Heat exchanger

A technology of plate heat exchangers and partition plates, which is applied in the direction of heat exchanger fixation, heat exchange equipment, indirect heat exchangers, etc., can solve problems such as sealing, and achieve the effect of high sealing and mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

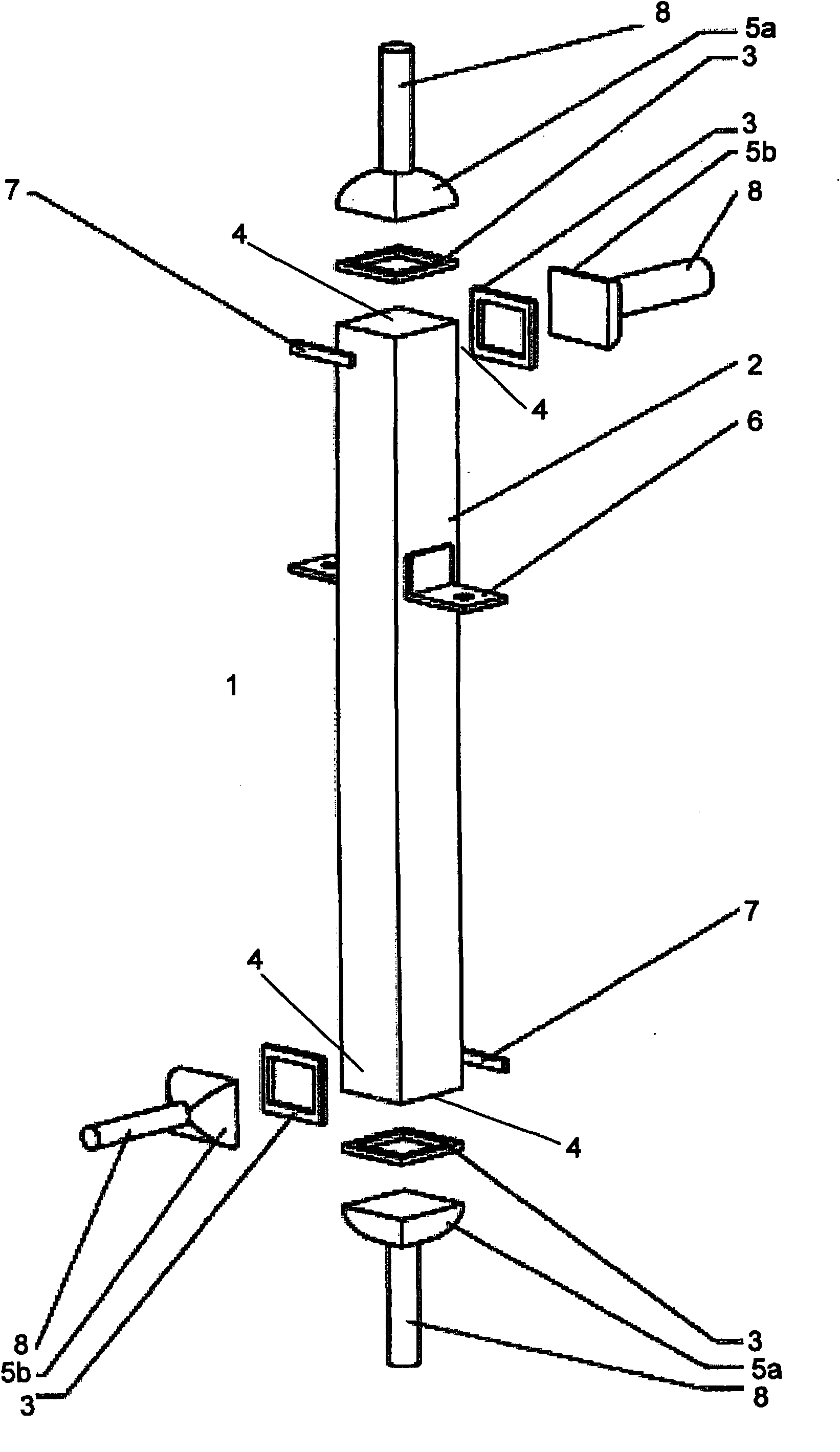

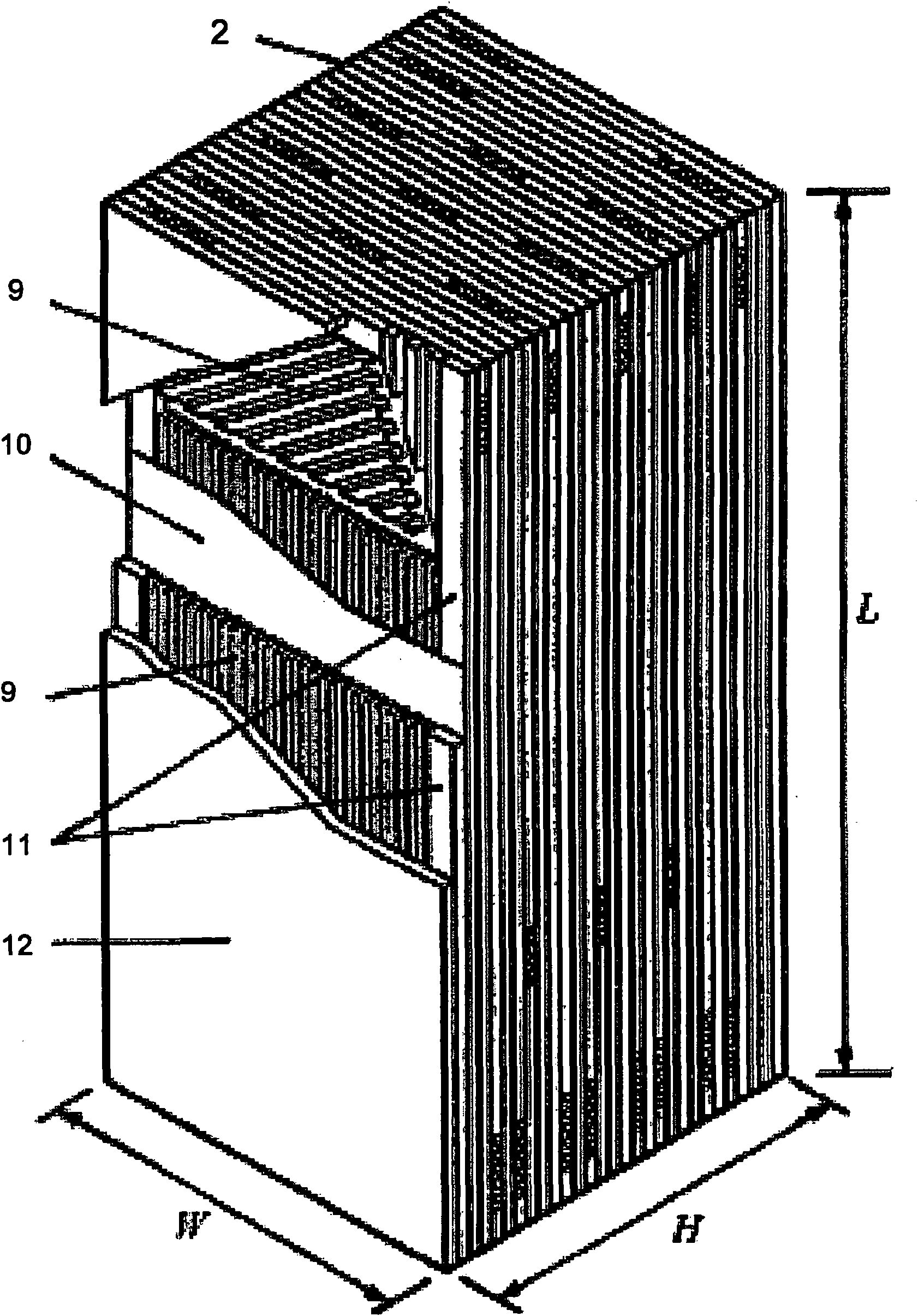

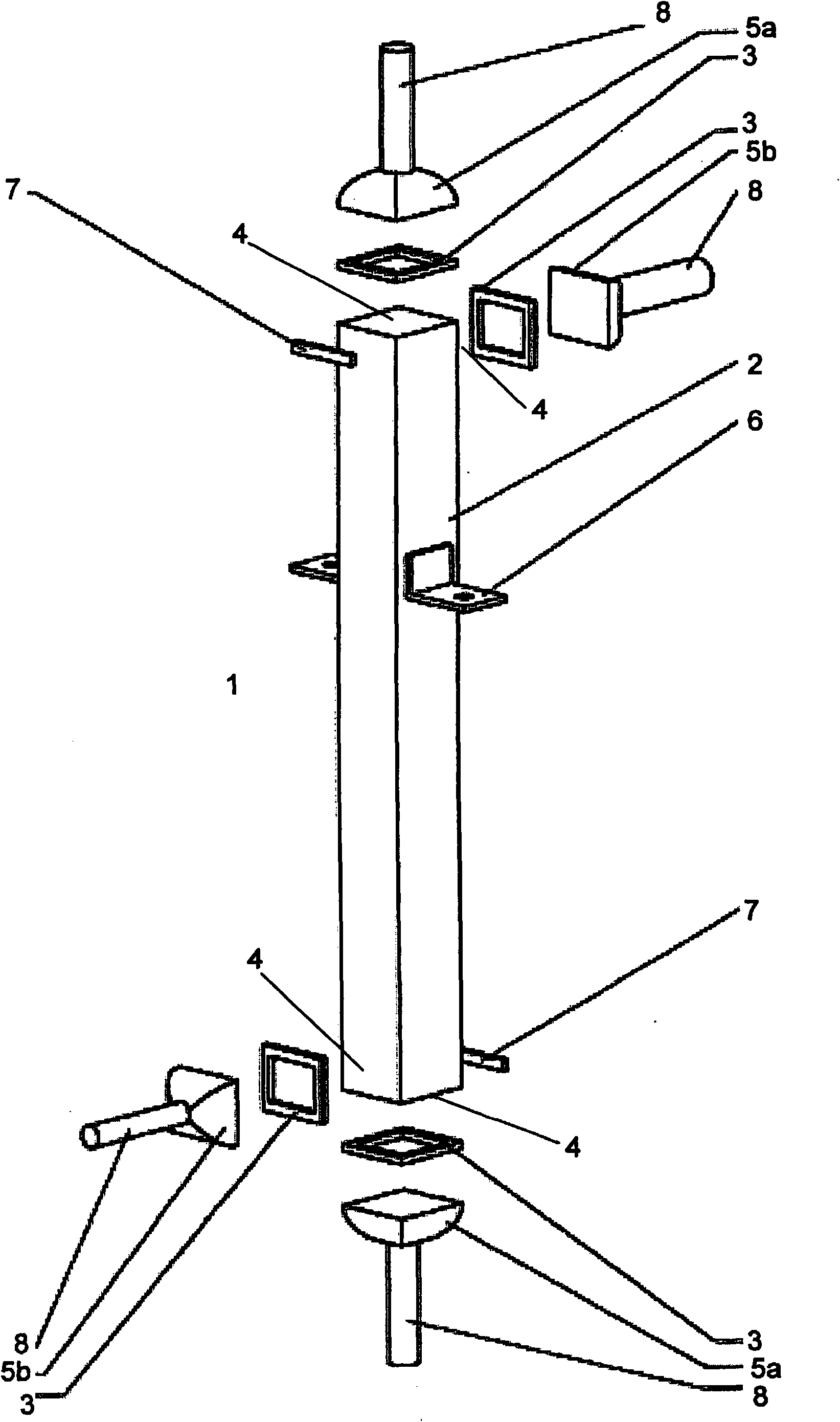

[0026] figure 1 A plate heat exchanger 1 constructed according to the method according to the invention is shown. According to this embodiment of the invention, the at least partially corrugated plates 9 and separating plates 10 with side bars 11 are stacked one above the other, provided with solder and soldered in such a way that a unit 2 is produced. The unit is closed to the outside by a cover plate 12 . On the unit 2 produced in this way, the contour of the intermediate part 3 is milled out at corresponding locations 4 . In this embodiment of the invention a frame is used as intermediate part 3 . The frame 3 is positioned in a milling out at the location 4 , provided with solder and attached by means of spot welding. The frame 3 is then soldered to the heat exchanger unit 2 in a second step. Headers 5a and 5b are welded to the frame 3, respectively. The heat exchanger 1 thus produced serves to exchange heat between two different fluids which are fed in and out via hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com