Angular impact table

A technology of impact table and table body, which is applied in the direction of speed/acceleration/shock measurement, test/calibration of speed/acceleration/shock measurement equipment, measurement device, etc. It can solve the problem of low accuracy, improve accuracy, reduce interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

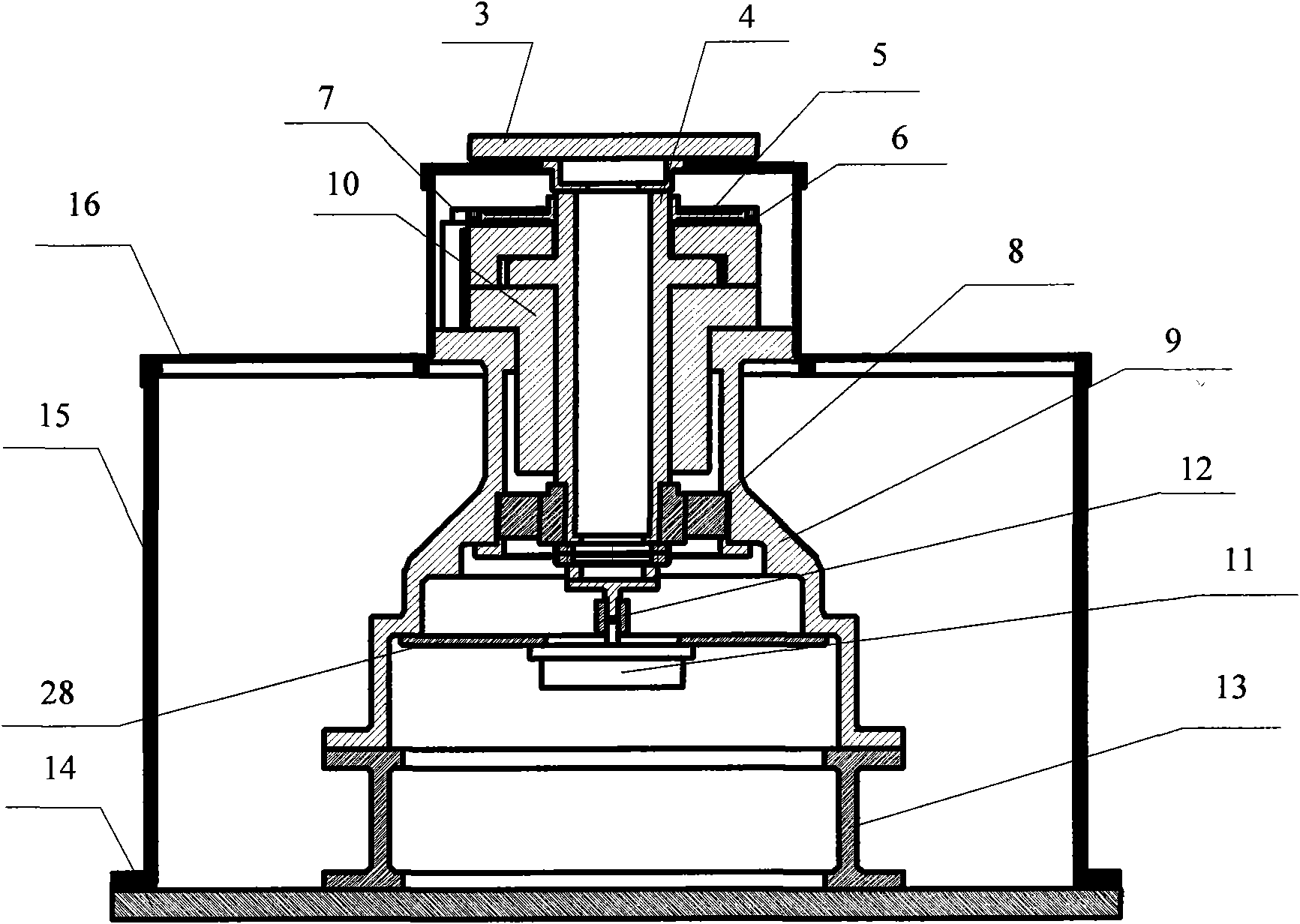

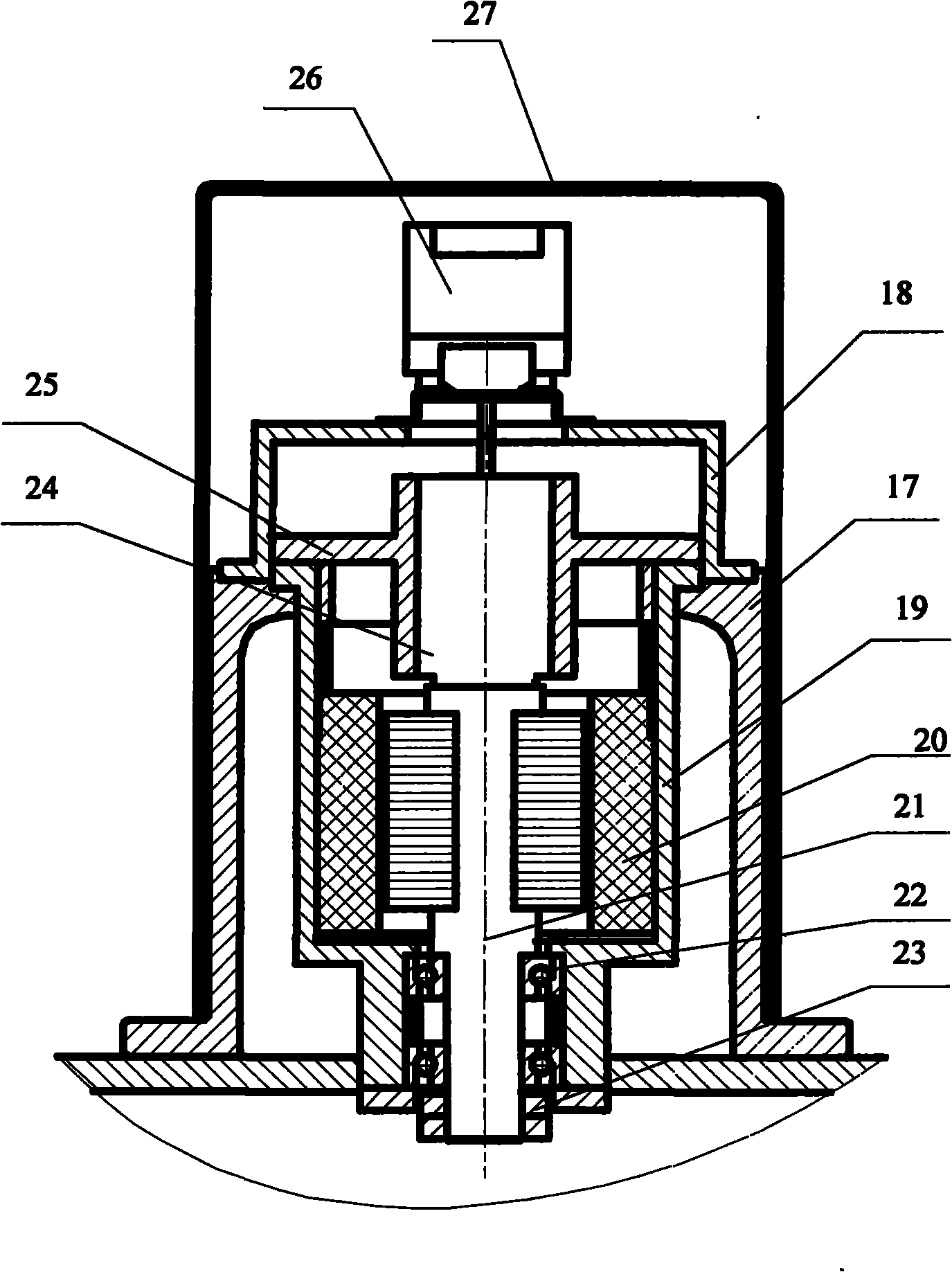

[0014] The angle impact table includes a main motion structure 1 and a slave motion structure 2,

[0015] The main moving structure 1 includes: a working table 3, a moving spindle 4, a measuring grating 5, a grating base 6, a grating reading head 7, a casing 9, a main driving motor 8, an air bearing sleeve 10, a rigid coupling 12, Grating 11 for control, support seat 13, base 14, table body 15, upper cover plate 16, worktable 3 is installed on the upper shaft end of the movement spindle 4, grating 5 for measurement passes through the grating seat 6 and the movement spindle below the worktable 3 4 connected, the dynamic movement main shaft 4 rotates in the air bearing sleeve 10, the air bearing sleeve 10 is installed on the housing 9, the grating reading head 7 is installed on the housing 9 and placed outside the air bearing sleeve 10; The stator of the driving motor 8 is installed on the casing 9, and the rotor of the main driving motor 8 is connected with the moving main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com