Operating mechanism for molded case circuit breaker

A technology of molded case circuit breaker and operating mechanism, which is applied in the direction of protection switch operation/release mechanism, etc., to achieve the effect of improving service life, reducing manufacturing cost, and accelerating breaking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

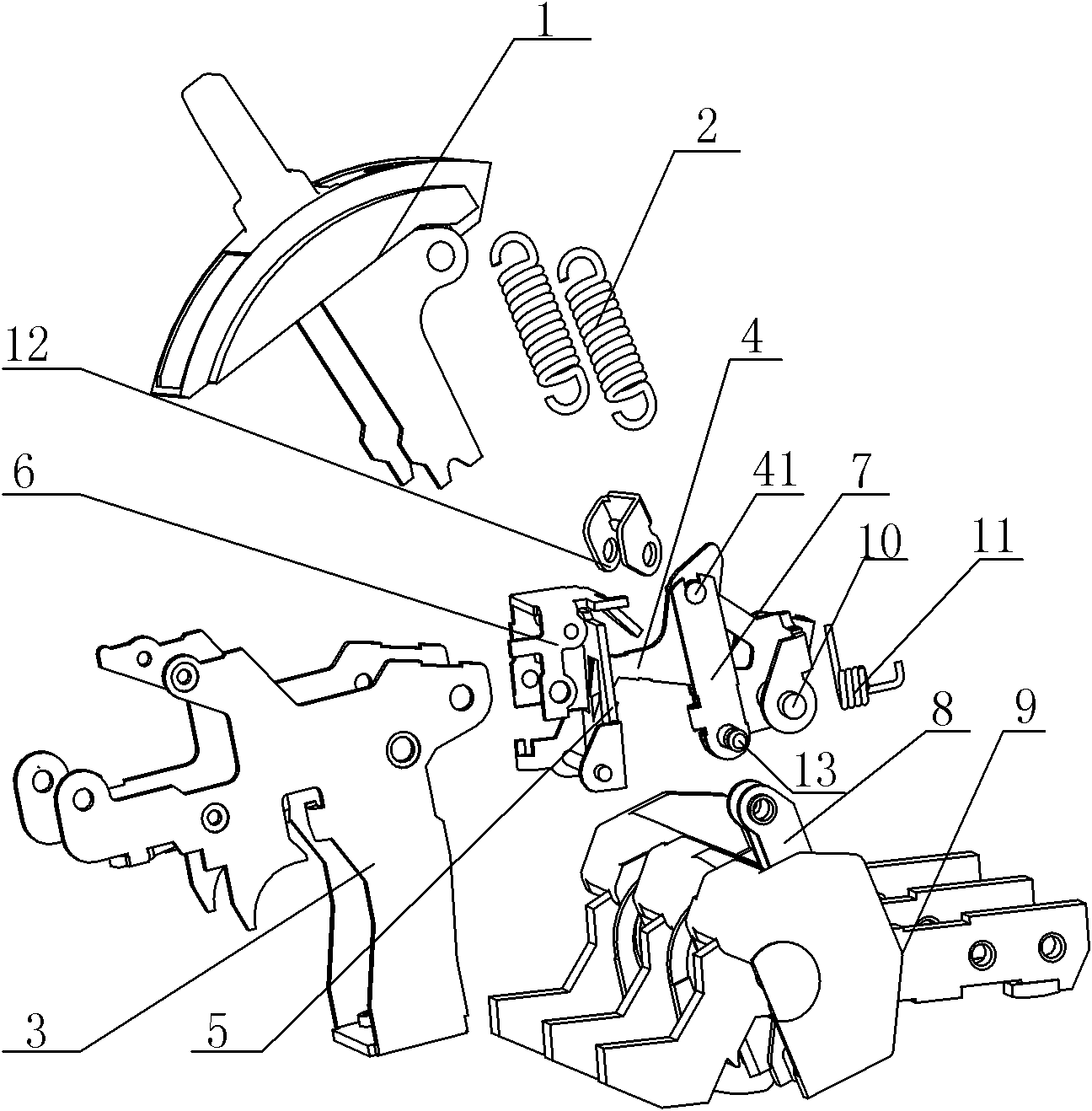

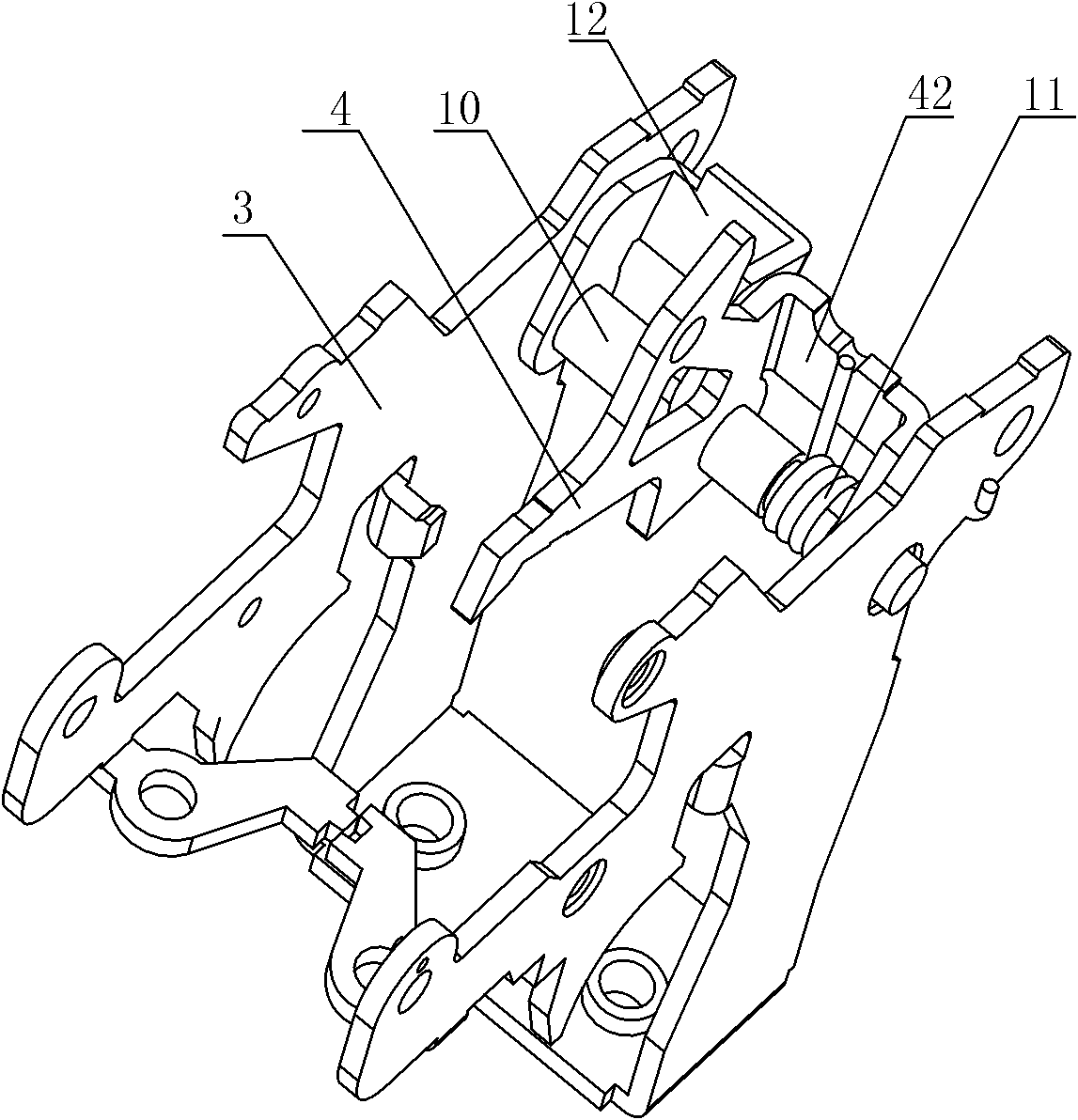

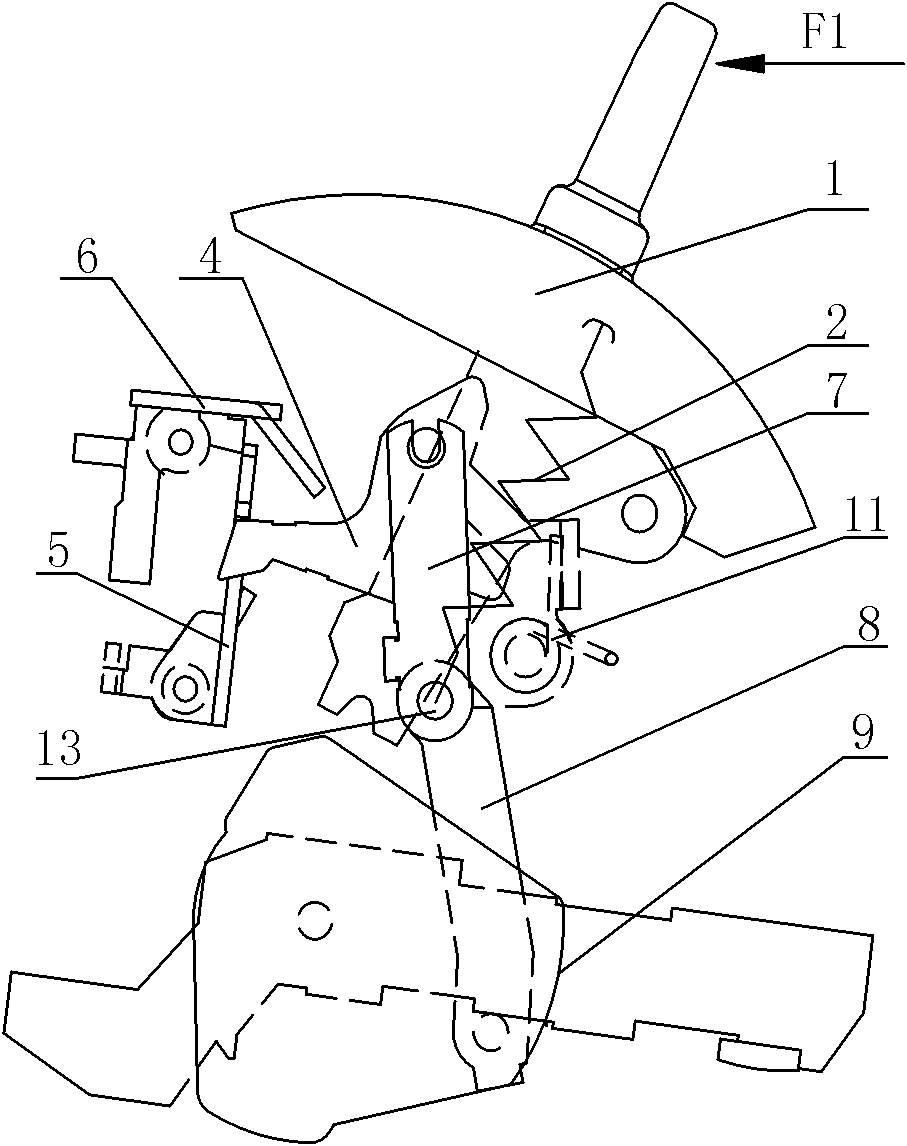

[0021] like figure 1 , figure 2 As shown, the operating mechanism of the molded case circuit breaker includes a handle 1, a main tension spring 2, a bracket 3, a jumper 4, a lock 5, a re-buckle 6, an upper link 7, a lower link 8 and a moving contact system 9, Wherein, the buckle 5 and the buckle 6 are respectively installed between the brackets 3 through a pin shaft. A pin 41 is fixed on the jumper 4, and the upper end of the upper connecting rod 7 is rotatably connected to the pin 41, and the lower end of the upper connecting rod 7 is connected to the upper end of the lower connecting rod 8 by a connecting rod shaft 13. Hinged, the lower end of the lower link 8 is connected with the moving contact system 9. The upper end of the main tension spring 2 is hung on the handle 1, and the lower end of the main tension spring 2 is hung on the connecting rod shaft 13. The operating mechanism has three states during the working process of the circuit breaker: closing state, opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com