Process for producing a motion sensor

A motion sensor and injection molding machine technology, which is applied to the assembly/disassembly of instruments, measuring instrument components, and contact pieces, can solve the problems of increasing manufacturing costs and manufacturing costs, reduce floor space requirements, facilitate costs, and avoid The effect of pressure load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

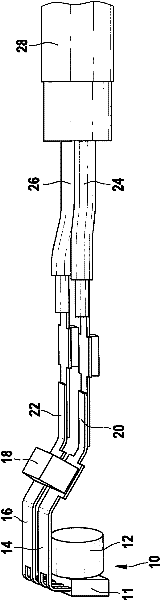

[0015] figure 1 An electric component 10 , which is injection-moulded with a thermoplastic material according to the proposed method, is shown for a rotational speed sensor for detecting the rotation of a vehicle wheel. The electrical assembly contains an IC functional block 11 with an integrated circuit for supplying measurement signals and outputting measured values. The magnetic field for generating the measurement signal is provided by a cylindrical permanent magnet 12 which is arranged directly adjacent to the IC functional block 11 . The two printed conductor strips 14 and 16 of the integrated circuit 11 are bridged via a capacitor 18 to eliminate signal peaks and are connected via crimped connections (crimping) 20 and 22 to the connecting conductors 24 and 26 of a cable 28 whose Together with the leads 24 and 26, the capacitor 18, the permanent magnet 12 and the integrated circuit 11, the front end is injection-molded with plastic to form a finished motion sensor whose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com