Cutter lubricating device on sanitary towel and diaper production lines

A technology of lubricating device and diapers, which is applied in the direction of engine lubrication, metal processing, engine components, etc., can solve problems such as tool friction damage, lubricant dripping products, product quality problems, etc., to achieve energy saving, good lubrication effect, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

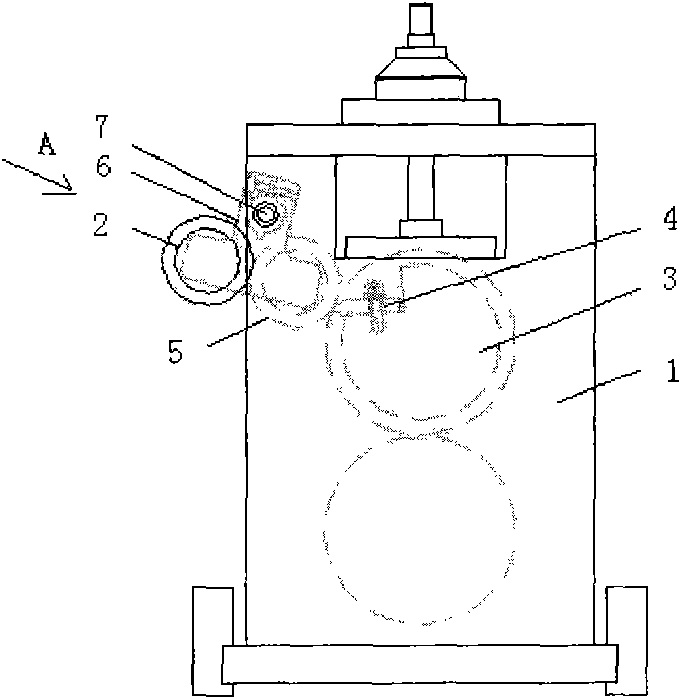

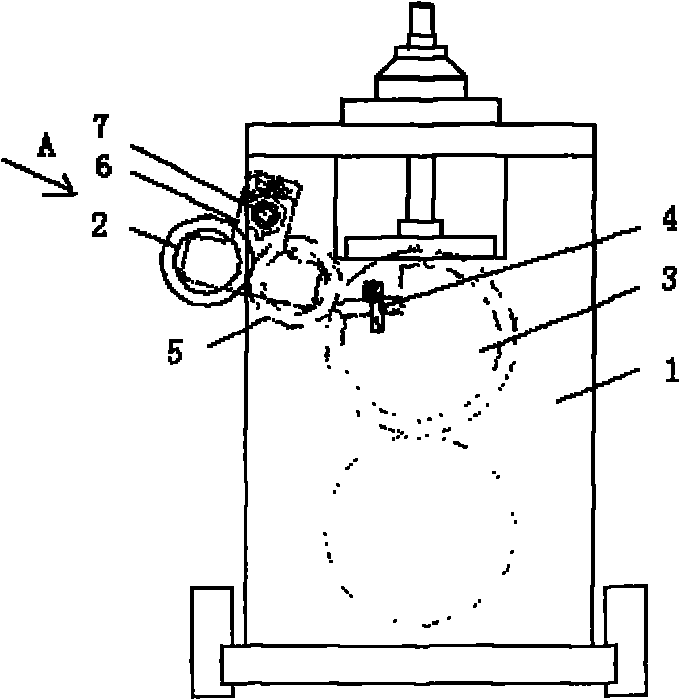

[0015] Such as figure 1 As shown, the cutter lubricating device on the production line of sanitary napkins and diapers includes a lubricating oil carrying wheel 2 arranged in a cutting box 1, a cutter roller 3 and its cutter 4.

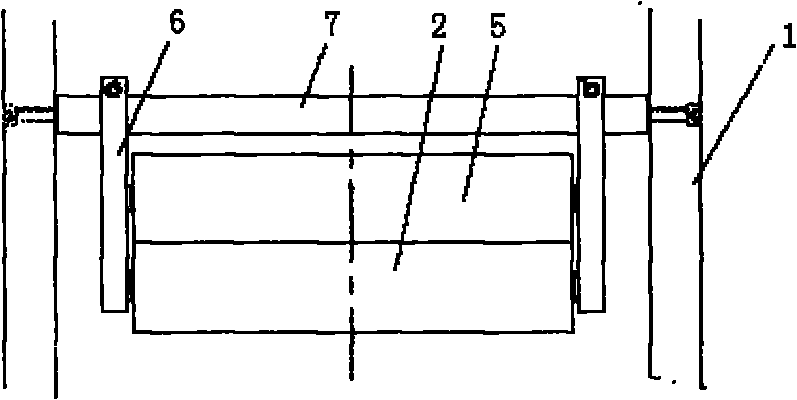

[0016] Such as figure 1 , 2 As shown, a friction lubricating wheel 5 is provided between the lubricating oil carrying wheel 2 and the cutter roller 3 . The lubricating oil carrying wheel 2 and the friction lubricating wheel 5 are movably connected to the mounting part 6 through the wheel shaft, and the mounting part 6 is fixedly connected to the cutting box 1 through the connecting part 7 . still as figure 1 As shown, the wheel peripheral surface of the friction lubricating wheel is in contact with the wheel peripheral surface of the lubricating oil carrying wheel, and is in contact with the cutter blade at the same time.

[0017] In this embodiment, the friction lubricating wheel 5 is made of silica gel. Lubricating oil carries wheel 2 and adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com