Processing method of light and luxury sea island cotton sweater

A processing method and sea island technology, applied in the field of garment processing, can solve the problems of insufficient flatness of fabrics, increased labor costs, waste water discharge, etc., and achieve the effects of good deformation resistance, avoiding scalding, and better wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

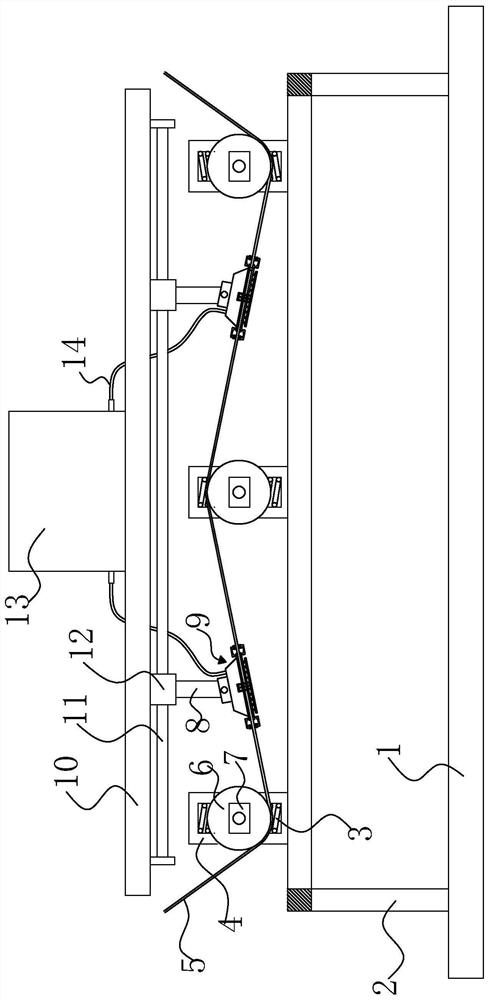

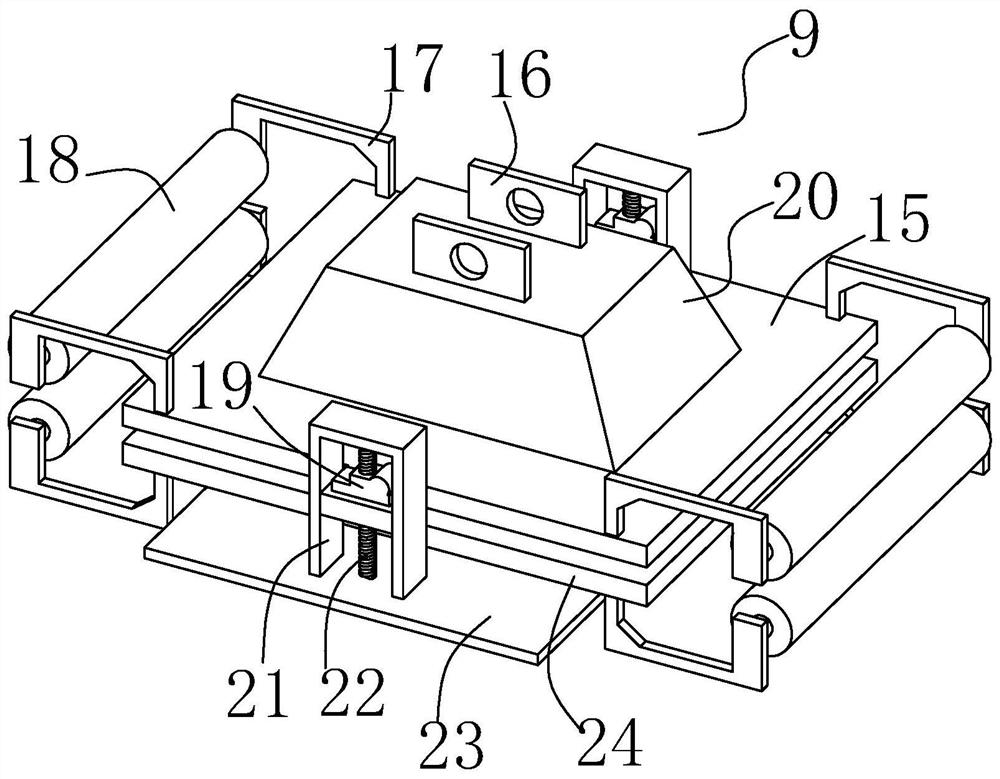

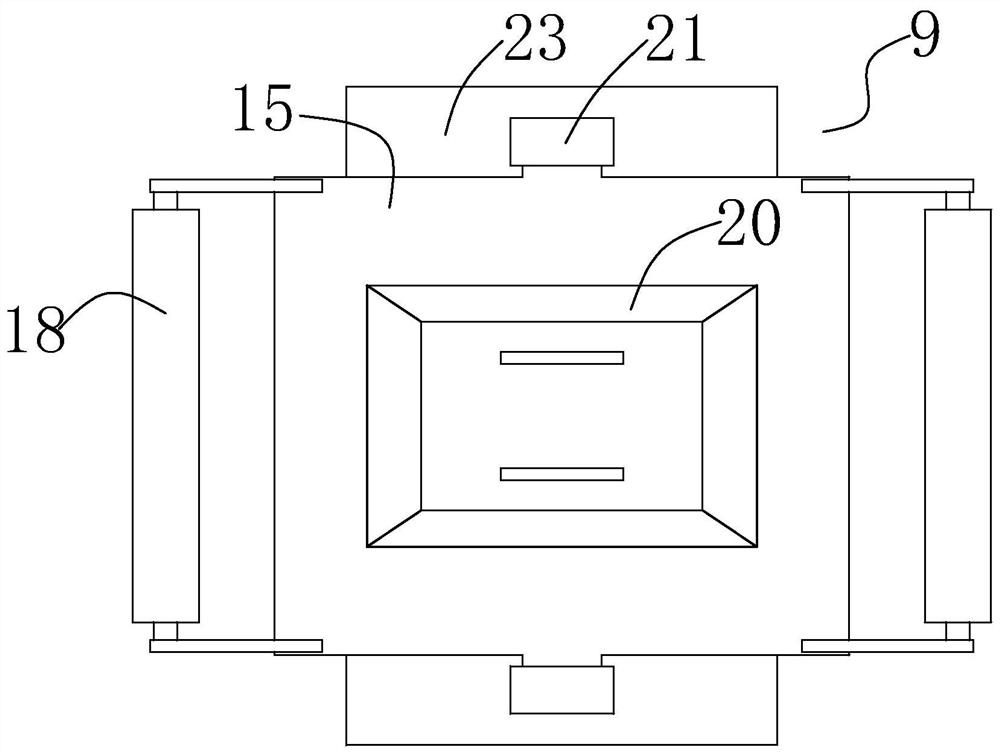

[0029] The embodiment of the present invention discloses a processing method of a light luxury sea-island cotton sweater. The sweater processing method mainly includes a fabric manufacturing process and a garment manufacturing process. The fabric production process includes the knitting step of feeding two strands of yarn alternately into a large circular knitting machine for knitting to form a knitted fabric; the fabric obtained in the knitting step is tensioned step by step through a leveling mechanism and steam ironed The leveling step of making the surface of the fabric smooth, the dyeing step of printing and dyeing the leveled fabric through the dyeing machine 26 and making fabrics with various colors.

[0030] In the knitting step, two kinds of yarns are alternately fed into the knitting machine for interweaving to form fabrics, wherein the two kinds of yarns can be yarns of the same material or yarns of different materials. , in order to obtain better performance of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com