Device and method for monitoring tension of steel wire rope of FBG (fiber bragg grating) compression type mine hoisting equipment

A fiber grating and monitoring device technology, applied in the direction of tension measurement, etc., can solve the problems of difficulty in timely detection of potential safety hazards, decreased linearity and sensitivity, weak anti-electromagnetic interference ability, etc., to solve the cross-sensitivity of strain and temperature and the monitoring process Easy, strong anti-electromagnetic interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

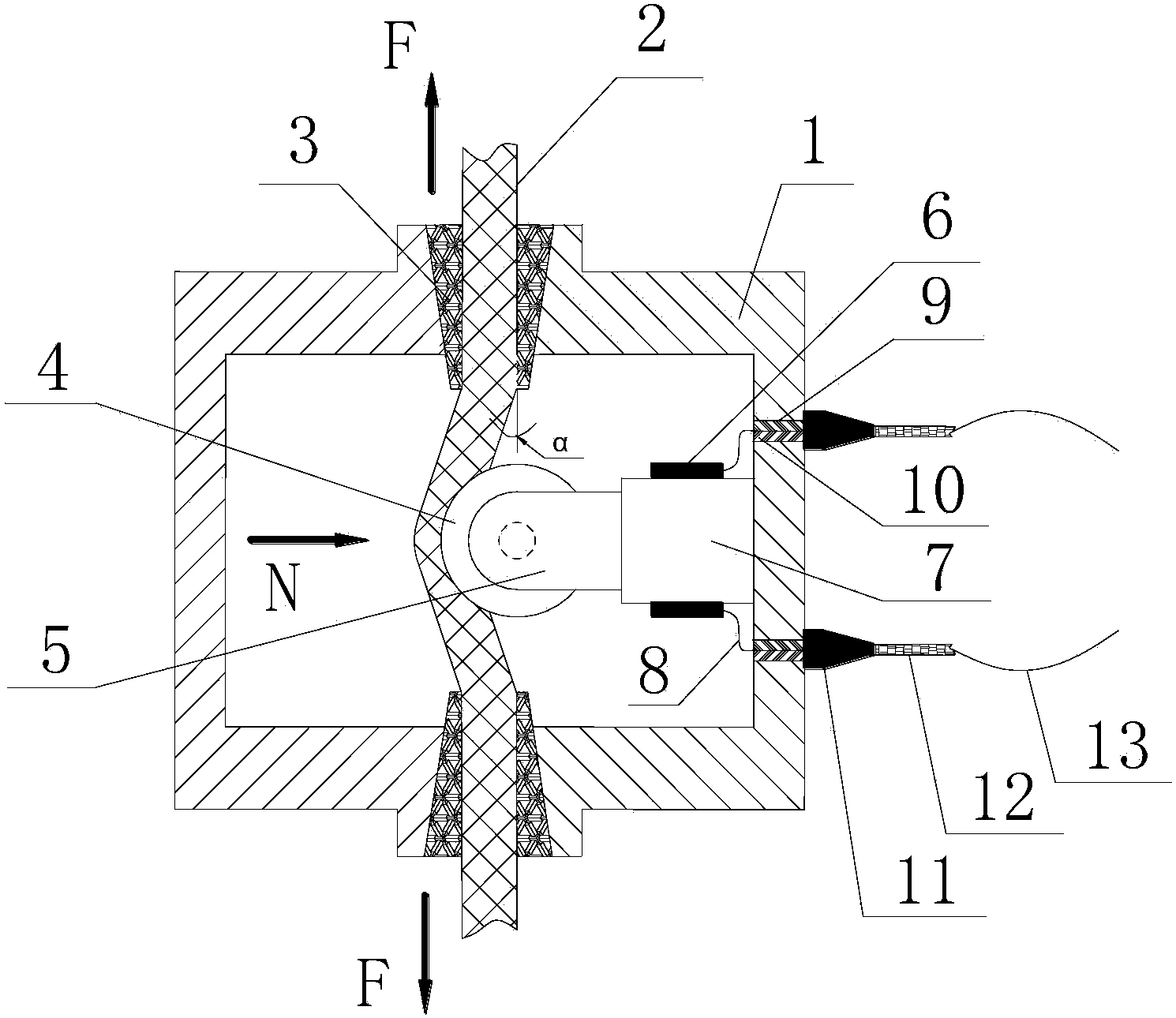

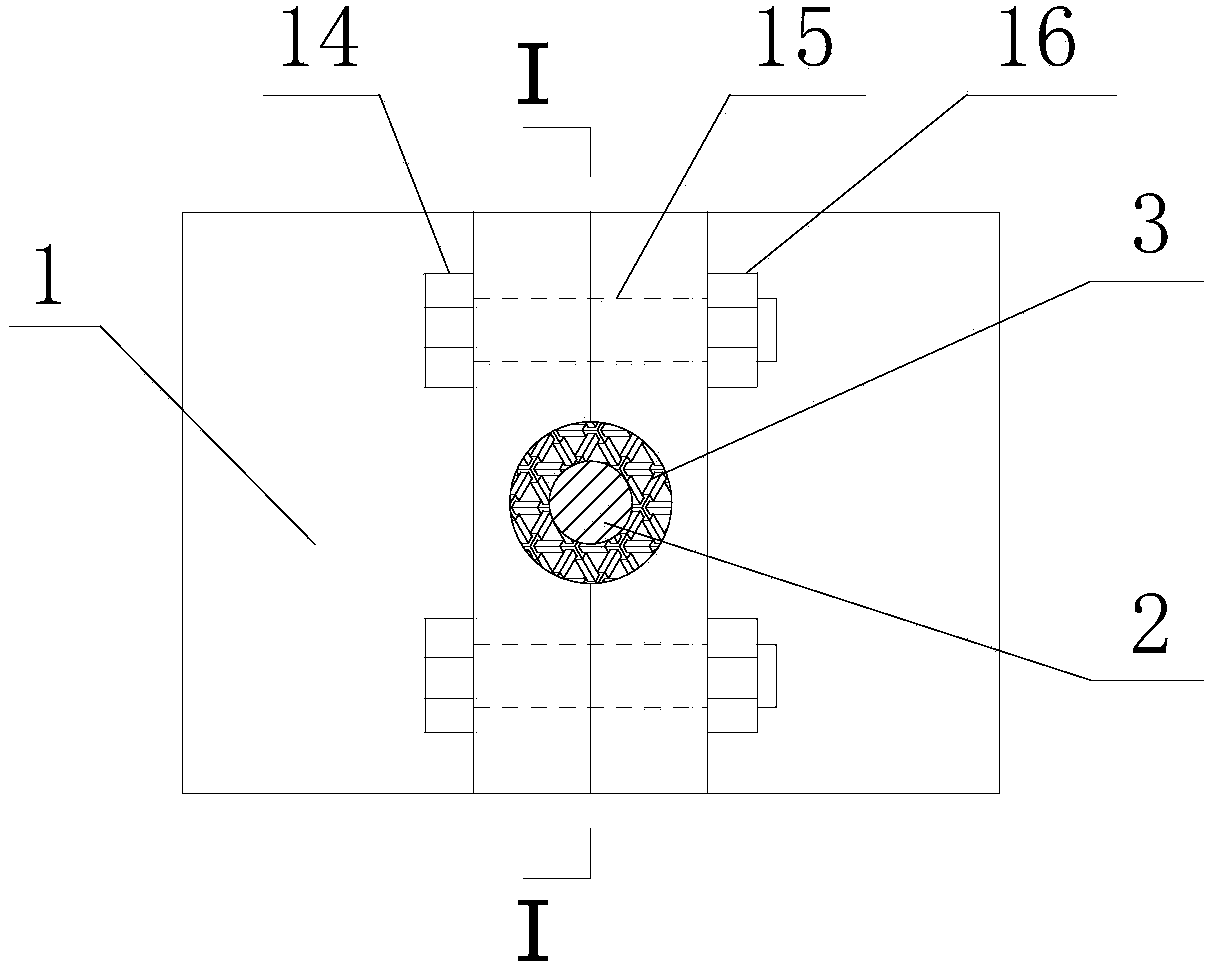

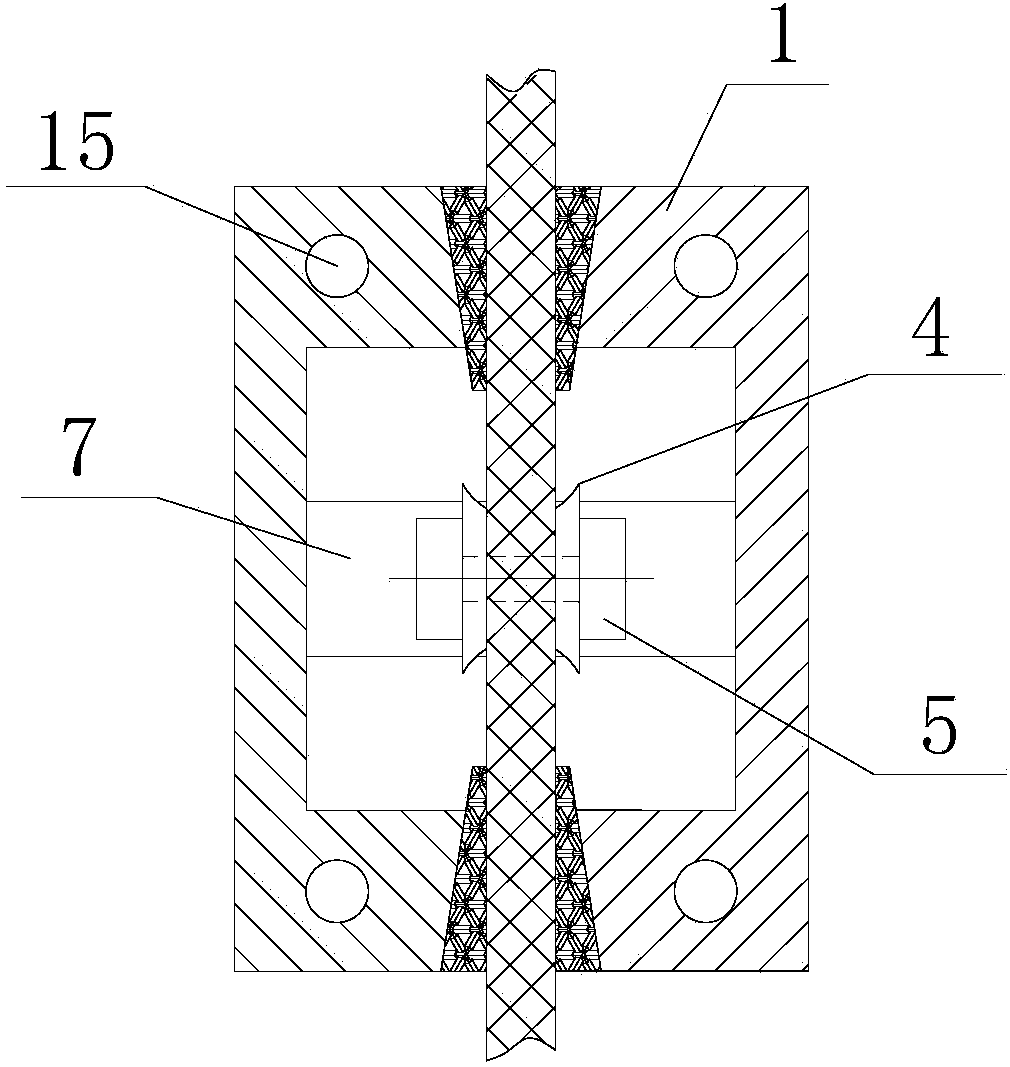

[0028] Such as figure 1 , figure 2 and image 3 As shown, the fiber grating compression type mine hoist wire rope tension monitoring device of the present invention includes a package casing 1, a steel wire rope 2, an anti-skid wedge-shaped rubber ring 3, a fixed pulley 4, a U-shaped fixed bracket 5, a fiber grating 6, and an elastic pressure column 7 , optical fiber 8, optical fiber lead-out hole 9, sealant 10, optical fiber connector 11, armored protective rubber 12, optical fiber pigtail 13, bolt 14, bolt hole 15, fastening nut 16; On the steel wire rope 2, an anti-slip wedge-shaped rubber ring 3 is installed between the top and bottom of the package shell 1 and the fixing point of the steel wire rope 2. The anti-slip wedge-shaped rubber ring 3 has a larger size at the end close to the outside of the package shell 1, and is closer to the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com