Pulley for use with toothed belt

A technology of timing belts and pulleys, used in belts/chains/gears, components with teeth, gear vibration/noise attenuation, etc., can solve the problems of fluid sound or loud cracking sound, and reduce fluid sound or cracking sound. , The effect of reducing meshing noise and easy discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

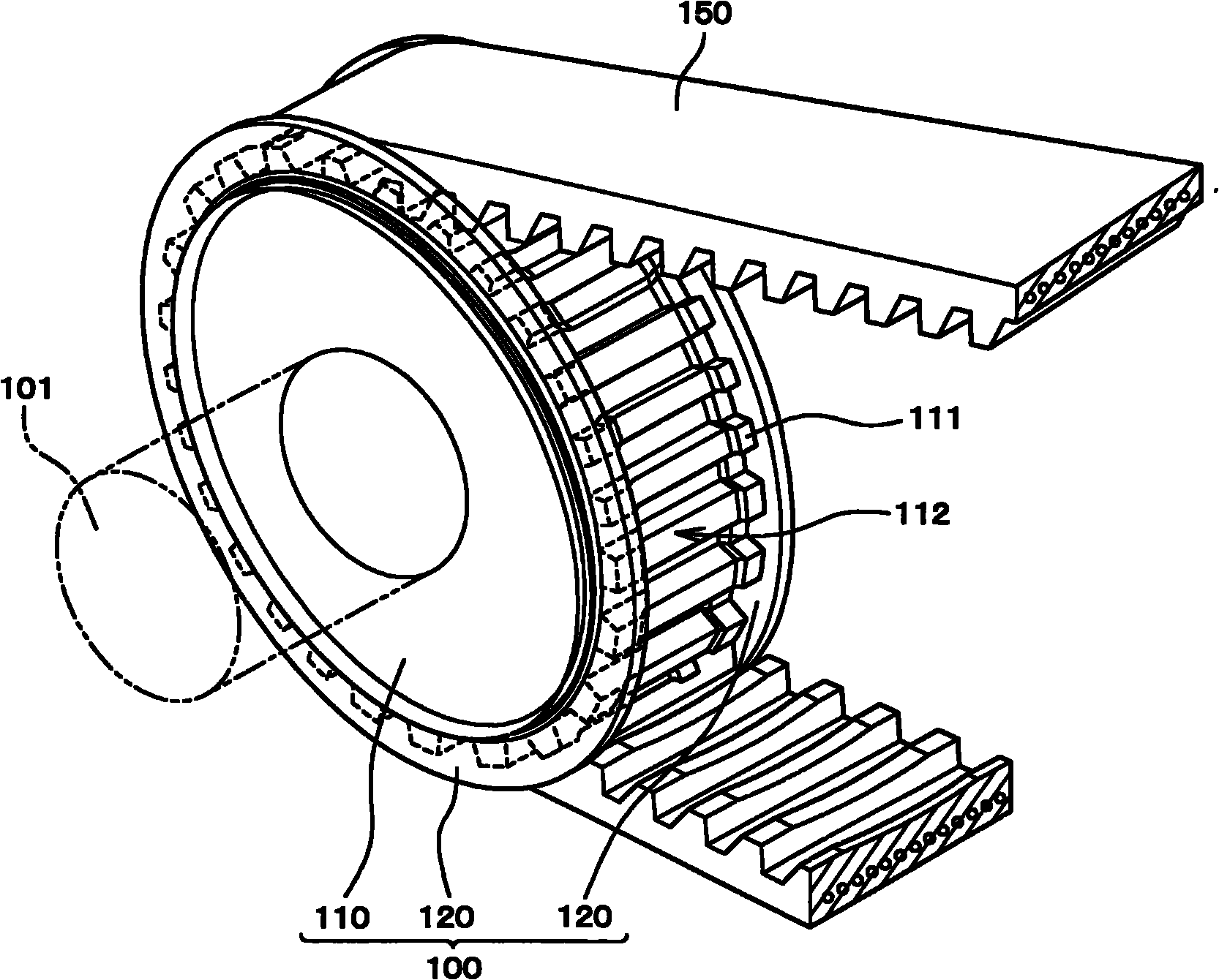

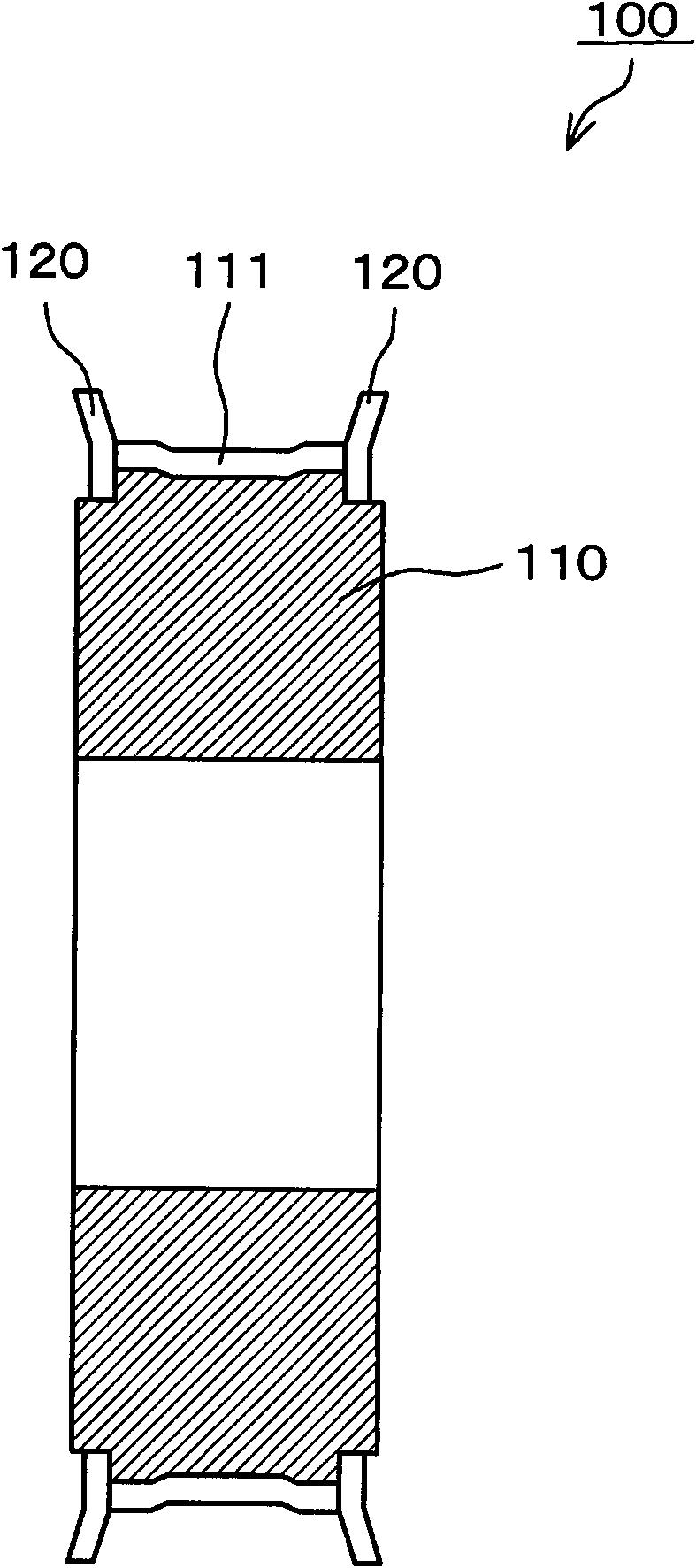

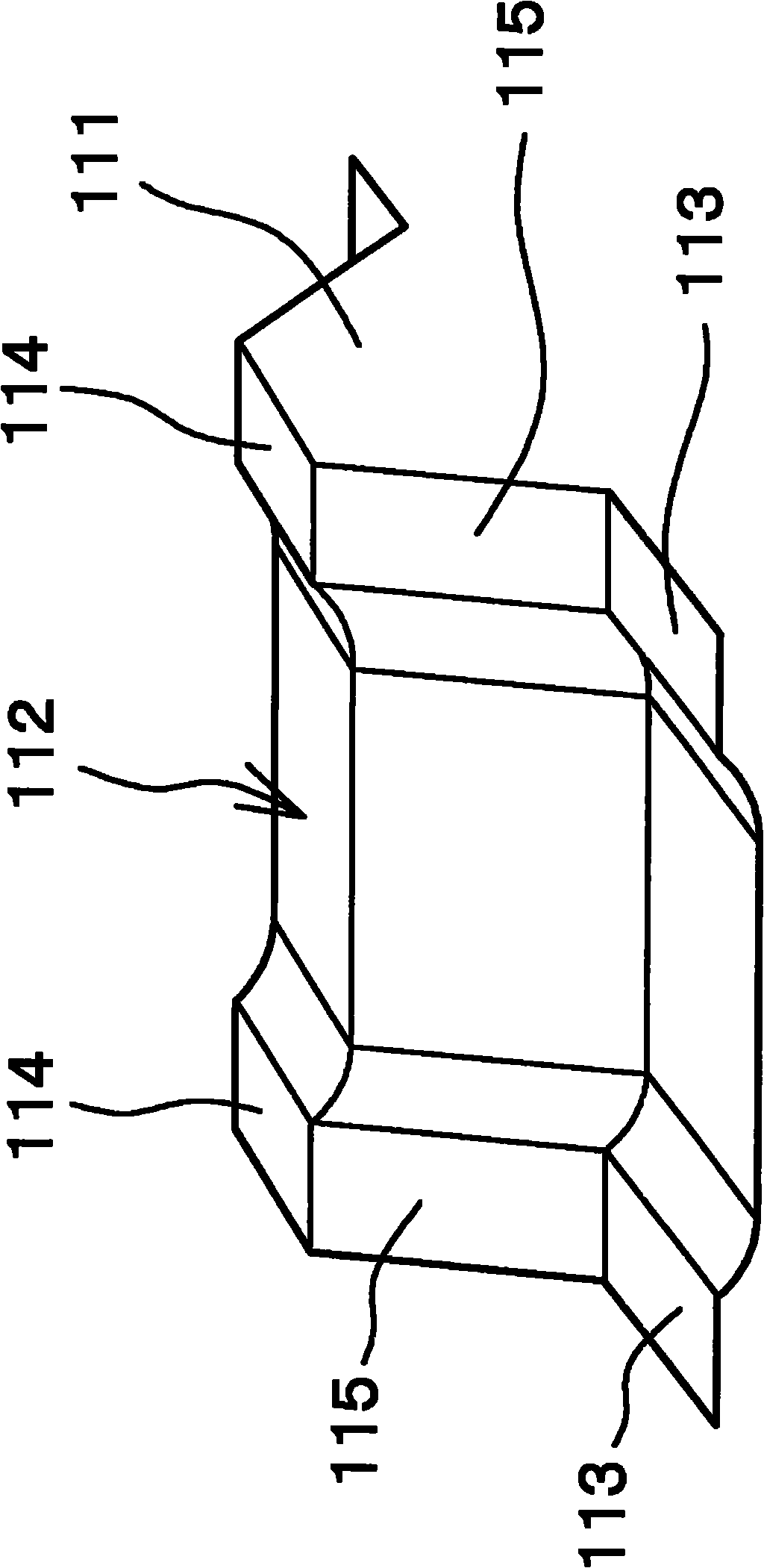

[0068] As the pulley 100 for a timing belt according to the first embodiment of the present invention, as figure 2 , image 3 As shown: the outer periphery of the disc body 110 with flanges 120 on both sides is provided with teeth 111 meshing with the timing belt 150 , and a recess 112 is formed in the center of the width direction of the teeth 111 . The recessed portion 112 extends over the entire outer circumference of the disk body 110 including the tooth end portion 114 , the tooth surface portion 115 , and the tooth bottom portion 113 of the tooth 111 , and has a constant width and a constant depth from the surface.

[0069] If the synchronous belt 150 is engaged with the pulley 100 for this synchronous belt, then as Figure 4 to Figure 6 Shown: only the two ends of the width direction of the synchronous belt 150 are in contact with the tooth end 114, the tooth surface 115 and the tooth bottom 113 of the original tooth 111, and the central part of the synchronous belt 1...

no. 2 example

[0076] As the pulley 200 for a timing belt according to the second embodiment of the present invention, as Figure 7 , Figure 8 As shown: the outer periphery of the disc body 210 with flanges 220 on both sides is provided with a tooth 211 meshed with the synchronous belt, and a recessed part 212 is formed in the central part of the width direction of the tooth 211, and the recessed part 212 The center in the width direction has a deeper concave groove portion 216 extending over the entire outer circumference of the disc body 210 . The recessed portion 212 extends over the entire outer circumference of the disc body 210 including the tooth end portion 214 , tooth surface portion 215 , and tooth bottom portion 213 of the tooth 211 , and has a constant width and a constant depth from the surface.

[0077] In this way, in addition to forming the remaining gaps near both ends of the recessed part 212, a gap is also formed by the groove part 216. When the pulley 200 for the timing...

no. 3 example

[0080] As the pulley 300 for a timing belt according to the third embodiment of the present invention, as Figure 9 , Figure 10 As shown: the outer periphery of the disc body 310 with the flange 320 on both sides is provided with a tooth 311 engaged with the synchronous belt, and a recessed part 312 is formed in the central part of the width direction of the tooth 311, while the recessed part 312 has a convex portion 317 extending over the entire outer circumference of the disc body 310 at the center in the width direction. The recessed portion 312 extends over the entire outer circumference of the disc body 310 including the tooth end portion 314 , the tooth surface portion 315 , and the tooth bottom portion 313 of the tooth 311 , and has a constant width and a constant depth from the surface.

[0081] In this way, even if the timing belt bends in an arcuate shape, it is still in contact with the convex portion 317 in the center of the width direction of the concave portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com