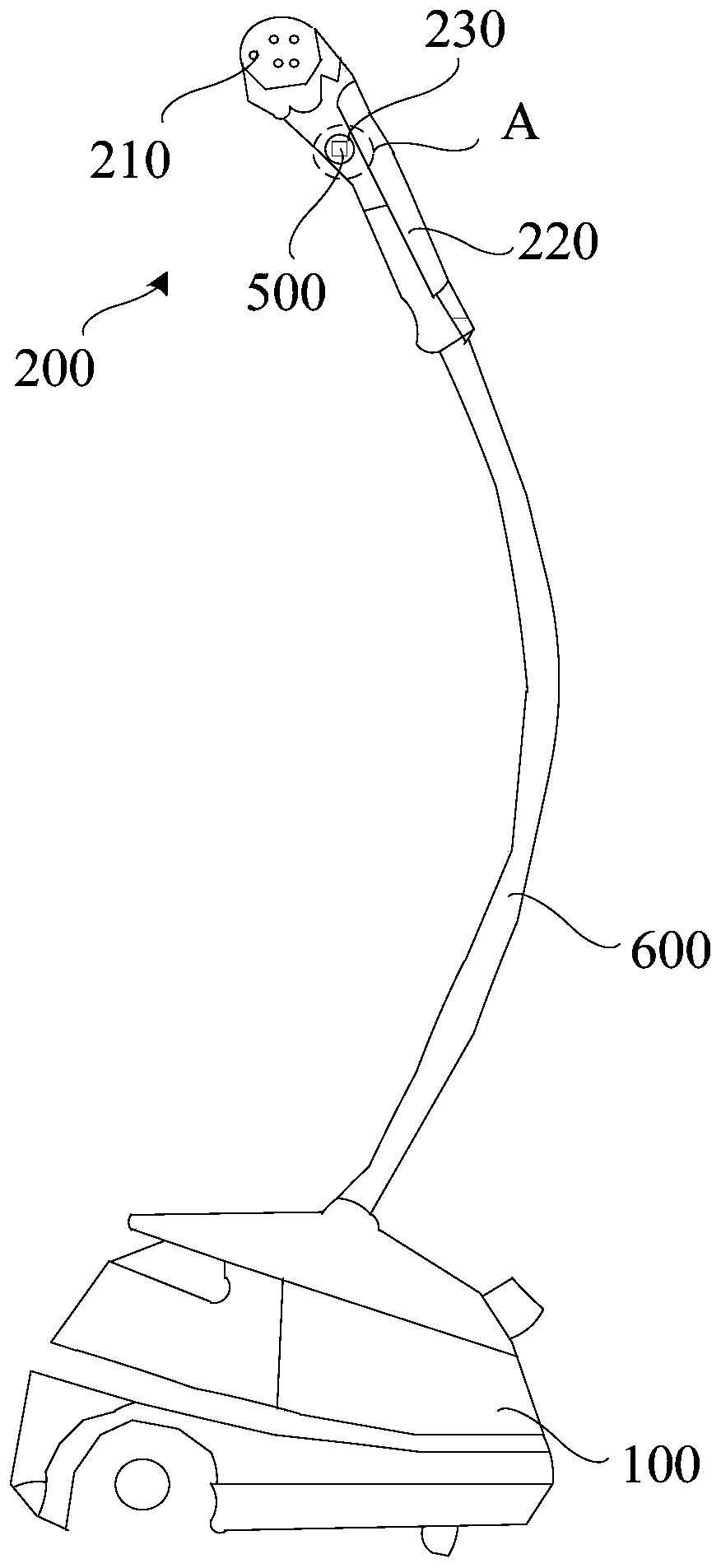

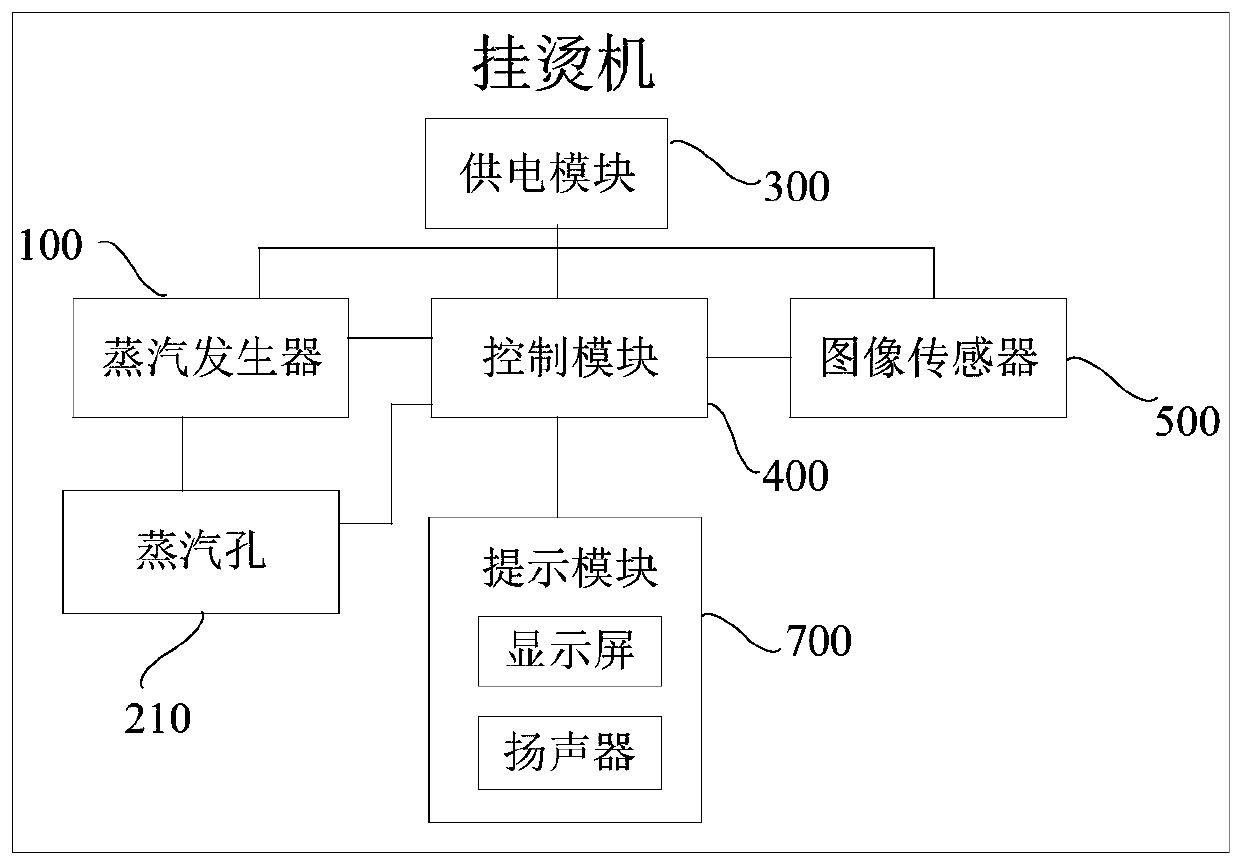

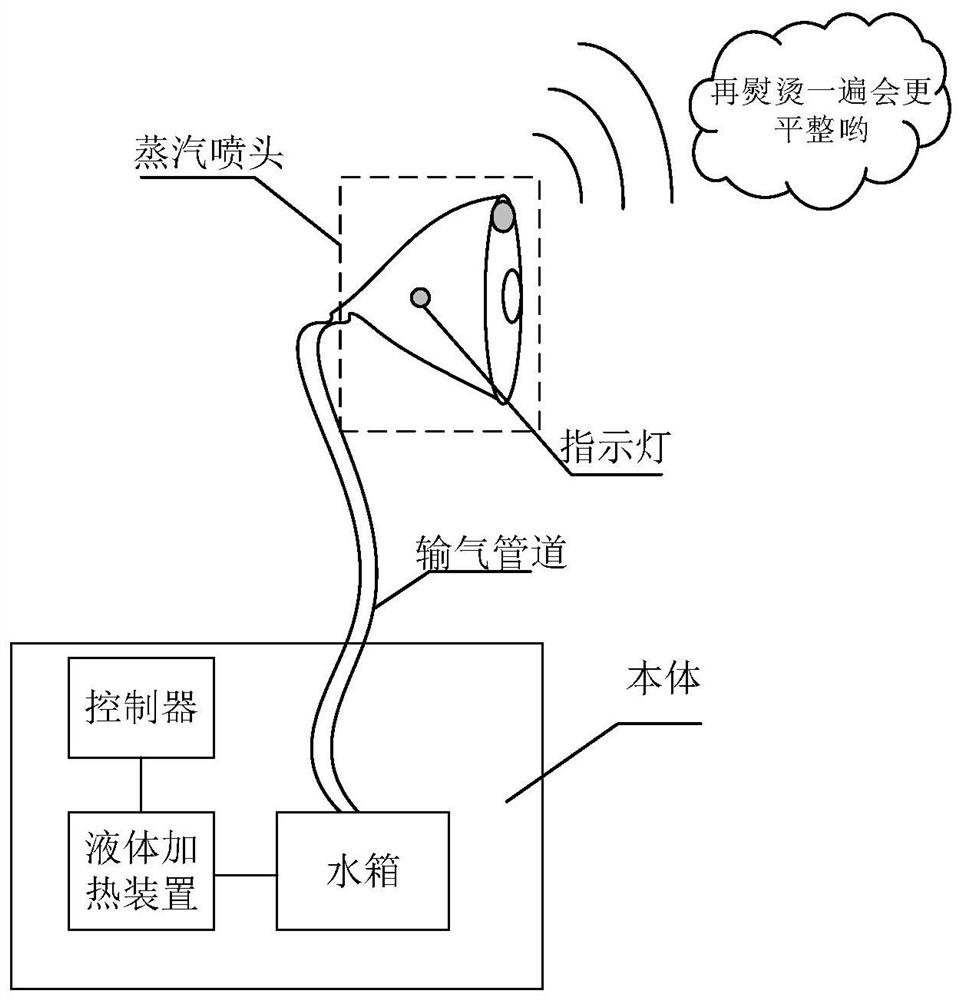

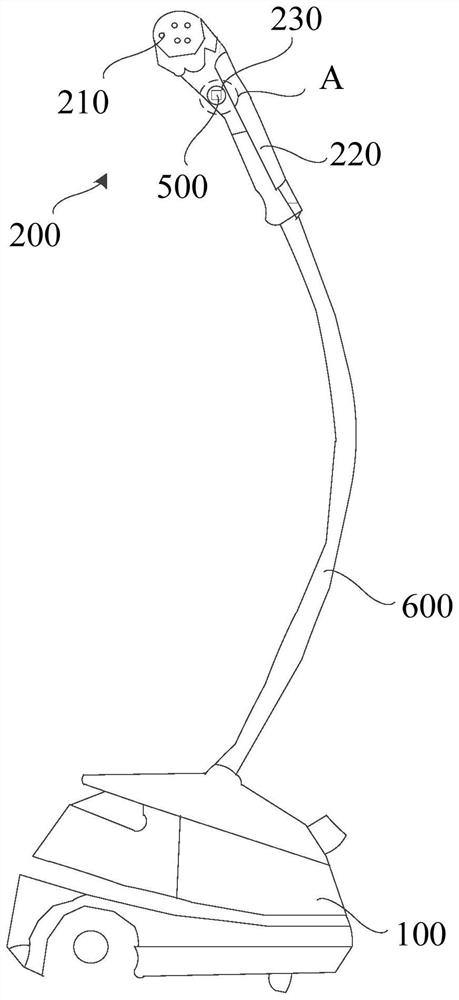

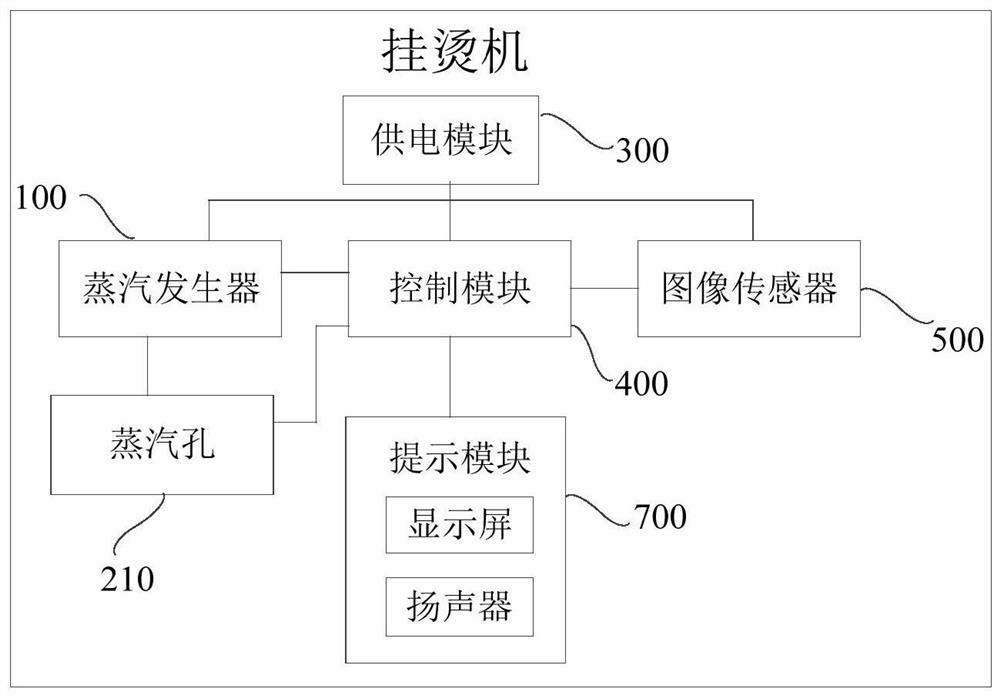

Hanging-ironing machine and control method thereof

ActiveCN109914083AImprove ironing efficiencyLow costIroning apparatusTextiles and paperElectricityAutomatic control

The invention relates to a hanging-ironing machine and a control method thereof. An image sensor is arranged at an ironing head of the hanging-ironing machine to collect image information of to-be-ironed clothing, the image sensor and a steam generator of the hanging-ironing machine are in communication connection with the control module of the hanging-ironing machine, the control module processesthe image information collected by the image sensor to obtain fold information of the to-be-ironed clothing, according to the fold information, the work parameter of the steam generator is adjusted,automatic control over the work parameter of the hanging-ironing machine is thus achieved, inconvenience caused by manual switching of ironing gears is avoided, and thus the ironing efficiency of thehanging-ironing machine. Meanwhile, the work parameter of the hanging-ironing machine can be automatically adjusted according to the fold information of the to-be-ironed clothing, and on the basis that the ironing effect is ensured, and the electricity and water consumption cost of the hanging-ironing machine is saved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

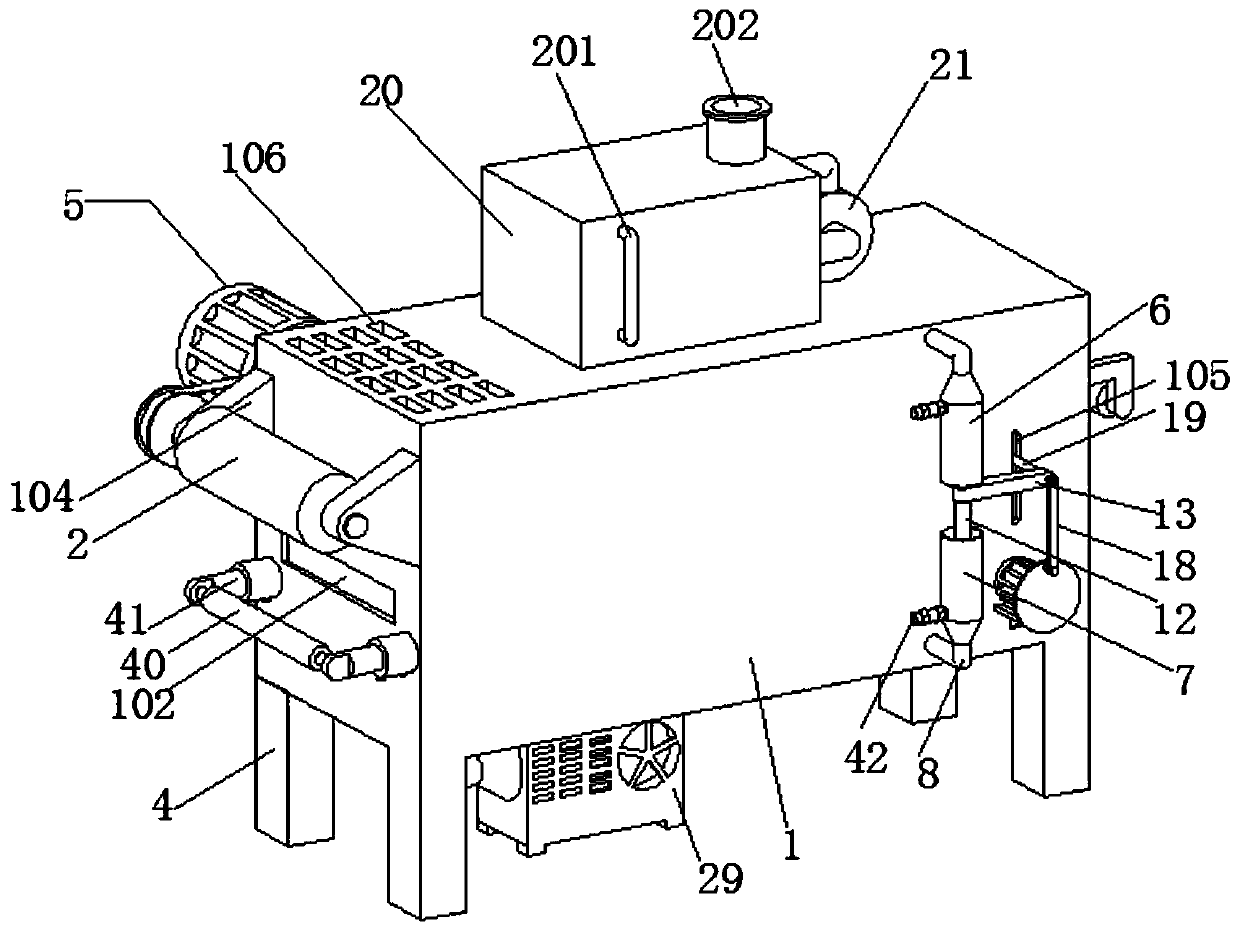

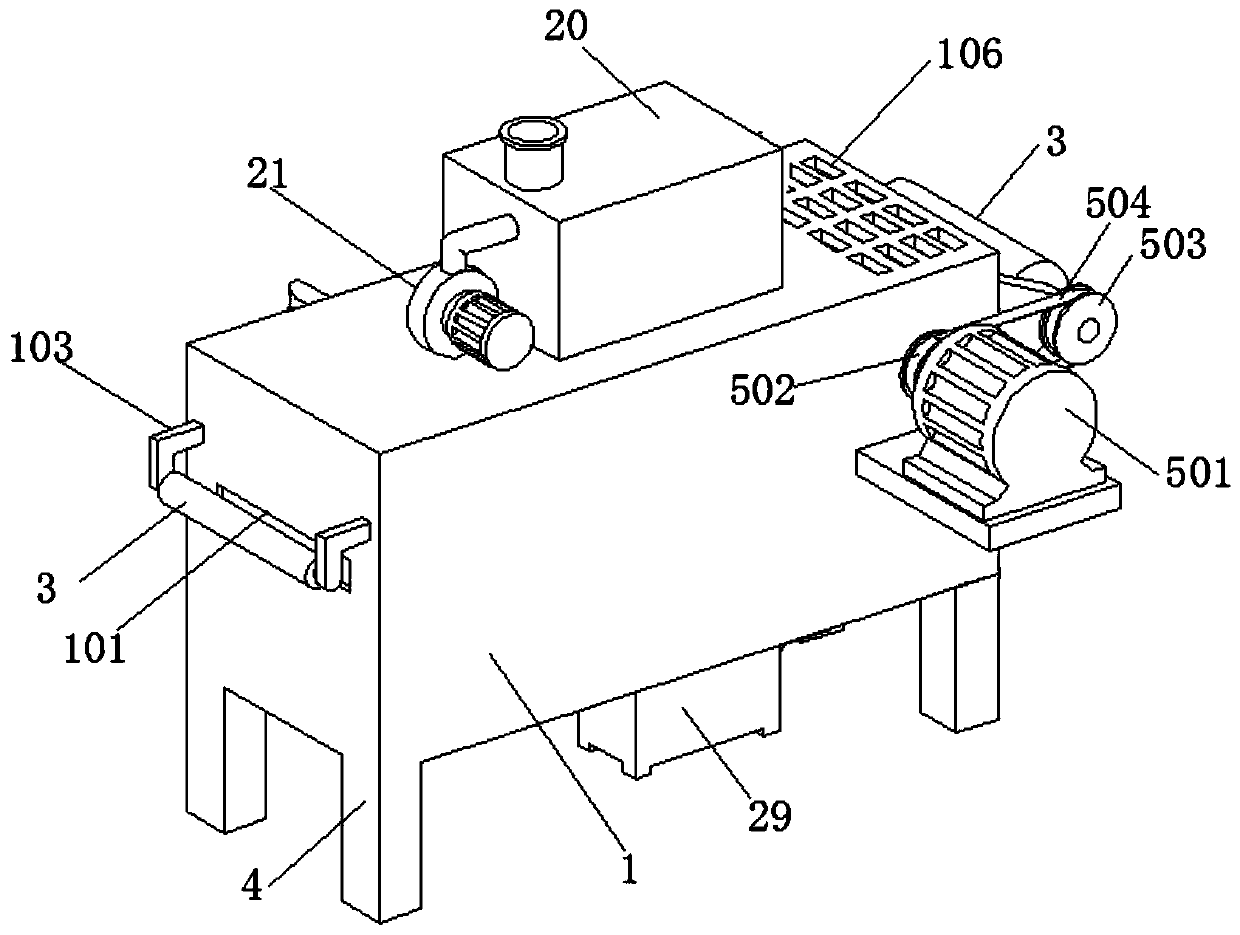

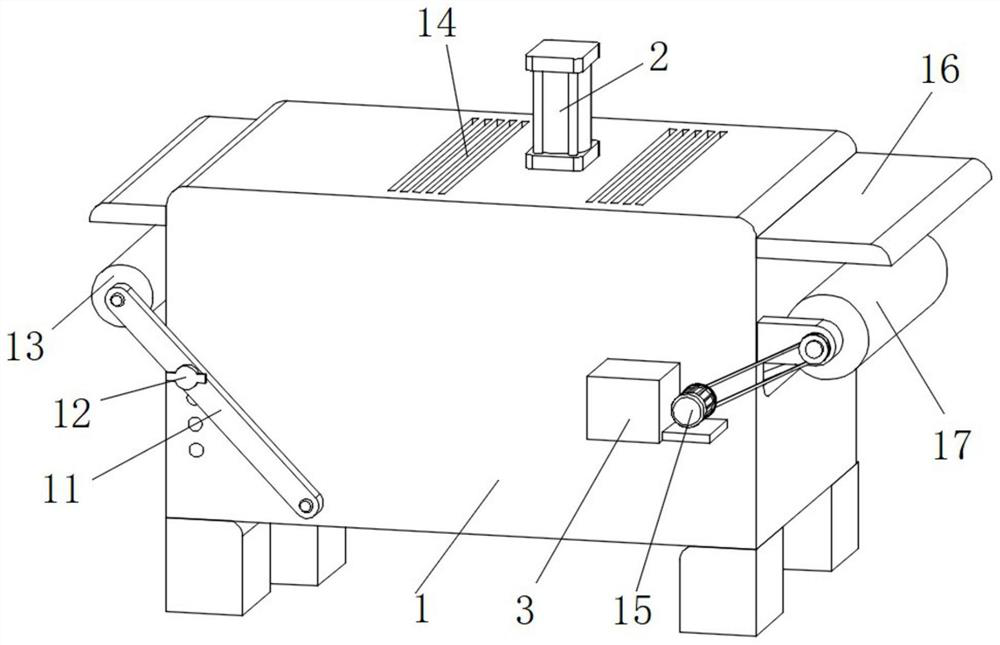

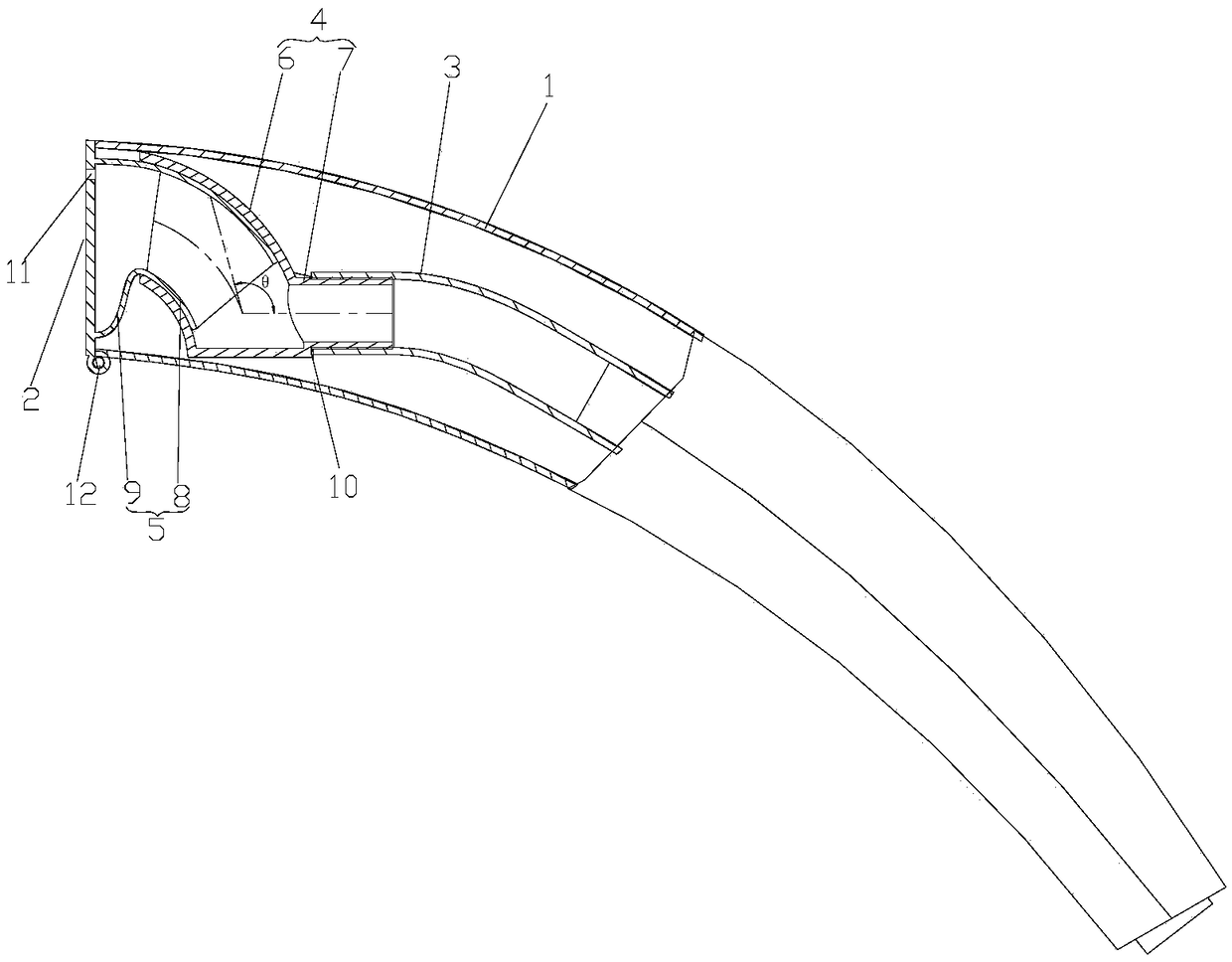

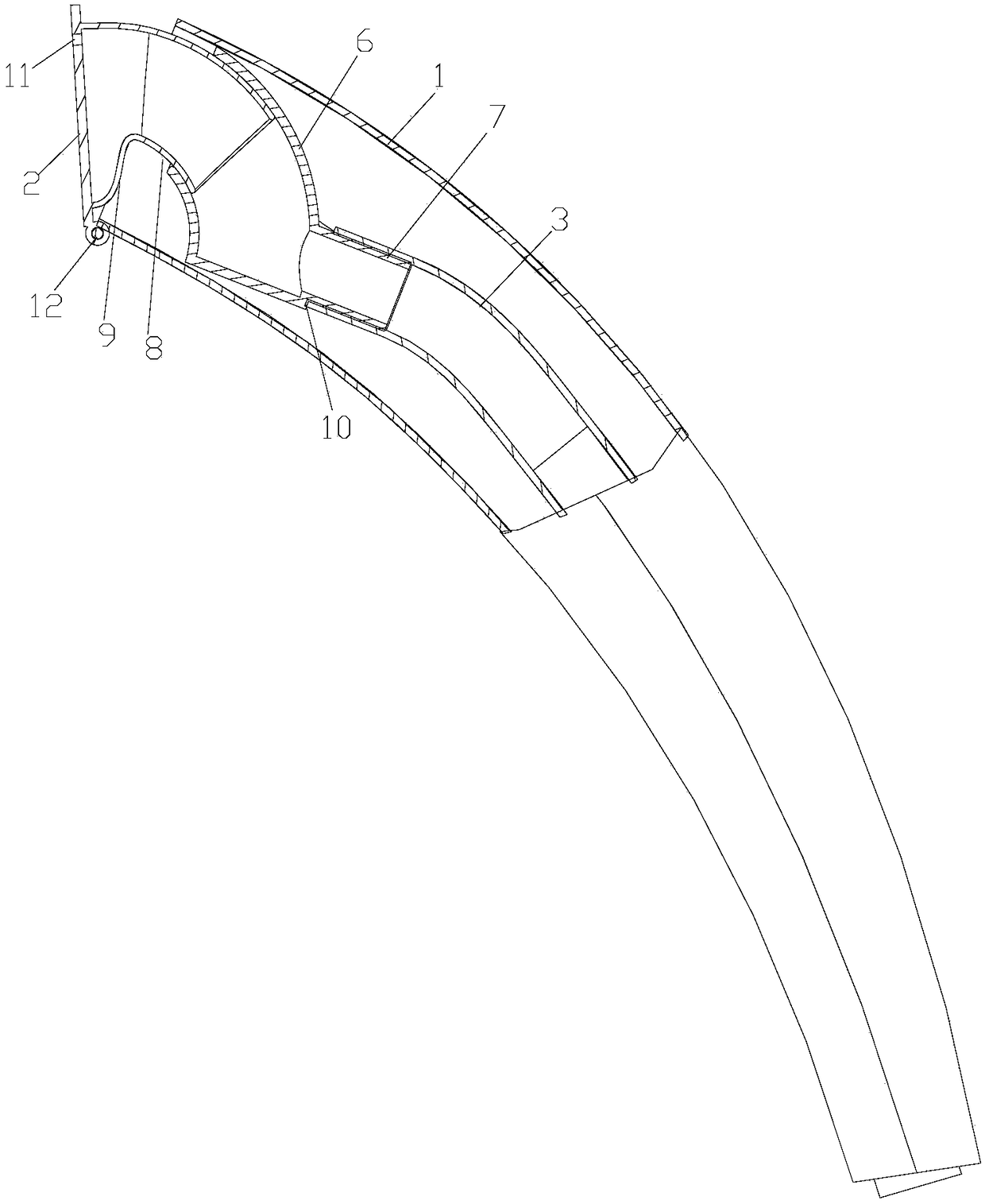

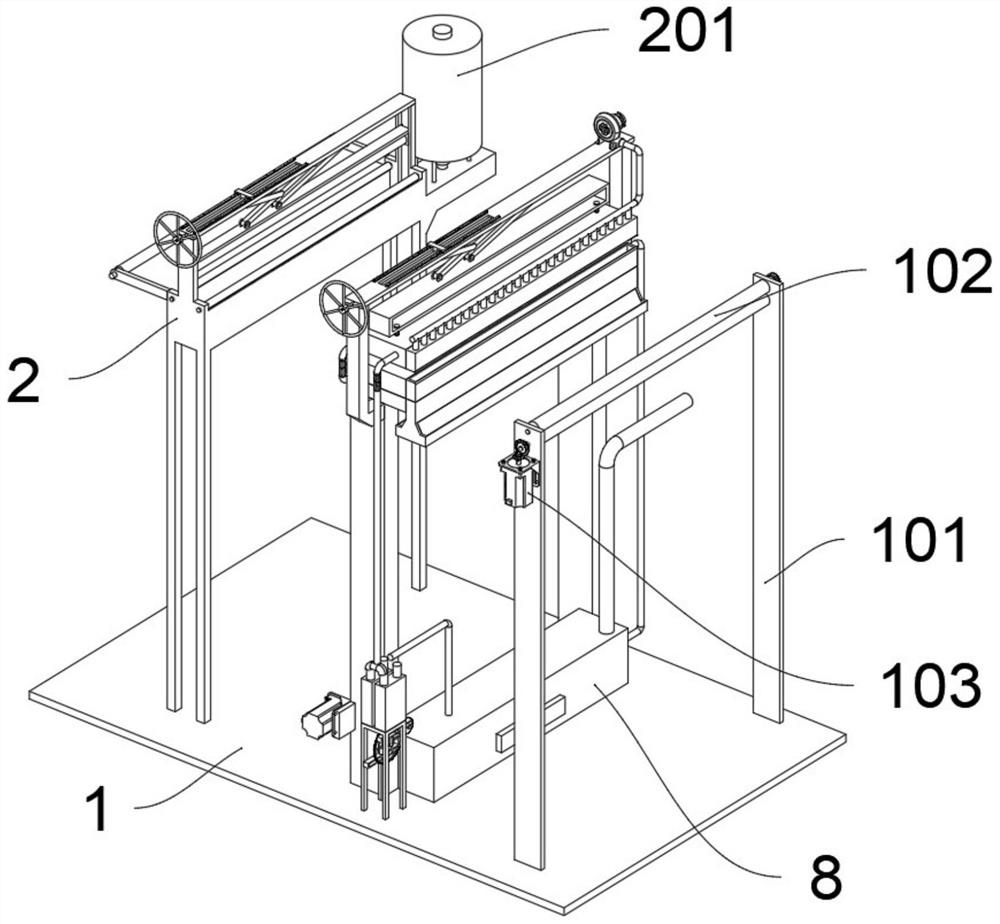

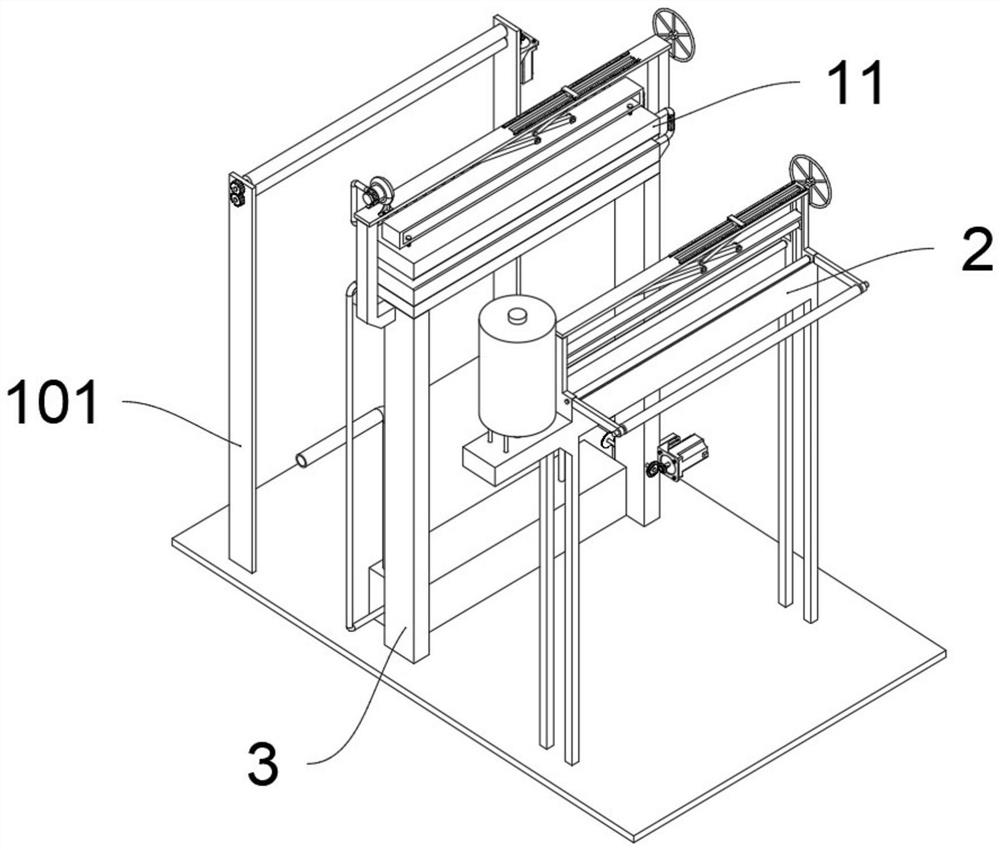

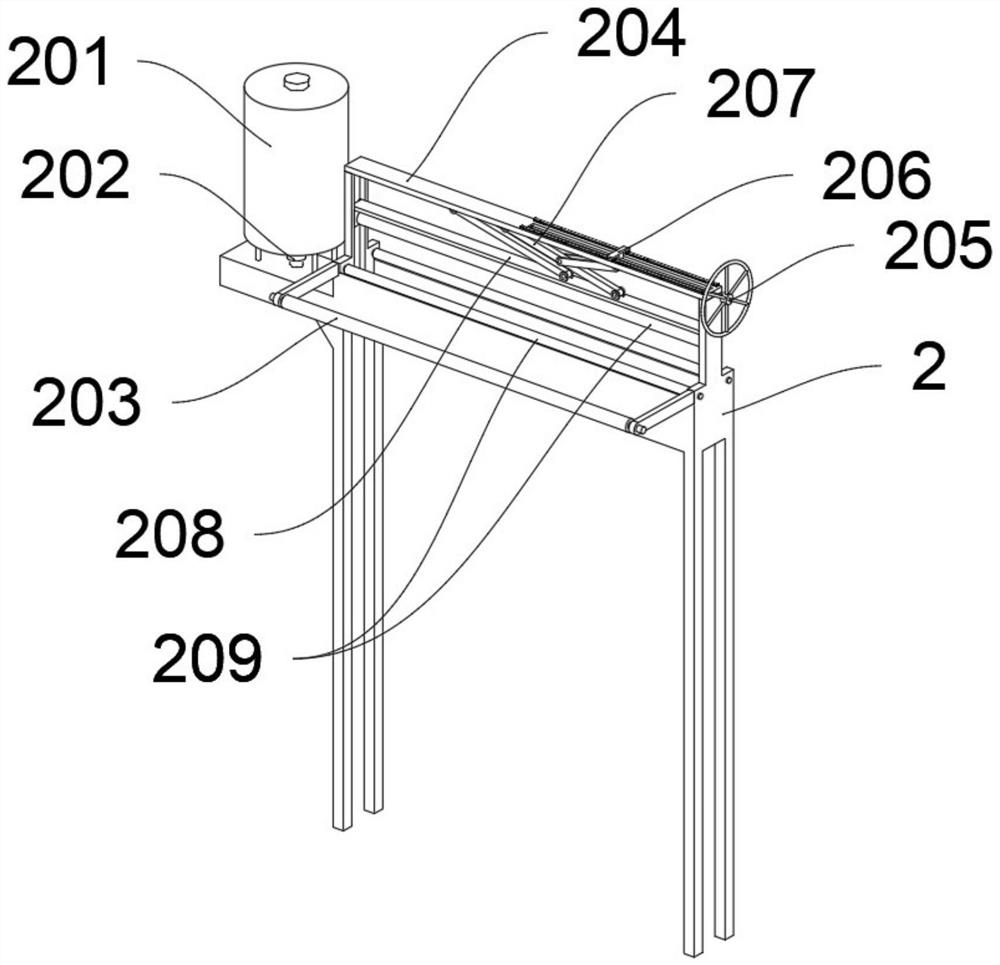

Processing method of light and luxury sea island cotton sweater

ActiveCN114032638AGood waxy feelingGood snagging resistanceWeft knittingGarmentsYarnIndustrial engineering

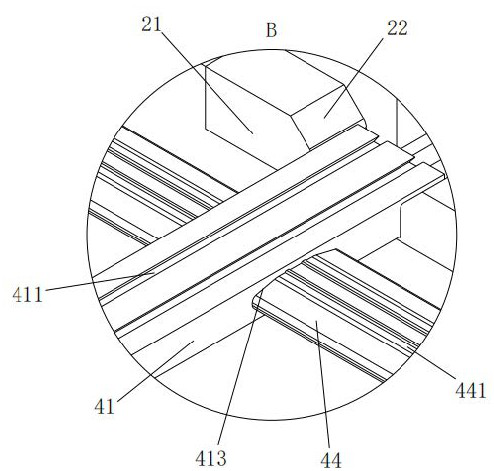

The invention provides a processing method of a light and luxury sea island cotton sweater. The method comprises a fabric manufacturing procedure and a garment manufacturing procedure; the fabric manufacturing procedure comprises a knitting step of alternately feeding two strands of yarns into a circular knitting machine for knitting into loops to form knitted fabric; the fabric obtained in the knitting step is tensioned step by step through a leveling mechanism and subjected to steam ironing so that the surface of the fabric can be flat, and the leveled fabric is subjected to printing and dyeing coloring through a dyeing machine and made into fabrics with various colors; the leveling mechanism comprises a machine frame, a tensioning roller and an iron assembly, at least three pairs of sliding supports are arranged on the machine frame in the length direction of the machine frame, each pair of sliding supports are symmetrically arranged at the two sides of the machine frame in the width direction, a first sliding block is longitudinally installed on the sliding supports in a sliding mode, the tensioning roller is rotatably installed between the pair of sliding supports, and first springs are fixedly mounted in the upper side and the lower side of the first sliding block.

Owner:FUJIAN SEPTWOLVES IND

an electric iron

ActiveCN108914520BSituations that affect user experienceEasy to useHand ironTextiles and paperEngineeringMechanical engineering

The invention discloses an electric iron. The electric iron comprises a first machine shell, wherein a storage cavity is formed in the first machine shell; a placement seat is arranged in the storagecavity; a placement groove is formed in the top of the placement seat; an ironing mechanism is arranged in the placement groove; the ironing mechanism comprises a second machine shell; a side face ofthe second machine shell is provided with a connection wire, and the inner part of the second machine shell is provided with a first draught fan and a second draught fan; the second draught fan is arranged at one side of the first draught fan; the connection wire is internally provided with a steam discharging pipe and a steam outlet pipe; a lead wire is arranged between the steam discharging pipeand the steam outlet pipe; a first steam guide pipe and a second steam guide pipe are arranged at the bottom of the first draught fan. According to the electric iron disclosed by the invention, the first draught fan is used for sucking surplus water steam and then the water steam is conveyed into an atomization cavity through the steam discharging pipe again, so that conditions that surplus warmwater enters the air and user experience of a user is influenced are effectively can be effectively prevented, and furthermore, the user can utilize the electric iron more conveniently.

Owner:宁波市聚梦智能科技有限公司

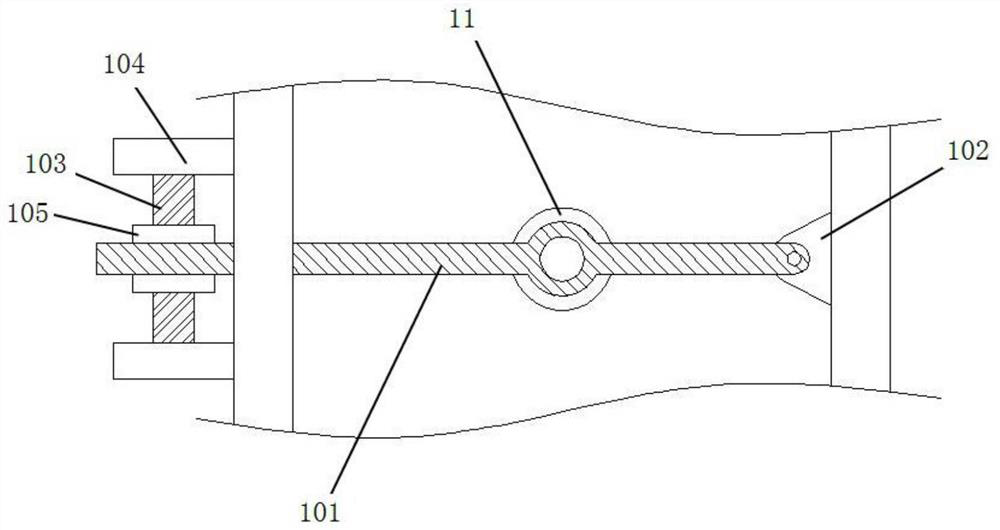

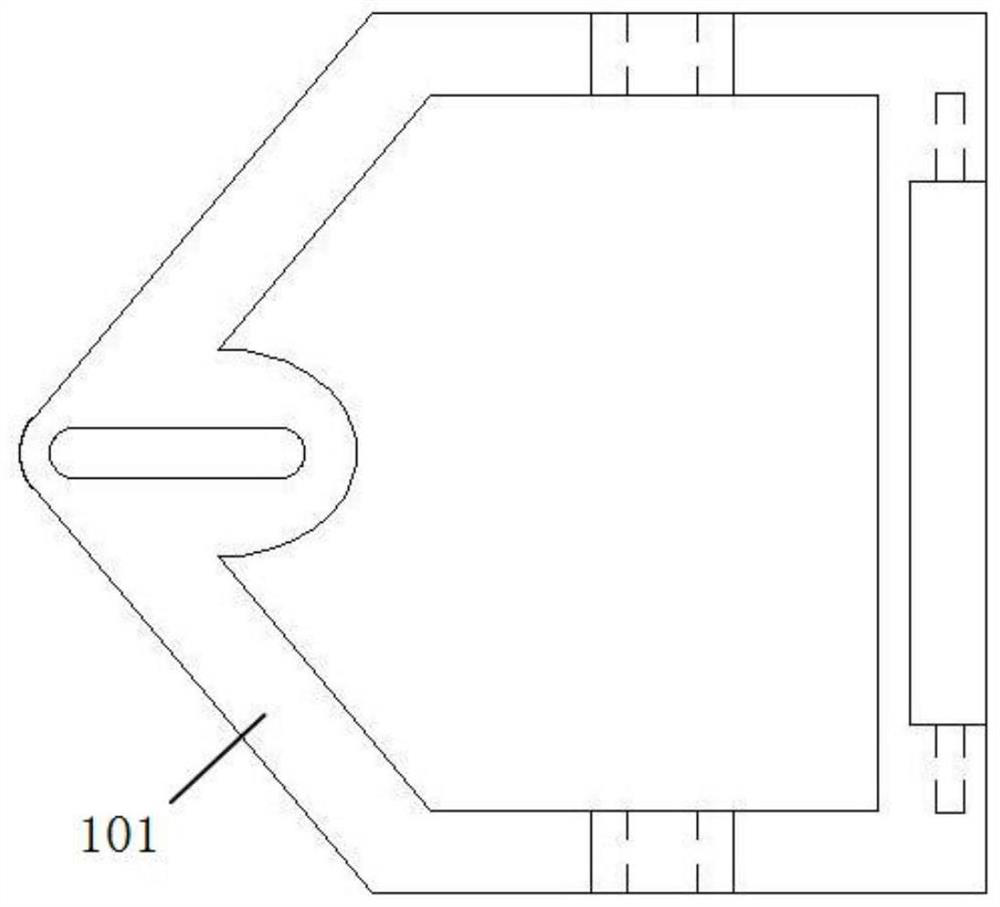

A new type of handheld -holding hot -mounted pants seam clip structure

ActiveCN109371647BImprove airtightnessStable structureIroning apparatusOther drying apparatusHand heldEngineering

The invention provides a trouser seam clamp structure of a novel hand-held garment ironing machine, which includes an auxiliary steam outlet for ironing trouser seams, a trouser splint for pressing clothes, and a trouser splint arranged in the hand-held garment ironing machine. Steam generator and main steam outlet. The auxiliary steam outlet includes a vaporization cover, a trousers pipe joint with an inner hole, a sealing plug with an inner hole, and an upper cover of the garment steamer; the trouser splint includes a rotating shaft bracket, a rotating shaft, a torsion spring for providing torsion, and Compress and fix the pressing plate of the clothes; the invention adopts the independent auxiliary steam port design, and its steam channel has a good airtight and stable structure, combined with the trouser seam clip structure designed integrally with the garment ironing machine, the structure is simple and practical , safety, the invention ensures the ironing effect of the trouser seam, improves the portability and ironing efficiency of the hand-held garment ironing machine, and solves the problem that it is difficult for the general hand-held garment garment ironing machine to iron the straight trouser seam.

Owner:NINGBO HEIGER ELECTRICAL APPLIANCES

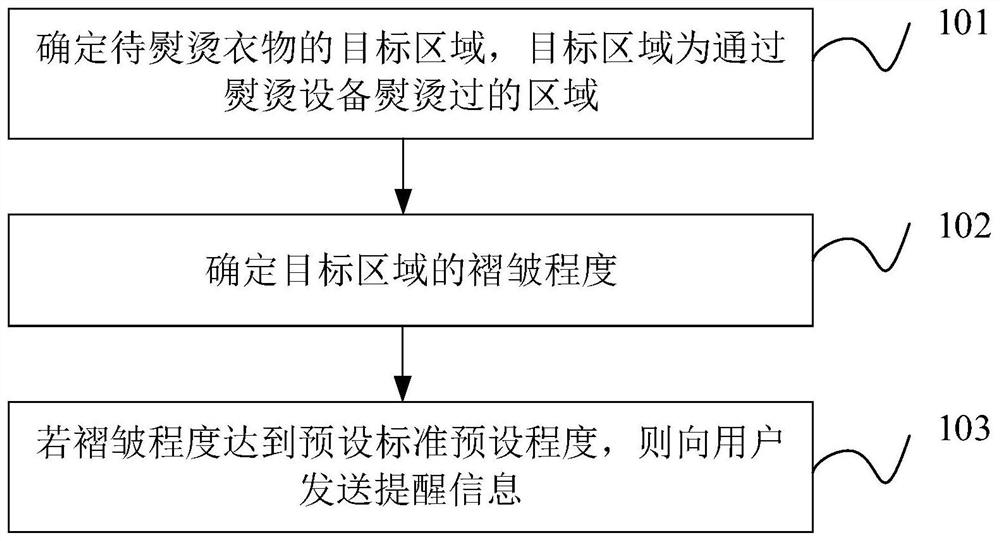

Ironing equipment reminding method and device, ironing equipment and storage medium

PendingCN112064311AImprove experienceGuaranteed ironing effectIroning apparatusTextiles and paperMechanical engineeringIndustrial engineering

The invention provides an ironing equipment reminding method and device, ironing equipment and a storage medium. The method comprises the steps that a target area of the to-be-ironed clothes is determined, and the target area is a region ironed by the ironing equipment; the wrinkle degree of the target area is determined; and if the wrinkle degree reaches a preset degree, reminding information issent to the user. According to the embodiment of the ironing equipment reminding method, whether the ironing effect reaches the preset effect or not is judged according to the wrinkle degree of the target area ironed by the ironing equipment, and when the wrinkle degree reaches the preset degree, the reminding information is sent to the user to remind the user to iron the target area again, so that the ironing effect of the to-be-ironed clothes is guaranteed, and the user experience is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Ironing machine for cloth shrinking treatment

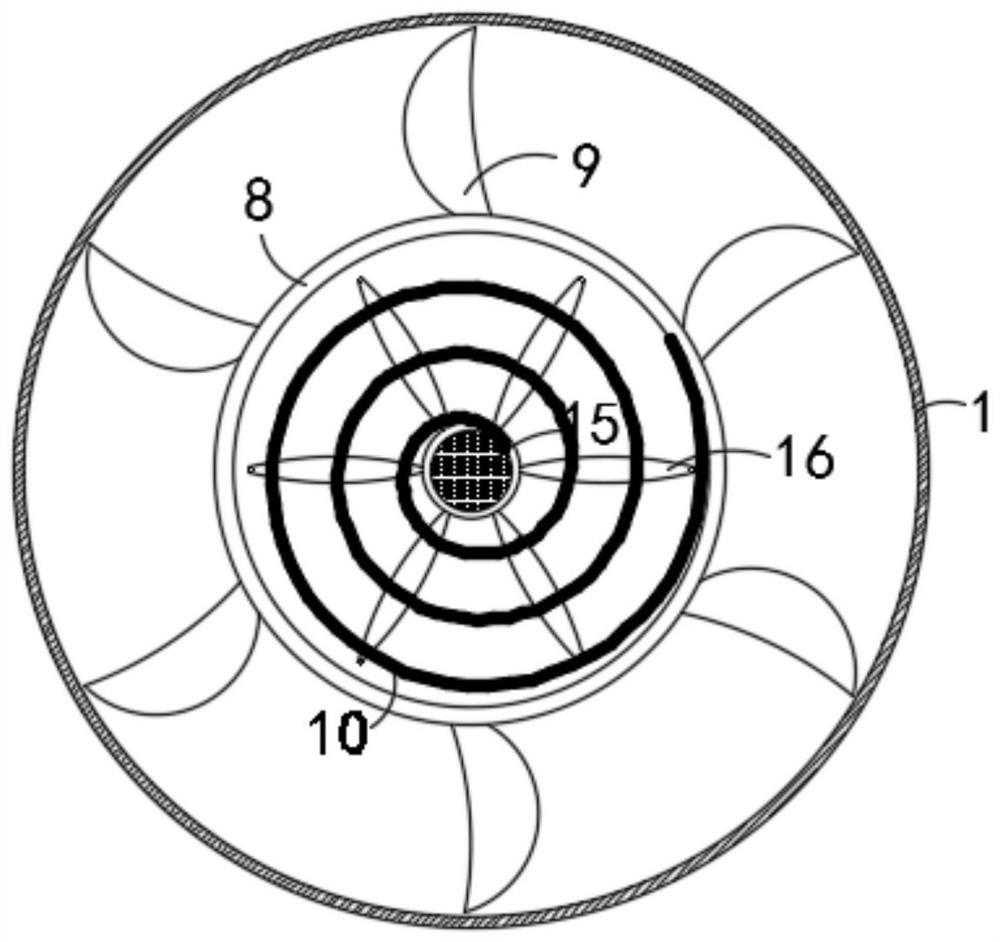

The invention discloses an ironing machine for cloth shrinking treatment. The ironing machine comprises a bottom frame of which the two sides are symmetrically and fixedly provided with two U-shaped mounting frames; a transmission assembly mounted in the bottom frame; a rolling type ironing machine body with the two ends fixedly connected to the middles of the mounting frames; two wrinkle supporting mechanisms which are symmetrically installed on the two sides of the bottom frame, wherein each wrinkle supporting mechanism comprises a driving assembly, a connecting assembly and a supporting wheel assembly, the driving assemblies are installed at the upper end of the side wall of the bottom frame, the connecting assemblies are annularly and fixedly connected to the driving ends of the driving assemblies, and the supporting wheel assemblies are fixedly connected to the ends of the wrinkle supporting mechanisms. and an unfolding assembly which is fixedly installed on the side, away from the rolling type ironing machine body, of the wrinkle supporting mechanisms. The cloth is stretched and flattened in the cloth moving process, manual stretching is not needed, a large amount of time is saved, the ironing efficiency is improved, and meanwhile the ironing effect can be guaranteed.

Owner:南通棉田纺织品有限公司

Ironing device for textile fabric production and processing

InactiveCN112593374AEasy to store and useGuaranteed heightTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsMechanical engineeringTextile processing

The invention discloses an ironing device for textile fabric production and processing, relates to the technical field of textile processing, and solves the problems that the ironing device used at present does not have the functions of continuously soaking fabric and automatically balancing a water surface, and does not have the functions of quickly ironing the fabric and quickly air-drying the fabric. The ironing device for textile fabric production and processing comprises a base, wherein a soaking channel is fixedly arranged on the front side of the top of the base; the bottom of one sideof the soaking channel extends outwards to form a convex bin, a self-filling cylinder is fixedly arranged at the top of the convex bin through a support, and a sealing plug is arranged at the top of the self-filling cylinder. Through arrangement of the soaking channel, a wetting function is provided for the fabric, and the fabric can continuously make contact with water when penetrating through the soaking channel, so that the fabric is soaked, and the ironing effect is improved; the water level of the soaking channel can be automatically kept, and after the water level in the soaking channelis lowered, water in the self-filling cylinder can flow into the soaking channel to keep the water level.

Owner:温州瓦序鞋业有限公司

A foldable ironing machine

The invention provides a foldable ironing machine, belongs to the technical field of ironing equipment and solves the problem that existing ironing machines cannot be folded or are inconvenient to fold. The foldable ironing machine comprises a base and an ironing board, wherein the ironing board comprises a main body part and a folding part which comprise a main body inner cavity and a folding inner cavity respectively, the folding part is hinged to the main body part, a folding yielding notch is formed in one side of the hinge direction, and a supporting structure for keeping the unfolding state of the folding part as well as a closing structure for covering the folding yielding notch when the folding part is unfolded are arranged between the folding part and the main body part. The ironing board can be folded through simple operation, and the storage space is reduced. During unfolding, sides and the bottom of the whole cavity of the ironing board are well closed, air and most steam pass in and out of vent holes in the working surface when a fan blows and sucks air, and the ironing effect is guaranteed.

Owner:ZHEJIANG SONGYANG ELECTRIC

Baby garment processing device

InactiveCN112458684AImprove processing efficiencyIncrease frictionTextile treatment by spraying/projectingTextile shapingStructural engineeringMechanical engineering

The invention discloses a baby garment processing device. The baby garment processing device comprises a base, an upper support, baffles, a sliding block, a power mechanism, a storage mechanism, an ironing mechanism and the like, wherein the upper support is fixedly connected to the base; three slideways are arranged on the top surface of the base; the two baffles are arranged on the base; the baffles are in sliding connection with the base; slideways are arranged on the top surface of the upper support; the sliding block is arranged on the upper support and is in sliding connection with the upper support; and the two baffles are fixedly connected to the two sides of the sliding block. According to the invention, the wrinkle removing and peculiar smell removing functions are integrated onone machine, and baby clothes accumulated in a warehouse are automatically and completely treated, so that the treatment efficiency is improved; the friction force between the clothes and a friction plate is increased through protrusions on the friction plate, so that the clothes cannot be driven by a moving iron, the clothes are prevented from slipping during ironing, and the ironing effect is guaranteed; and the friction plate can be automatically lifted through a turnover mechanism, so that workers can collect the treated clothes conveniently.

Owner:SHISHI FANYUAN CLOTHING CO LTD

Drying device for child garment processing

PendingCN114045653AGuaranteed flatnessLeveling effectIroning boardsIroning apparatusEngineeringMoisture absorption

The invention relates to the technical field of child garment products, in particular to a drying device for child garment processing. The drying device comprises a moisture absorption ironing table, the moisture absorption ironing table comprises a case, a workbench, a working arm and a steam iron, and the moisture absorption ironing table further comprises a moisture absorption shaping frame; the moisture absorption shaping frame is arranged to fix an overcoat, supporting rods and side rods at the two sides of a main rod play a role in supporting and fixing a front piece and a rear piece, wing plates stretch into sleeves of the overcoat and play a role in supporting and shaping the sleeves of the overcoat, and in the process, due to the supporting and shaping effects of the moisture absorption shaping frame on the overcoat, even in the overturning process, it can be guaranteed that the flattening effect after the overcoat is ironed is not greatly affected, on one hand, the ironing effect is guaranteed, wrinkles of the overcoat are reduced, and on the other hand, the machining efficiency of workers is improved.

Owner:邵阳县萌贝佳童装有限公司

Asphalt Paver for Rapid Vibration of Road and Bridge

ActiveCN110258266BImprove compactnessAvoid accumulationRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses an asphalt paver for road and bridge rapid vibration, which comprises: an asphalt storage box I is arranged at the front end of the asphalt paver body; a distributing auger group is arranged directly under the asphalt discharge port I; It is arranged behind the cloth auger group; the vibrating assembly includes a bracket, a pair of vibrating hammers, a pair of hinges and an ironing plate, which is arranged behind the vibrating assembly, and the upper end of the ironing plate is hingedly arranged at the rear end of the body. The asphalt paver for road and bridge rapid vibration provided by the present invention has uniform distribution of the material distribution auger group, and can perform vibration operation on asphalt in real time, so as to improve the firmness of asphalt paving and ensure the effect of asphalt paving.

Owner:江苏金堰交通工程有限公司

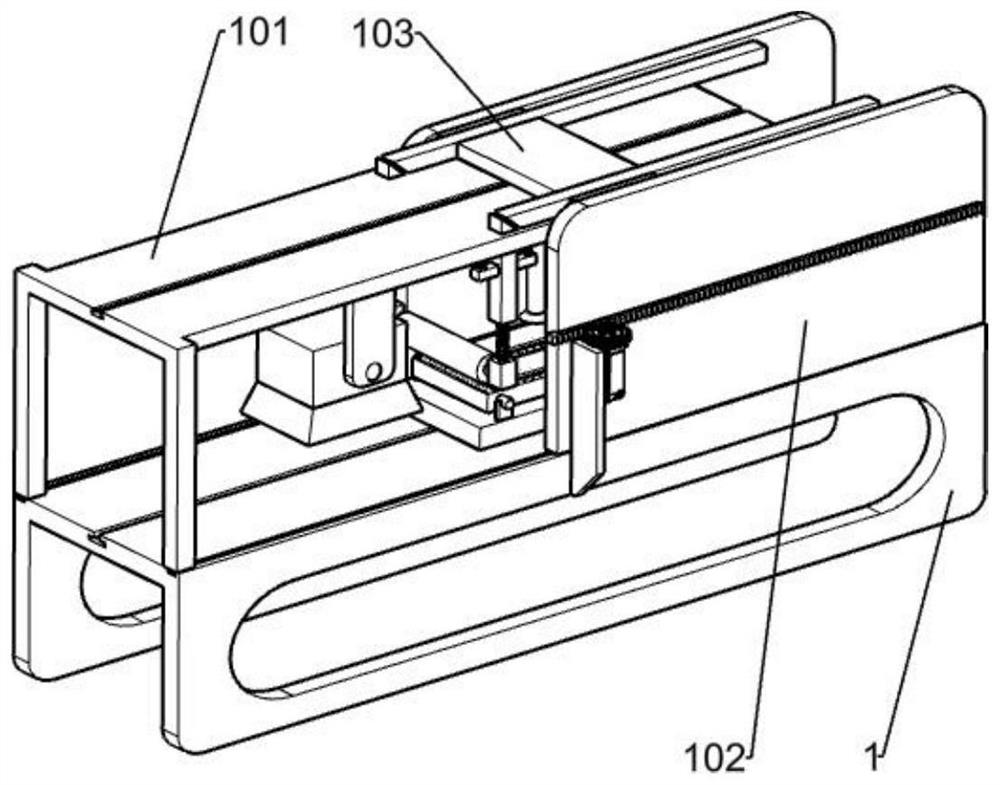

Foldable ironing board for ironing machine

ActiveCN104878581BRealize functionSave storage spaceIroning apparatusTextiles and paperEngineeringBreathing

The invention provides a folding ironing board of an ironing machine and belongs to the technical field of ironing equipment. The folding ironing board of the ironing machine solves the problem that an existing ironing machine cannot be folded or is inconvenient to fold. The folding ironing board of the ironing machine comprises a main body part and a folding part, wherein each of the main body part and the folding part comprises a main body inner cavity and a folding inner cavity; the folding part is hinged to the main body part, a folding yield notch is formed in one side in the hinge direction; a supporting structure for maintaining the unfolding state of the folding part as well as a sealing structure for covering the folding yield notch when the folding part is unfolded is arranged between the folding part and the main body part. The ironing board can be folded through simple operation, and the storage space is reduced. When the ironing board is unfolded, side parts and the bottom of the whole cavity of the ironing board are well sealed, air and most of steam go in and out via ventilation holes in a work surface when a fan blows and sucks air, and the ironing effect is guaranteed.

Owner:ZHEJIANG SONGYANG ELECTRIC

Garment ironing device

PendingCN111270501AIncrease temperatureGuaranteed temperatureIroning machinesIroning apparatusEngineeringMechanical engineering

Owner:安徽豹子头服饰股份有限公司

Control method of garment steamer and garment steamer

ActiveCN109914083BImprove ironing efficiencyLow costIroning apparatusTextiles and paperControl engineeringMechanical engineering

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

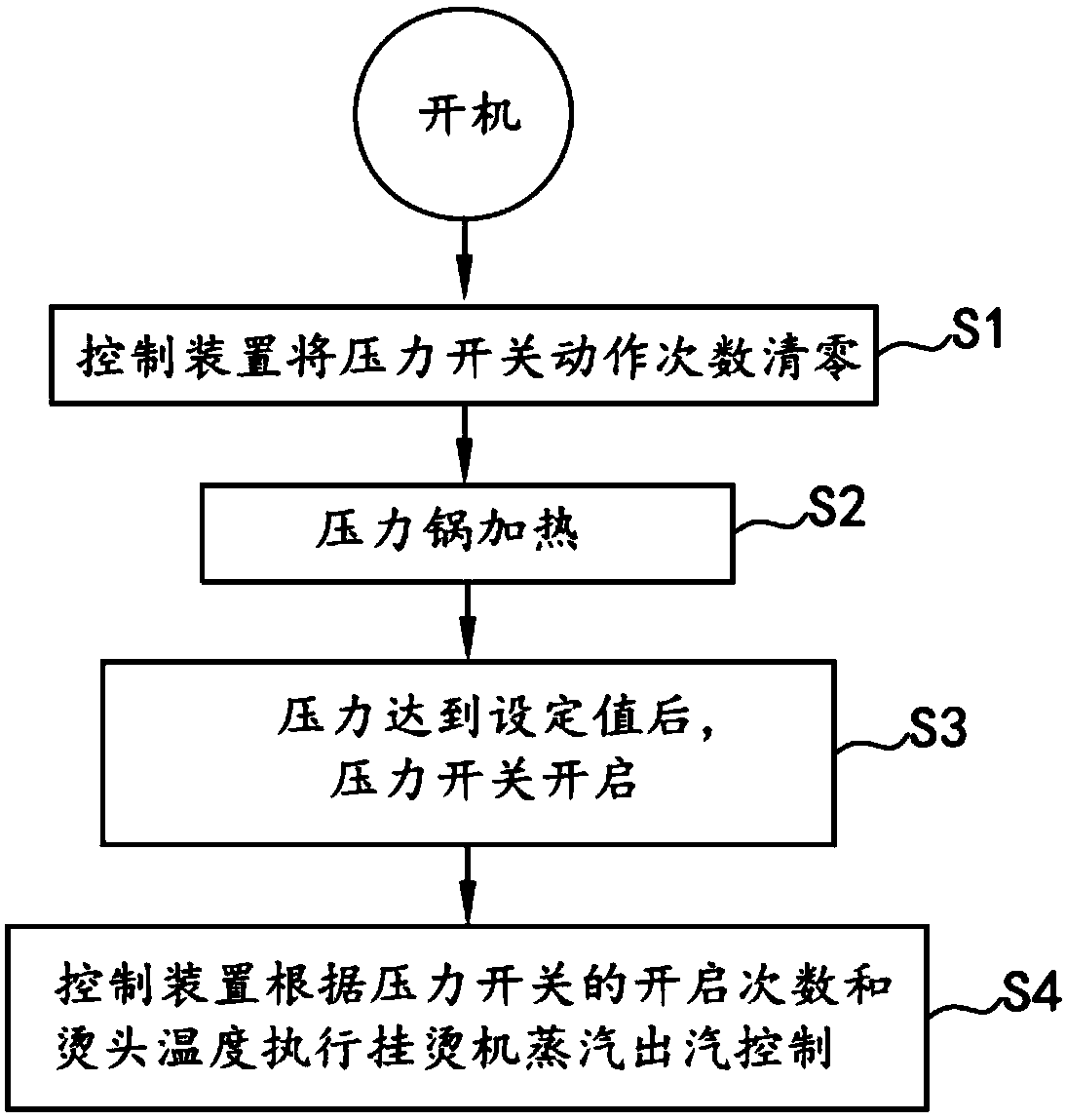

Steam control method of a garment steamer and the garment steamer

ActiveCN107237112BAvoid continuityImprove reliabilityIroning apparatusTextiles and paperControl theoryStart up

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Textile cloth ironing and winding device

PendingCN114261813AGuaranteed ironing effectReduce ironing temperatureTextile shapingWebs handlingProcess engineeringMechanical engineering

The invention discloses a textile cloth ironing and winding device which comprises an ironing platform, a high-temperature ironing mechanism, a waste heat recovery mechanism and a low-temperature ironing mechanism, a winding roller used for winding ironed textile cloth is rotationally arranged at the tail end of the ironing platform, the high-temperature ironing mechanism is installed on the ironing platform, and the waste heat recovery mechanism is installed on the winding roller. The waste heat recovery mechanism is arranged behind the high-temperature ironing mechanism and located on a textile cloth conveying line, the low-temperature ironing mechanism is arranged in front of the rear ironing mechanism and located on the textile cloth conveying line, and the low-temperature ironing mechanism is connected with the waste heat recovery mechanism through a heat transfer pipeline. Through cooperation of the low-temperature ironing mechanism and the high-temperature ironing mechanism, the ironing effect is guaranteed, meanwhile, the ironing temperature of single-time ironing is reduced, the ironing process is softer, and the waste heat recovery mechanism is beneficial to reducing energy consumption.

Owner:南通冠恒纺织有限公司

A cutting machine for cloth processing with ironing function

The invention discloses a cutting machine used for cloth processing and having an ironing function, which comprises a support base, two support plates are symmetrically fixed on both sides of the support base, a workbench is installed between the two support plates, and the workbench A cutting mechanism is arranged above the two support plates, a first fixed rod is fixed between the two support plates, a strip-shaped through groove is opened at the bottom of the first fixed rod, and a first cylinder is arranged in the strip-shaped through groove, and the first cylinder's A heating plate is installed at the bottom. In the present invention, the surface of the heating plate is small, which avoids the waste of energy and saves electricity; by setting the second cylinder to control the clamping of the pressing roller and the driving roller to the cloth, it is ensured that the cloth will not be rolled up, ensuring Ironing effect; the cutting machine cuts accurately, conveniently and quickly. By controlling the pressure of the pressing plate on the fabric, wrinkles are avoided and the cutting effect is guaranteed. The cutting machine irons the fabric before cutting, so that The fabric is flatter and the cutting effect is improved.

Owner:安徽东锦高科新材料有限公司

A kind of energy-saving ironing equipment

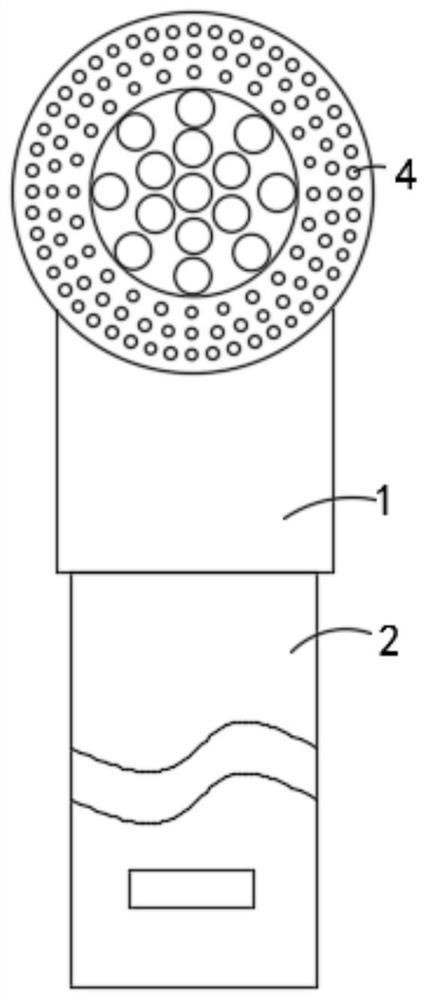

ActiveCN109235000BReduce churnGood energy saving effectIroning apparatusTextiles and paperCoil springEngineering

The invention belongs to the technical field of ironing equipment, and particularly relates to energy-saving ironing equipment. The equipment includes a nozzle, an air inlet passage is formed in the nozzle, the nozzle is provided with an air inlet pipe communicated with the air inlet channel, the side wall of the air jet end of the nozzle is internally provided with an annular first chamber, the side wall of the first chamber is densely provided with several air suction holes, the side wall of the end, near the air inlet passage, of the nozzle is internally provided with an annular second chamber, the top surface of the second chamber is provided with a first air guide hole communicated with the first chamber, the air inlet passage is internally provided with an air flow drive mechanism, the drive end of the drive mechanism is fixedly connected with a coil spring, the inner end socket of the coil spring is fixedly connected with the drive end of the drive mechanism, and the inner wallof the air inlet passage is provided with an annular connection hole communicated with the second chamber. The equipment has the advantages that energy saving performance of the ironing equipment canbe improved, and the ironing effect of clothes can be improved.

Owner:嘉兴晟源工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com