Novel seal washer structure

A sealing gasket, a new type of technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of hidden dangers in the production process, damaged gasket performance, low service life and durability, etc., to improve leakage prevention ability and improve Sealing performance, effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings .

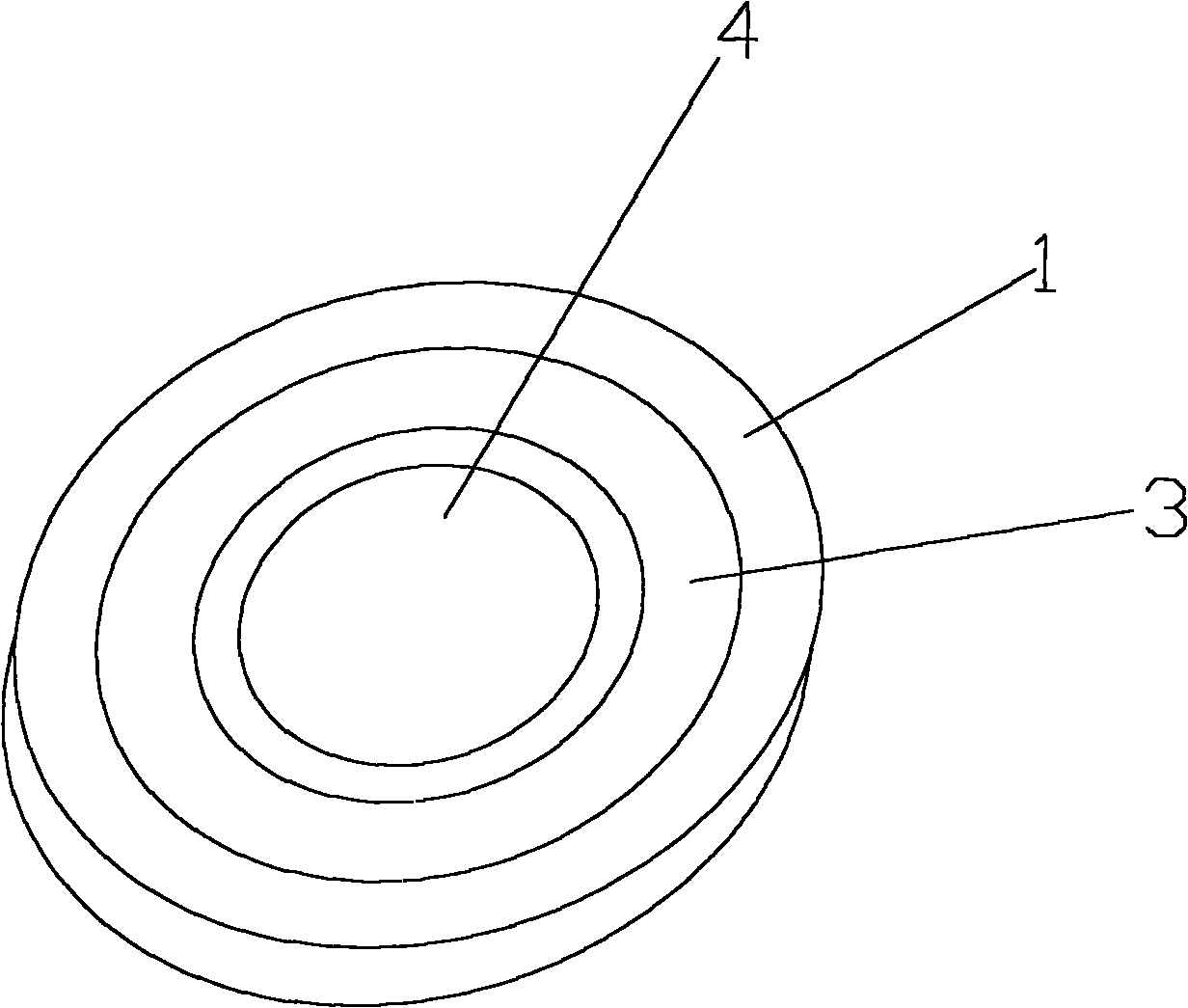

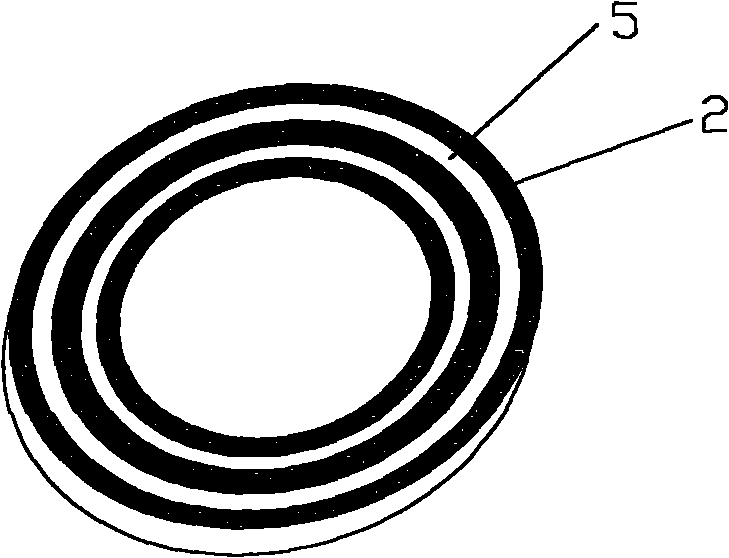

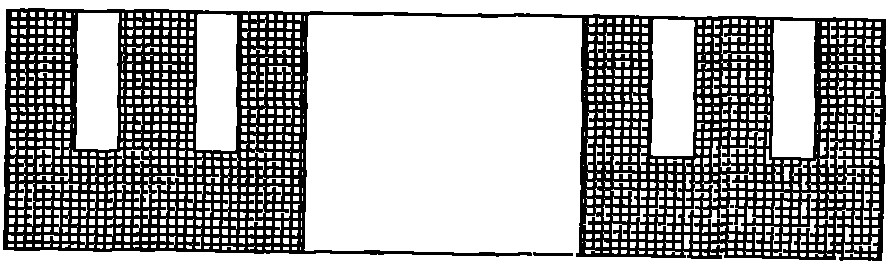

[0019] figure 1 It is a structural schematic diagram of a new sealing gasket according to an embodiment of the present invention, figure 2 It is a structural schematic diagram of a new sealing gasket inner ring according to an embodiment of the present invention, image 3 It is a sectional view of the inner ring of a new sealing gasket according to the embodiment of the present invention; the gasket includes a body 1 and an inner ring 2, the body 1 is provided with an annular groove 3 and an inner hole 4, and the inner ring 2 is provided with There is an annular groove 5, and the body 1 and the inner ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com