Inorganic binder and preparation method thereof

An inorganic binder and dispersant technology, applied in cement production, etc., can solve the problems of serious secondary pollution, affecting enterprise production, poor bonding effect, etc., and achieve the effects of reducing emissions, fast response, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

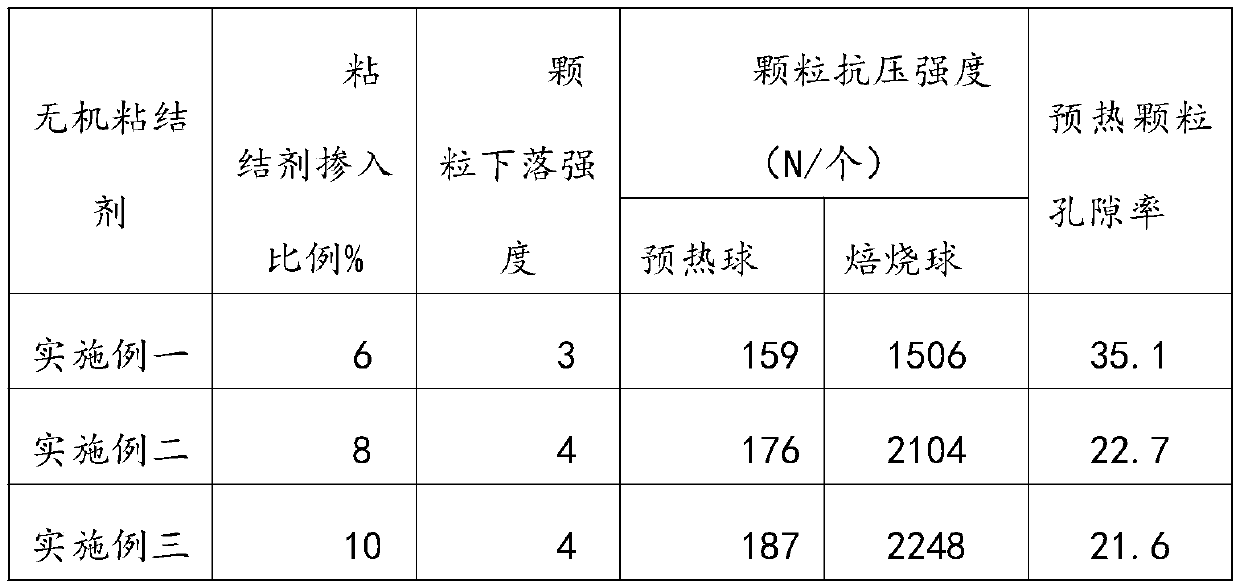

Embodiment 1

[0032] Step S1, weighing the solid components in the following parts by weight.

[0033] Iron and steel sintering plant desulfurization ash: 50 parts, power plant desulfurization ash: 30 parts, limestone: 9 parts, dolomite: 9 parts, dispersant: 2 parts.

[0034] Step S2, the above-mentioned components are dissolved in water to prepare a slurry with a solid component of 20% by mass.

Embodiment 2

[0036] Step S1, weighing the solid components in the following parts by weight.

[0037] Iron and steel sintering plant desulfurization ash: 60 parts, power plant desulfurization ash: 25 parts, limestone: 7 parts, dolomite: 7 parts, dispersant: 1 part.

[0038] Step S2, the above-mentioned components are dissolved in water to prepare a slurry with a solid component of 20% by mass.

Embodiment 3

[0040] Step S1, weighing the solid components in the following parts by weight.

[0041] Iron and steel sintering plant desulfurization ash: 65 parts, power plant desulfurization ash: 20 parts, limestone: 6 parts, dolomite: 6 parts, dispersant: 3 parts.

[0042] Step S2, the above-mentioned components are dissolved in water to prepare a slurry with a solid component of 20% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com