Humidification mixer

A technology of mixer and air humidification, which is applied in air humidification system, heating method, lighting and heating equipment, etc. It can solve the problems of flow detection, follow-up environmental simulation cannot be carried out, long humidification distance and bulky volume, etc., to achieve humidification Good mixing effect, improved humidification effect, and small cross-sectional area of the air duct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

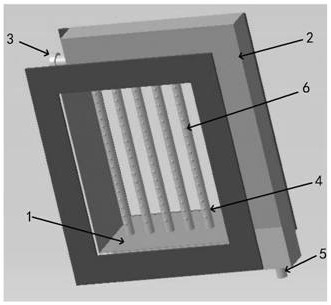

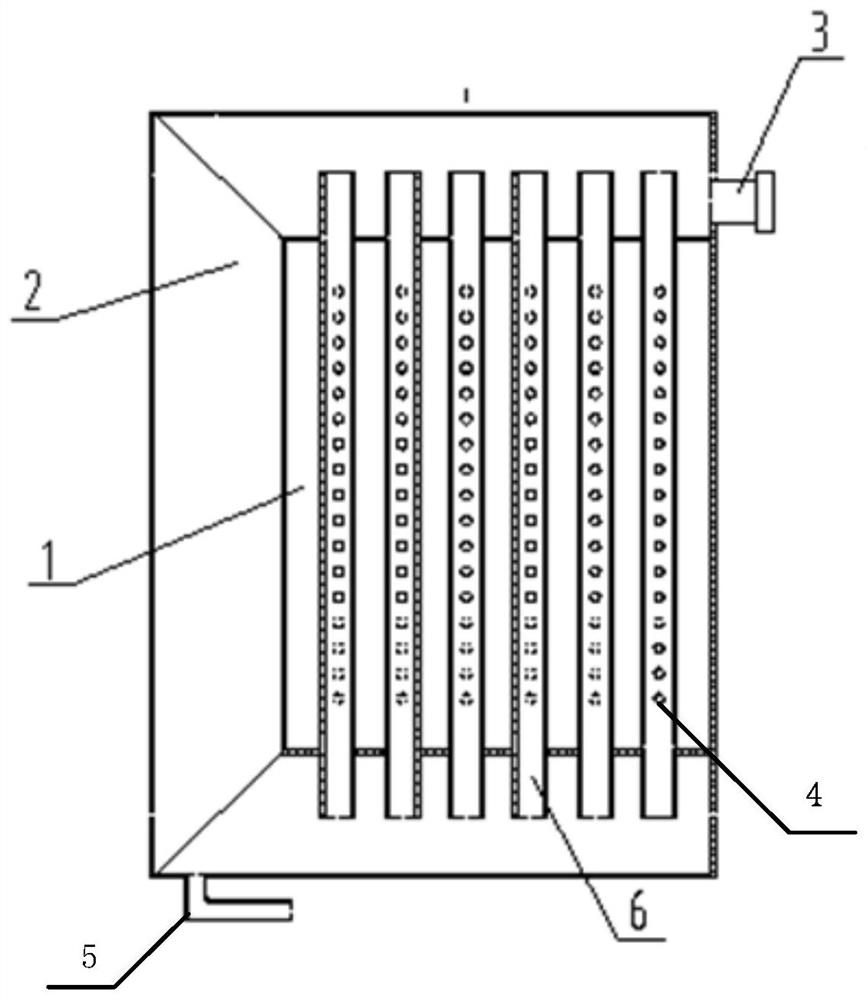

[0027] A kind of humidifying mixer disclosed in the embodiment of the application, such as figure 1 As shown, it includes the air intake pipe 1, which provides space for the air to enter the humidification mixer passage, and at the same time for the steam to mix with the air;

[0028] The air collecting pipe 2, which is partly welded to the air intake pipe 1 at the top, is a C-shaped through pipe with a hollow structure;

[0029] The steam inlet pipe 3 installed at the top end of the gas collecting pipe 2 is the channel for steam to enter the humidifying mixer;

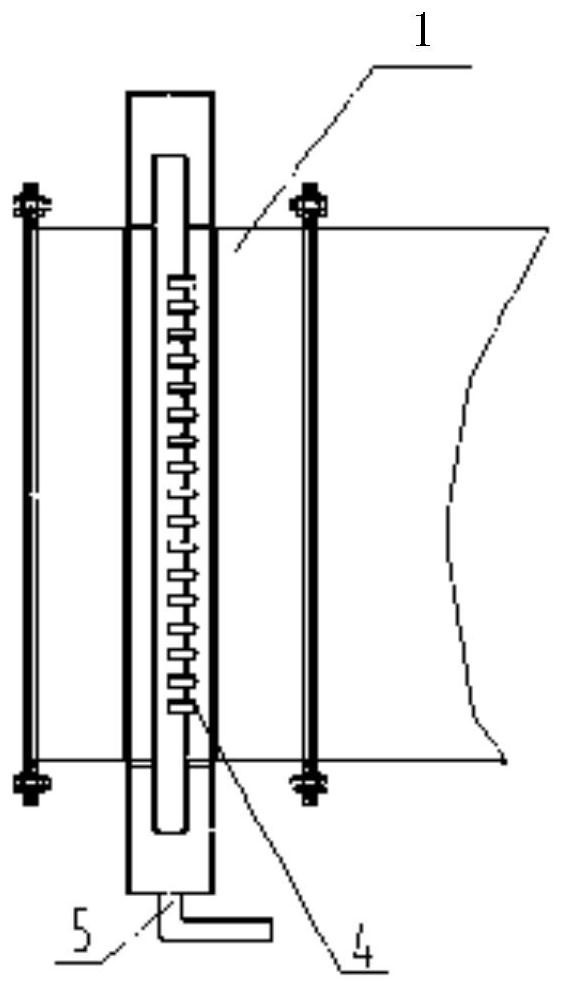

[0030] The humidifying rod 6 connected up and down with the gas collecting pipe 2, the humidifying rod 6 is a tubular structure, the upper and lower ends communicate with the gas collecting pipe 2, and the pipe body is welded somewhere in the air intake pipe 1, such as figure 2 shown;

[0031] There is a nozzle 4 on the humidifying rod 6, and the steam is ejected through the nozzle 4;

[0032] The condensation wat...

Embodiment 2

[0050] A working method of a humidifying mixer disclosed in an embodiment of the present application includes the following steps:

[0051] (1) The external saturated steam enters the humidifying mixer;

[0052] (2) The steam is ejected from the humidifying mixer and mixed with the air to humidify the air.

[0053] The specific implementation method of step (1) is: the external saturated steam enters the gas collecting pipe 2 through the steam inlet pipe 3, the steam on the upper part of the gas collecting pipe 2 enters the humidifying rod 6, and the steam that does not enter the humidifying rod 6 passes through the gas collecting pipe 2 to the humidifying rod 6. Part of the air intake pipe 1 is heated to reduce the condensation of this part of the steam, and at the same time, the remaining steam and part of the condensed water enter the condensed water pipe 5 through the air collecting pipe 2 and are discharged.

[0054] The specific implementation method of step (2) is: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com