Conveyors and Conveyor Systems

A technology of transmission device and transmission mechanism, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problem of large space occupation, and achieve the effect of reducing the demand for site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

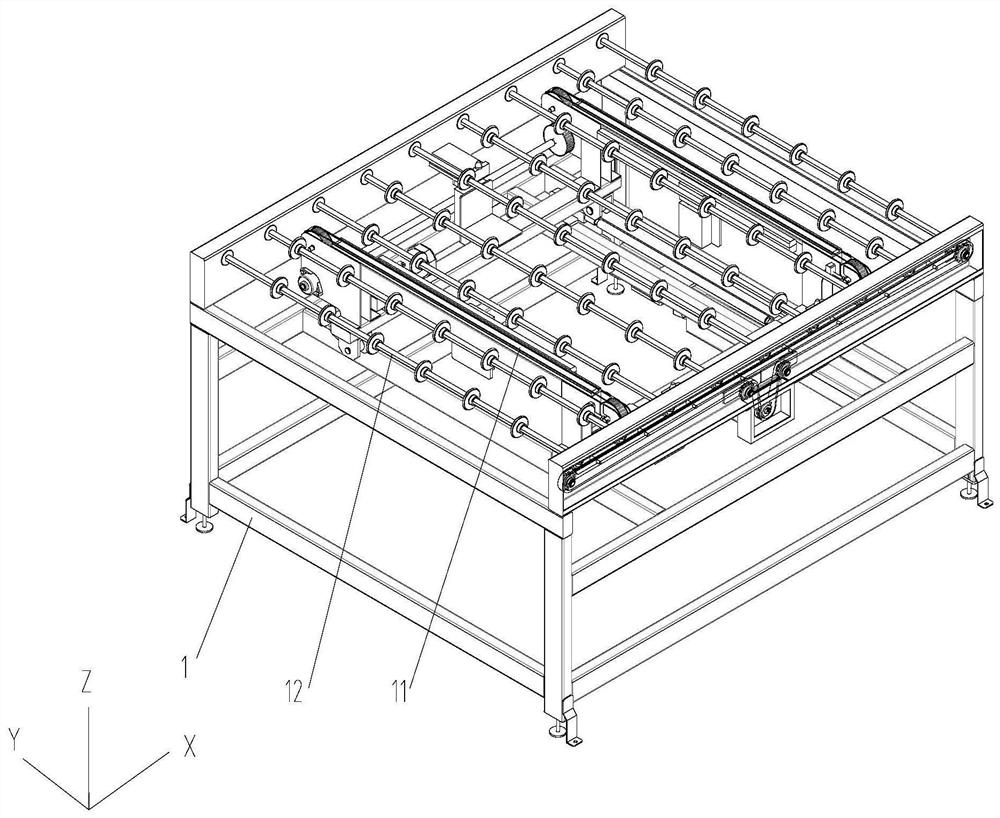

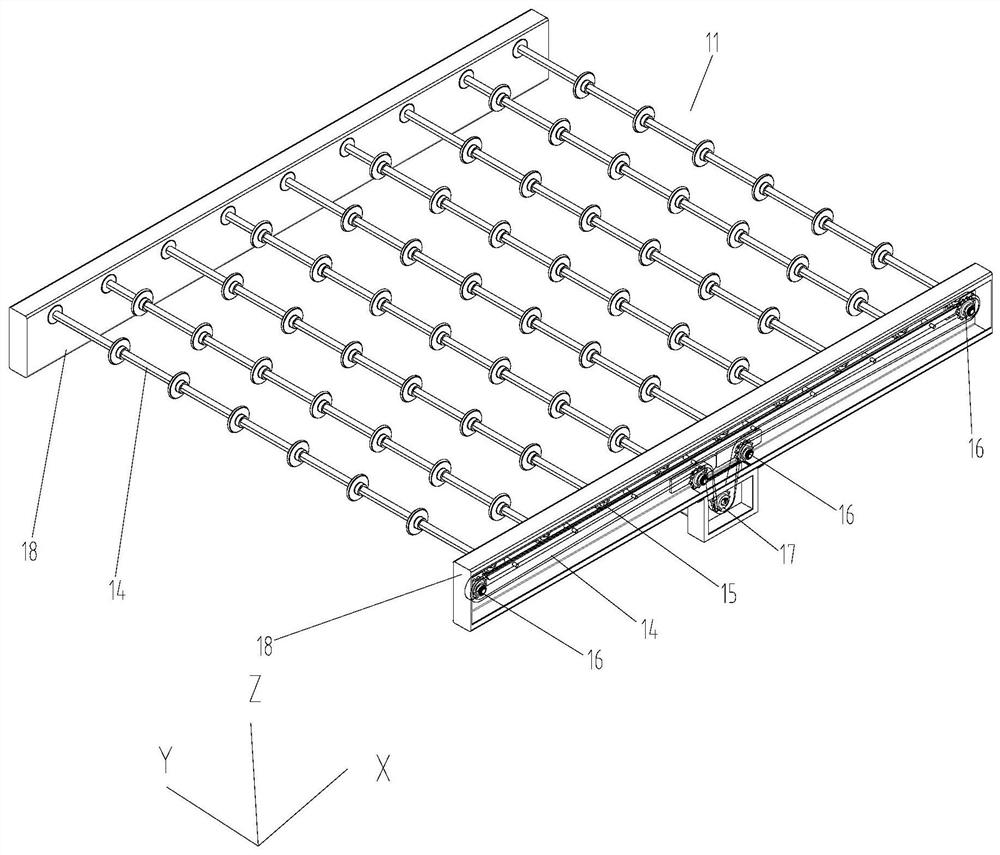

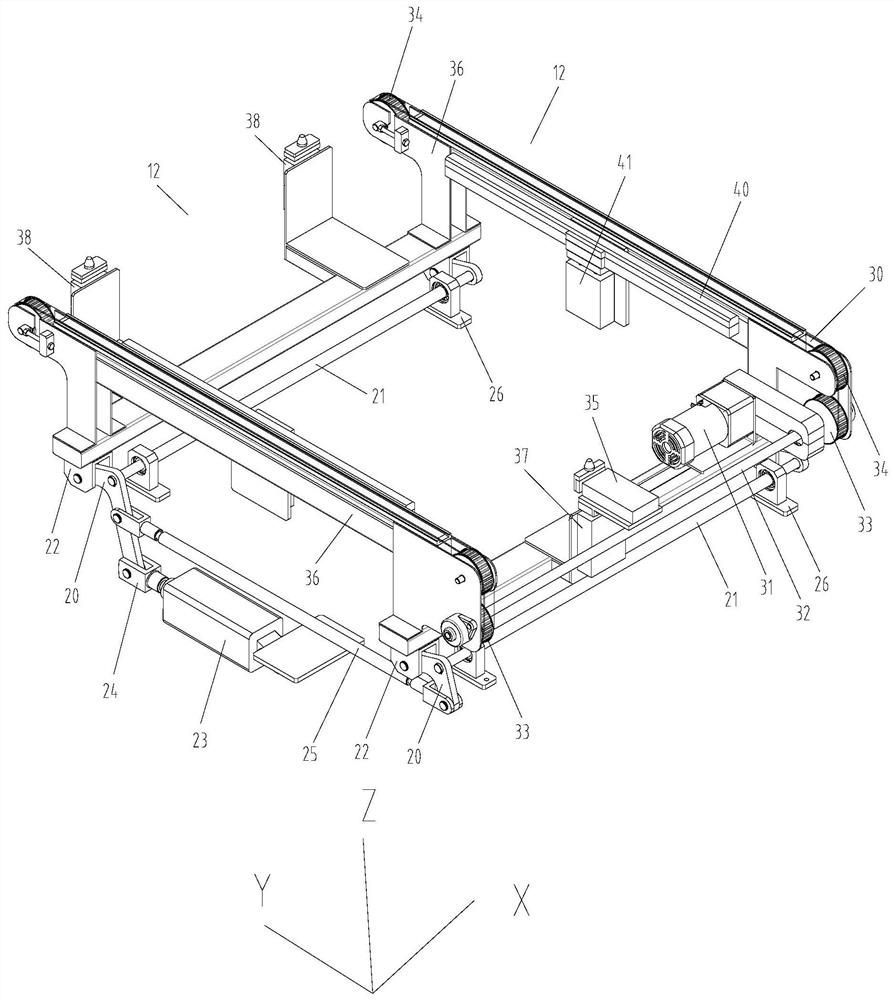

[0024] The present invention provides a conveying device, which includes a frame 1 and a first conveying mechanism 11 and a second conveying mechanism 12 arranged on the frame 1, the first conveying mechanism 11 is used to drive objects along the X The second transmission mechanism 12 includes a lifting unit and a reversing unit, and the lifting unit can move along the Z axis at a first position higher than the first transmission mechanism 11 and lower than the first transmission mechanism 11, wherein, in the process of moving from the first position to the second position, the lifting unit can lift the object on the first conveying mechanism 11 , the lifting unit at the second position can support the object, the reversing unit can push the object on the lifting unit at the second position along the Y-axis direction, the line where the X-axis is located, The line where the Y axis is located and the line where the Z axis is located are perpendicular to each other. Wherein, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com