An inside-welder water pipe connecting device

A technology for connecting devices and inner water pipes, which is applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of complicated installation of water pipes and obstruction of work, and achieve the effect of beautiful appearance design, smooth circulating water and clear pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

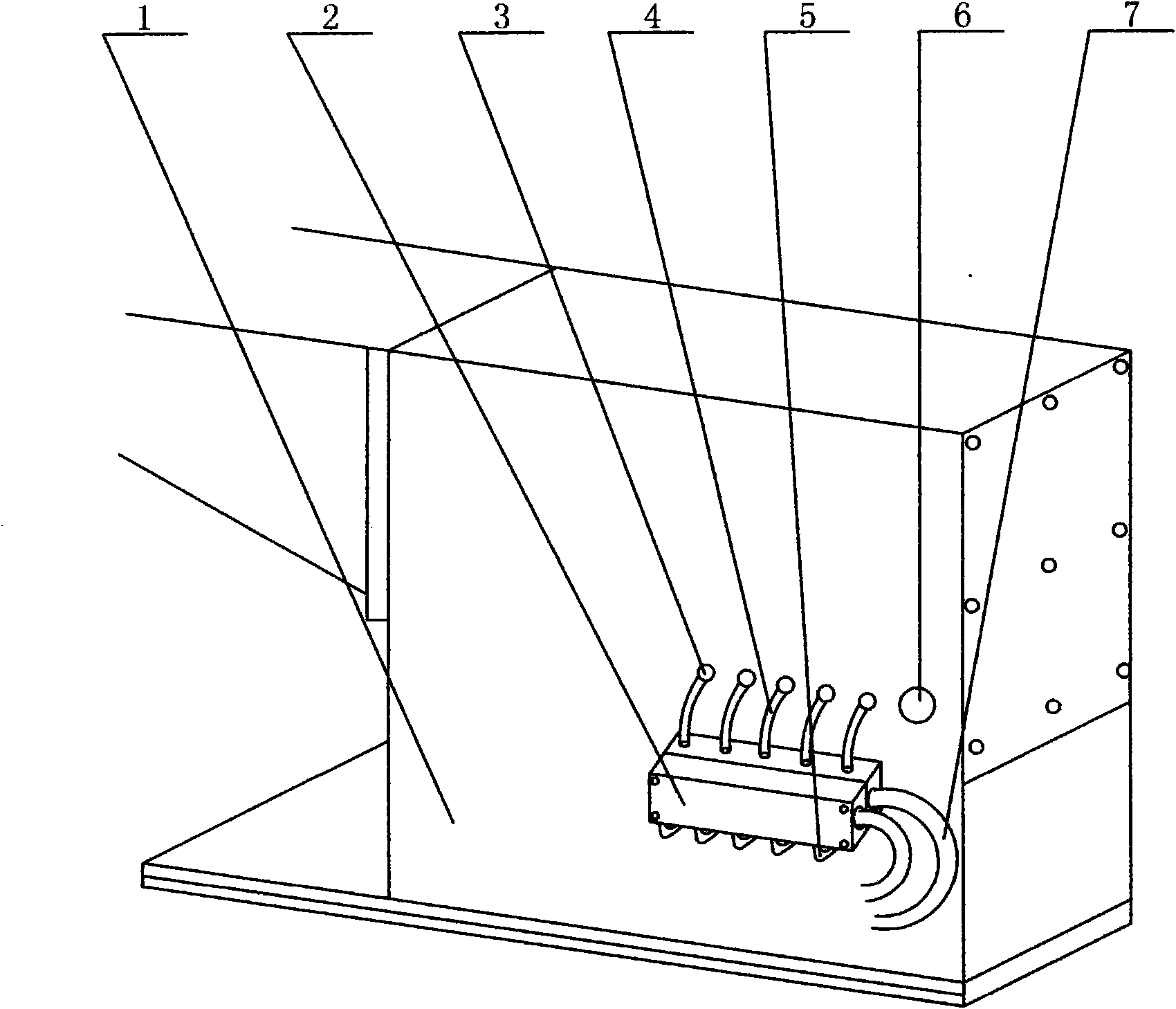

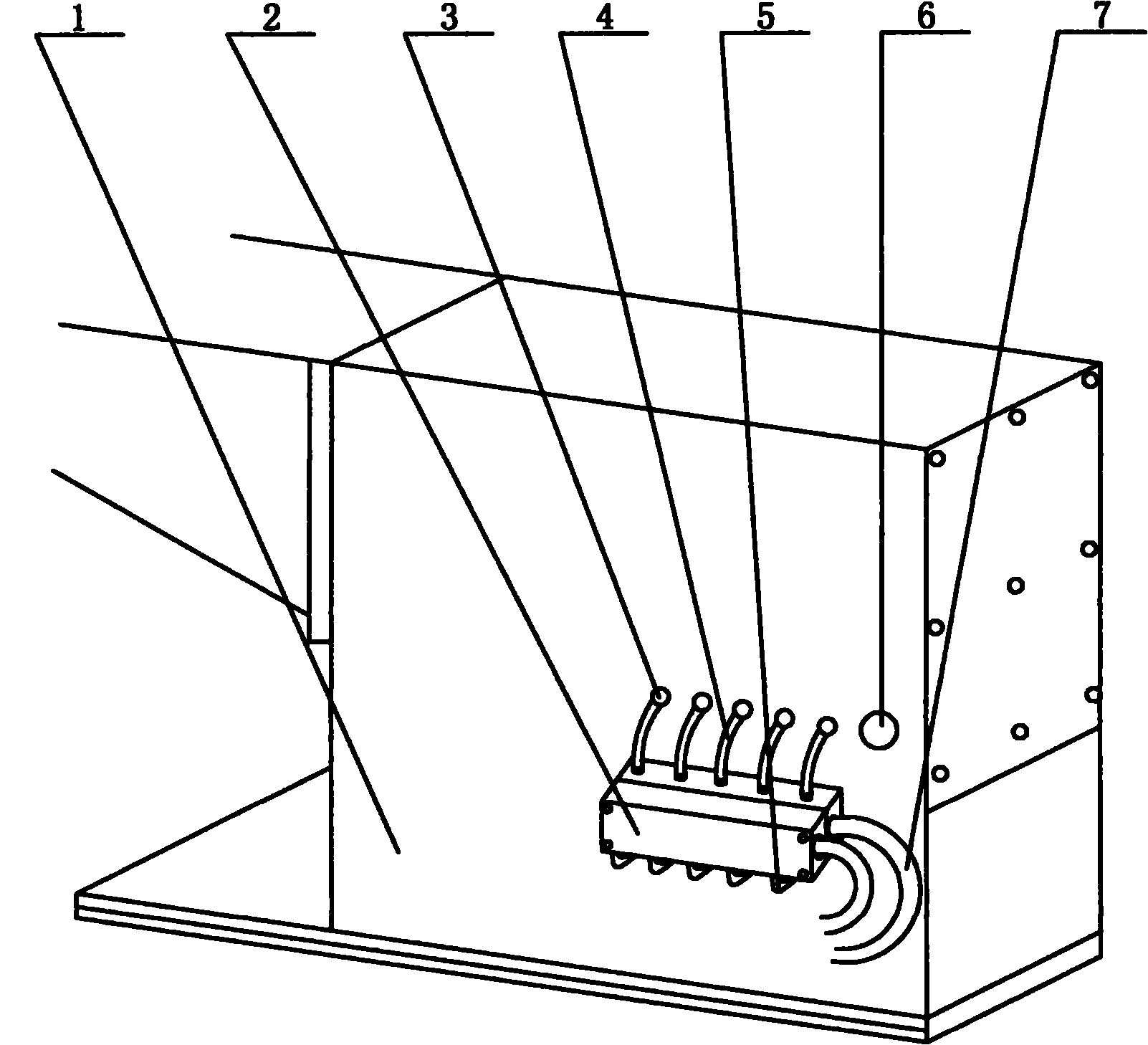

[0007] see figure 1 , the specific embodiment is to adopt the following technical scheme: it comprises welding machine body 1, water storage pipeline 2, pipe inlet hole 3, fine water inlet pipe 4, water outlet pipeline 5, air inlet 6, main water inlet and outlet pipe 7; 2. It is set outside the lower right end of the welding machine body 1. A row of inlet pipe holes 3 is uniformly arranged on the water storage pipe 2. One end of the fine water inlet pipe 4 is connected to the top of the water storage pipe 2, and the other end is placed in the inlet pipe hole 3. The water outlet The pipeline 5 is arranged below the water storage pipeline 2, the air inlet 6 is arranged on the upper side of the water storage pipeline 2, and the main water inlet and outlet pipe 7 is arranged on the water storage pipeline 2 sides.

[0008] In this specific embodiment, effective positions can be used to install circulating water pipe passages in order to ensure smooth circulating water, beautiful ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com