Moving beam trolley and method for horizontally and vertically moving beams using same

A technology for moving beam trolleys and trolleys, which is applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of limited selection of beam yard sites, large investment, inconvenient promotion and application, etc., and achieves the reduction of site area requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

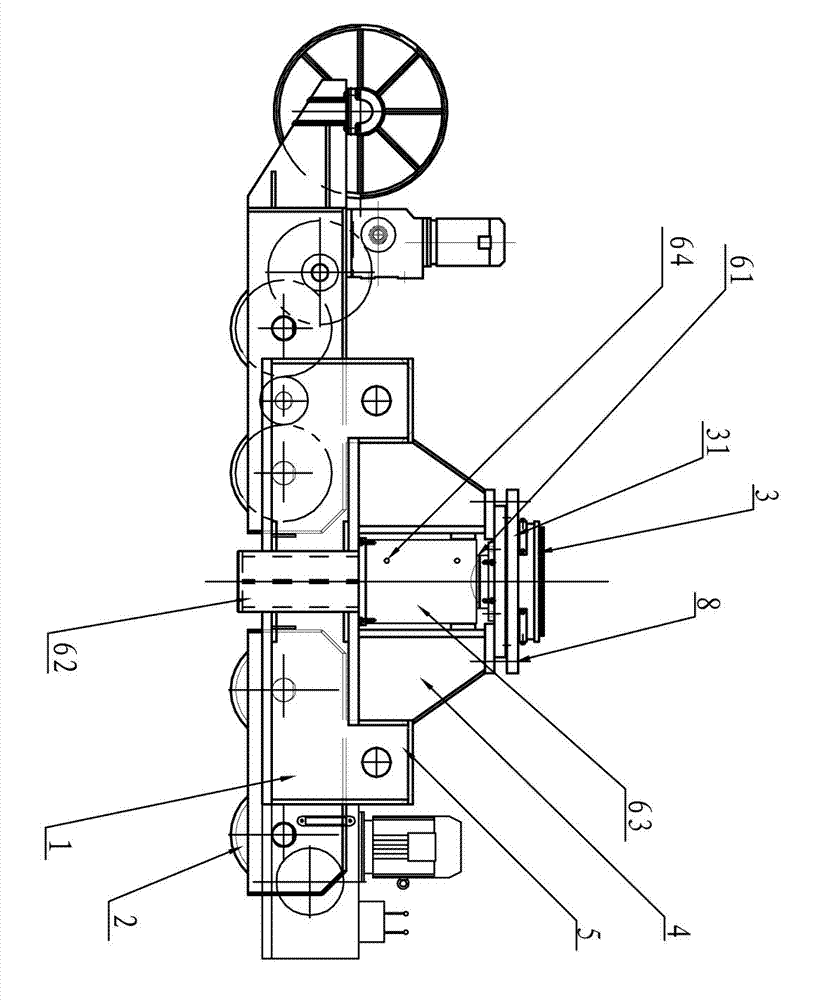

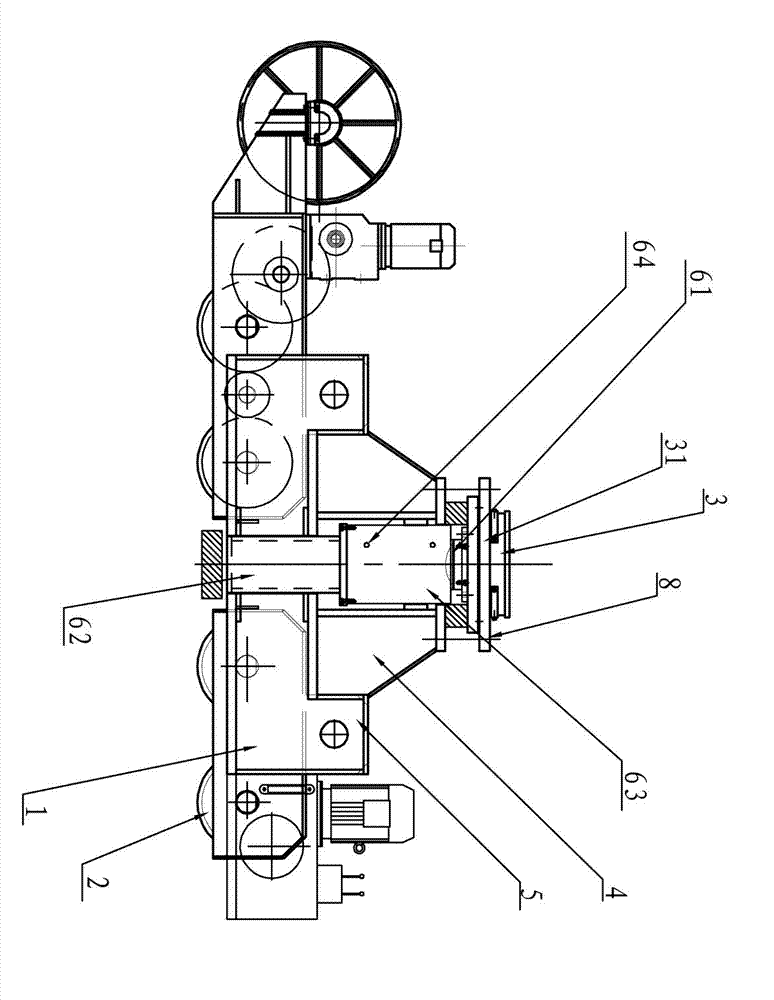

[0024] refer to figure 1 , the present invention is a beam moving trolley, the lower part of the trolley is provided with a number of traveling wheel boxes 1, the traveling wheel boxes 1 are installed with traveling wheels 2, the upper part of the trolley is provided with a beam support plate 3, and the lower part of the beam support plate 3 is provided with The support frame 4 is provided with a connecting beam 5 between the support frame 4 and the traveling wheel box 1, and a jacking and rotating device is provided between the beam support plate 3 and the support frame 4.

[0025] The beam moving trolley can lift the beam support plate 3 on the trolley through the jacking and rotating device. During the reversing process of the beam moving trolley, the beam support plate 3 on the trolley can be fixed and only the main body of the trolley can be rotated.

[0026] As a preferred embodiment of the present invention, the jacking and rotating device includes a jack rod 61 fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com