Stud type ice cream rod inserting machine

An ice cream and stick inserter technology, which is applied in the fields of frozen desserts, food science, and applications, can solve problems such as reduced production efficiency, broken sticks, and inaccurate insertion, and saves time, improves work efficiency, and saves energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings and embodiments.

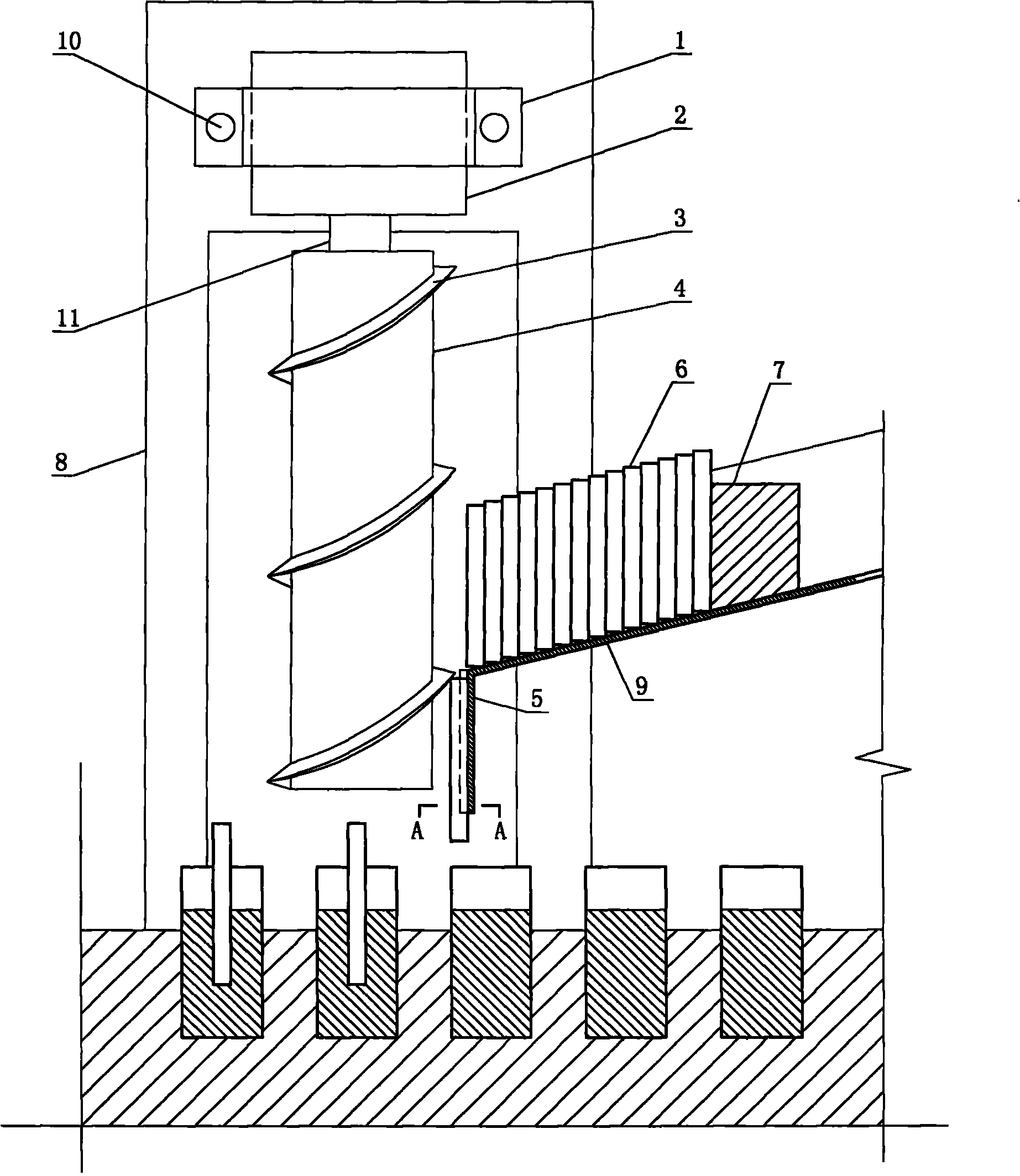

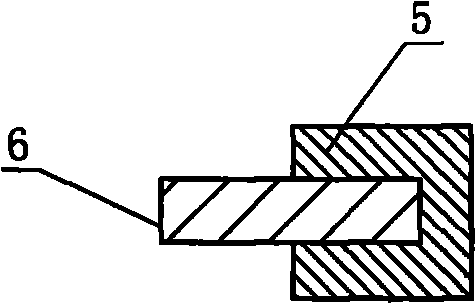

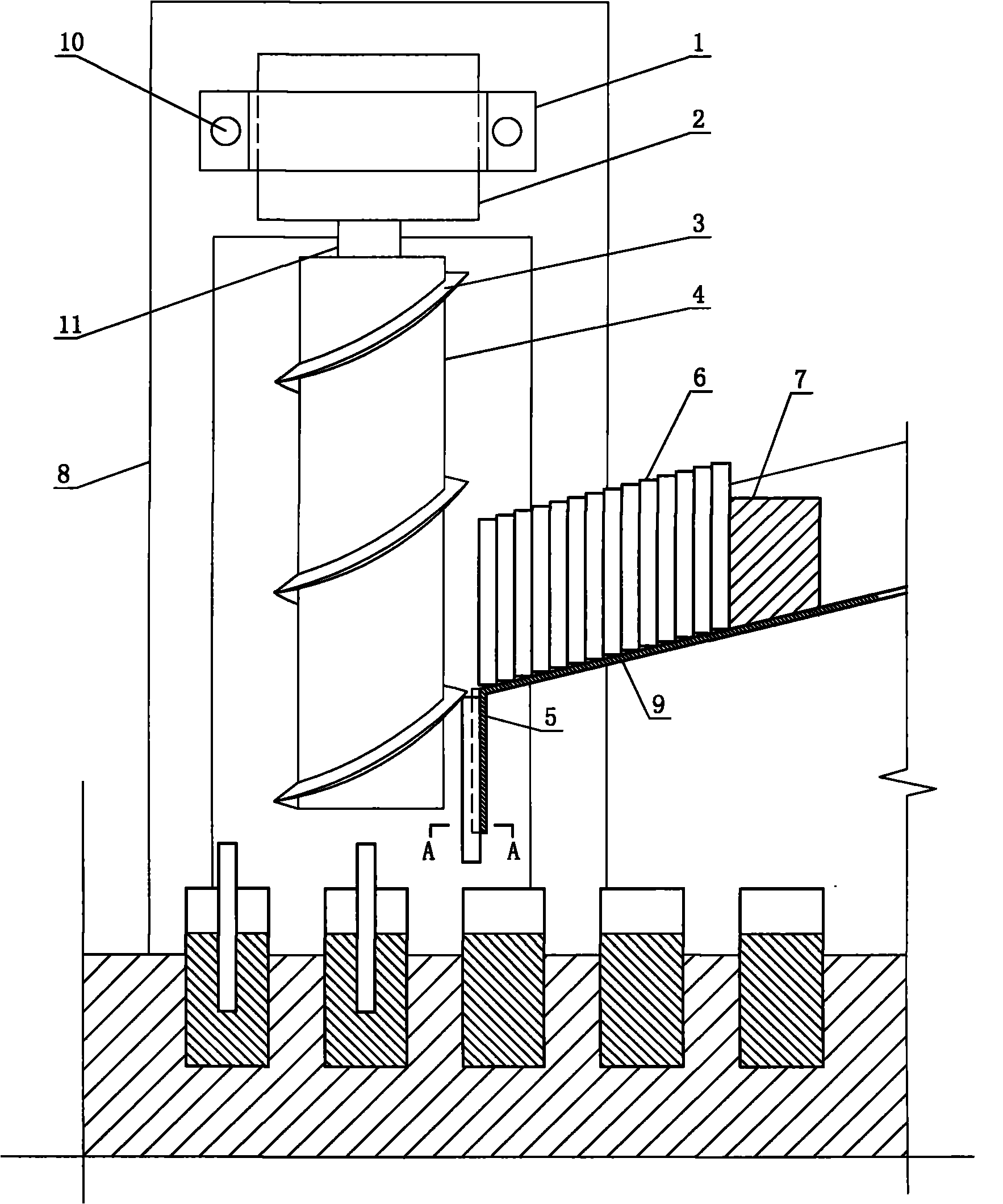

[0015] The stud type ice cream stick inserter is composed of a fixed card frame 1, a motor 2, a thread 3, a stud 4, a guide groove 5, an ice cream stick 6, a gravity block 7, a motor frame 8, a storage rod slot 9, a bolt 10 and a motor shaft 11 constitute. There is a vertical guide groove 5 integrated with the rod storage groove 9 at the lower end of the obliquely arranged rod storage groove 9. A plurality of ice cream sticks 6 are vertically placed on the rod storage groove 9. The highest ice cream stick 6 There is a gravity block 7 on the outside of the rod storage slot 9, the bottom surface of the gravity block 7 is an inclined surface, and the material of the bottom surface of the gravity block 7 is polytetrafluoroethylene. The cross section of the guide groove 5 is “]” shape, the groove depth of the guide groove 5 is half the width of the ice cream ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com