Miniature circular shaded pole motor bobbin bracket

A winding frame, circular technology, applied in the field of miniature circular shaded pole motor winding frame, can solve the problems of difficult winding of wires, difficult operation, inaccuracy, etc., and achieves the effect of convenient winding of wires and solving the problem of cross insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

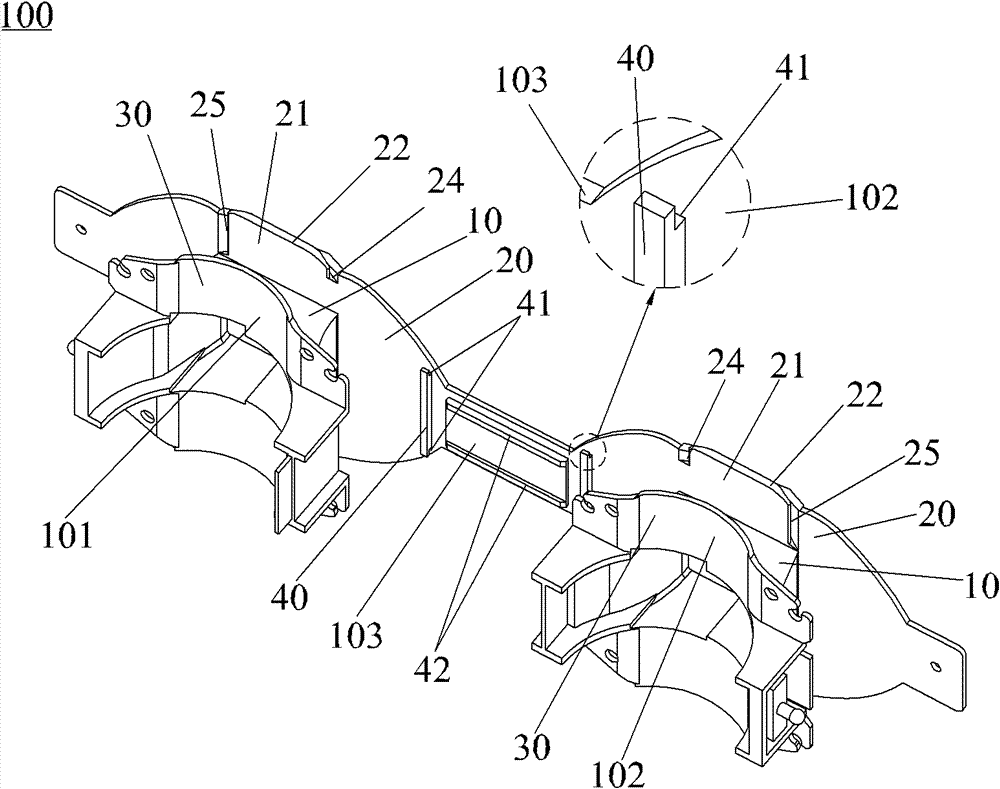

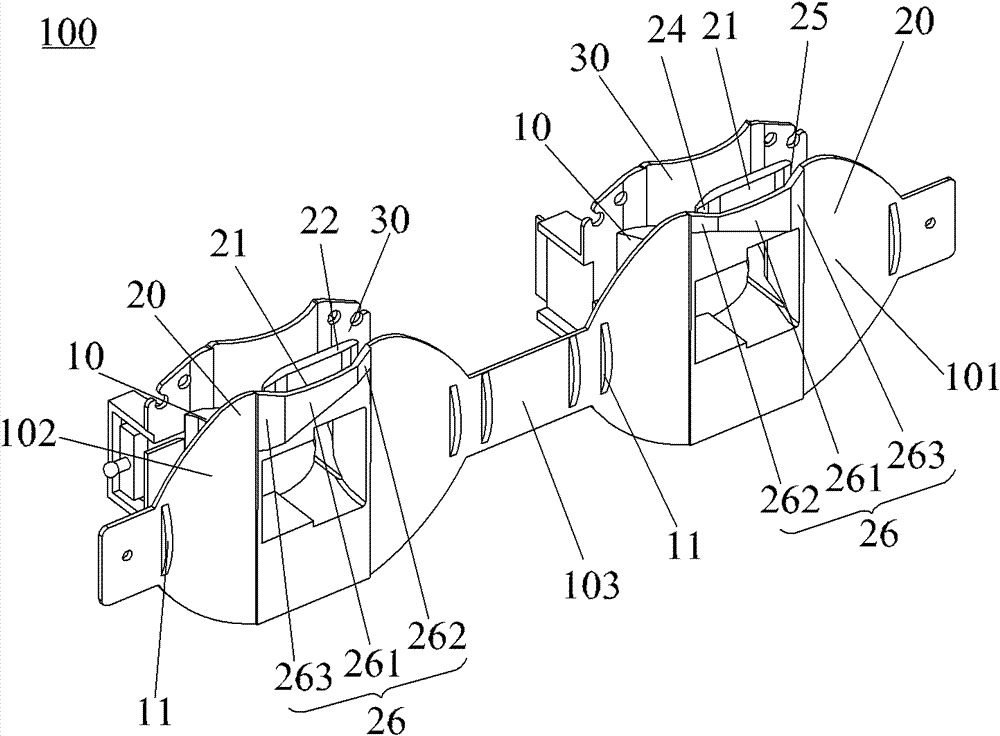

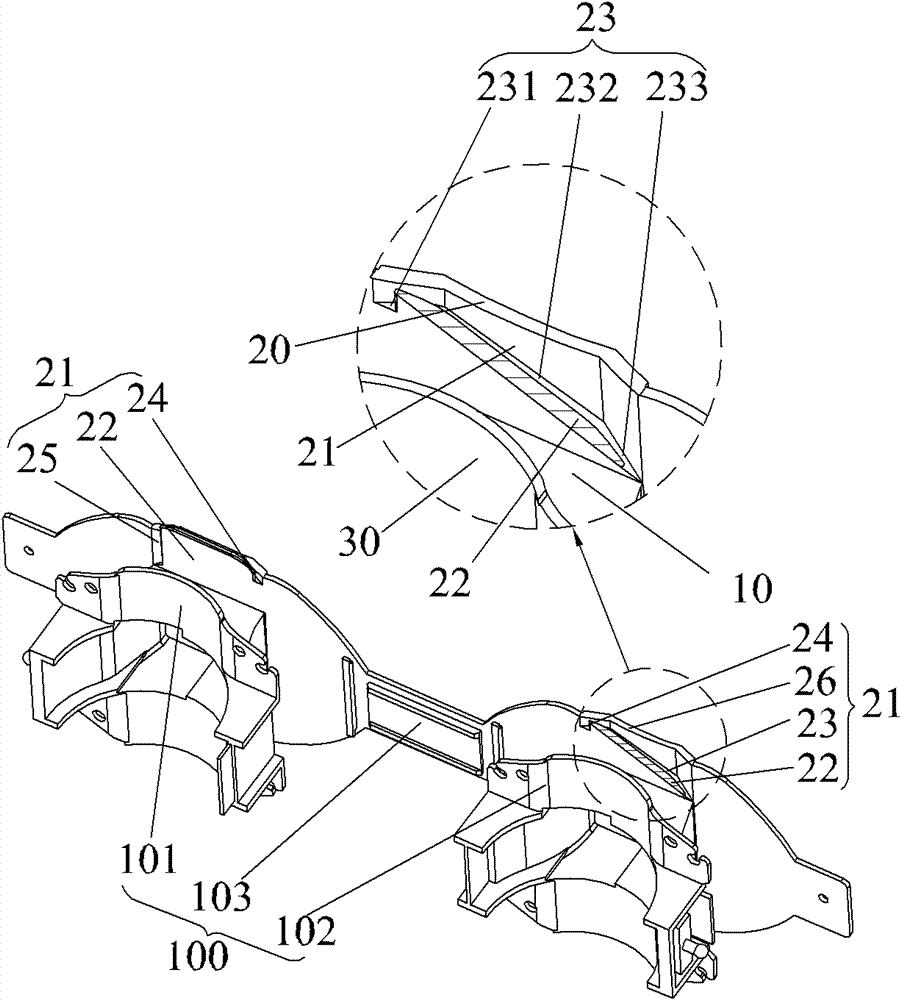

[0019] refer to figure 1 and figure 2 , the miniature round shaded pole motor winding frame 100 of the present invention is made of foldable insulating material such as glue, and is used for winding wires. The miniature round shaded pole motor winding frame 100 includes two winding shafts 101, 102 and connecting Bridge 103, the winding shafts 101, 102 include a shaft cylinder portion 10, an upper flange 20 extending from the upper end of the shaft cylinder portion 10 and a lower flange 30 extending from the lower end of the shaft cylinder portion 10, the connection bridge 103 The two sides are respectively connected with the upper flanges 20 of the two connecting shafts 101, 102, refer to Figure 4 and Figure 5 The two connecting shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com