Automatic centering argon blowing device connector

An automatic centering and connector technology, used in casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing driver fatigue, damage to the argon blowing device at the bottom of the ladle, easy to break, etc., to improve refining production. Efficiency, easy operation by crane drivers, and shortened connection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

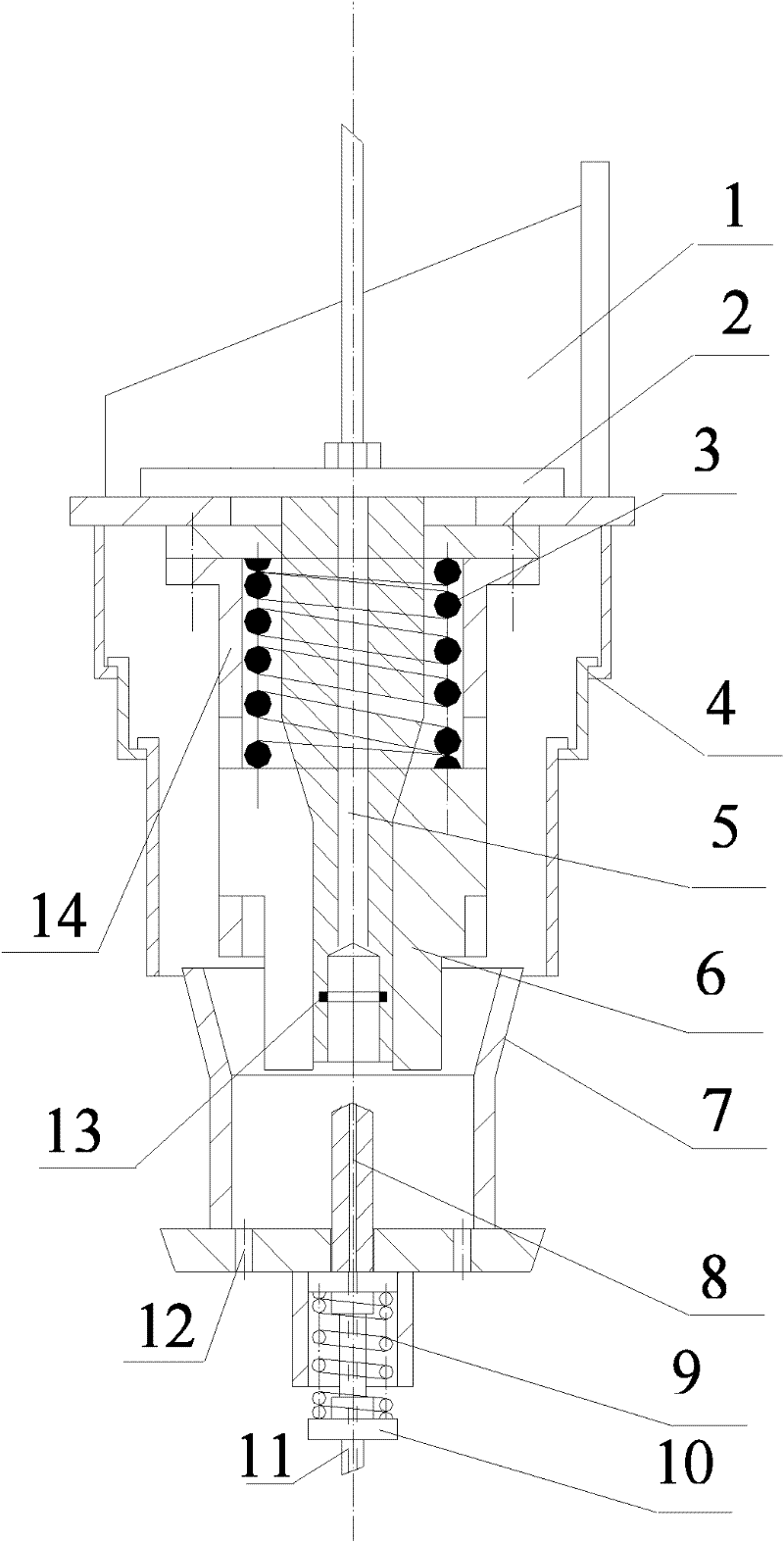

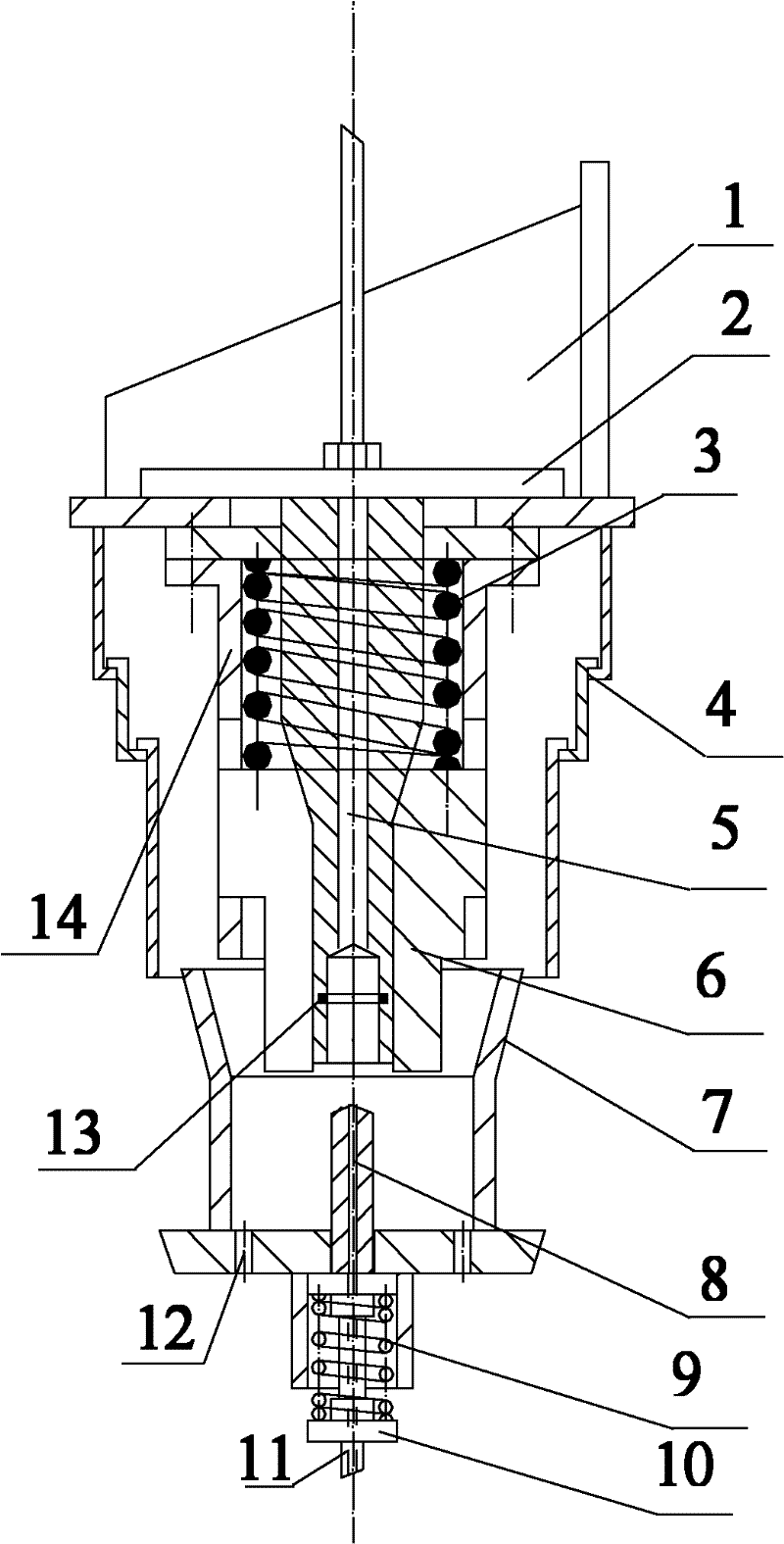

[0026] The connector of the self-centering argon blowing device of the present invention will be described in detail below through specific embodiments with reference to the accompanying drawings.

[0027] The connector of the self-centering argon blowing device includes a support 1, a supporting plate 2, a spring 3, a telescopic protective cover 4, 5, a three-claw centering device 6, a guide sleeve 7, a plug 8, a spring 9, a spring seat 10 and Argon metal hose 11, dust discharge hole 12, O-ring 13 and socket jacket 14.

[0028] The support 1 is provided with an elliptical groove along the infinite direction of the ladle car, and the socket 5 slides in the elliptical groove under the guidance of the three-claw centering device 6 .

[0029] The plug 8 is installed on the ladle transport vehicle, and the whole is made of stainless steel, and the head is hemispherical. The plug 8 is provided with an air inlet for argon to pass through.

[0030] The telescopic protective cover 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com