Yarn feeding mechanism of warp knitting machine

A technology of yarn feeding mechanism and warp knitting machine, which is applied in the field of warp knitting machines, can solve problems such as invariance and affecting the overall aesthetics of patterns, and achieve the effect of avoiding different pattern spacing and being easy to observe and check

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

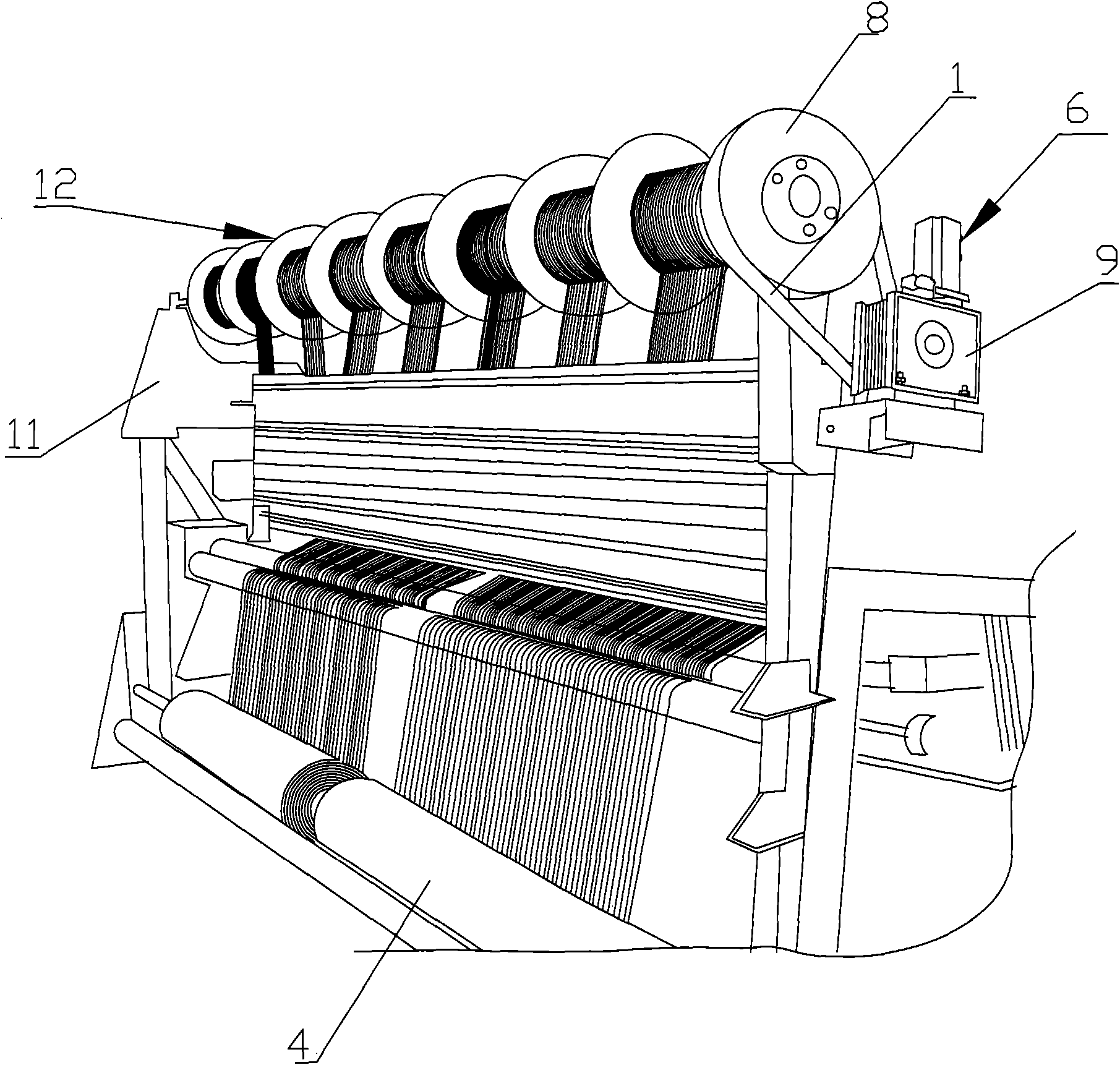

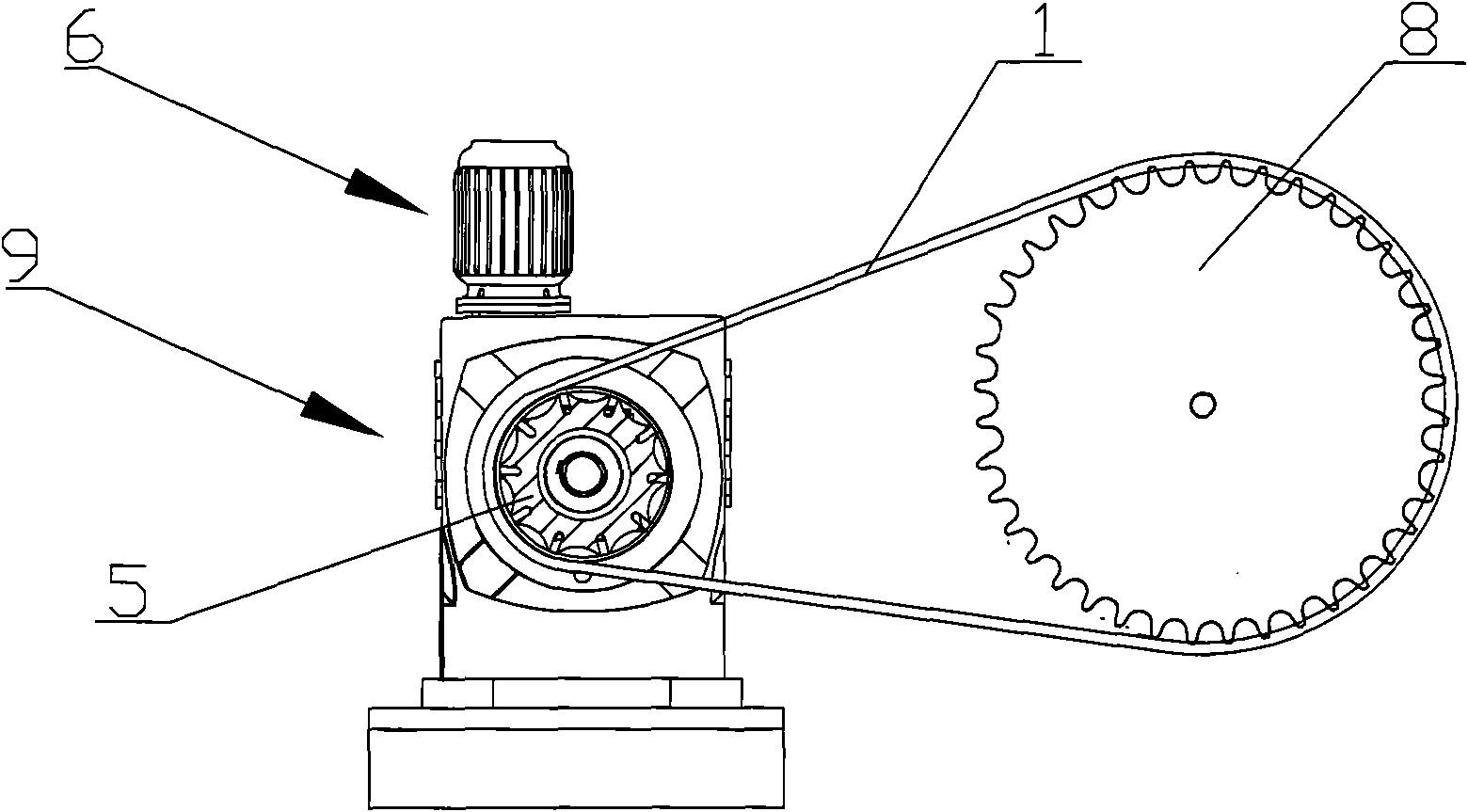

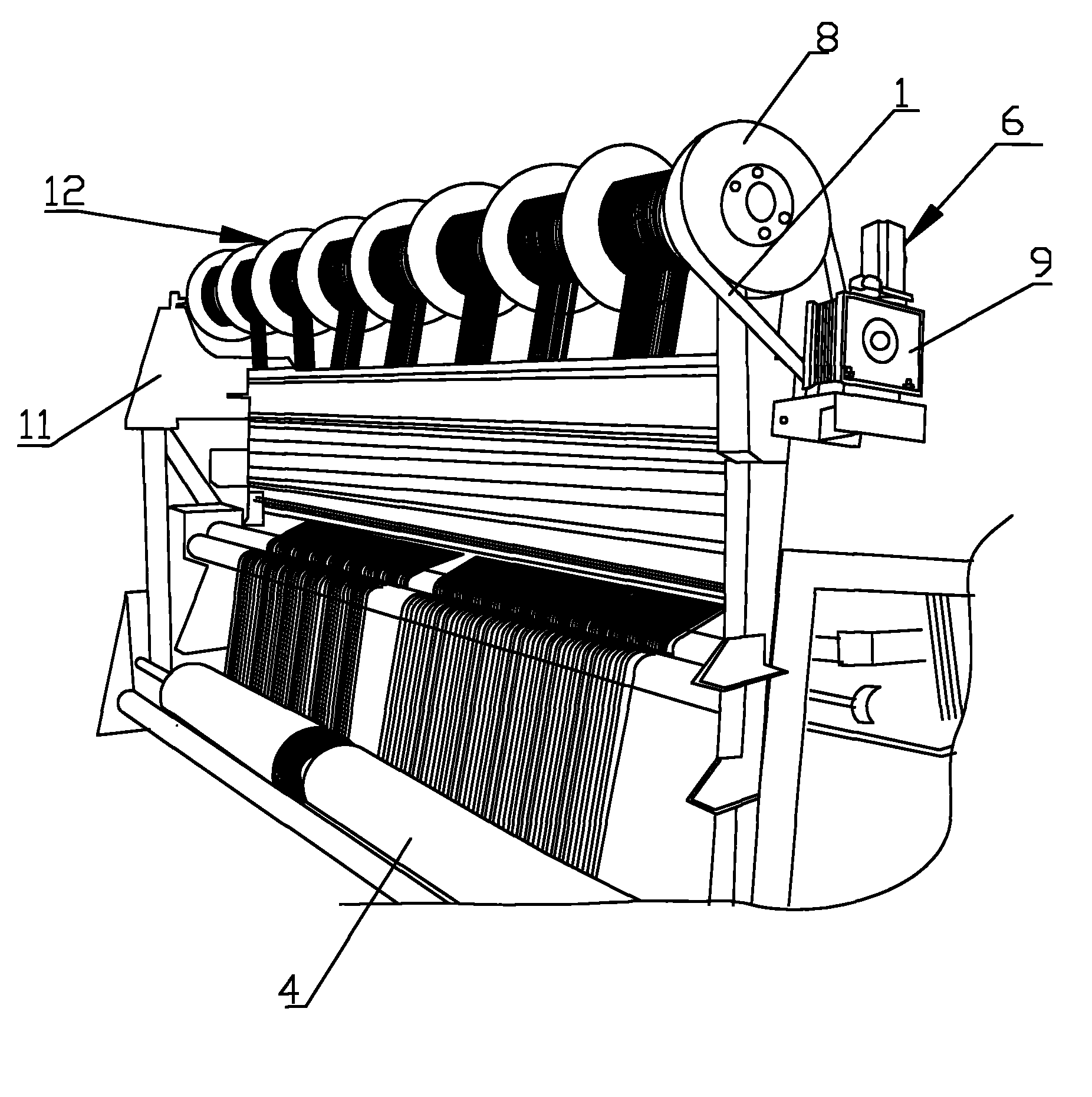

[0010] attached figure 1 For applying the perspective view of the warp knitting machine of the present invention, it mainly comprises frame 11, the yarn feeding mechanism positioned at frame 11 top, warp knitting mechanism, transmission mechanism and winding roller 4, and yarn feeding mechanism mainly includes being rotatably arranged on The yarn feeding transmission shaft 12 on the frame 11 of the warp knitting machine, the plurality of yarn tubes 3 fixedly arranged on the said yarn feeding transmission shaft 12, the motor 6 and the motor 6 are also arranged on the said frame 11. Connected worm gear reducer 9, the end of the yarn feeding drive shaft 12 is coaxially connected with a large gear 8, the output shaft of the reducer 9 is coaxially connected with a pinion 5, and the large gear 8 is connected with the pinion 5 through a synchronous belt 1 transmission.

[0011] The yarn feeding mechanism of the warp knitting machine also includes a controller and a monitor (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com