Blast furnace material loading process for realizing 3-grade or 4-grade charging of sinter ore

A technology of sinter and blast furnace, applied in blast furnace, blast furnace details, furnace and other directions, can solve the problem that sinter ore can not meet the needs of production when entering the furnace in two stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

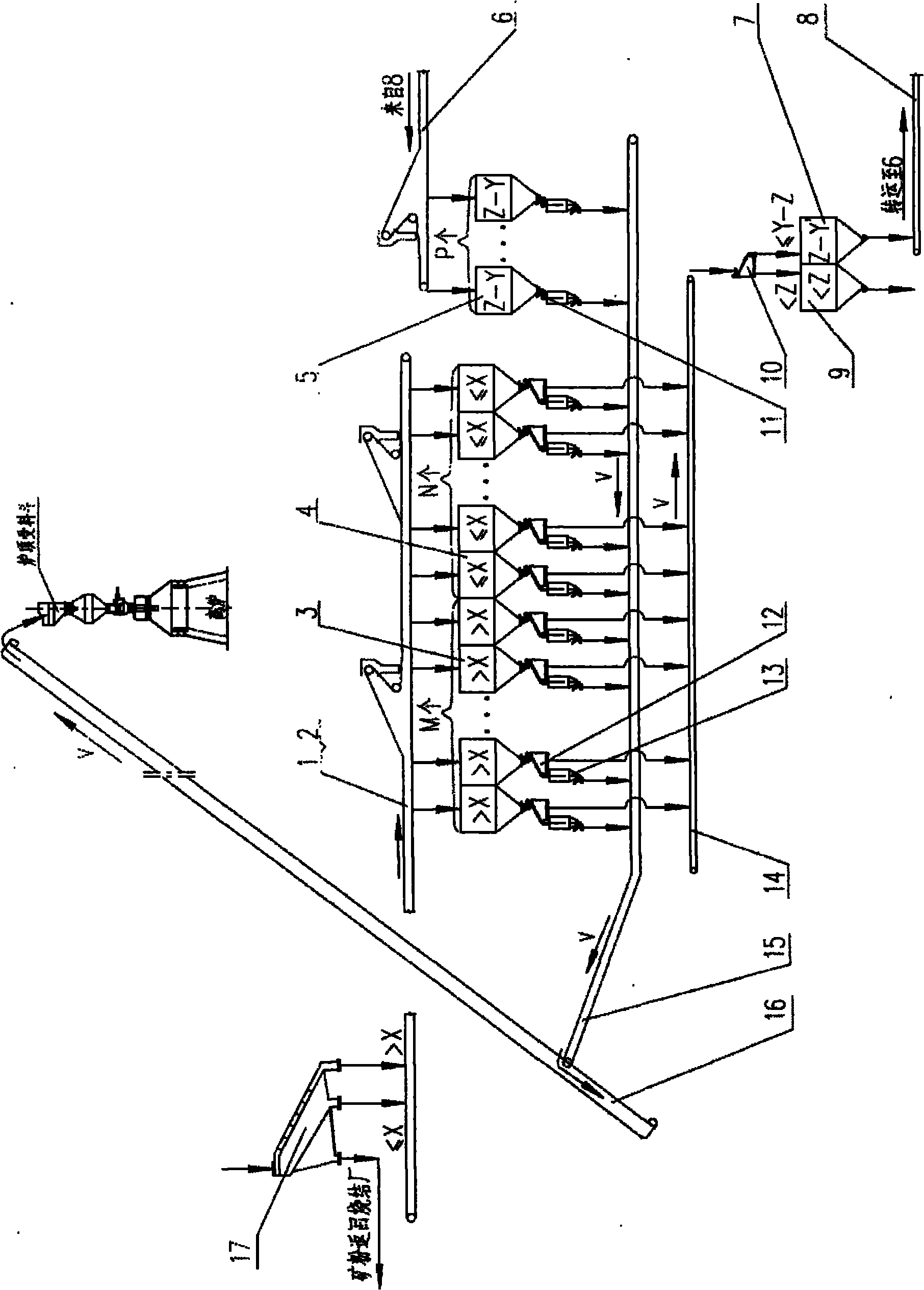

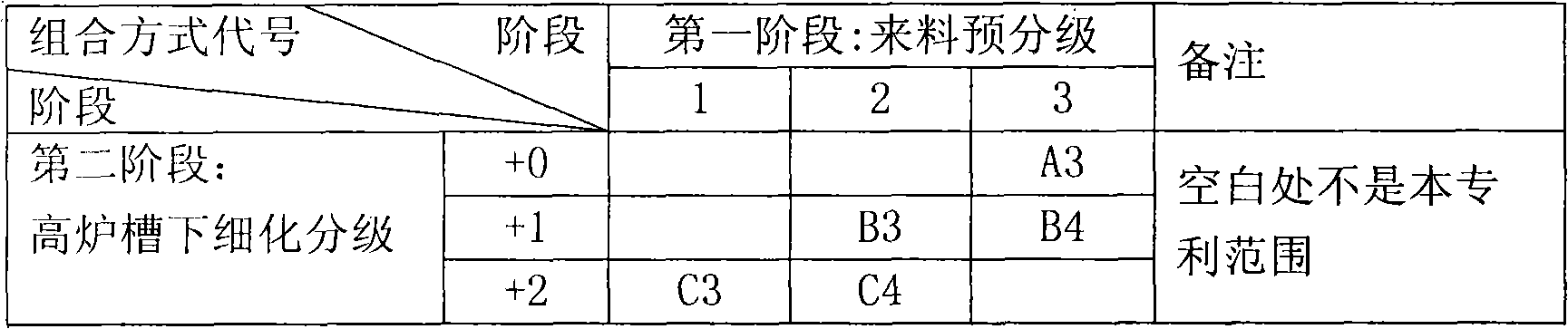

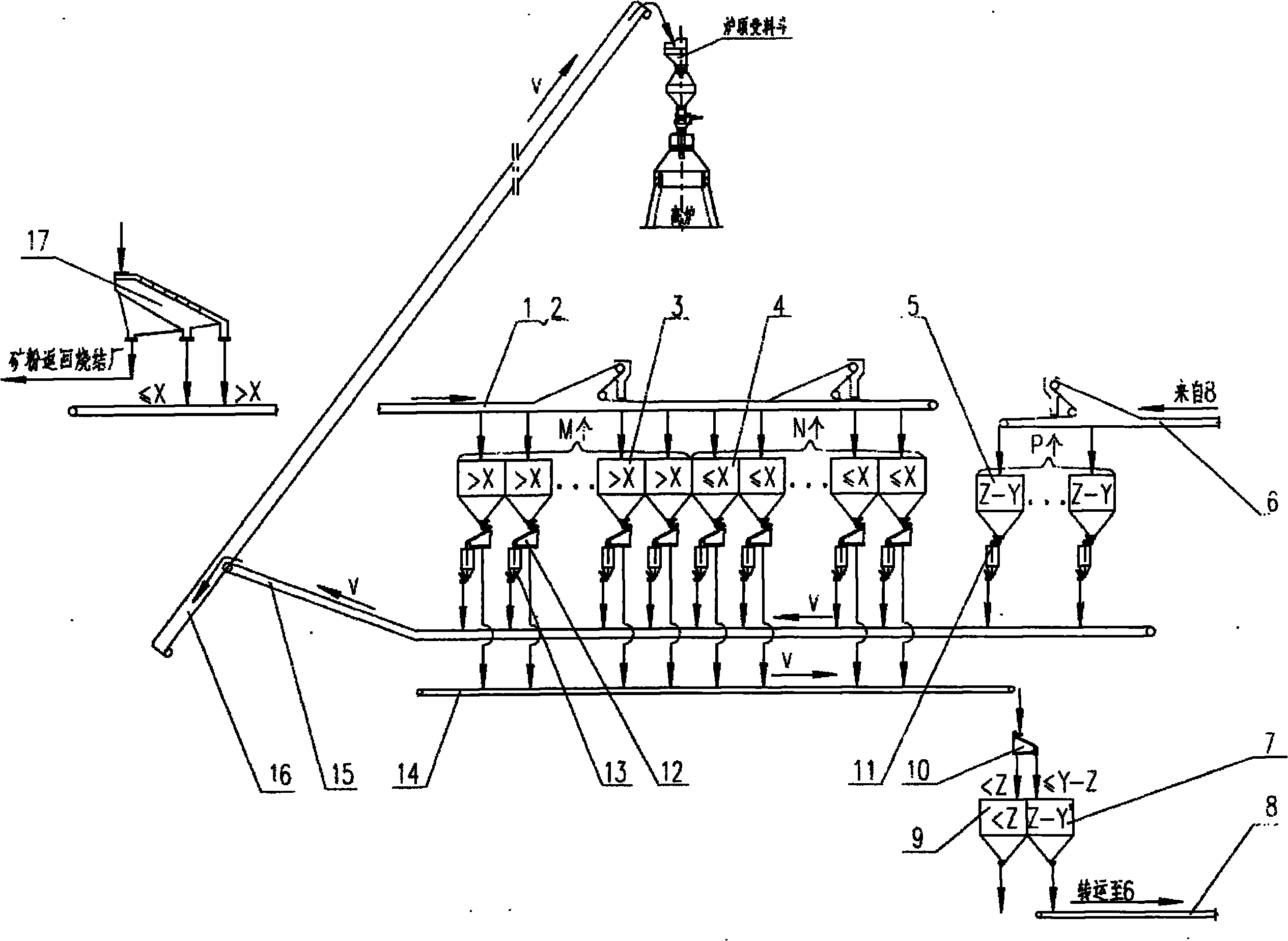

[0056] figure 1 It is one of the specific implementation modes of the present invention, and adopts the process flow of 3 stages of entering the furnace by adopting the method of segmentation and classification. It has the characteristics of grading particle size up to 3 grades, flexible adjustment of grading particle size range, wide application range (adapting to both traditional process and "short process"), etc., and conforms to the "reduction" production concept promoted by ironmaking design And "fine material" policy.

[0057] The present invention divides the sintered ore into two stages by means of segmented classification. The first stage is the pre-grading of incoming materials in the sintering plant; In this embodiment X=20, Y=10, Z=3.

[0058] 1. Pre-grading of incoming materials in sintering plant. In the sintering plant, the finished sintered ore is pre-divided into sintered ore with two particle sizes. After the sintered ore is screened by the pre-grading vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com