Pneumatic tire

A technology for pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problem that the improvement effect of drainage performance is not necessarily sufficient, achieve excellent drainage performance, and improve deflection resistance Abrasion resistance, effect of maintaining uneven wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

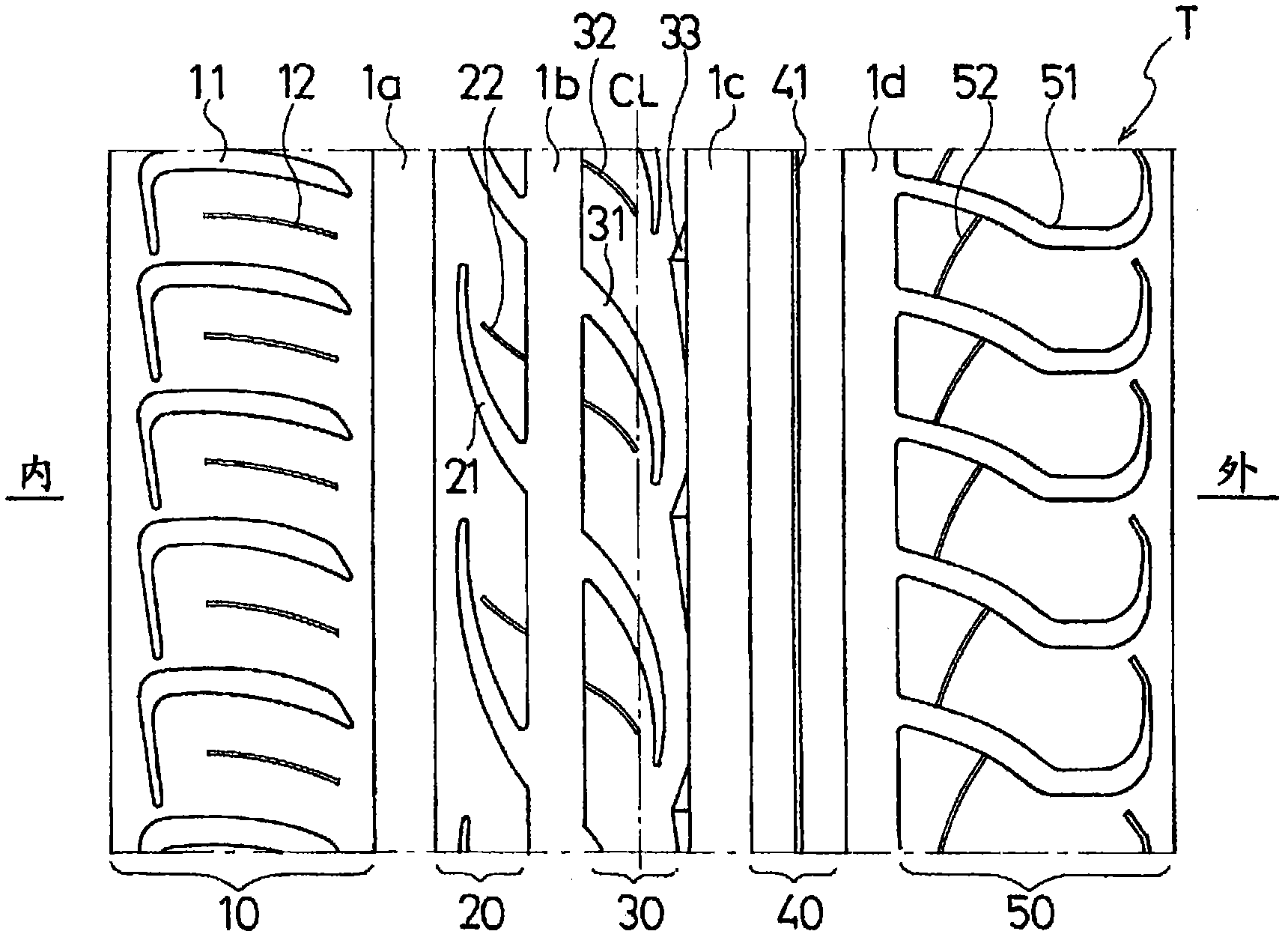

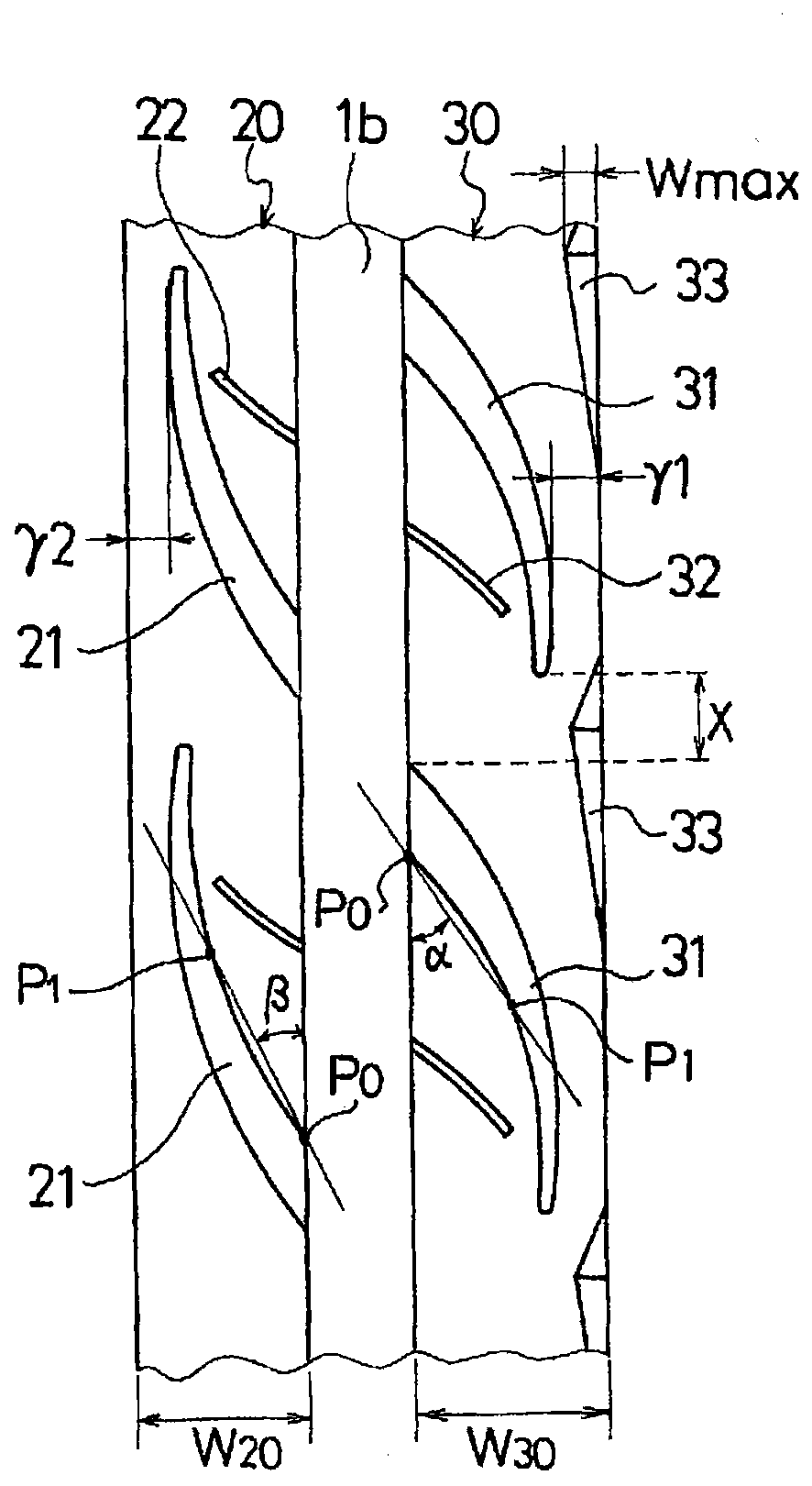

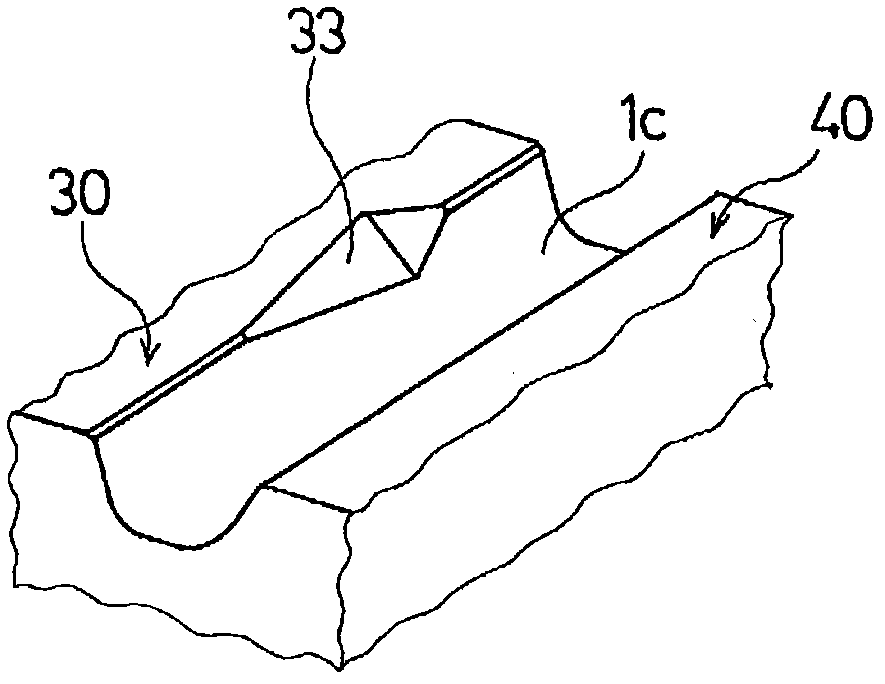

[0089] Tires of Examples 1 to 7 were produced. The tires of Examples 1 to 7 are pneumatic tires with a tire size of 205 / 55R16, designated front and rear assembly directions when mounted on a vehicle, and asymmetric tread patterns on both sides of the tire equator, wherein: figure 1 As shown, four main grooves extending in the tire circumferential direction are provided on the tread portion, five rows of land portions are divided by these main grooves, and a plurality of land portions inclined with respect to the tire circumferential direction are provided on the central land portion located on the tire equator. The first inclined groove is provided with a plurality of second inclined grooves inclined in the same direction as the first inclined groove on the inner middle land portion located on the vehicle inner side of the central land portion, so that one end of each first inclined groove is located on the central land portion. Open the main groove between the inner middle la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com