A kind of energy-saving ironing equipment

A technology for ironing equipment and nozzles, which is applied to wrinkle and flattening equipment, finishing utensils, textiles and papermaking, etc., can solve problems such as clothing fit, low energy saving, energy waste, etc., to reduce heat loss, The effect of improving energy saving and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

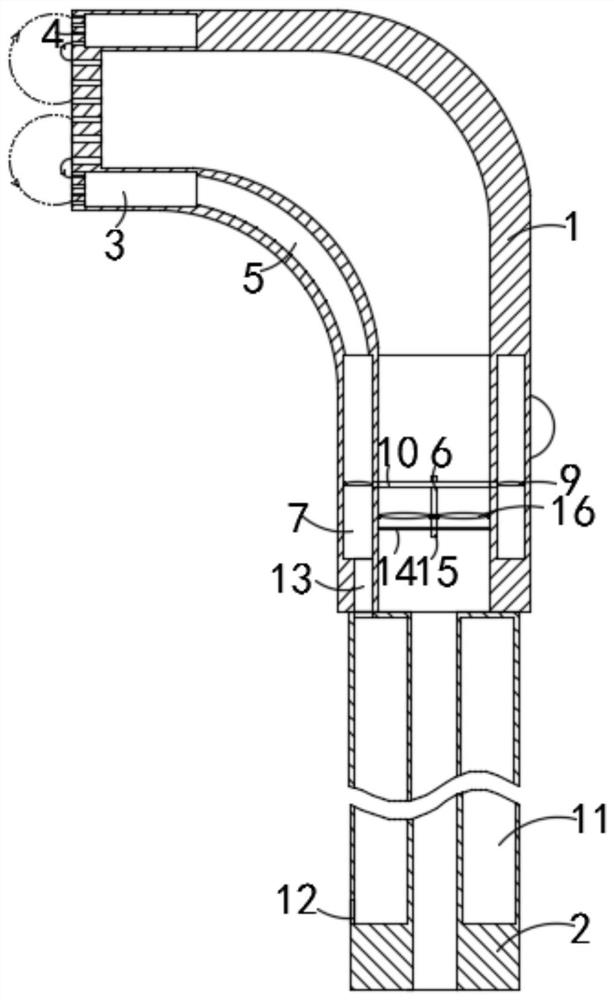

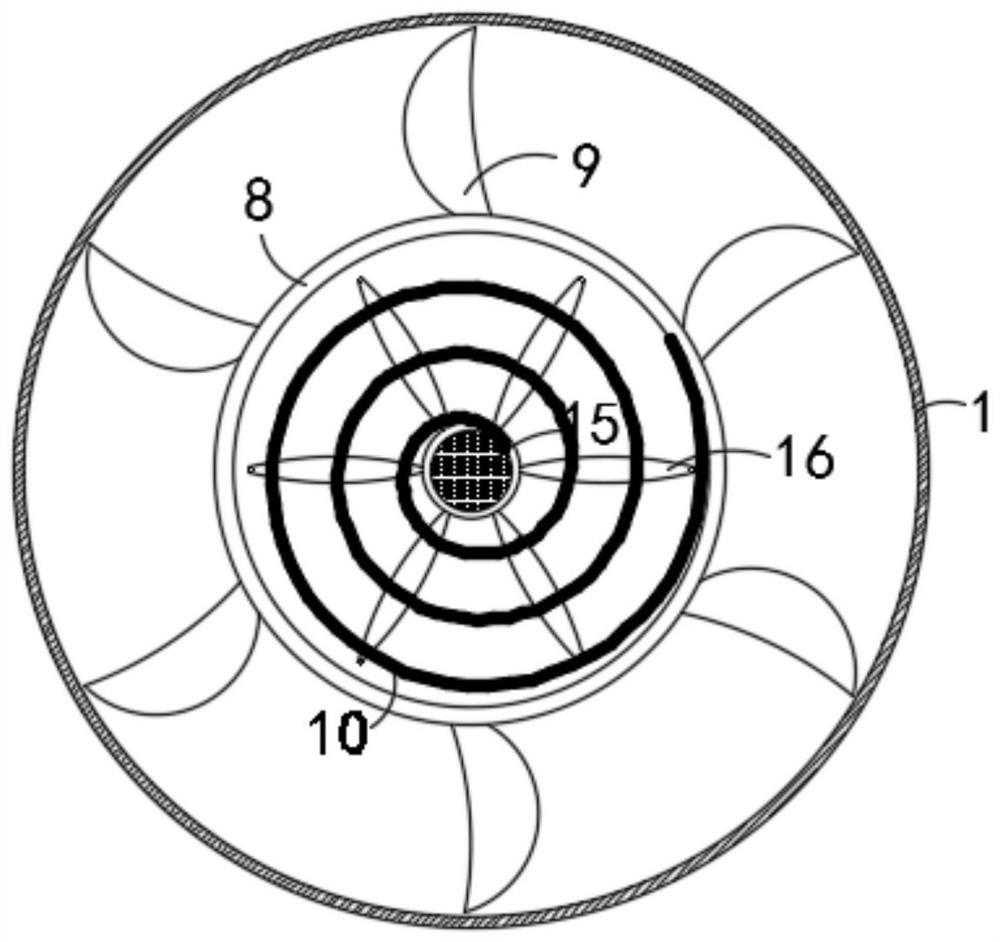

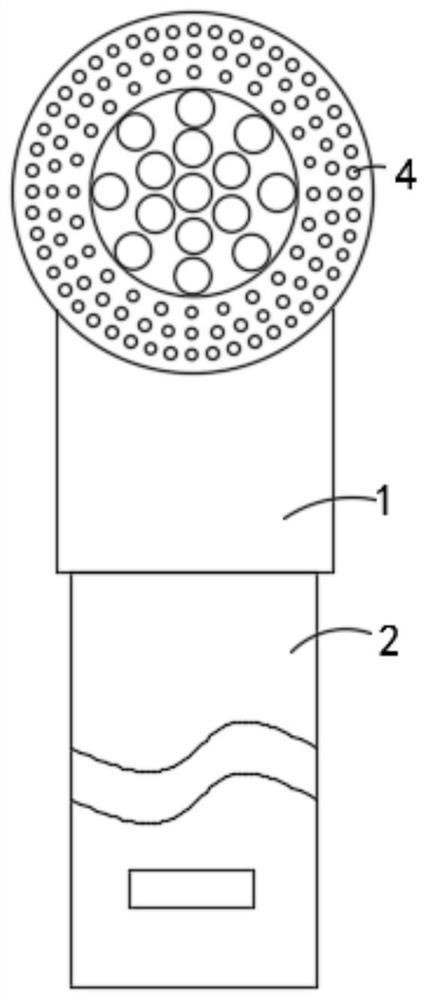

[0018] Such as Figure 1-3 As shown, an energy-saving ironing device includes a nozzle 1, an air inlet passage is arranged inside the nozzle 1, an air inlet pipe 2 connected with the inlet passage is arranged on the nozzle 1, and an air inlet pipe 2 is arranged on the side wall of the nozzle end of the nozzle 1 An annular first chamber 3, the side wall of the first chamber 3 is densely covered with a plurality of suction holes 4, wherein the plurality of suction holes 4 absorb the discharged steam, and then can absorb the clothes, so that the spray head 1. It can fit more closely with the clothes. There is an annular second chamber 7 in the side wall of the nozzle 1 near the end of the air intake passage. The top surface of the second chamber 7 is provided with the first chamber 3. The first air guide hole 5, the air intake passage is provided with a driving mechanism 6, the driving end of the driving mechanism 6 is fixedly connected with a coil spring 10, the inner end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com