Method for indicating power consumption for yield in per unit in tunnel kiln brick sintering plant and knockout section metering device

A tunnel kiln and brick factory technology, which is applied in the field of power consumption control in sintered brick production, can solve the problems of energy waste and high production cost, and achieve the effect of huge market capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

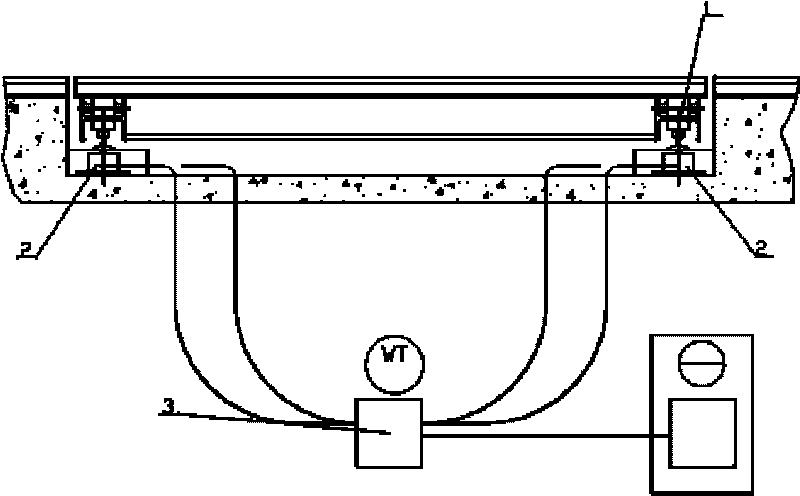

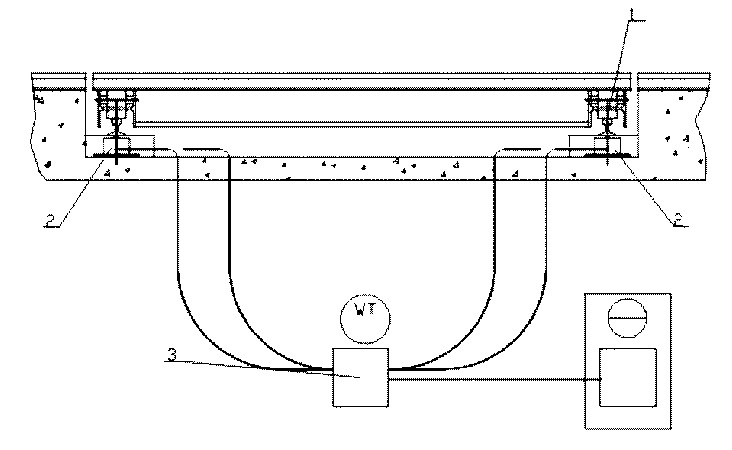

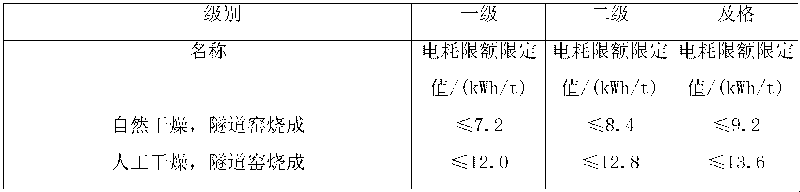

[0022] An embodiment of the present invention: a method for indicating power consumption per unit production in a tunnel kiln sintered brick factory, comprising the following steps:

[0023] a. According to the production process of the sintered brick factory, set up measuring equipment in the billet exit section of the tunnel kiln to measure the output of the product, and obtain the cumulative output A;

[0024] b. Install electricity testing equipment at the production power and lighting power supply feeders of the whole plant, and calculate the total power consumption of the whole plant to obtain the total power consumption B;

[0025] C. Set up a monitoring computer to perform B / A calculations on the cumulative output A and the total power consumption B to obtain the power consumption per unit of production, and perform online instructions, the instructions are instantaneous instructions, and one day, three days, fifteen days, one month or cumulative indications for one ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com