Defect marking method and device for cloth inspecting machine

A technology of a marking device and a marking method, which is applied in the fields of marking textile materials, inspection of textile materials, textiles and papermaking, etc., and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

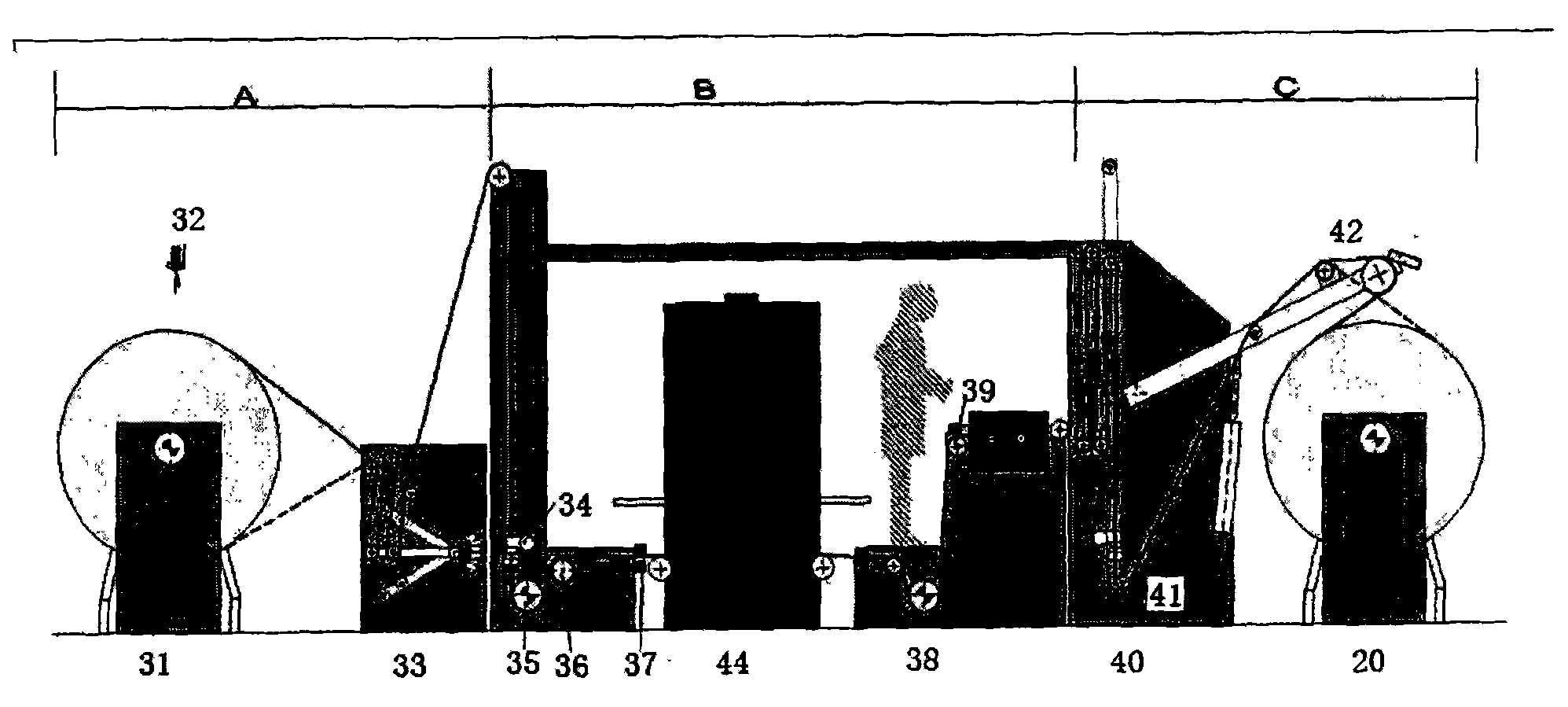

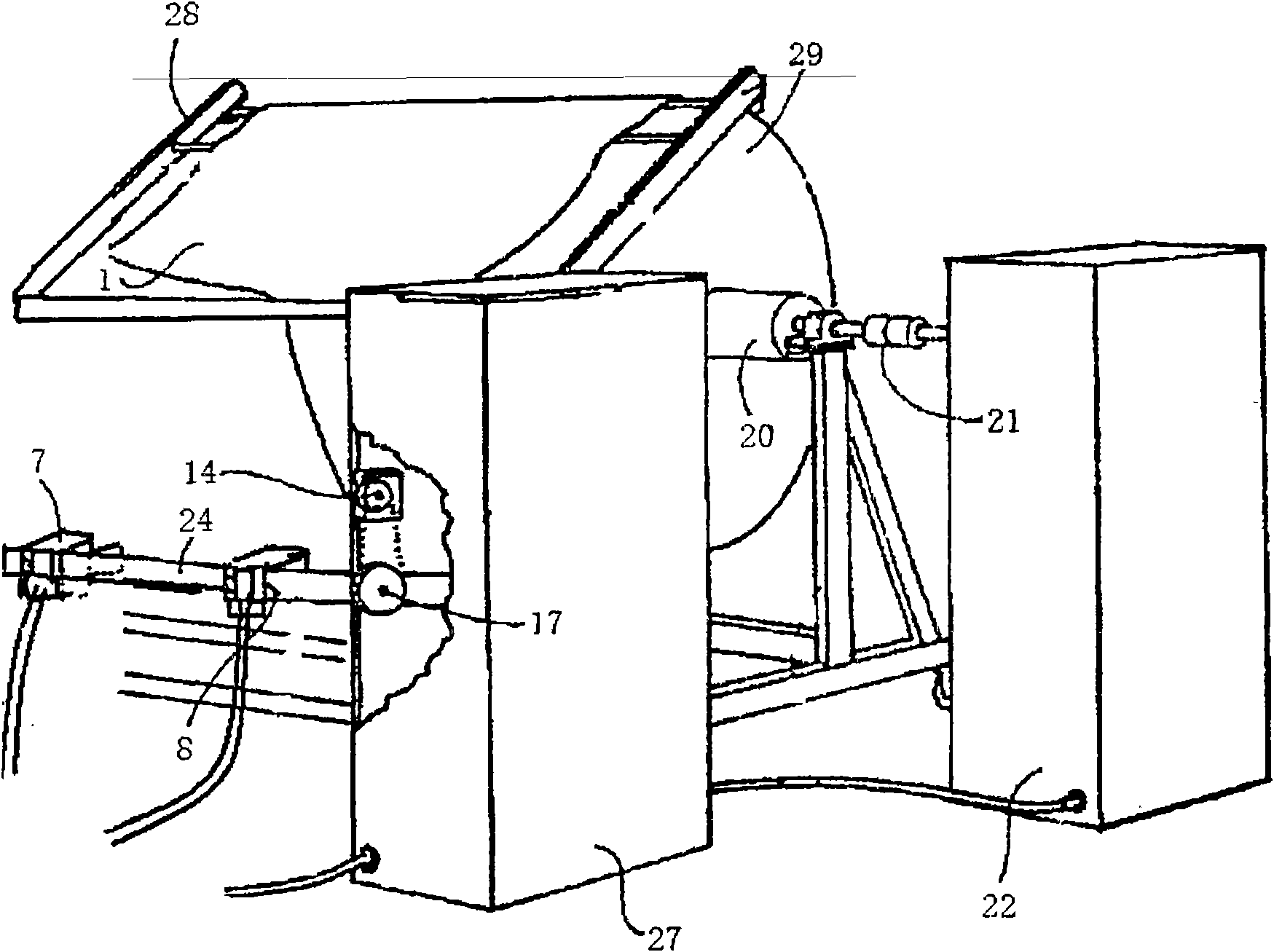

[0021] Such as figure 2 , 3 As shown, the cloth inspection machine defect marking device of the present invention includes a frame 28, a cloth transmission system for sending the inspected cloth 1 into the frame 28 for defect marking, an automatic marking system for marking cloth defects, A cloth winding system that winds the marked cloth and controls the cloth to wind at a constant speed.

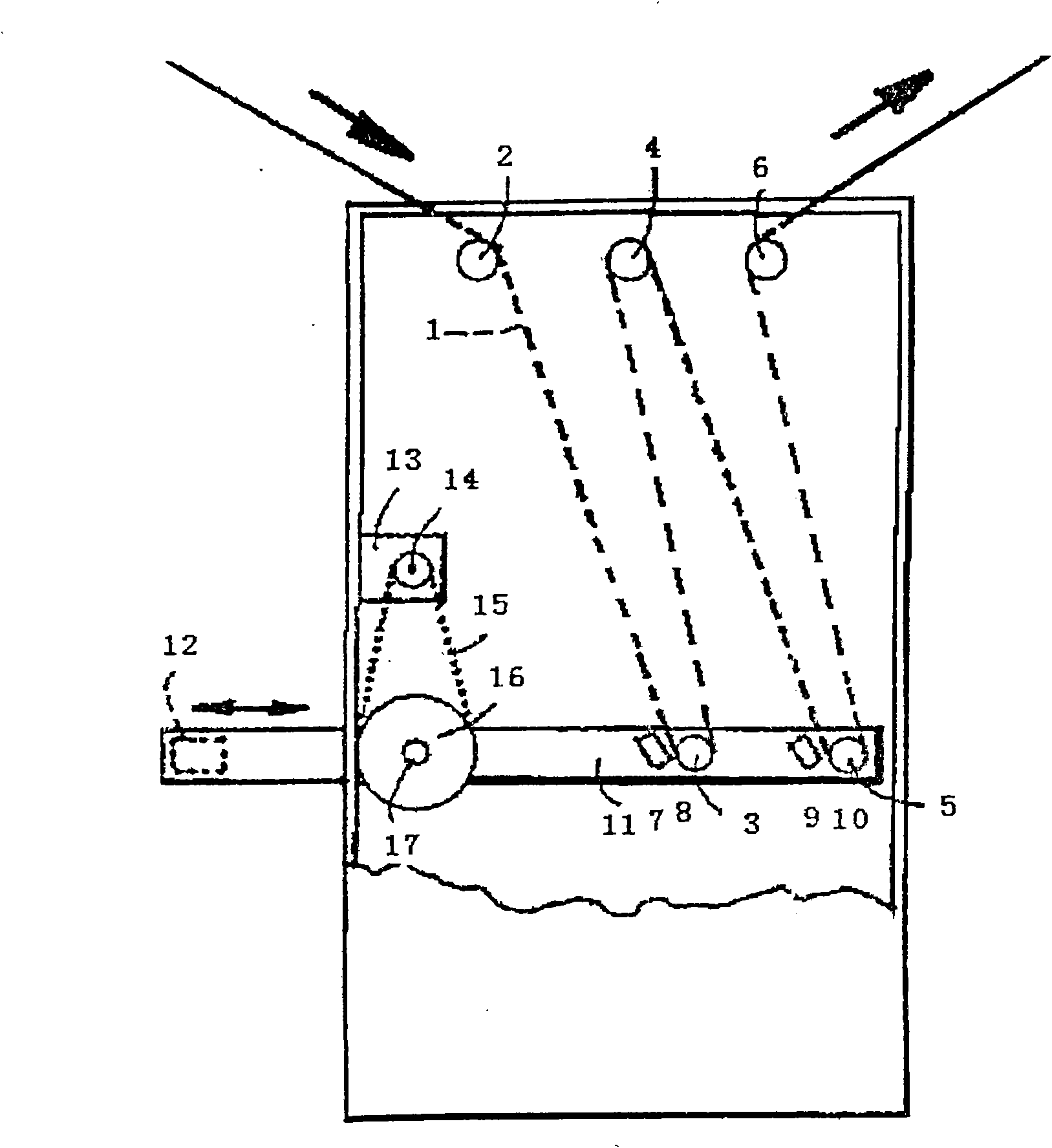

[0022] The cloth transmission system includes two pairs of crossbeams up and down on the frame, each pair of crossbeams is provided with rollers for transmitting cloth, the upper pair of crossbeams is provided with rollers 2 and 4, and the lower pair of crossbeams 11 is provided with rollers 3, Cloth 1 enters the defect marking device of the cloth inspecting machine along the direction indicated by the arrow, passes through rollers 2, 3, and 4 and finally leaves the defect marking device of the cloth inspecting machine of the present invention along the direction indicated by the arrow. ...

Embodiment 2

[0031] Such as image 3 As shown, the difference from Embodiment 1 is that the cloth transmission system includes two pairs of crossbeams arranged on the frame, each pair of crossbeams is provided with rollers for transmitting cloth, and the upper pair of crossbeams is provided with rollers 2, 4, 6, the lower crossbeam 11 is provided with rollers 3, 5, and the cloth 1 enters the defect marking device of the cloth inspection machine along the direction indicated by the arrow, and finally leaves the inspection machine of the present invention along the direction indicated by the arrow after passing through rollers 2, 3, 4, 5, and 6. Machine defect marking device.

[0032] Described automatic marking system comprises being fixed on the fixed beam 24 near the roller 3 on the cross beam 11 and the fixed beam near the roller 5; The inkjet heads 9, 10 located at the edge of the cloth on the fixed beam near the roller 5, the inkjet heads 7, 8, 9, 10 are connected with the main machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com