Drilling and reaming dual-purpose drilling tool and construction method thereof

A drilling expansion and dual-purpose technology, which is applied in the direction of drilling driving devices, drill bits, drilling equipment, etc. in the wellbore, can solve the problems of reducing the consistency of the bearing capacity of the reaming pile and failure of reaming, and achieves simple process monitoring and control Ease of operation, reduced disturbance, simple and clear control of power split

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

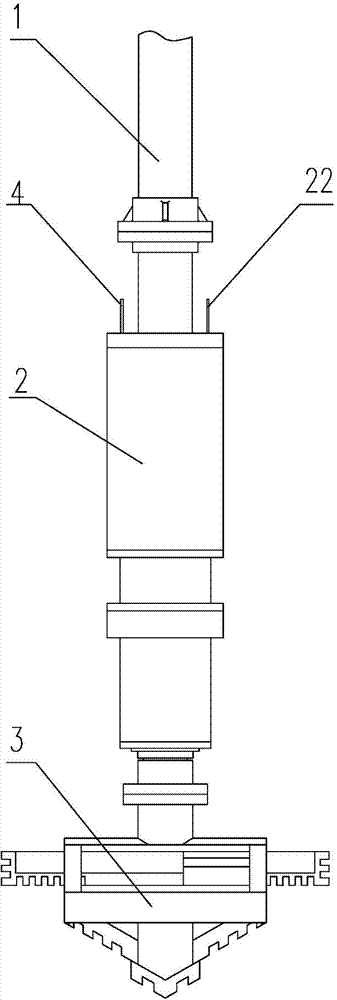

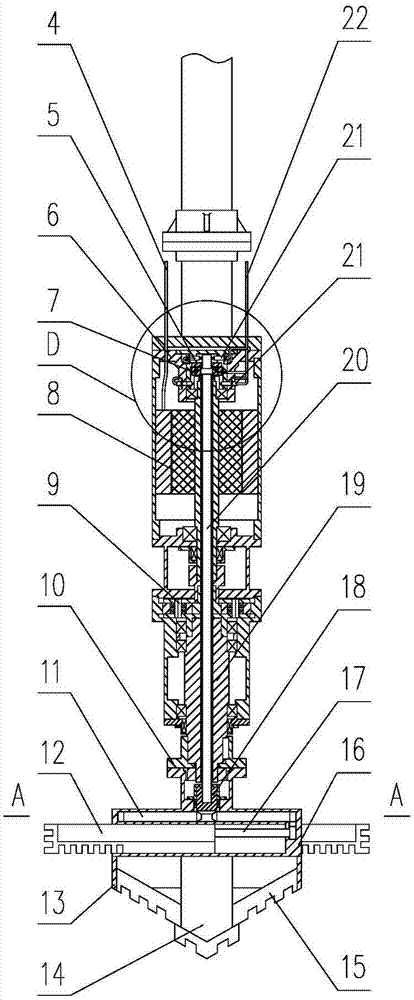

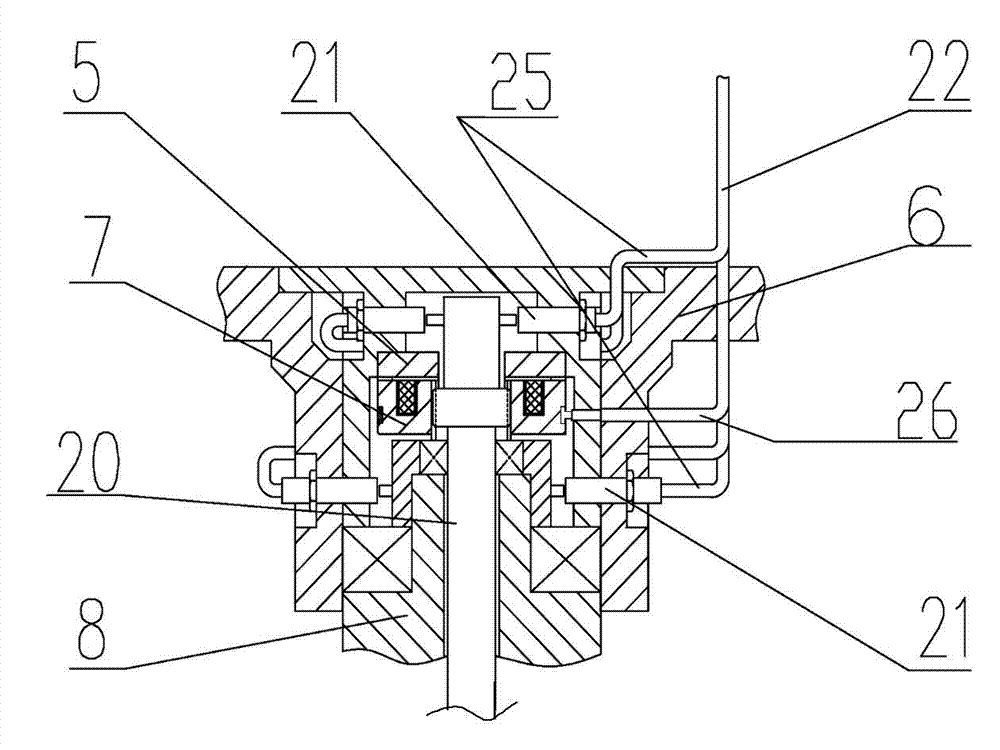

[0046] Examples see figure 1 , figure 2 and image 3 As shown, a dual-purpose drilling tool for drilling and reaming is composed of a hollow drill rod 1, a power cable 4, a measurement and control cable 22, a dual-purpose drilling machine 2 for drilling and reaming, and a dual-purpose drill bit 3 for drilling and reaming. The dual-purpose drilling rig 2 for drilling and reaming is composed of a submersible motor 8, a planetary reducer 9, a rig shaft 19, and a flange 10 connected from top to bottom, and the dual-purpose drill 3 for drilling and reaming is composed of a flange 10, a drill beam 16 It is composed of a top-to-bottom fixed connection with the drill tip at the lower part. The drill shaft 19 is connected with the dual-purpose drill bit 3 for drilling and reaming through a flange 10. It is characterized in that:

[0047] a. A long control shaft 20 is provided in the central through hole provided at the center of the shaft of the submersible motor shaft, the sun ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com