Roller as well as device and method for rolling steel rails

A roll and rail technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of affecting the formability of the rail, affecting the straightening effect of the rail, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Improve the universal pass finishing mill to obtain the equipment for rolling rails of the present invention, the improvement is to use the rolls of the present invention as various types of rolling rails with a bottom width of less than 250mm manufactured by German SMS Siemag. The rail bottom vertical roll of the finishing mill of the universal rolling mill unit of the rail.

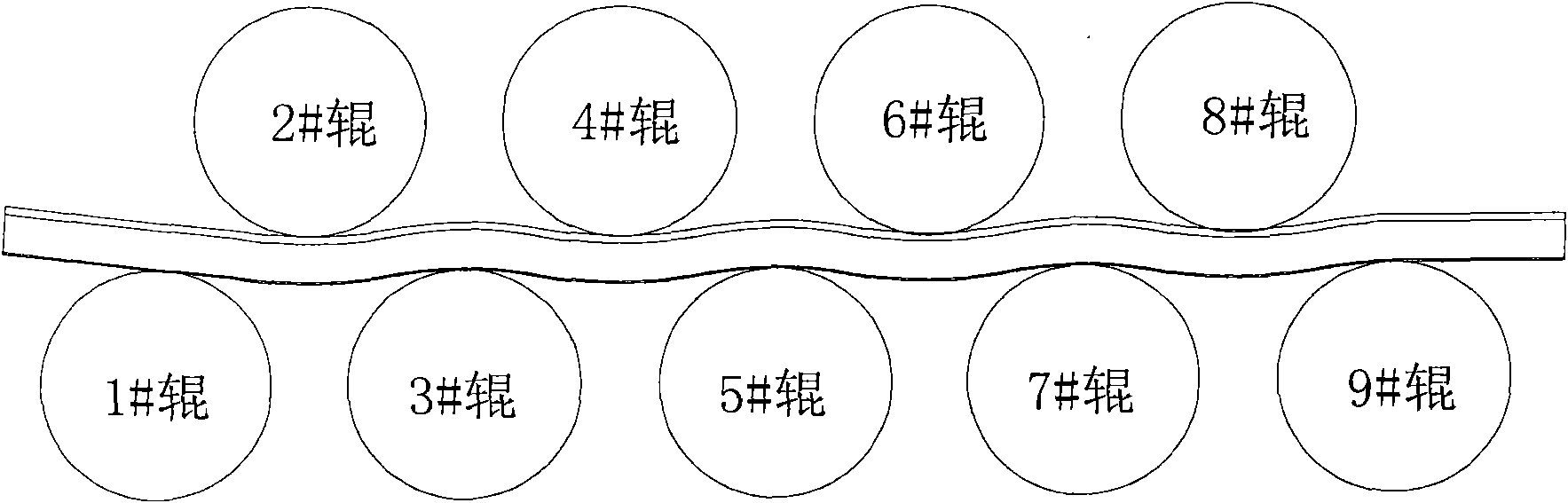

[0031]Use U75V material to roll steel rails; first, heat the rail blank to 1210°C for billet rolling, and the section shrinkage of billet rolling is 78.5%; use a universal reversible groove rolling mill to perform intermediate rolling at 1060°C, intermediate rolling The area shrinkage rate of the steel plate is 61.7%; use the above-mentioned improved universal pass finish rolling mill to carry out finish rolling at 950°C, and the area shrinkage rate of the finish rolling is 4.7%; after the rail is cooled for 3 hours, the rail temperature is lower than 60°C, and the roller Type straightening machi...

Embodiment 2

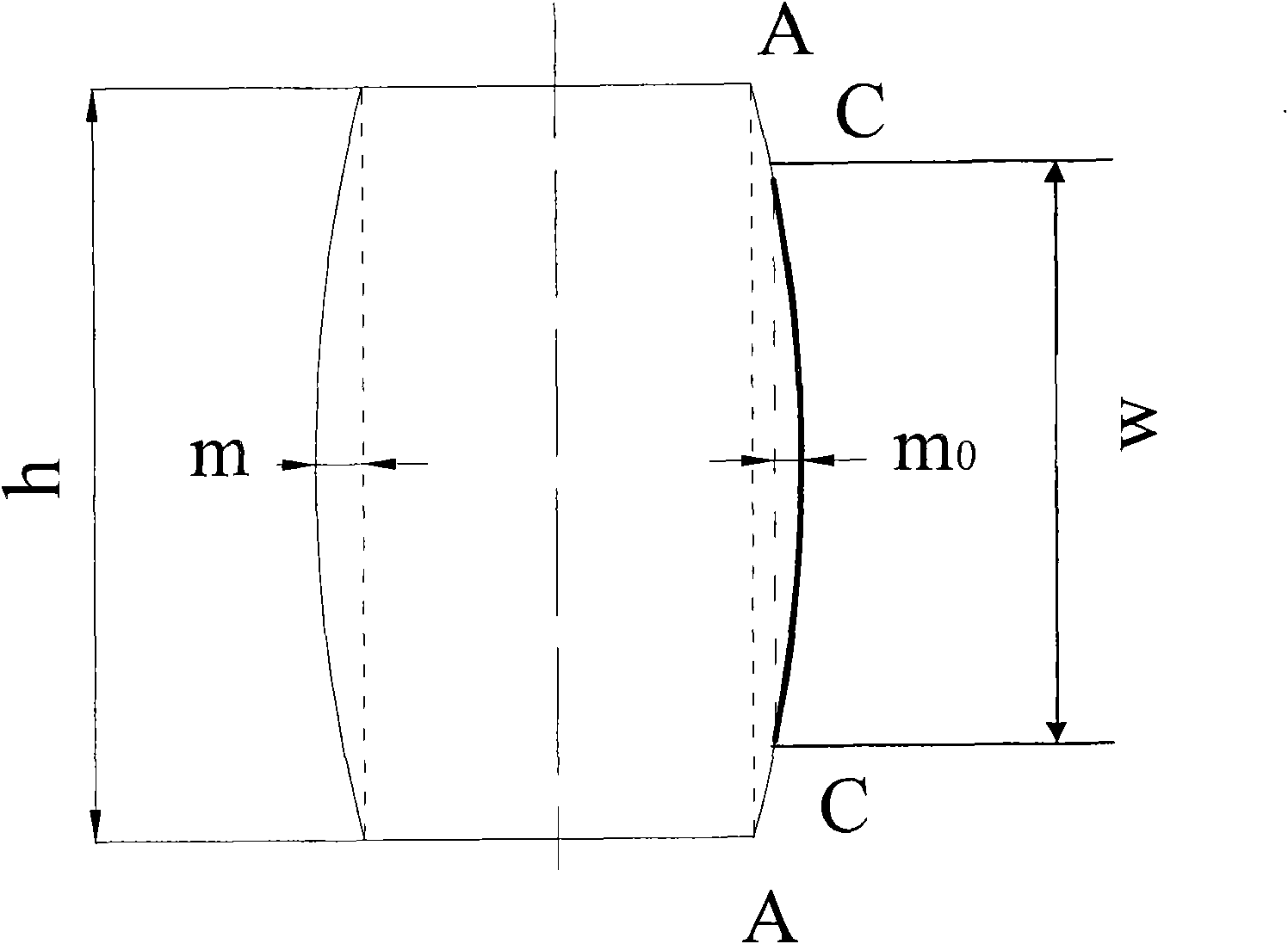

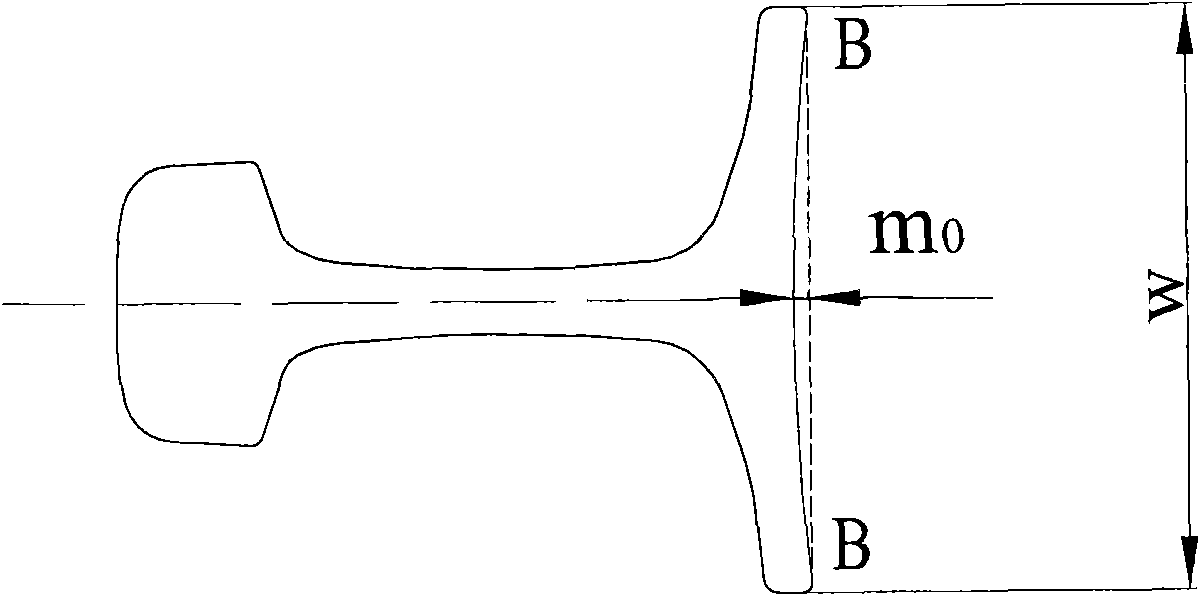

[0033] The rail is rolled according to the method of Example 1, the difference is that: the rail blank is heated to 1220°C for billet rolling, and the area shrinkage of billet rolling is 79.3%; The intermediate rolling is carried out, and the section reduction rate of the intermediate rolling is 62.5%; the finished rolling is carried out at 940°C using an improved universal pass finish rolling mill, and the section shrinkage rate of the finish rolling is 5.1%; after the rail is cooled for 2.5 hours, use a roller Type straightening machine for straightening, the straightening reduction is 37.5mm, wherein, the reduction of 2# roller, 4# roller, 6# roller and 8# roller are respectively 16mm, 14mm, 6mm, 1.5mm, with Obtain the steel rail that specification is 68kg / m. Among them, the chord height m of the arc shape A⌒A of the rail bottom vertical roll of the finishing mill is 1.69mm, and the chord height m of the arc shape C⌒C formed by the complete contact part 0 0.5mm.

Embodiment 3

[0035] The rail is rolled according to the method of Example 1, the difference is that: the rail blank is heated to 1230°C for billet rolling, and the area shrinkage of billet rolling is 80.6%; Carry out intermediate rolling, the area reduction rate of intermediate rolling is 62.4%; Use the improved universal pass finish rolling mill to carry out finish rolling at 920 ℃, the area reduction rate of finish rolling is 5.5%,; After the rail is cooled for 2.5 hours, use Roller straightening machine is straightened, and straightening reduction is 35mm, and wherein, the reduction of 2# roller, 4# roller, 6# roller and 8# roller is respectively 15mm, 13mm, 6mm, 1mm, to obtain The specification is 60kg / m rail. Among them, the chord height m of the arc shape A⌒A of the rail bottom vertical roll of the finishing mill is 1.39mm, and the chord height m of the arc shape C⌒C formed by the complete contact part 0 0.4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com