Installation method of indoor horizontal large flue in large sintering plant

An installation method and technology of large flue, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of inconvenient installation of large flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

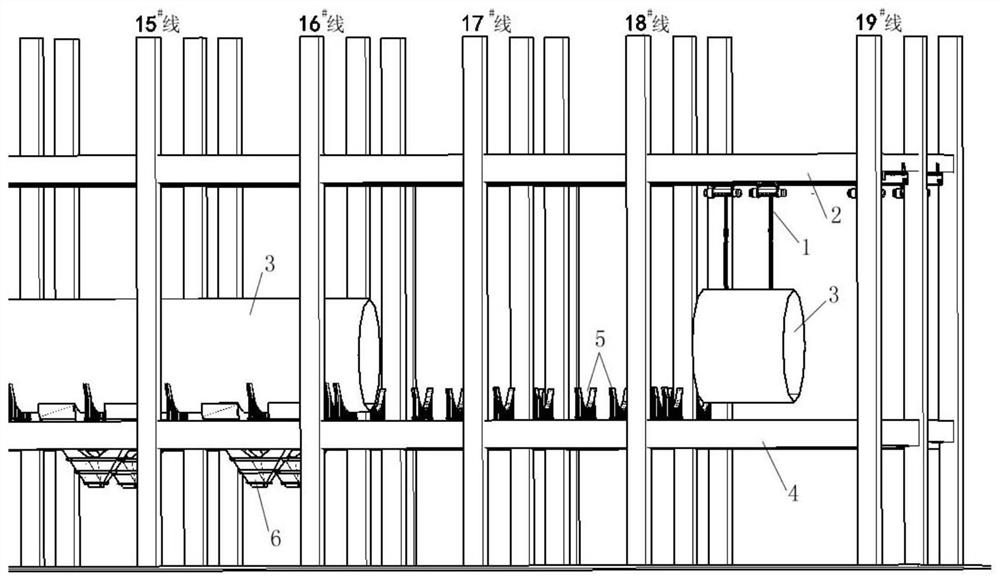

[0040] The technical solution of the present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0041] 1. Preset bolt holes and hoisting holes for the concrete frame beam on the upper layer of the flue

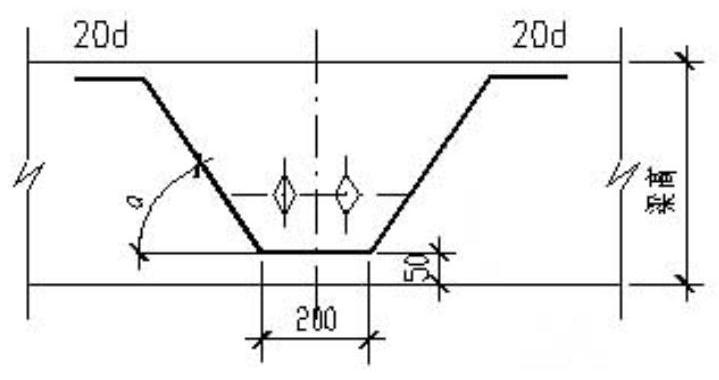

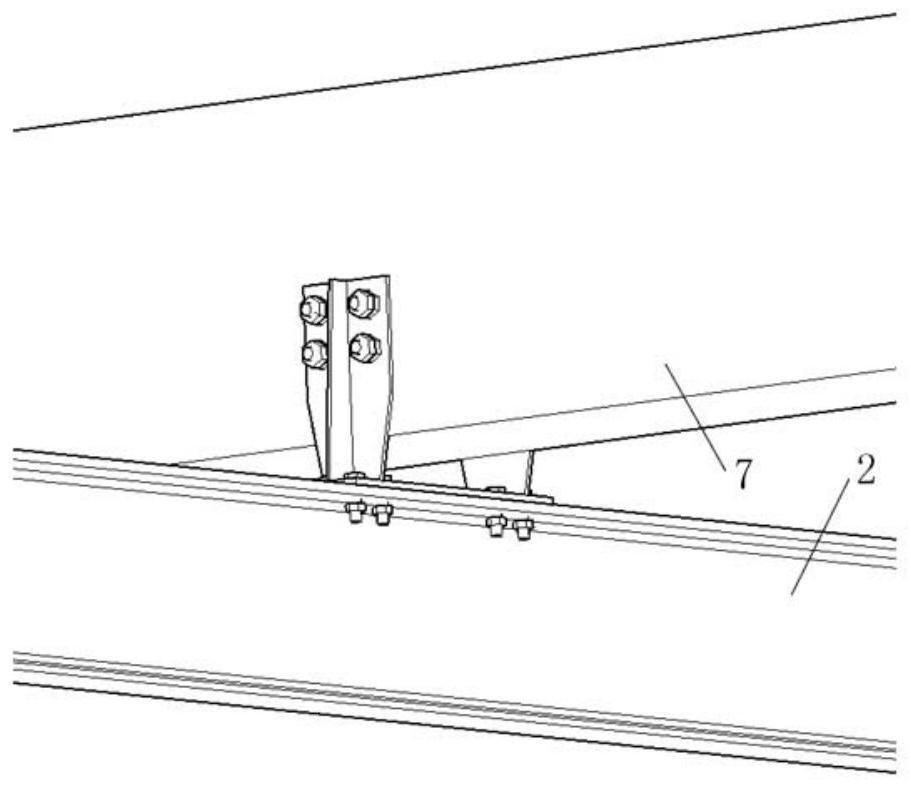

[0042] During the construction of the 19.8m platform in the factory building, that is, the upper platform of the flue, the bolt holes are preset in the platform concrete beam 7 and the three φ100 reserved holes for hoisting the steel hanging beam 2 according to the steel hanging beam installation requirements, and the preset bolt holes Specifications and positions refer to the requirements in the TJ16 Atlas. Hanging bars should be set in the platform concrete beam 7 to strengthen the part with preset bolt holes. The setting of the hanging bars is set according to the TJ16 Atlas. See the attached figure 2 , 3 .

[0043] 2. Install a temporary transfer platform

[0044] On the platform where the flue is located, a tempo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com