Patents

Literature

33results about How to "Accurately fall on" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

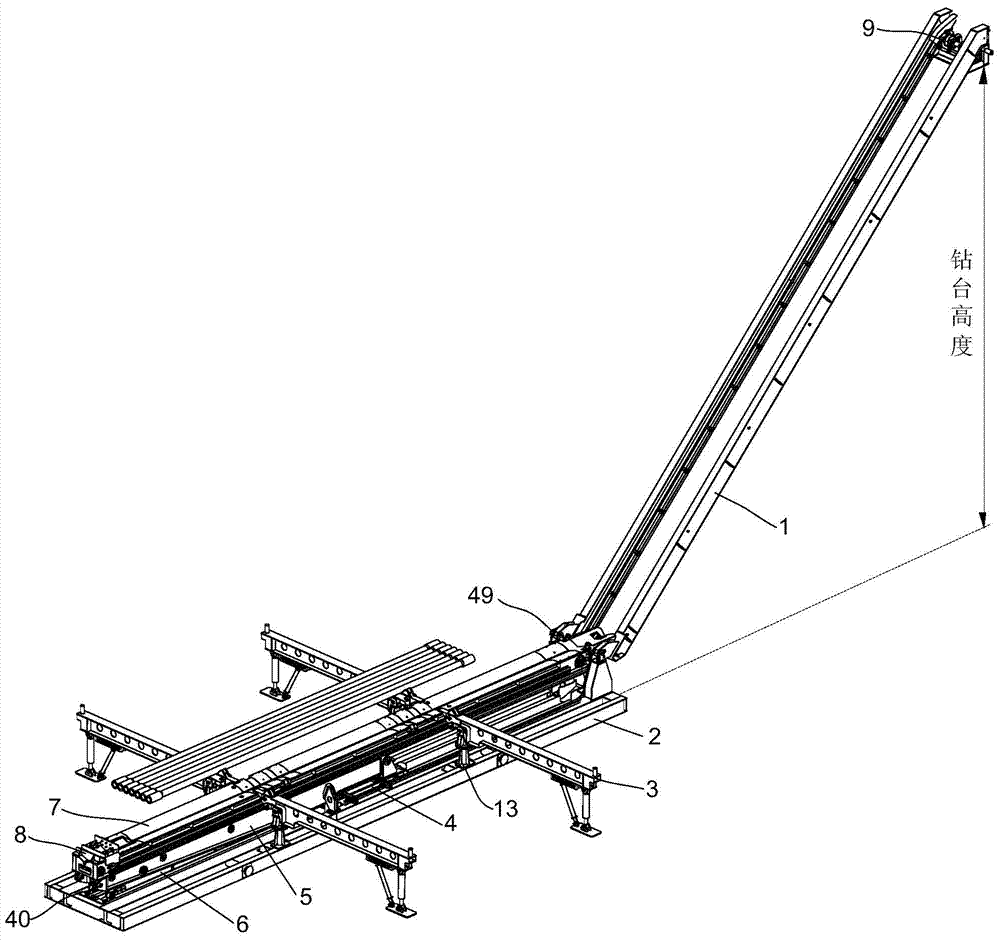

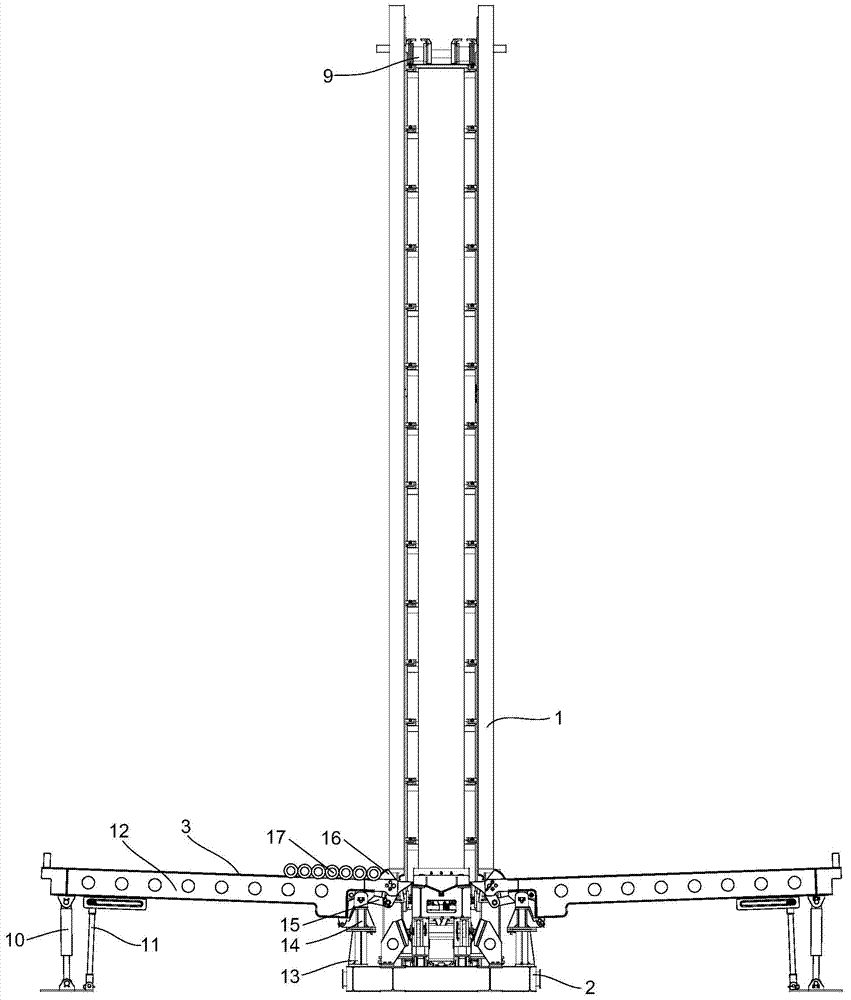

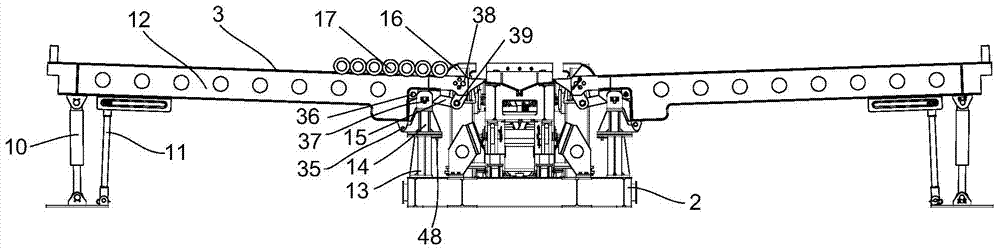

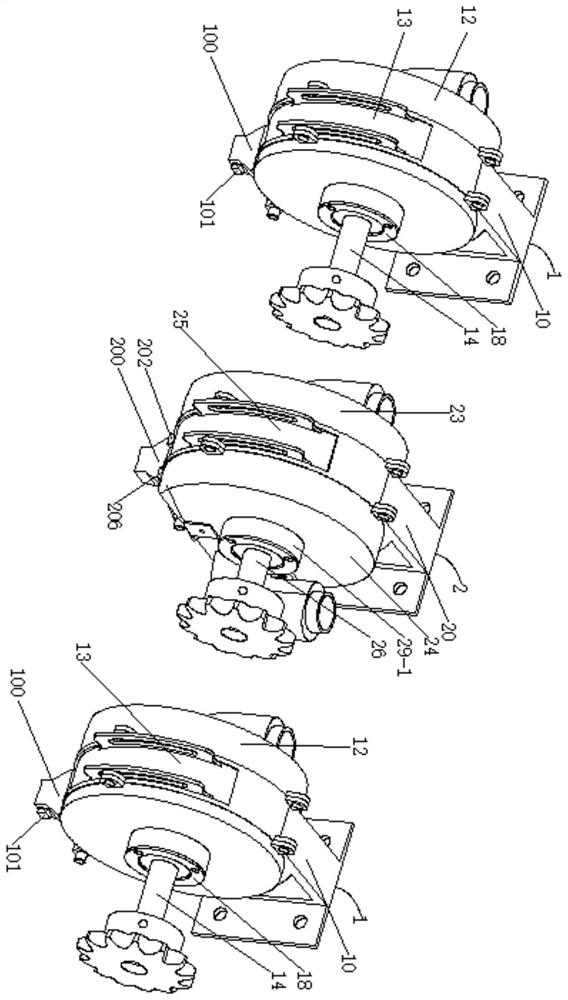

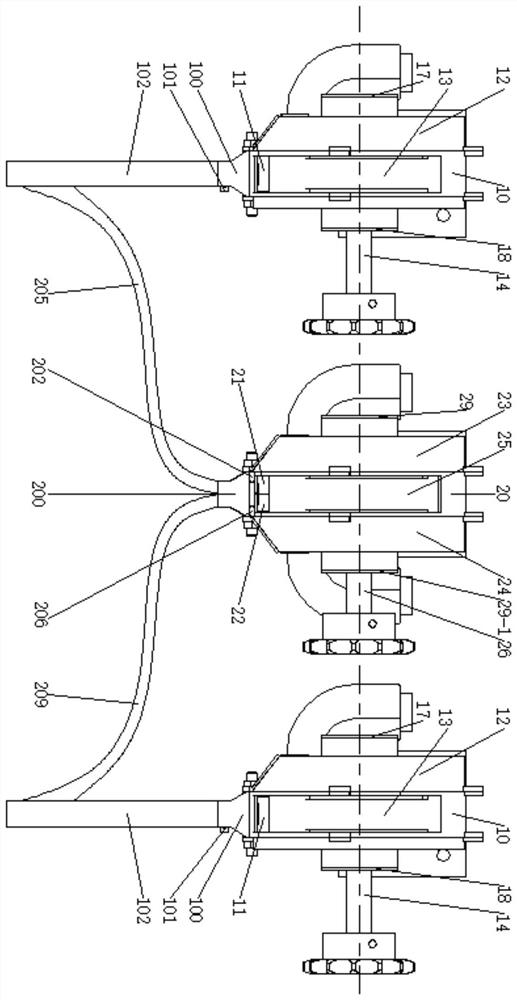

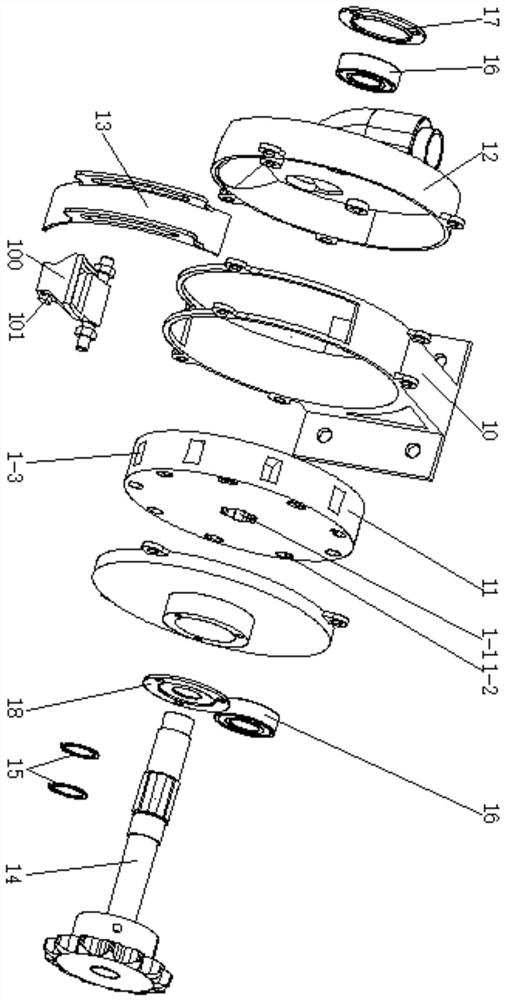

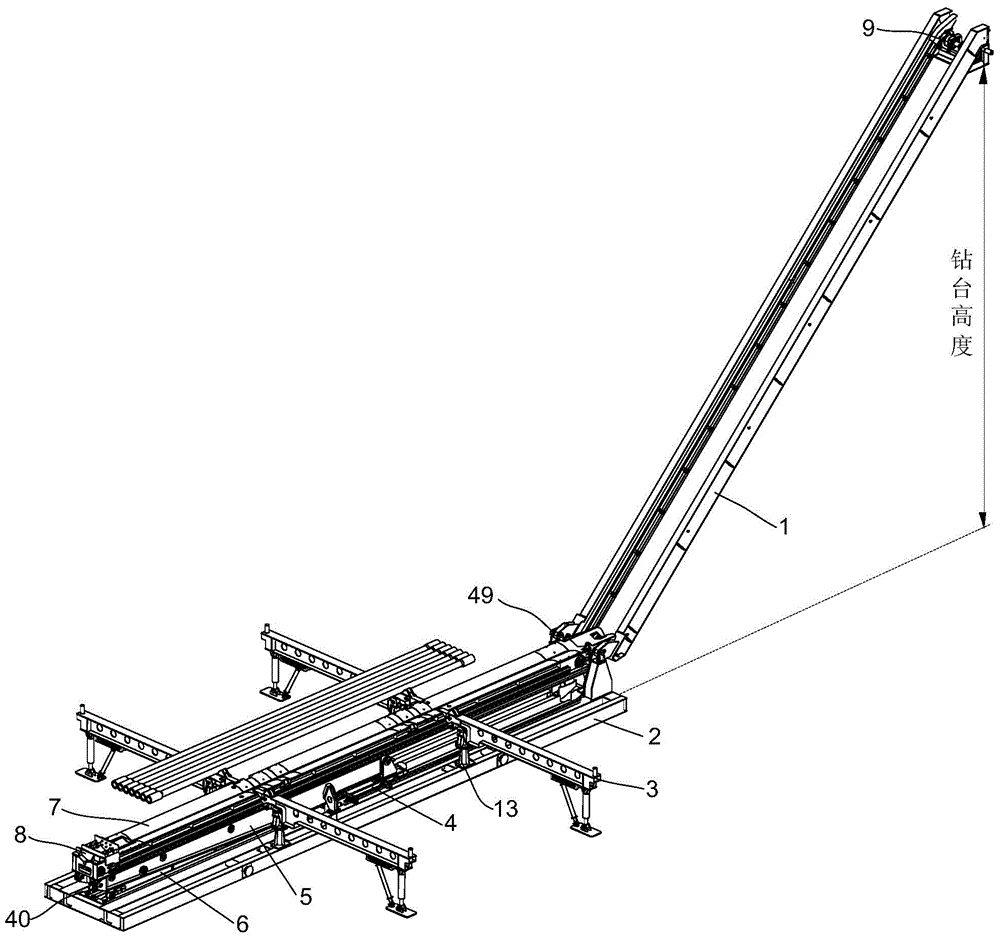

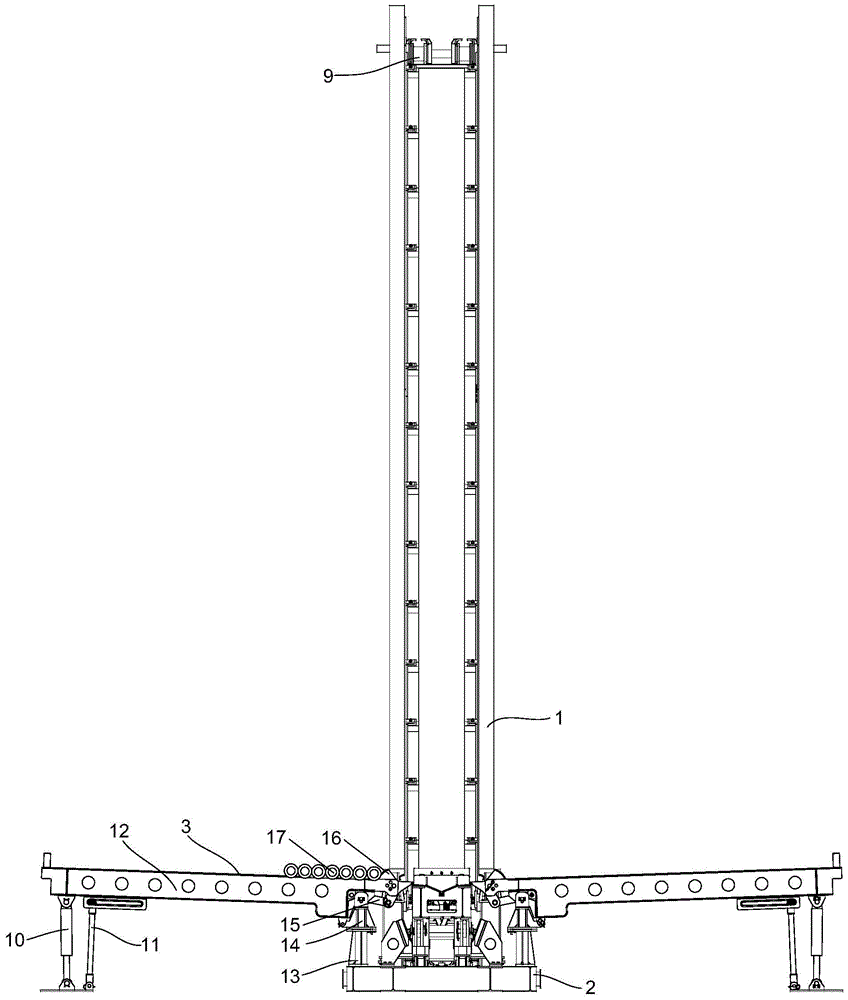

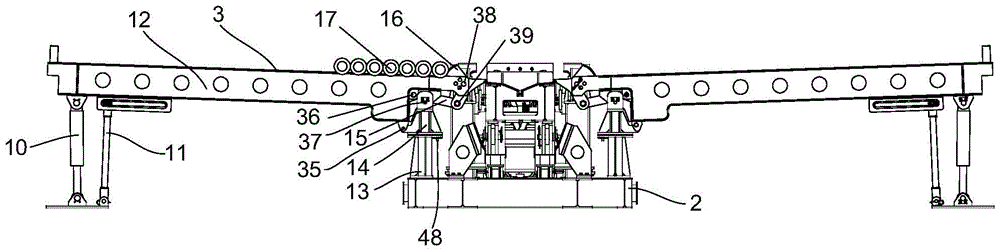

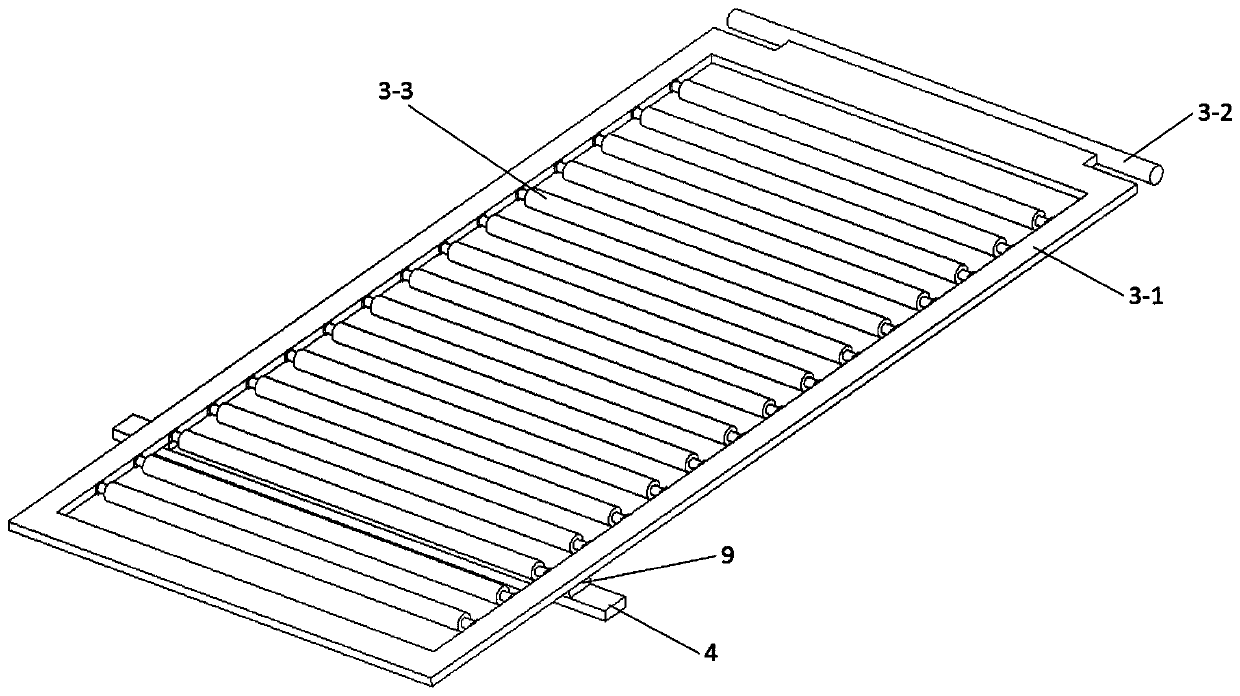

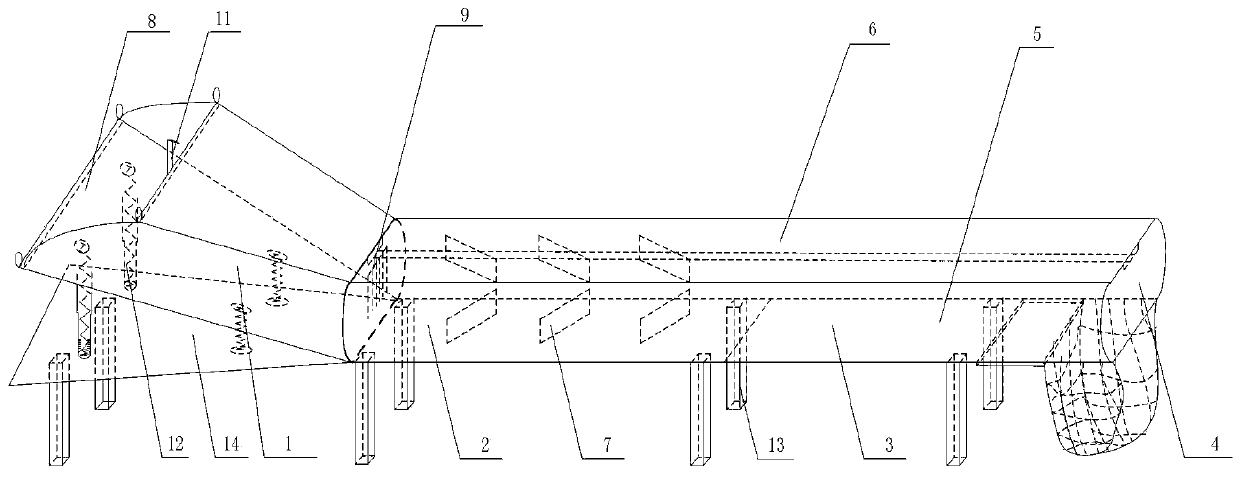

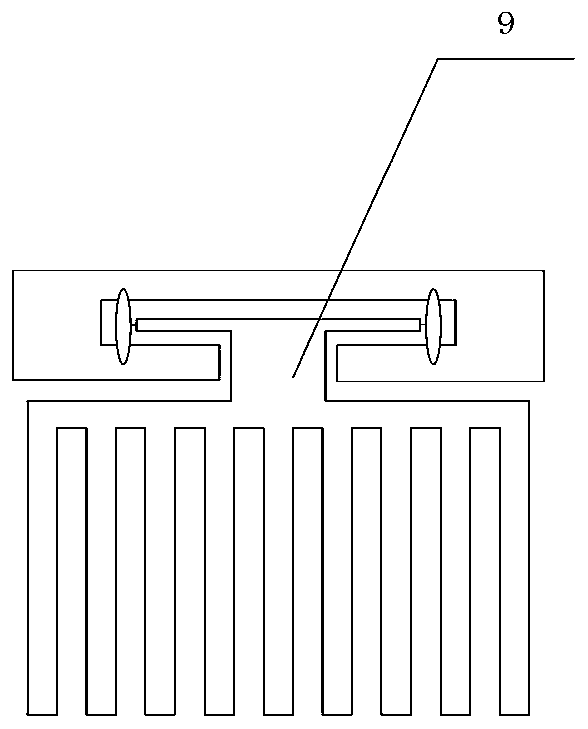

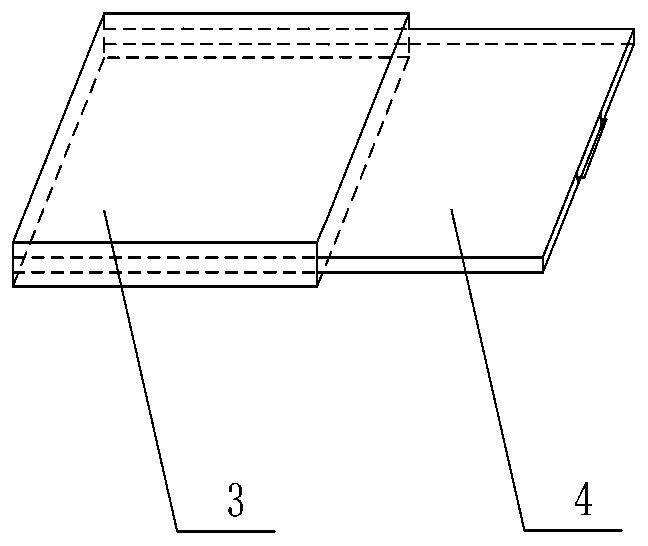

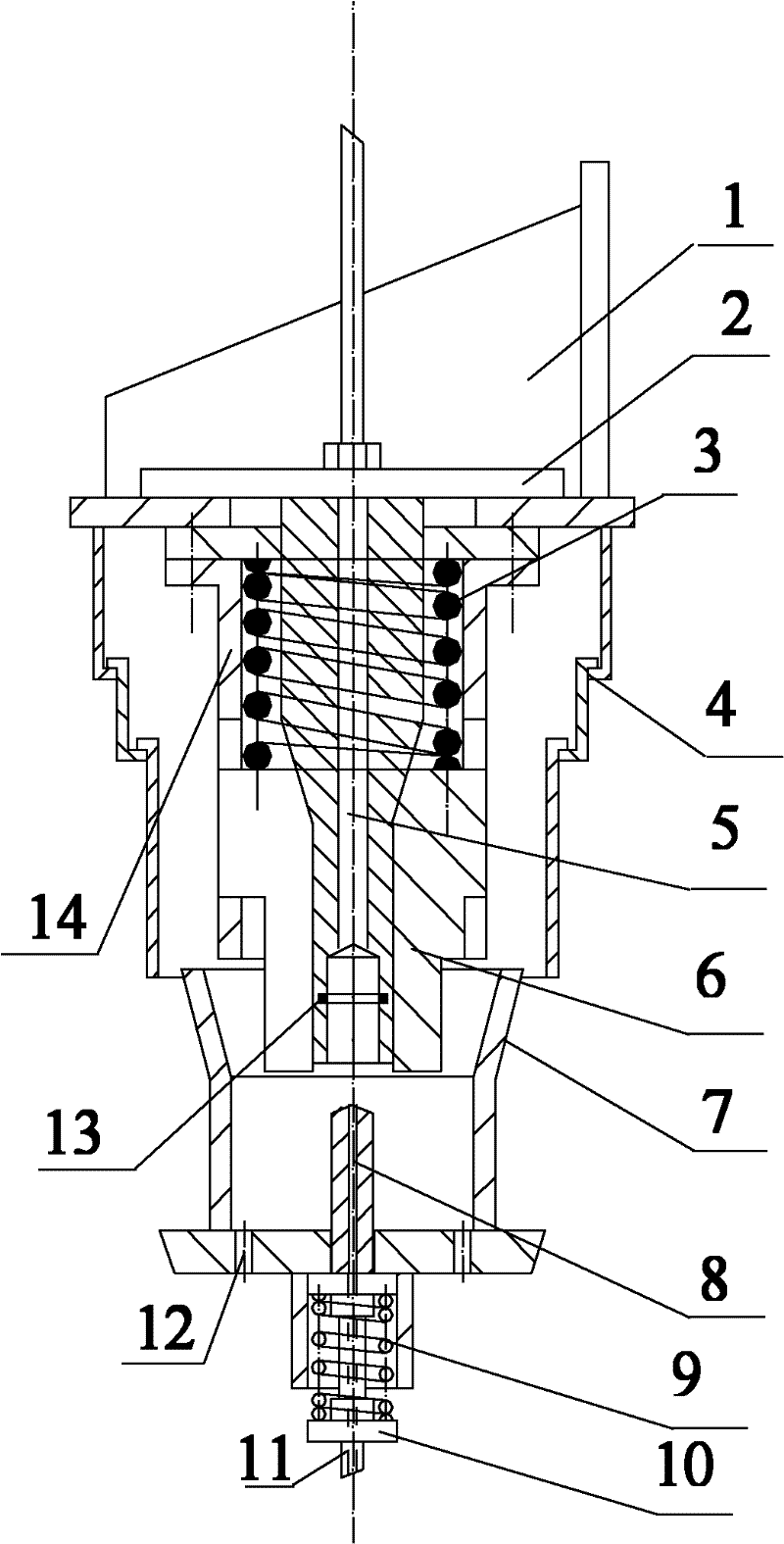

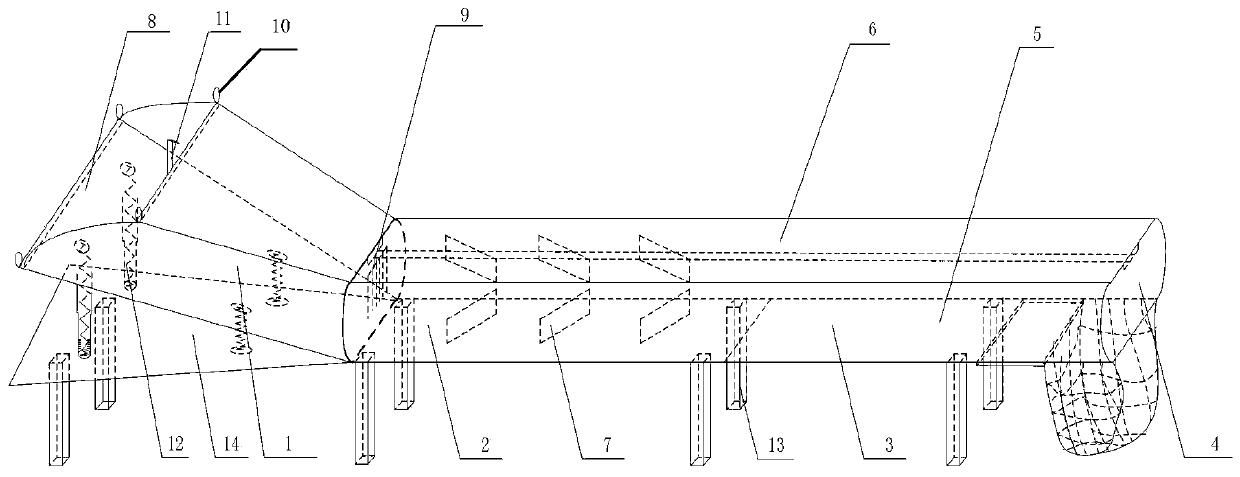

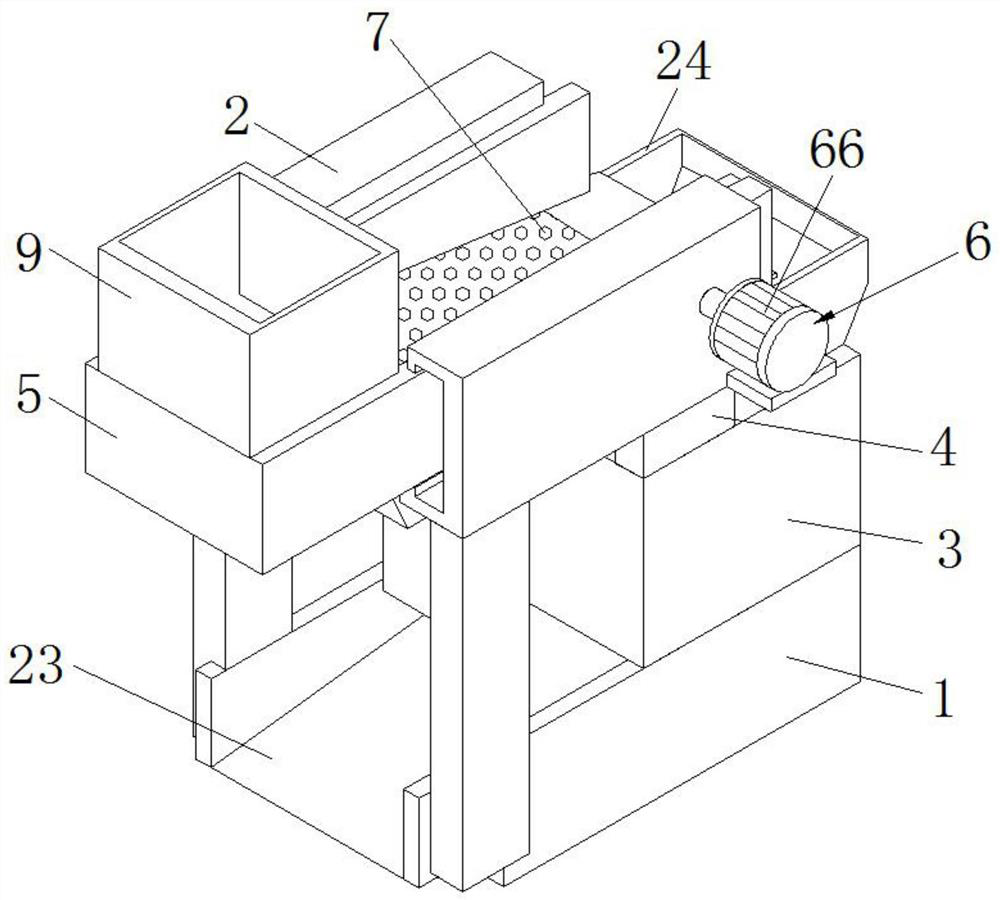

Hoisting land power catwalk of cylinder

ActiveCN104265207AImprove work efficiencyThe drill effect is obviousDrilling rodsDrilling casingsOil drillingPulley

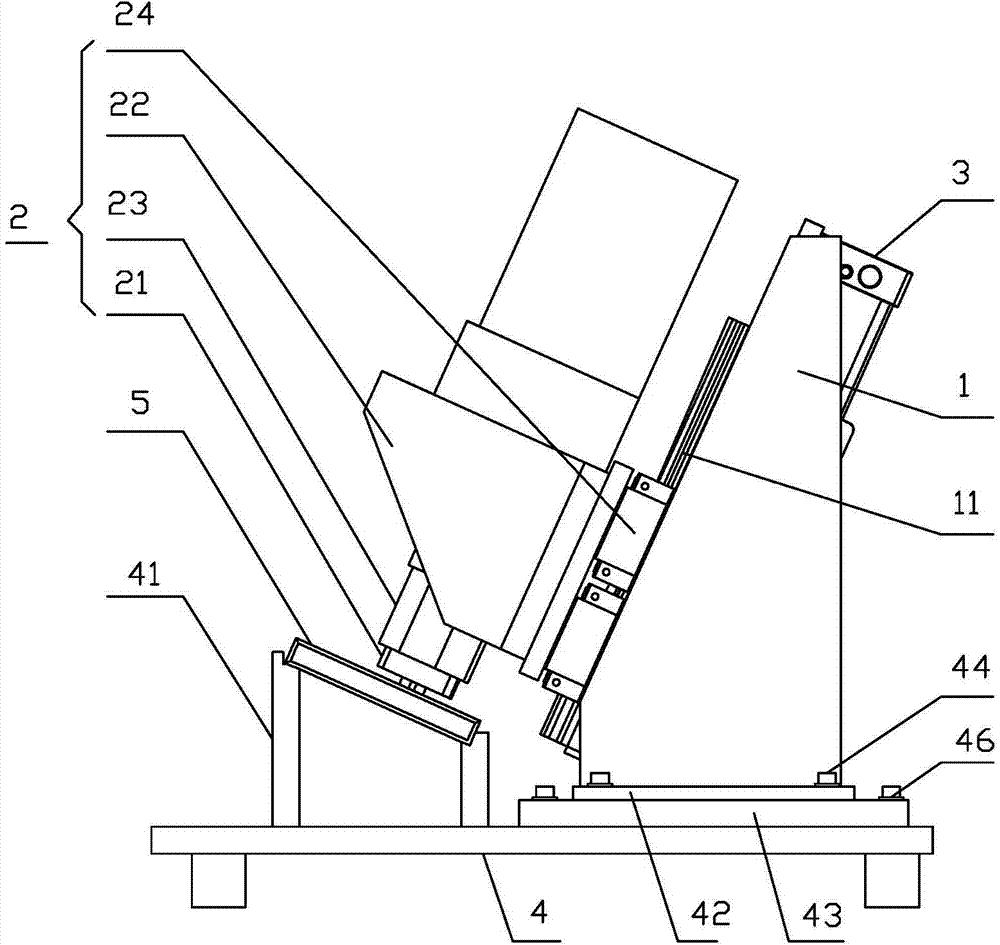

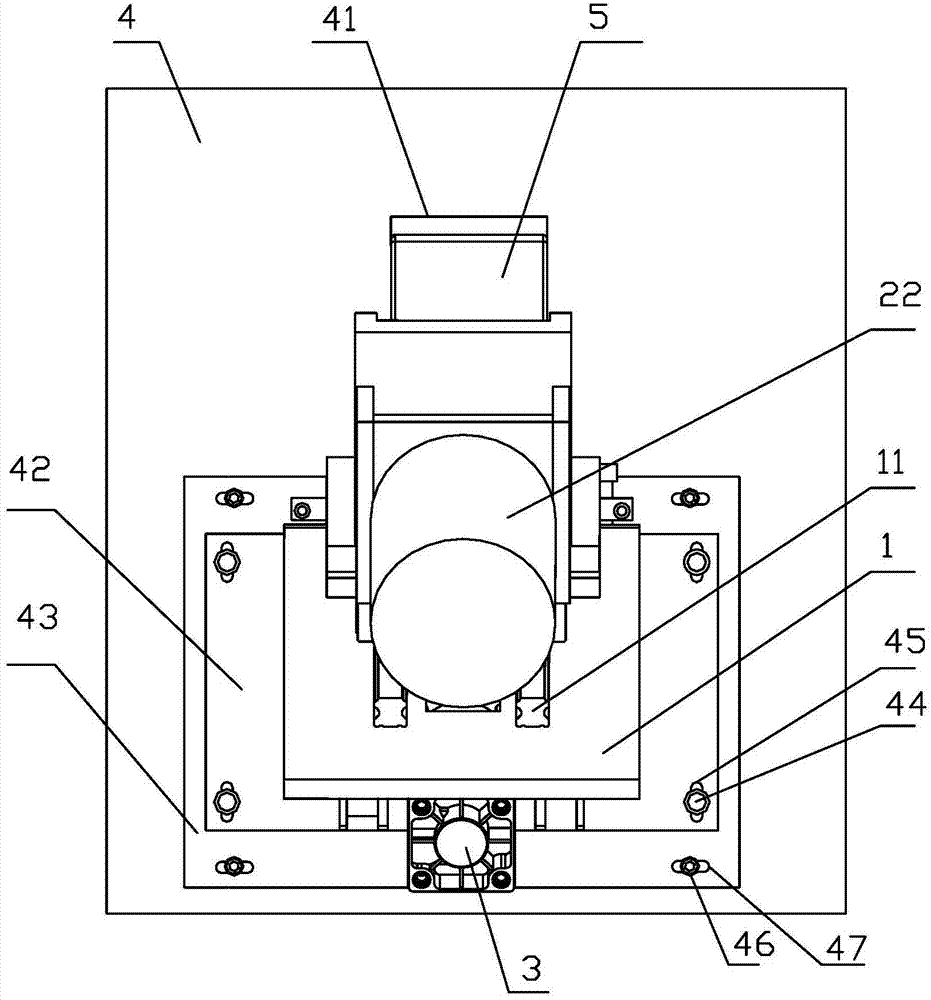

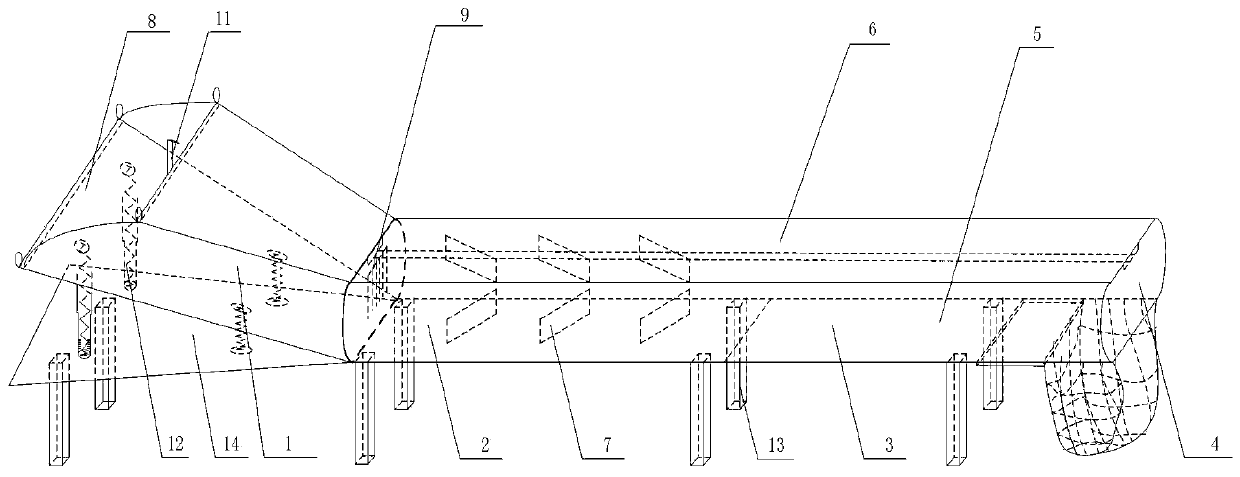

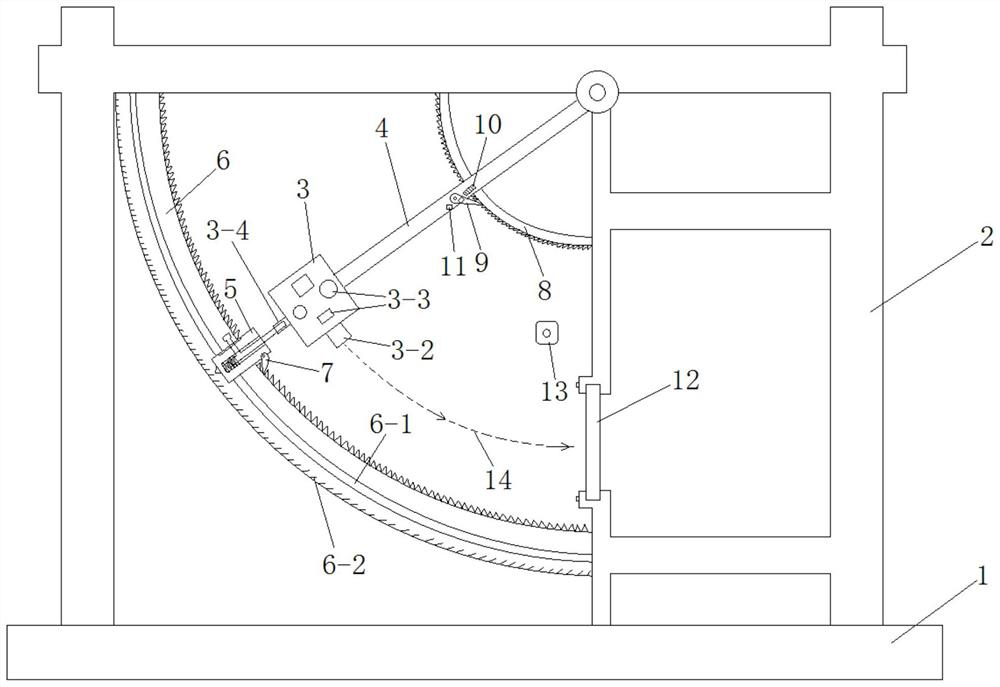

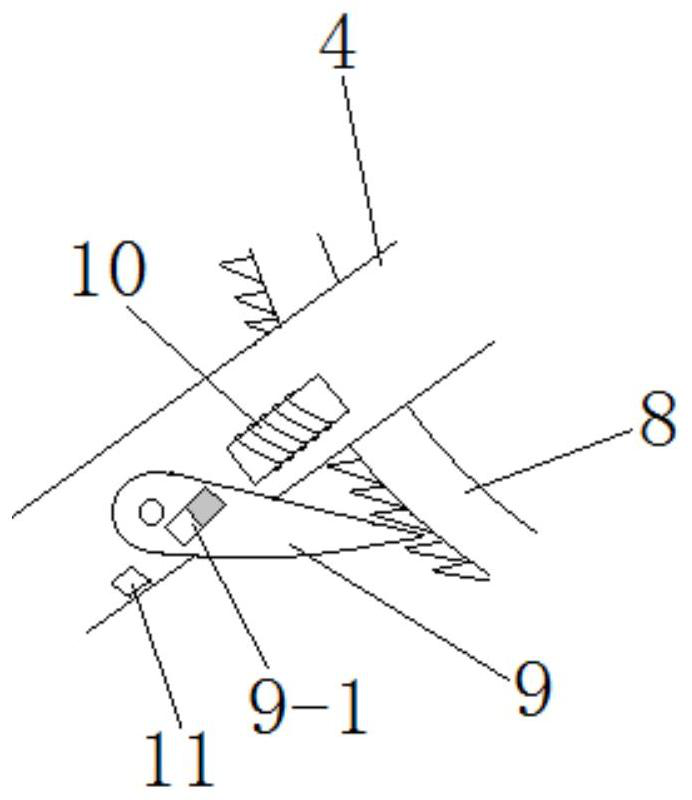

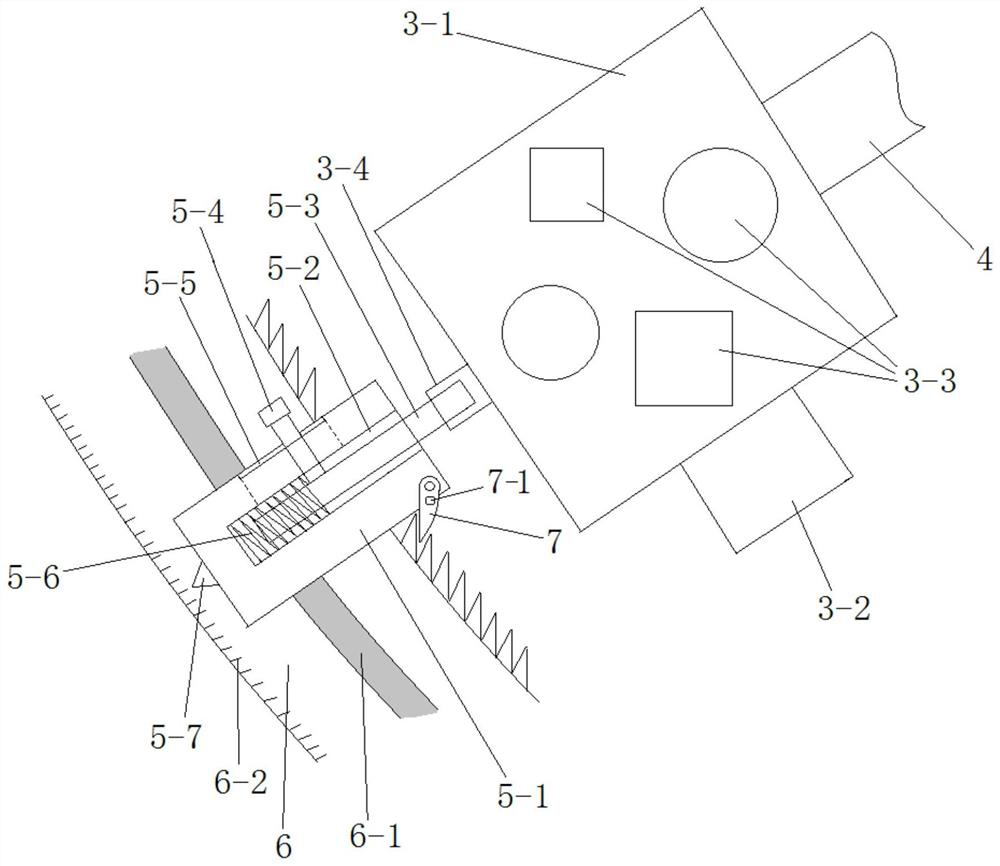

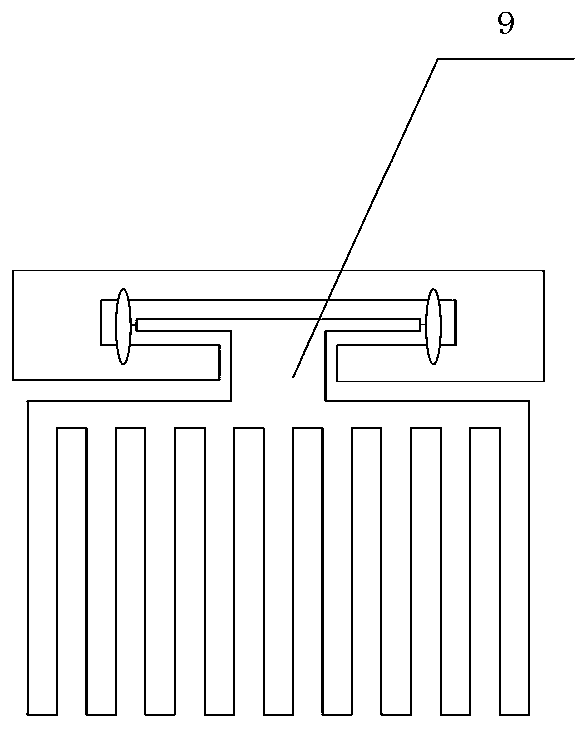

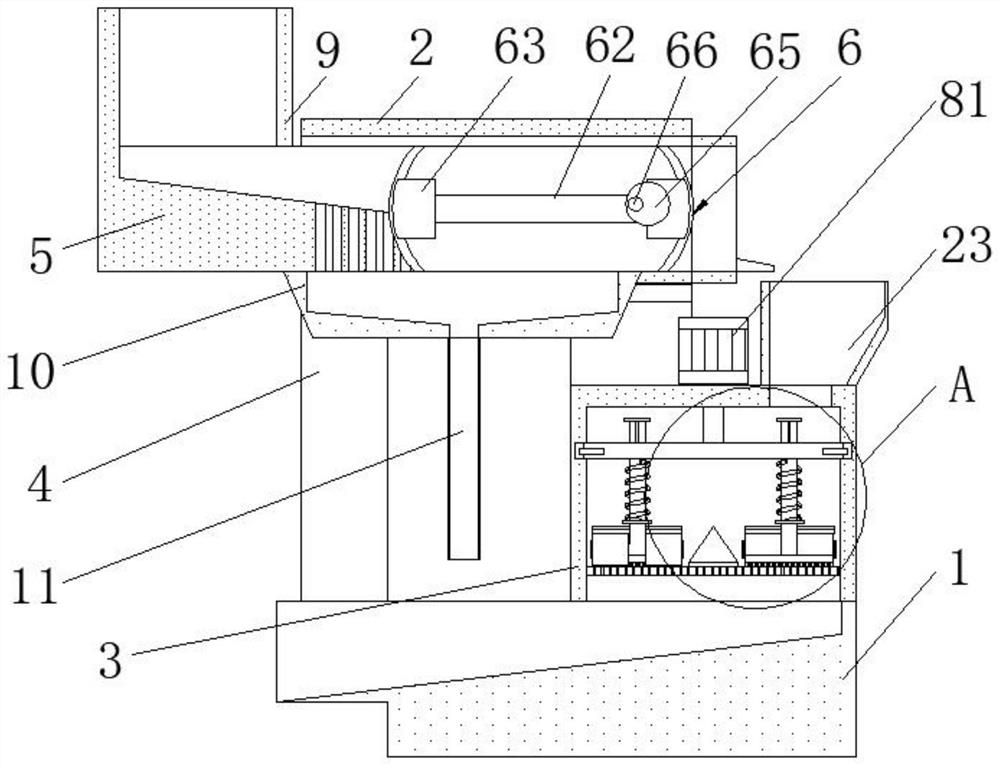

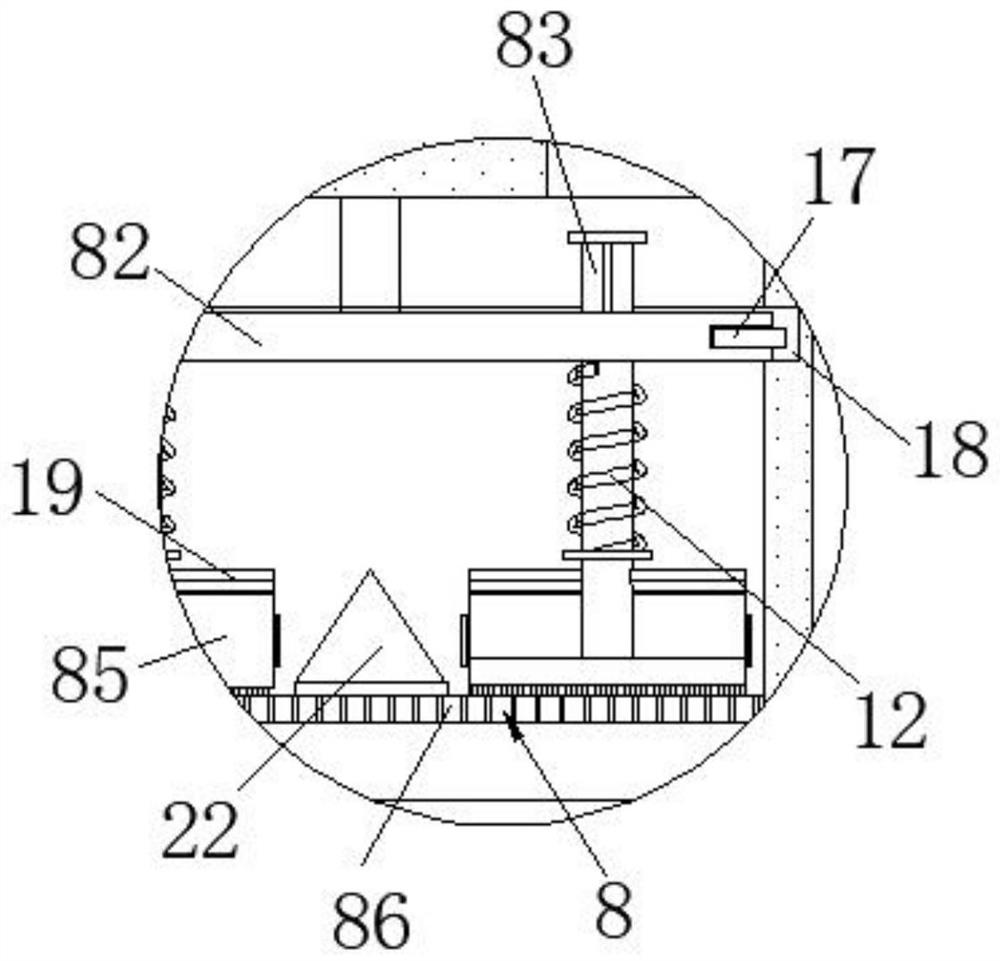

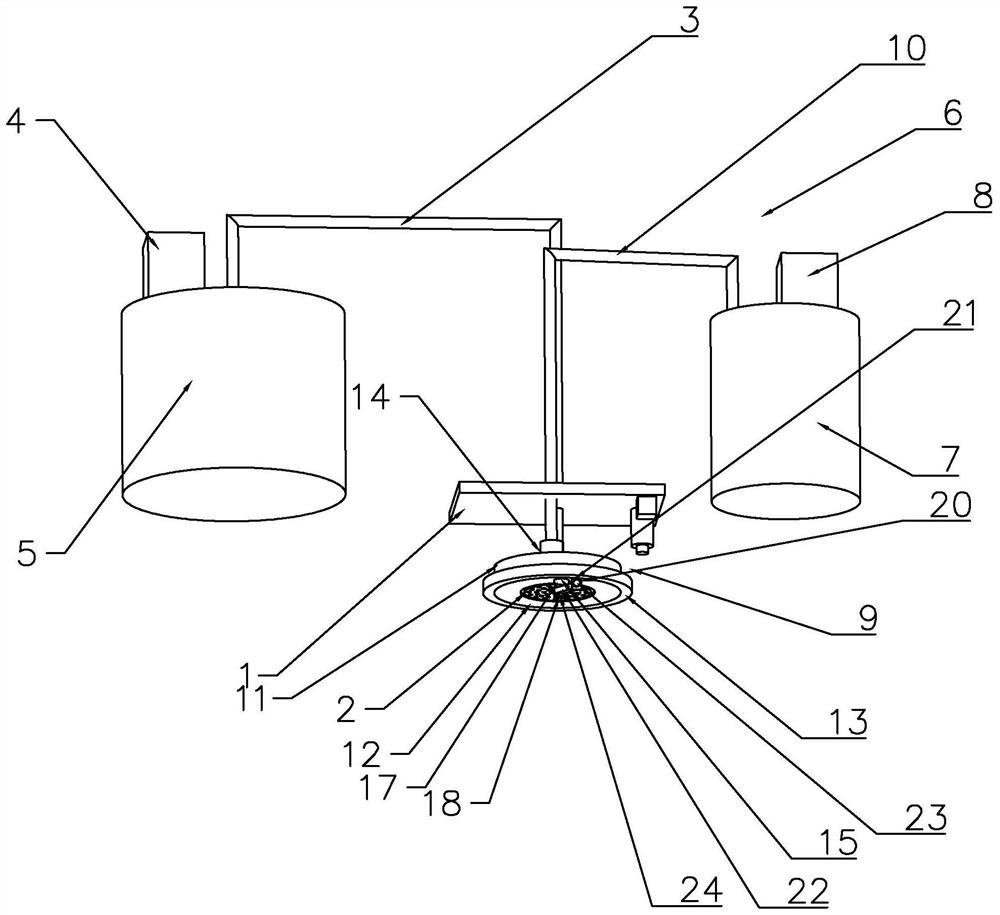

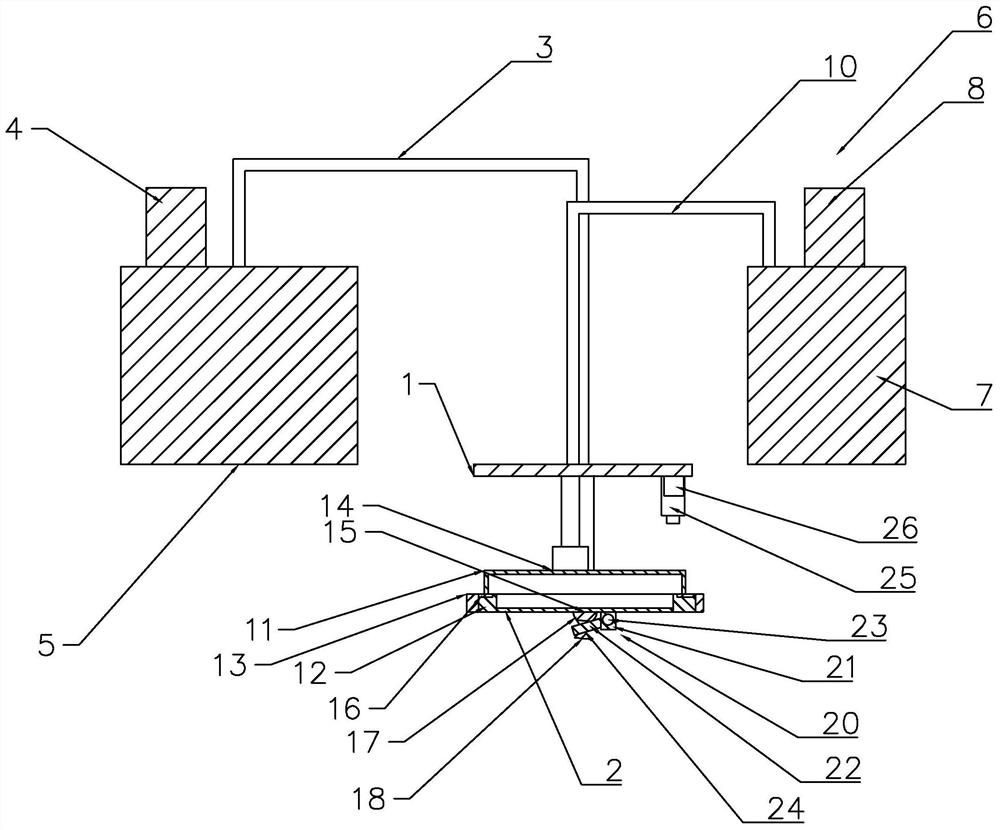

The invention discloses a hoisting land power catwalk of a cylinder and belongs to the technical field of oil drilling equipment. The hoisting land power catwalk comprises a ramp, a pedestal, a rotating arm and a V-shaped drilling tool support beam, the upper end of the ramp is provided with a ramp guide pulley which is positioned at the connection part of the ramp and the drilling platform; the bottom of the V-shaped drilling tool support beam is provided with a support beam guide rail combined with the ramp guide pulley, and the support beam guide rail can be moved with respect to the ramp guide pulley. The hoisting land power catwalk is characterized in that the support beam guide rail at the V-shaped drilling tool support beam bottom is combined with the ramp guide pulley on the upper end of the ramp to directly convey the drilling rod near the well mouth, thereby improving drill-feeding working efficiency, in particular, the structure has the more obvious drill-feeding effect in the high drilling platform.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

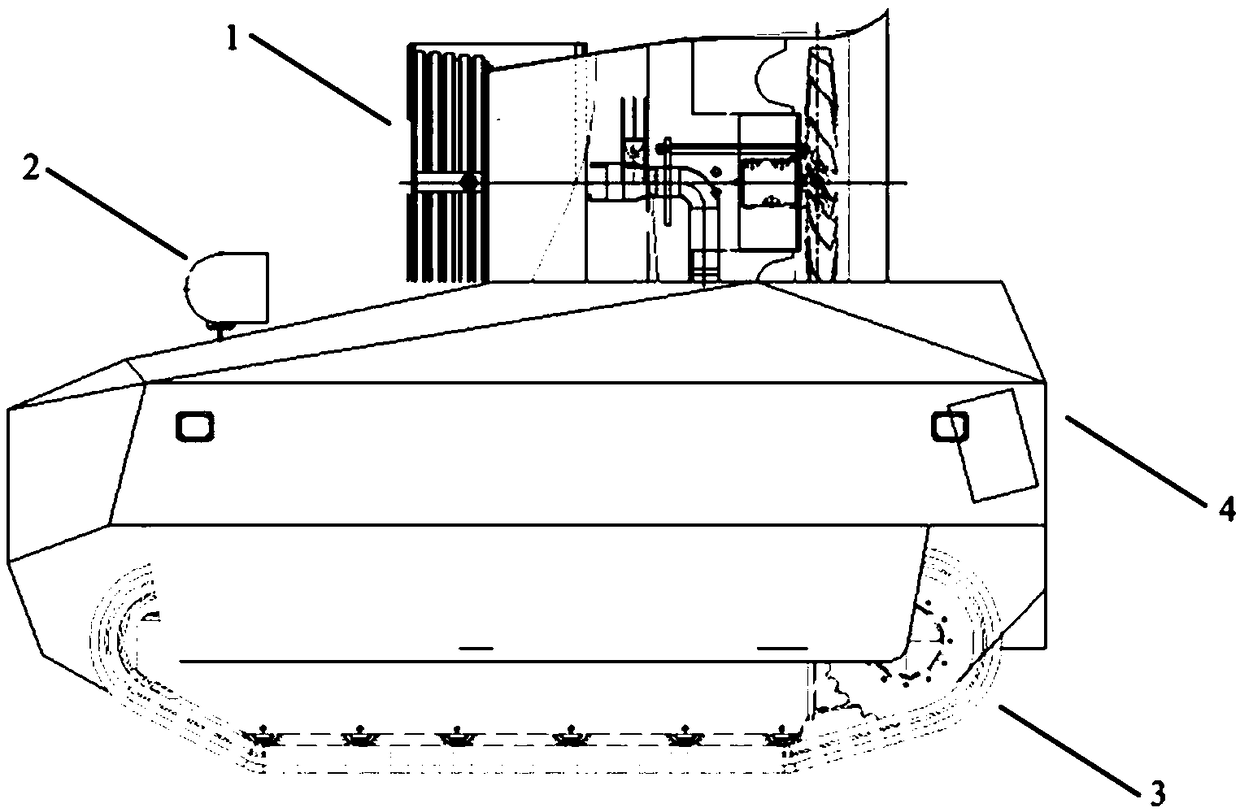

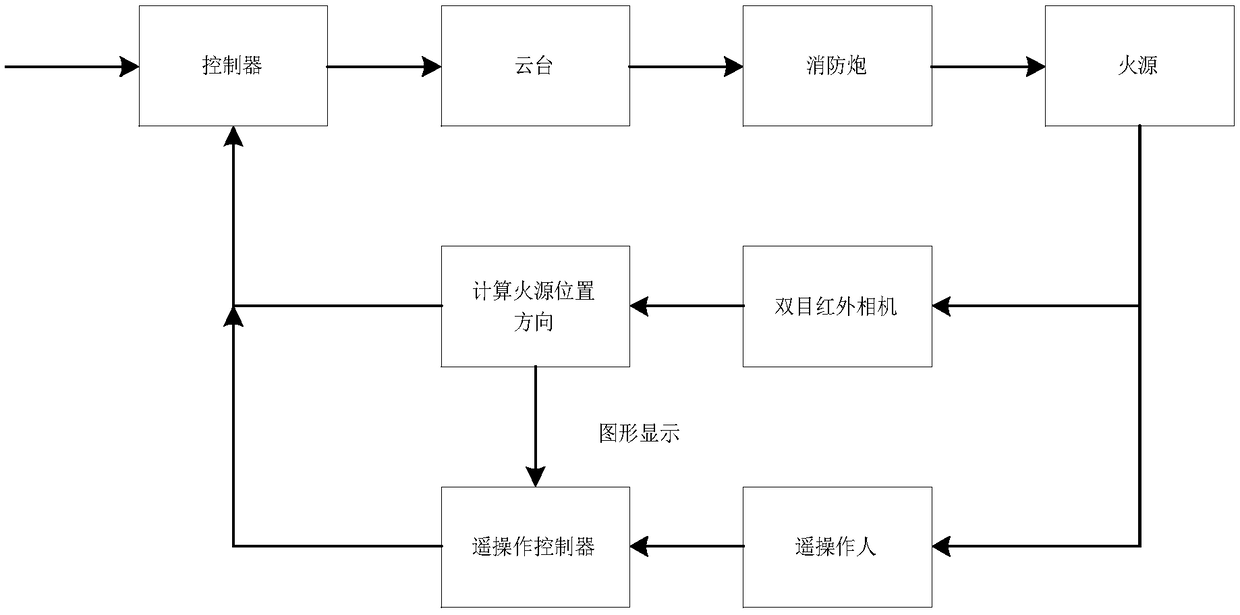

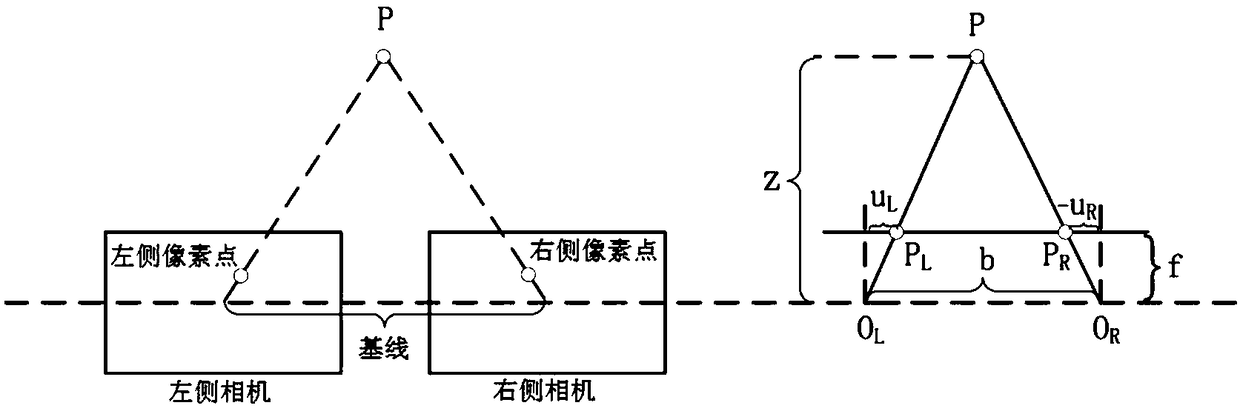

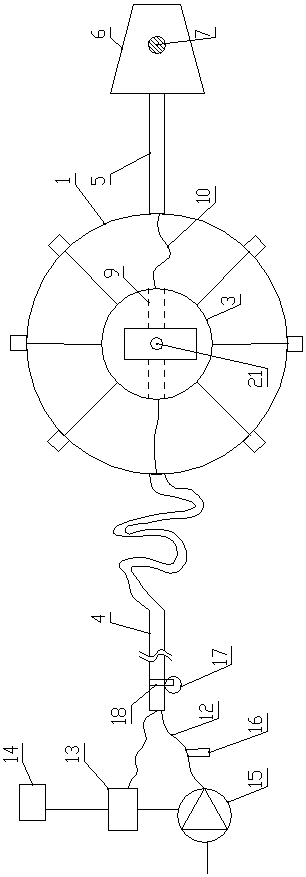

Fire fighting robot fire monitor control method based on fire source positioning and recognition

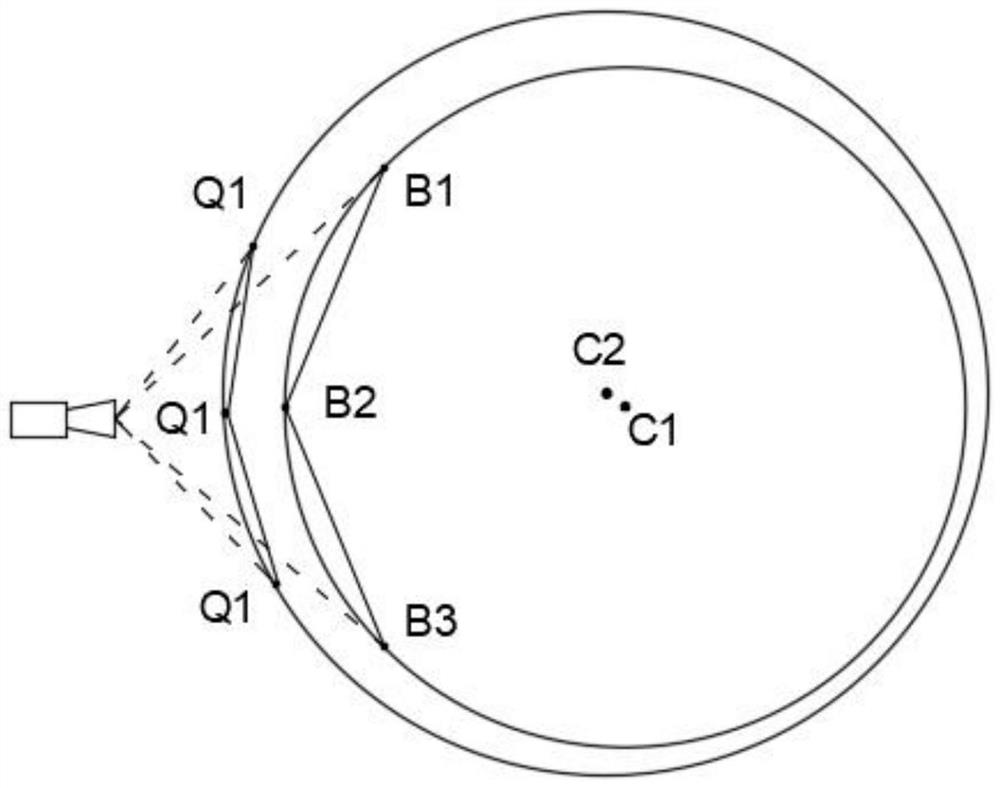

The invention discloses a fire fighting robot fire monitor control method based on fire source positioning and recognition. The method comprises the steps that a calibrated binocular infrared camera is utilized for recognizing a fire source and positioning the center point of the fire source, and according to position deflection obtained in two images collected by the binocular infrared camera atthe fire source center point, the distance between the fire source center point and a fire fighting robot is calculated and determined as the fire source center point depth; the fire source center point depth serves as the position parameter of the fire source center point in the three-dimensional space; jet flow track models are established, the yaw angle between a fire monitor and the fire source center point and the vertical distance between the fire source center point and the binocular infrared camera are calculated and serve as fire source center point three-dimensional position parameters; and the pitching angle is calculated, the fire monitor is controlled, and accordingly the fire monitor jet flow track fall point serves as the fire source center point. By means of the fire fighting robot fire monitor control method, the fire monitor of the fire fighting robot can be efficiently, rapidly and conveniently controlled to aim at the fire source, the fire monitor angle adjusting time is saved, the fire fighting work difficulty can be lowered, and efficiency is improved.

Owner:SOUTHEAST UNIV

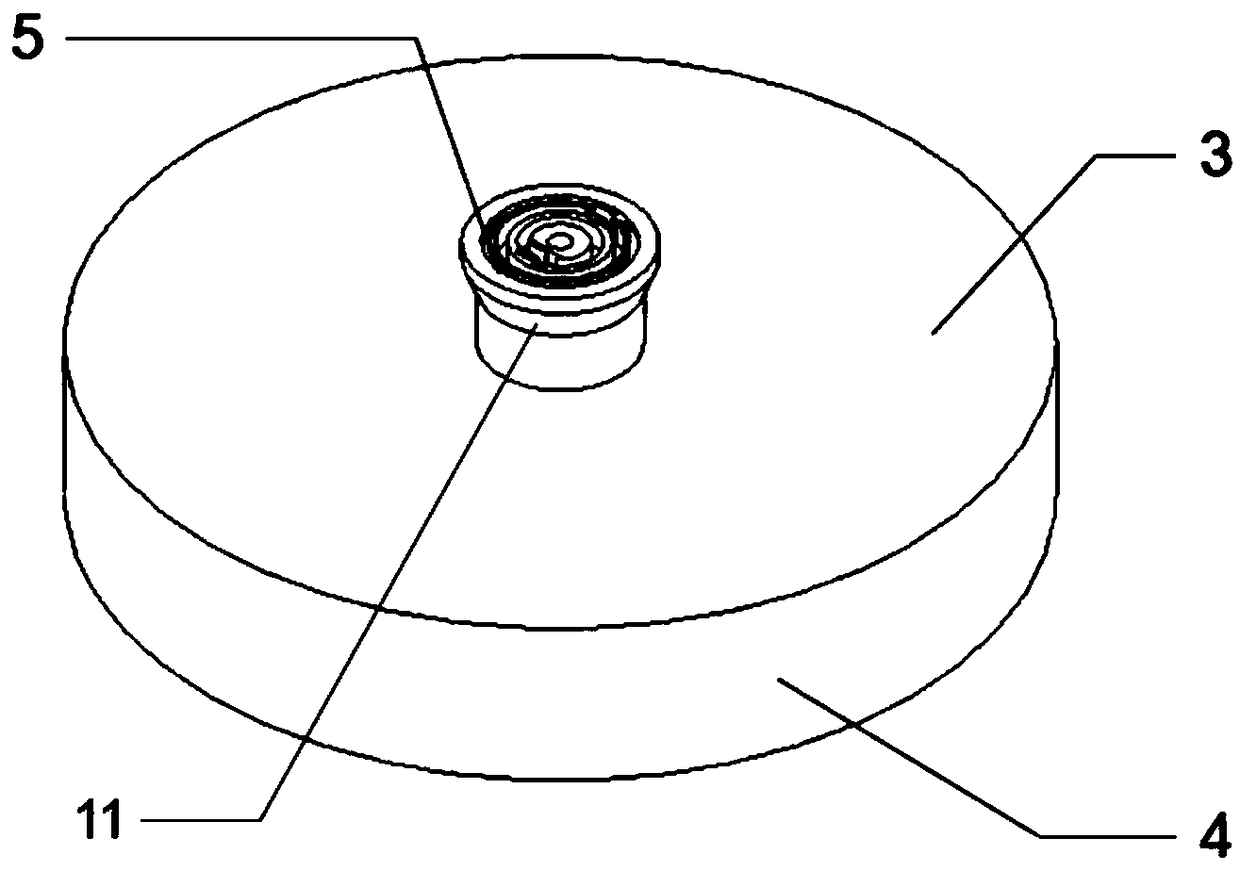

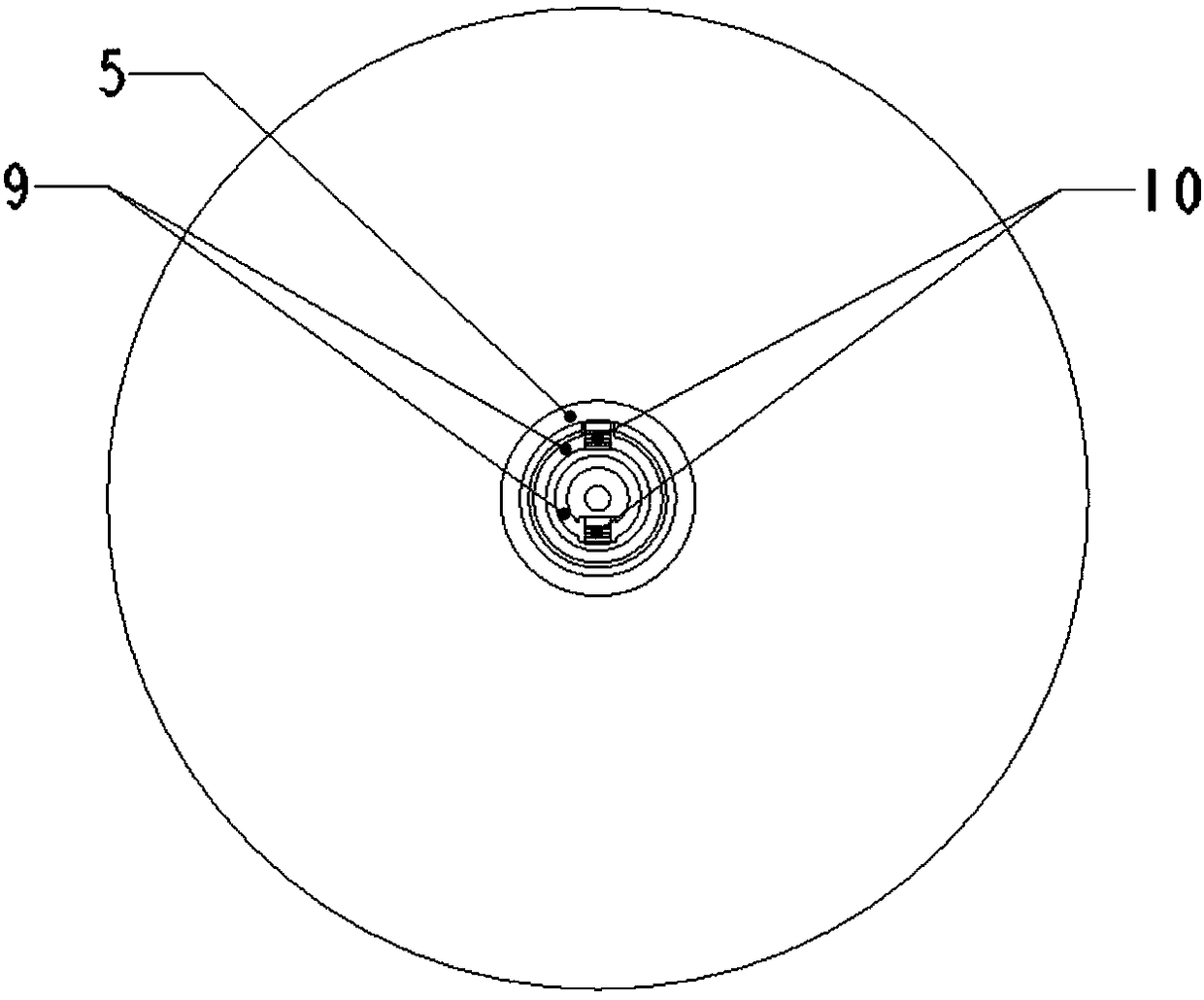

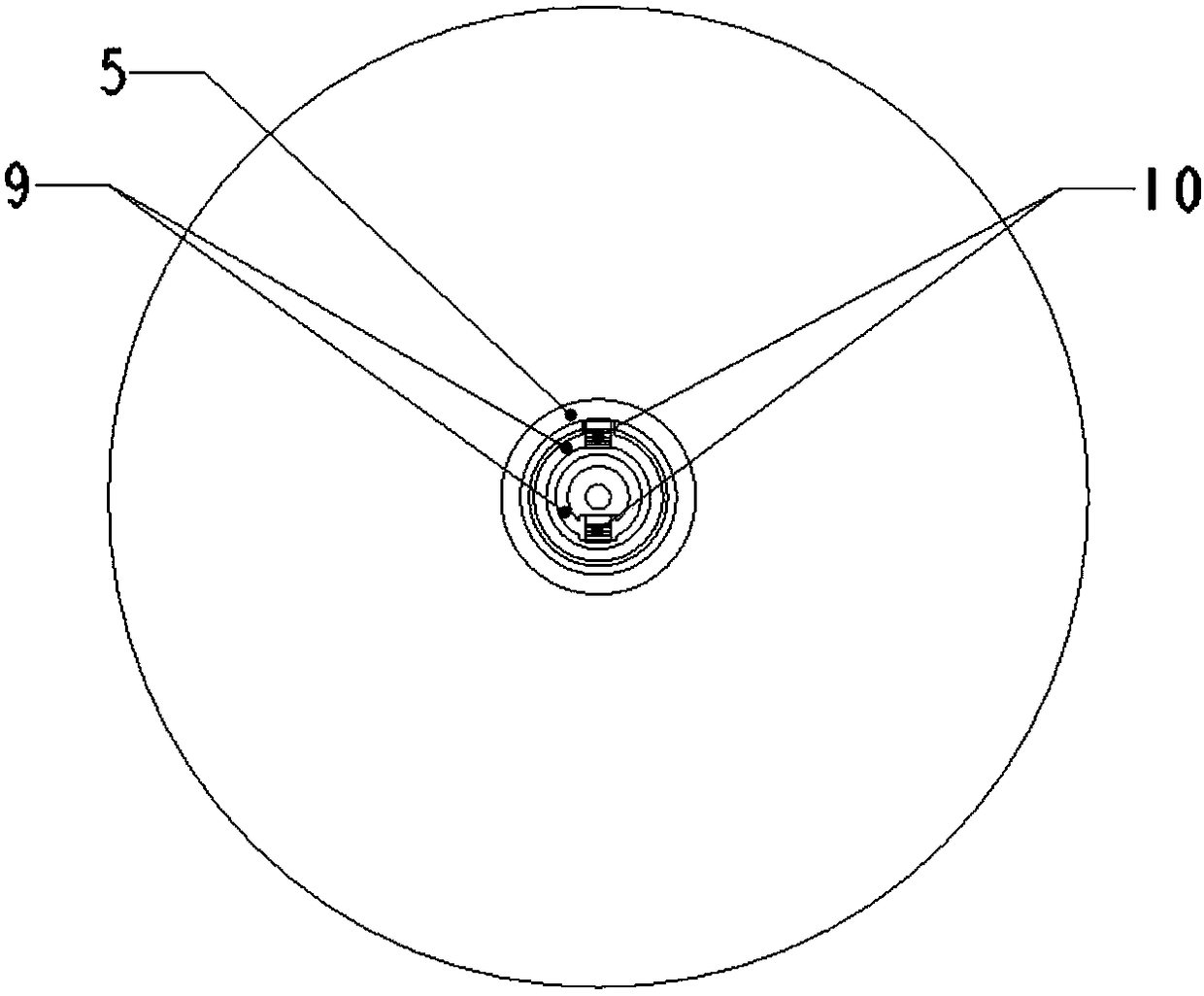

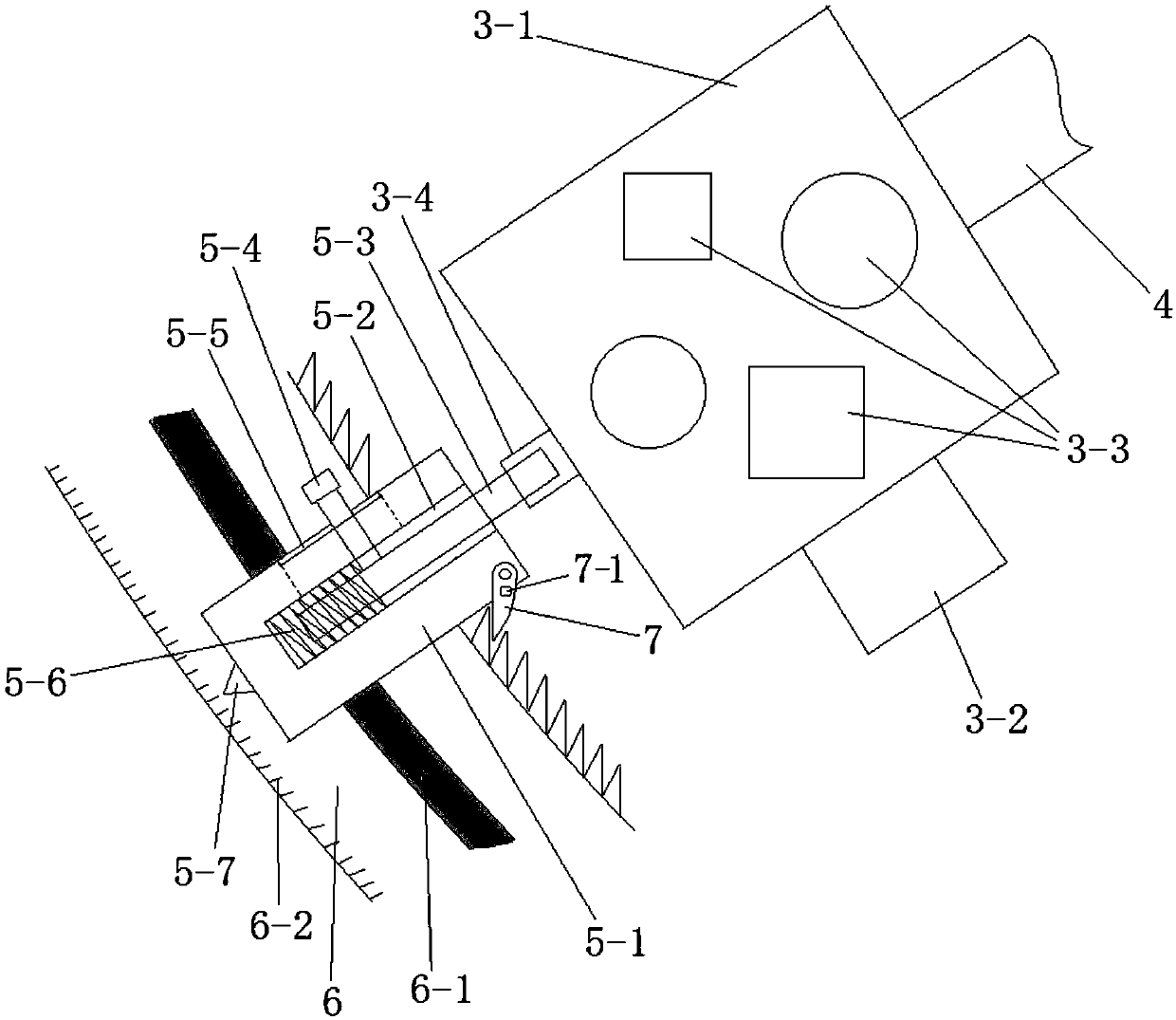

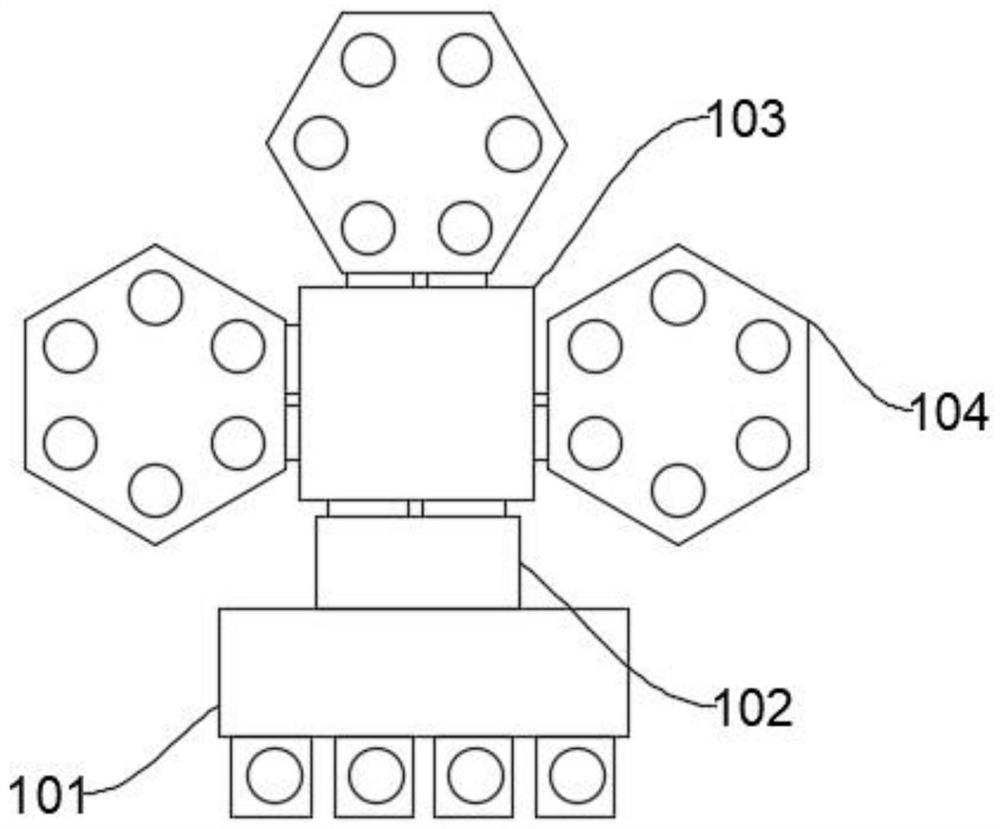

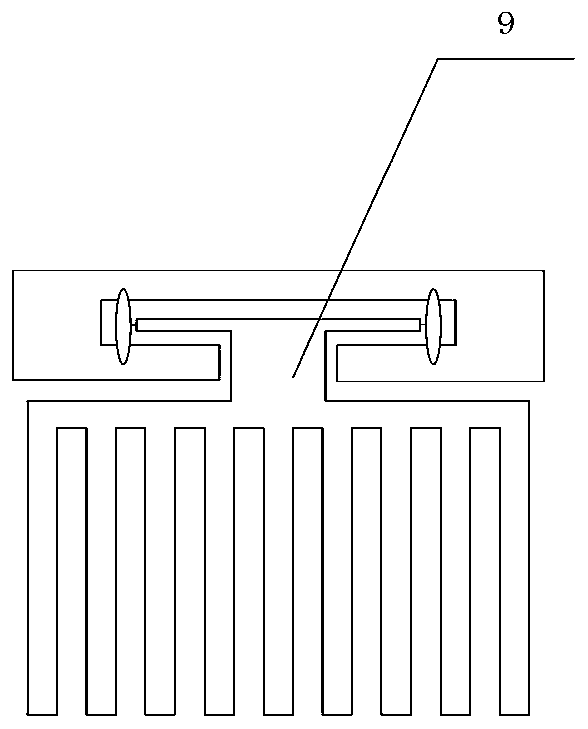

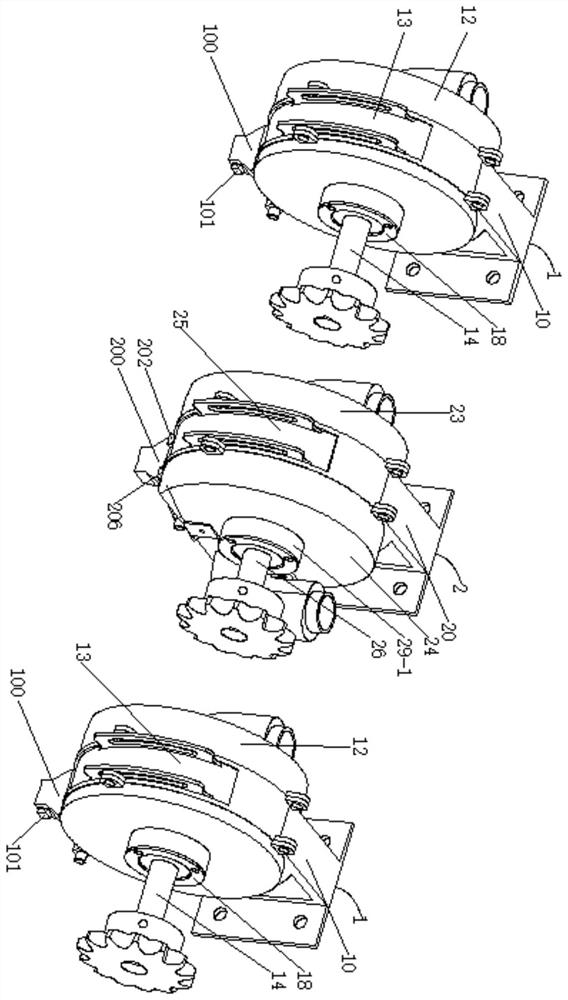

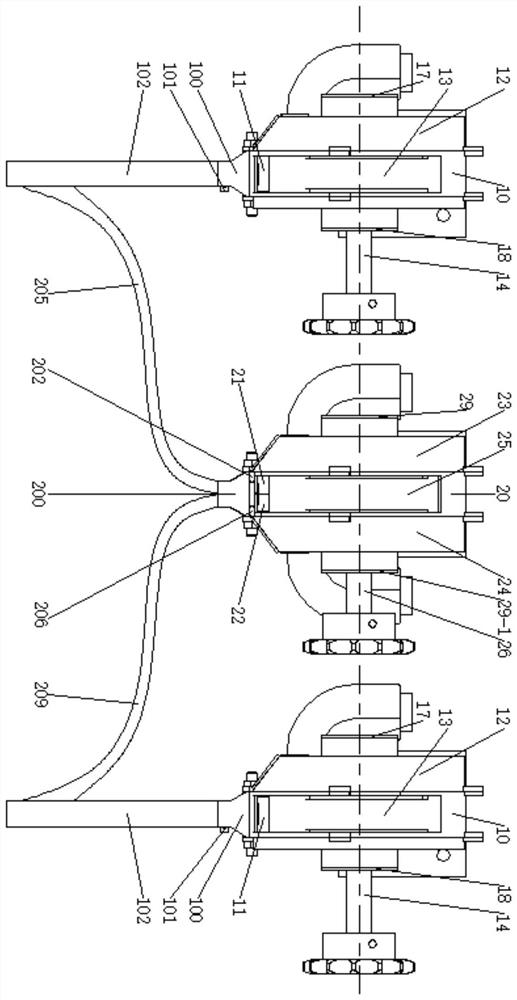

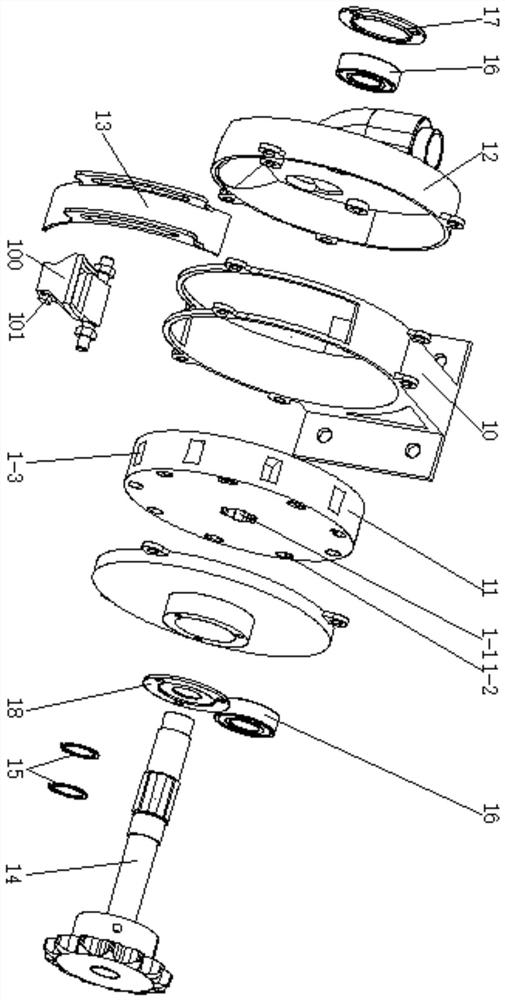

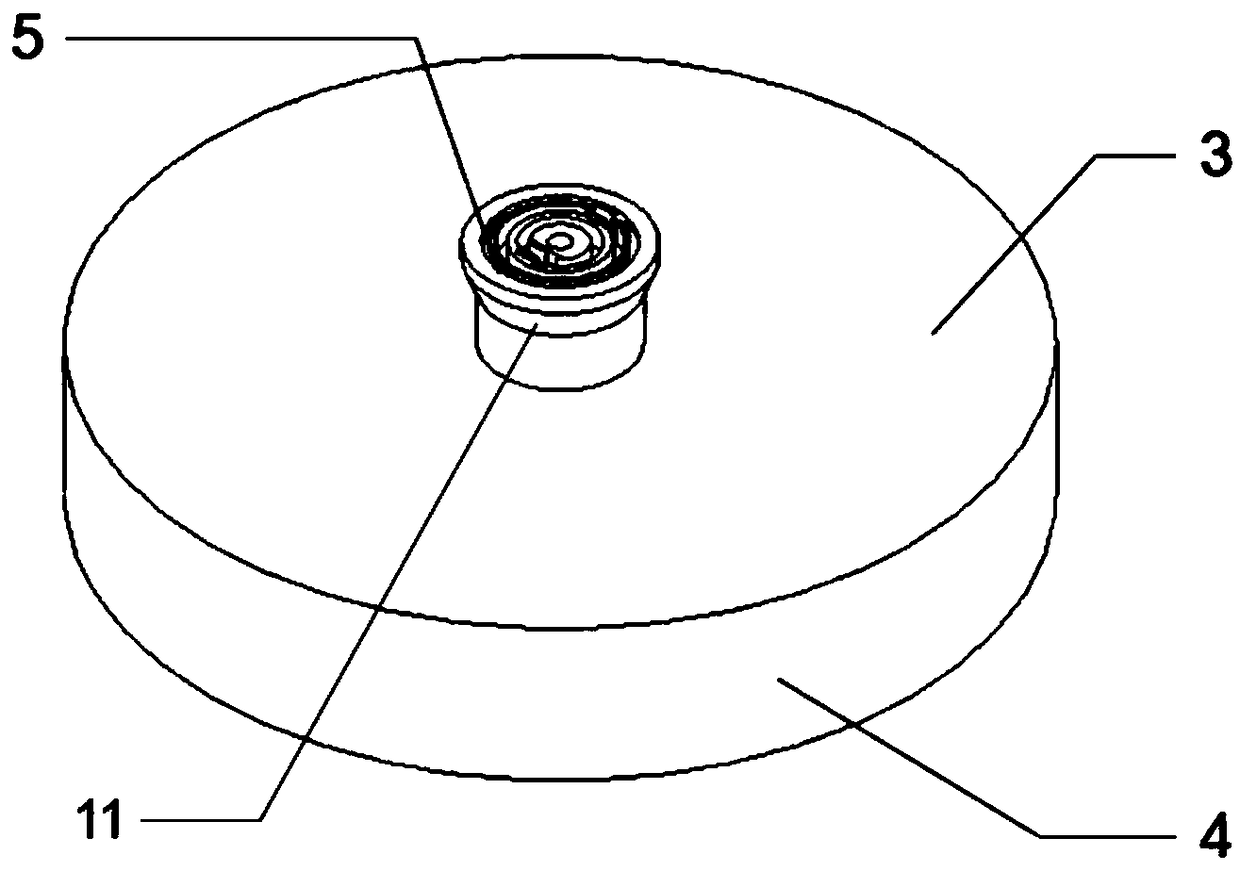

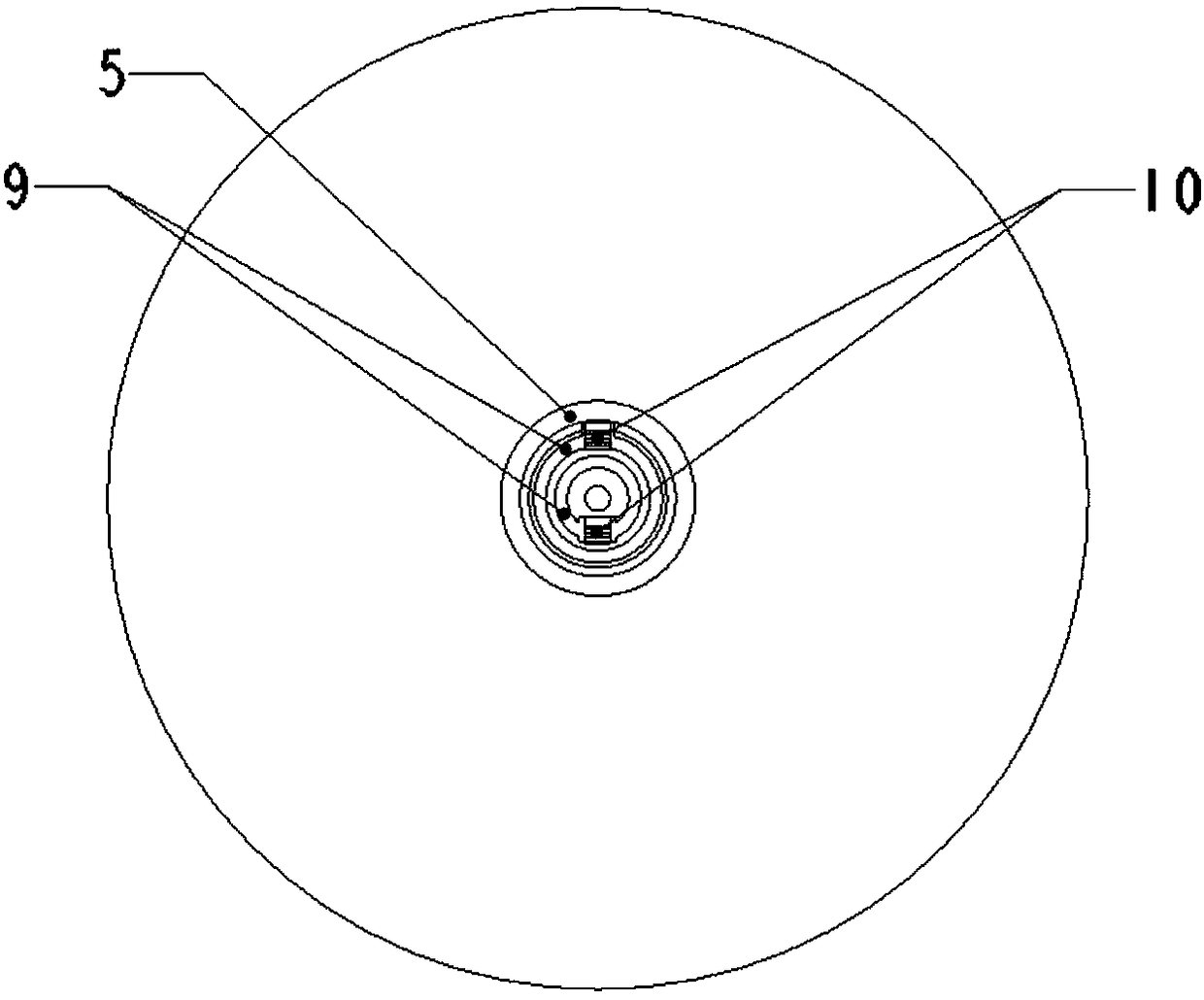

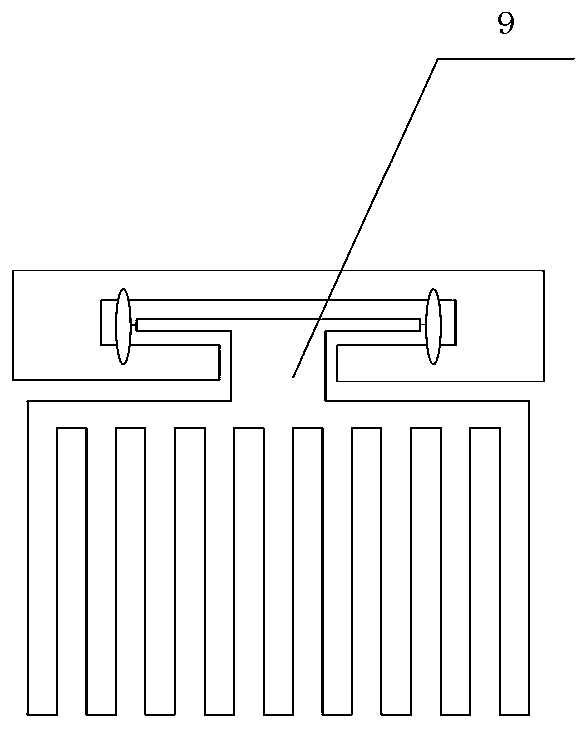

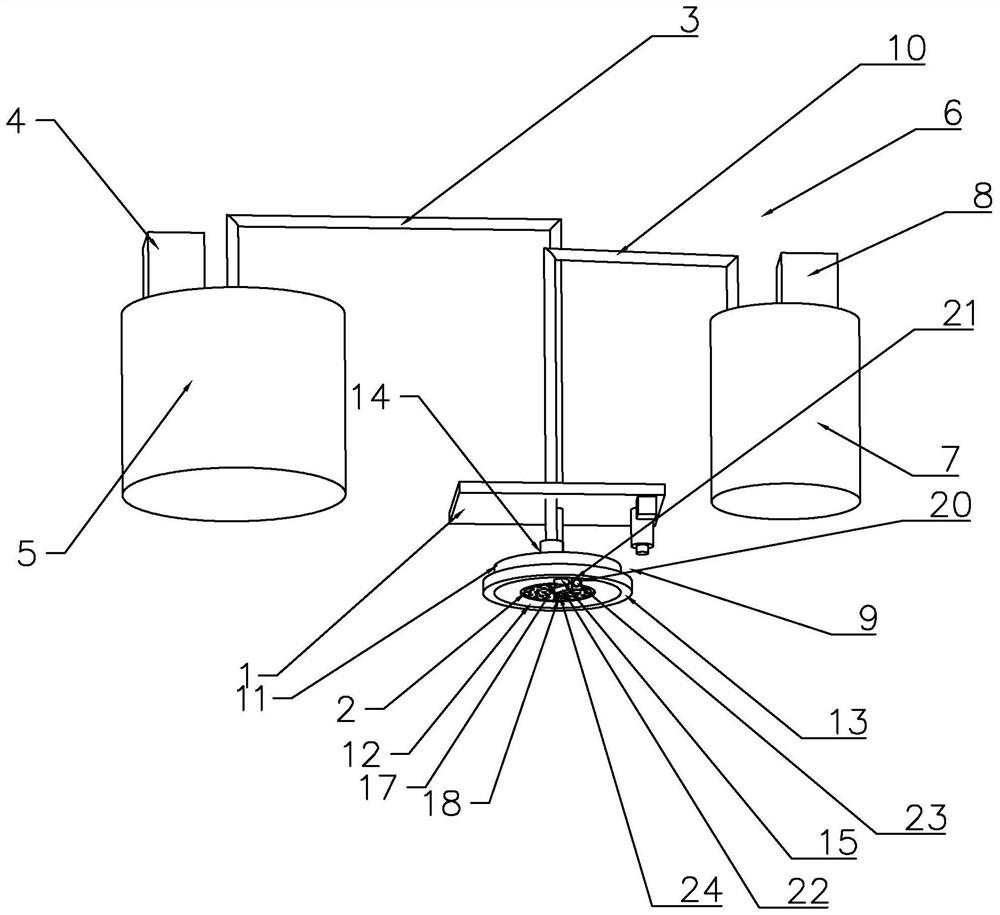

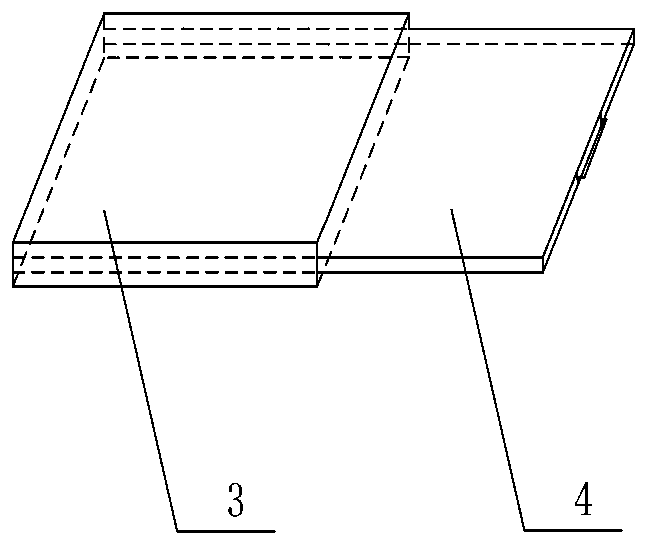

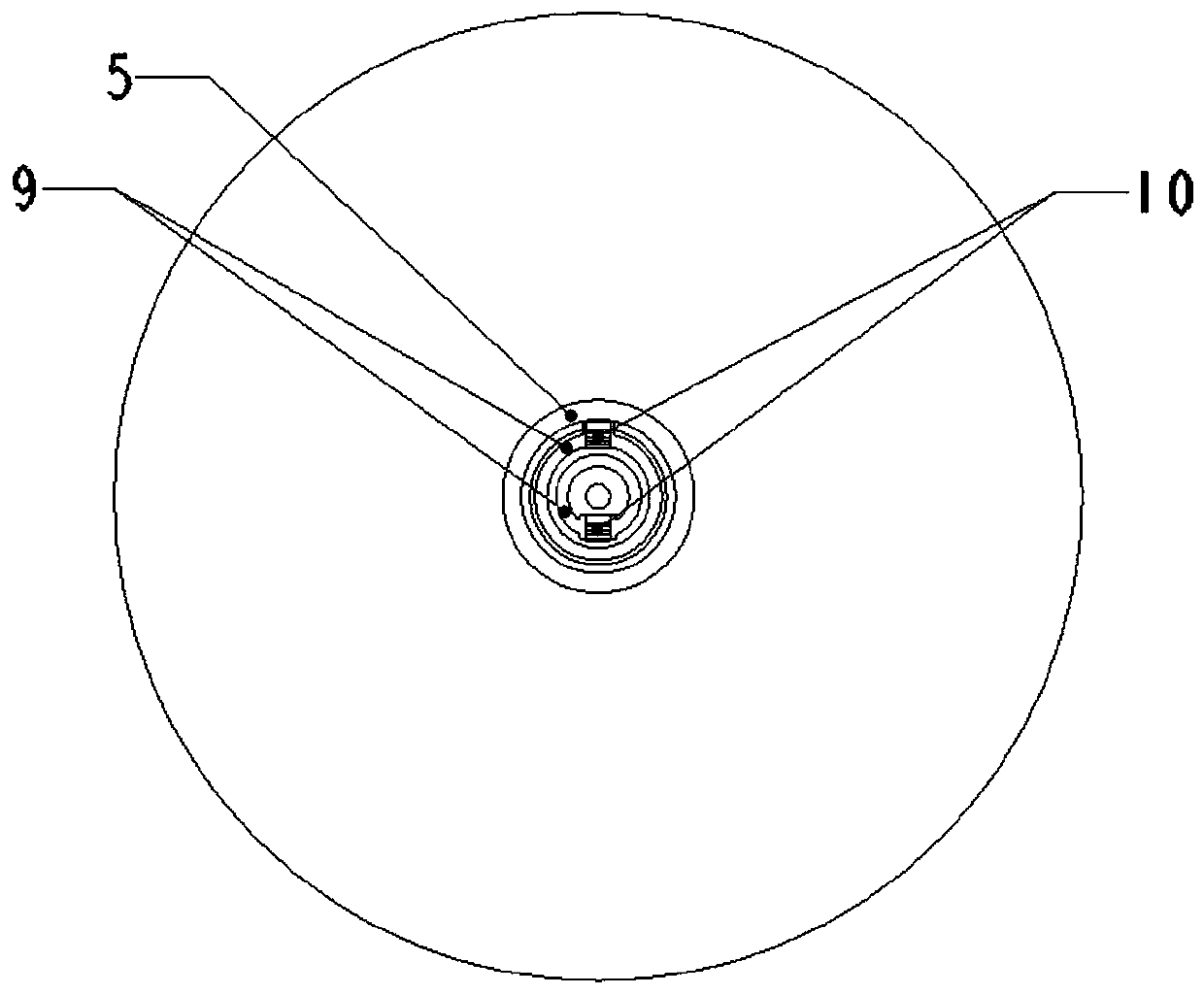

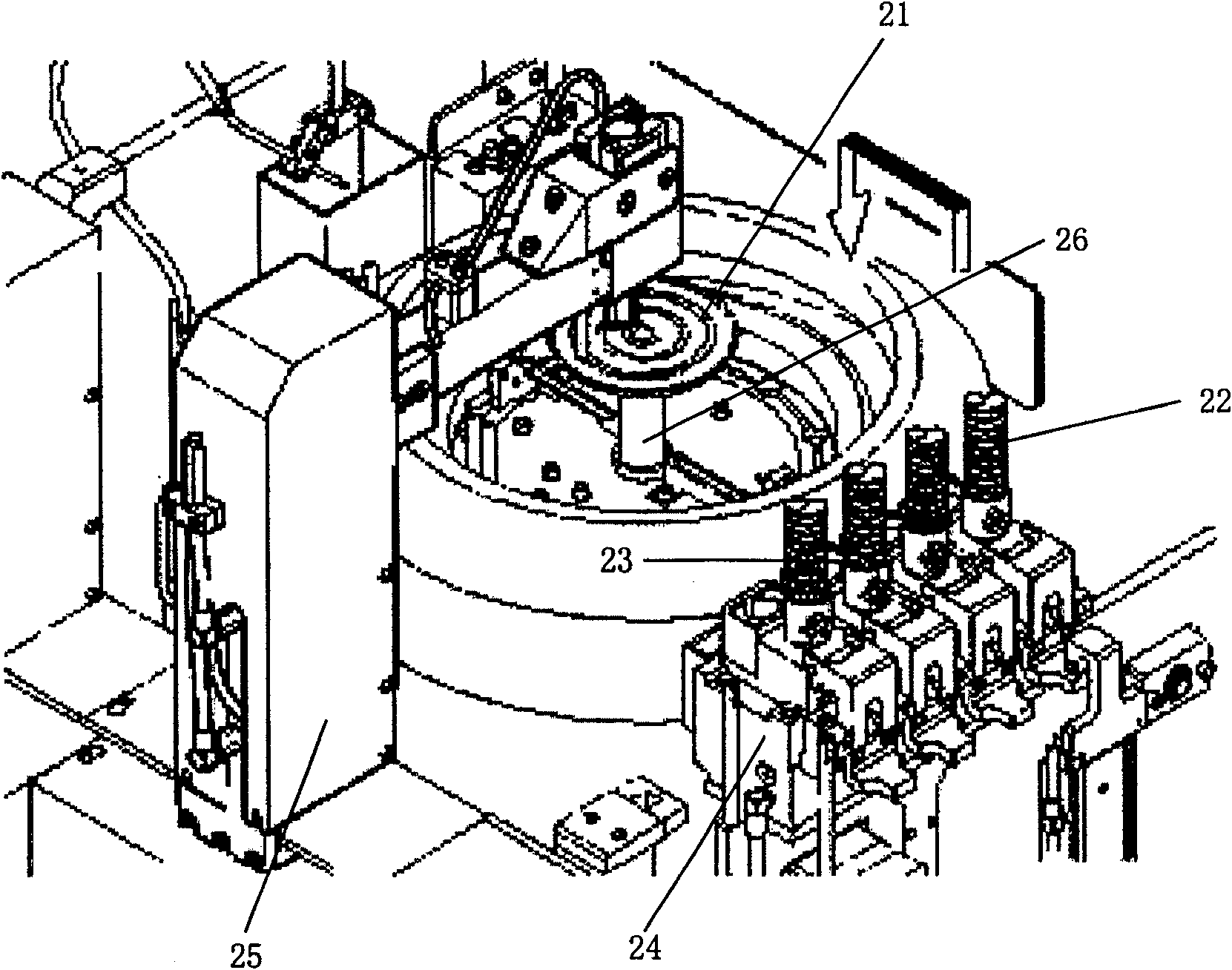

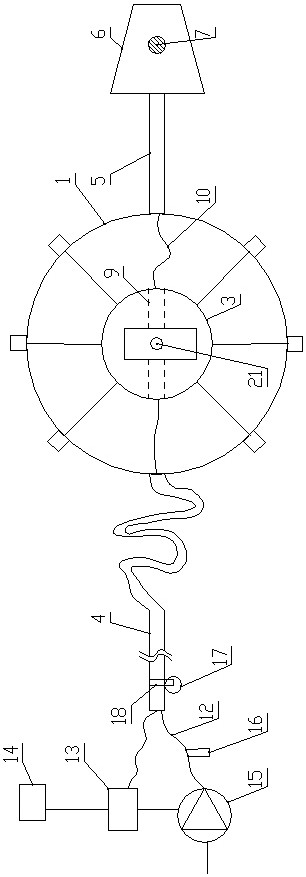

Battery replacement charging system of unmanned aerial vehicle

ActiveCN108528745AImprove fault toleranceReduced precision requirementsCharging stationsCurrent conducting connectionsUncrewed vehicleEngineering

The invention discloses a battery replacement charging system, and belongs to the technical field of machinery. The battery replacement charging system of an unmanned aerial vehicle comprises a detachable battery and a detachable battery replacement charging device. The system has the advantages that the use efficiency of the unmanned aerial vehicle is improved, the overall battery life of the unmanned aerial vehicle is prolonged, the application range is wide, the development period is short, the difficulty is moderate, and the cost is low.

Owner:JIANGNAN UNIV

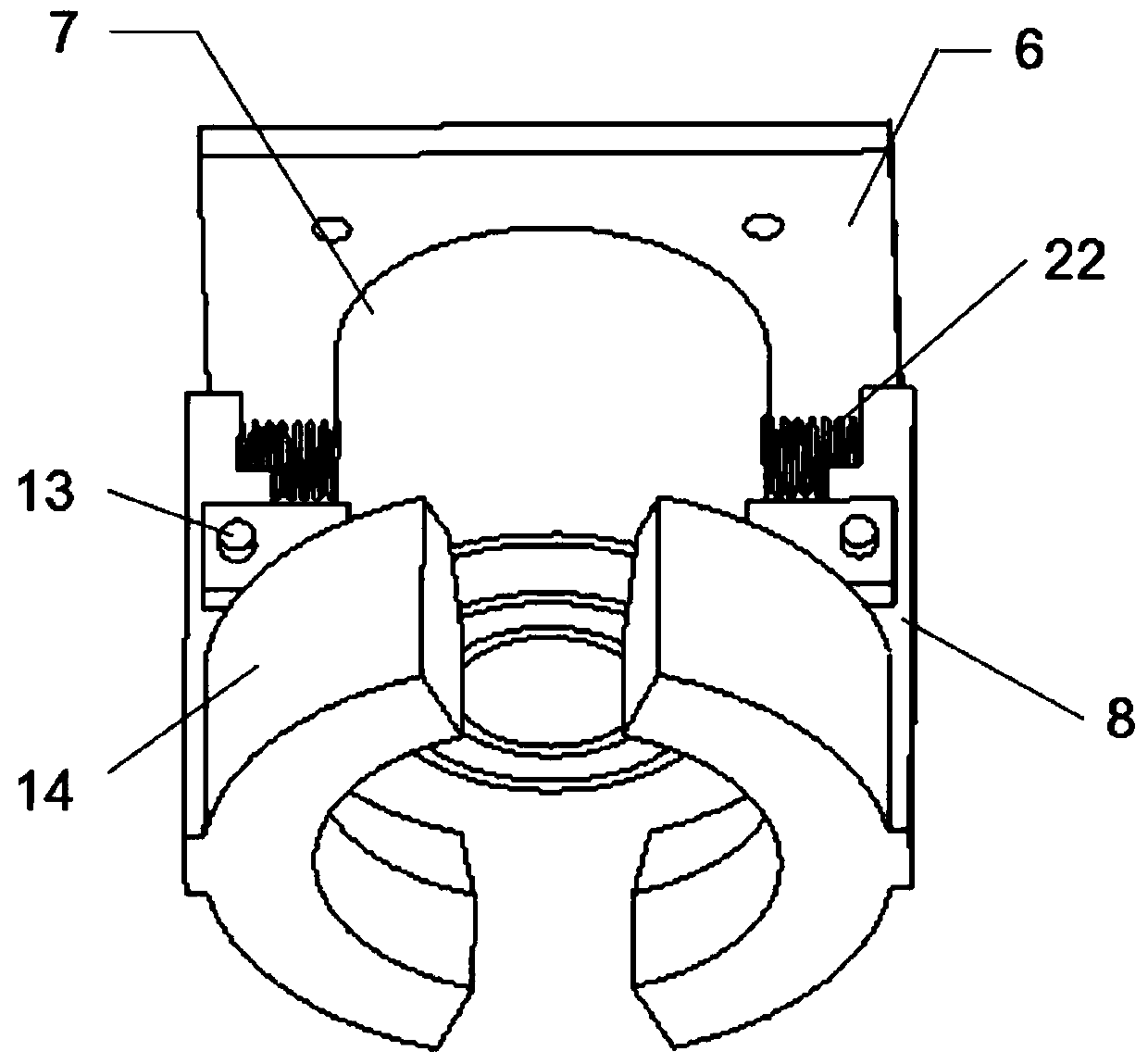

Detachable battery change-over charging device

ActiveCN108515866AImprove fault toleranceReduced precision requirementsCharging stationsElectric propulsion mountingElectrical batteryElectrical and Electronics engineering

Owner:JIANGNAN UNIV

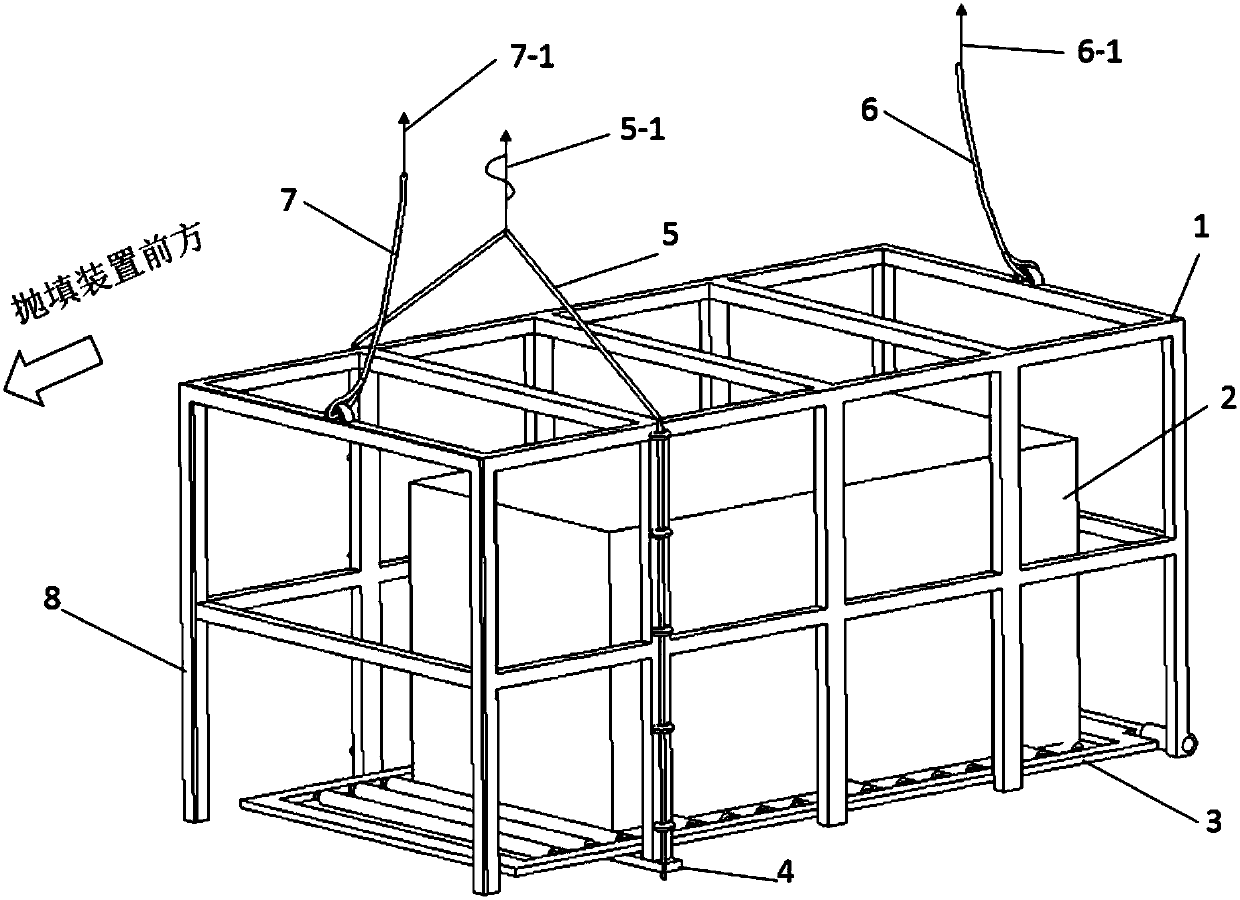

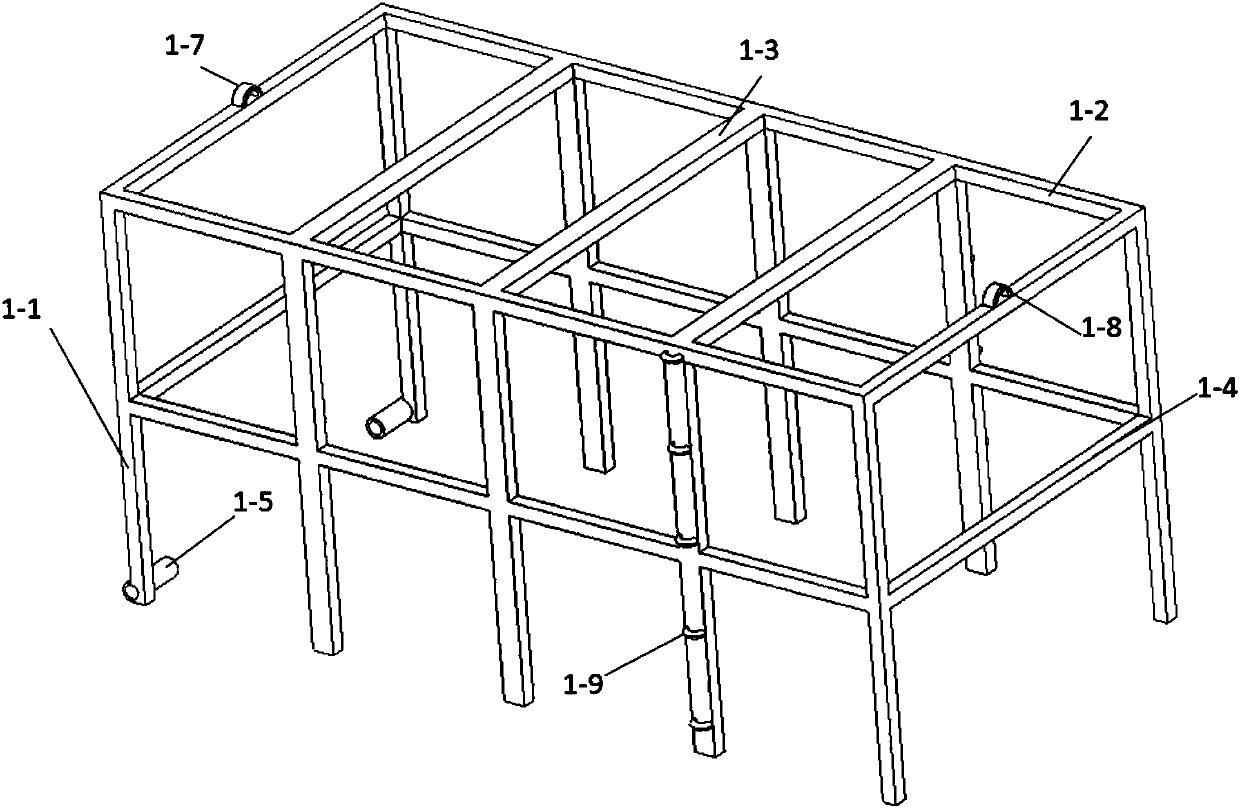

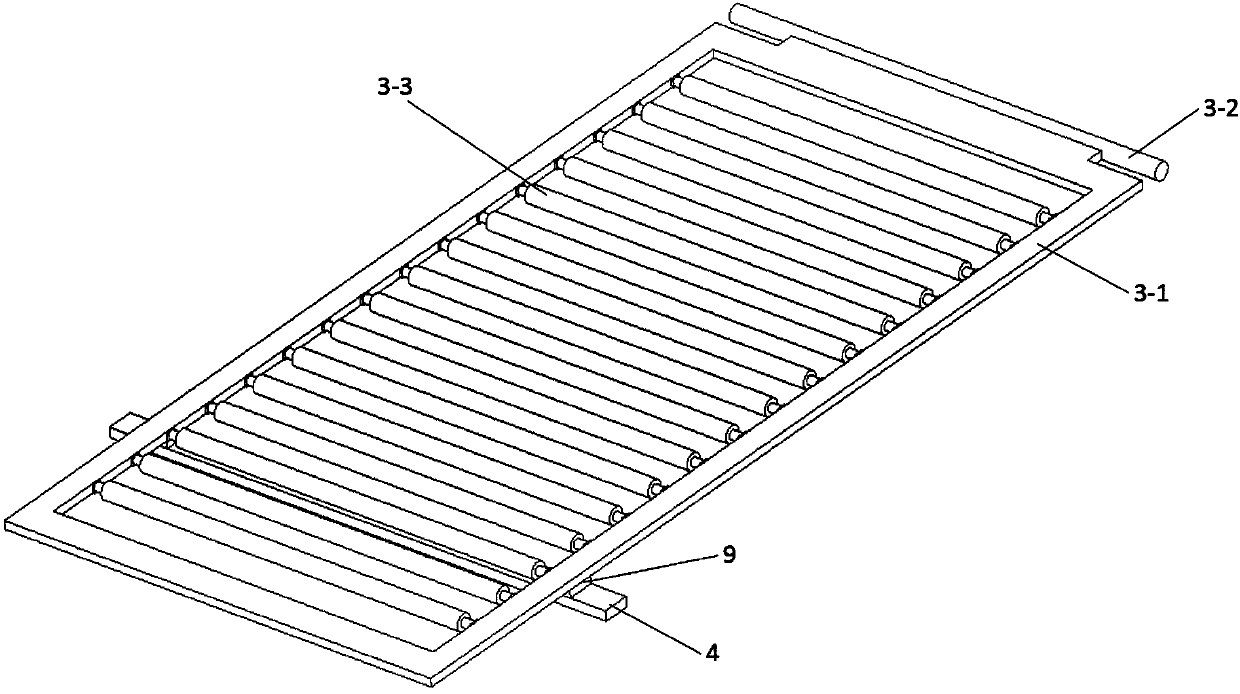

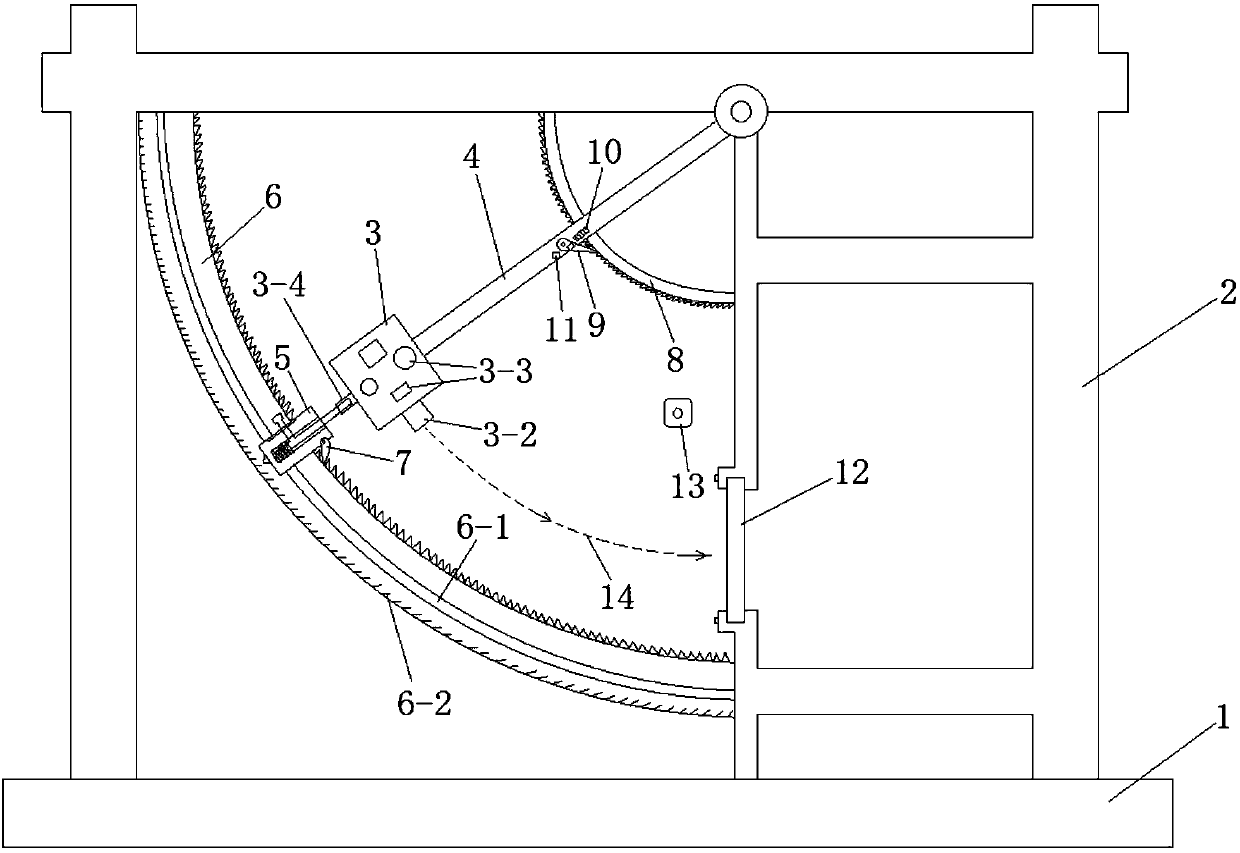

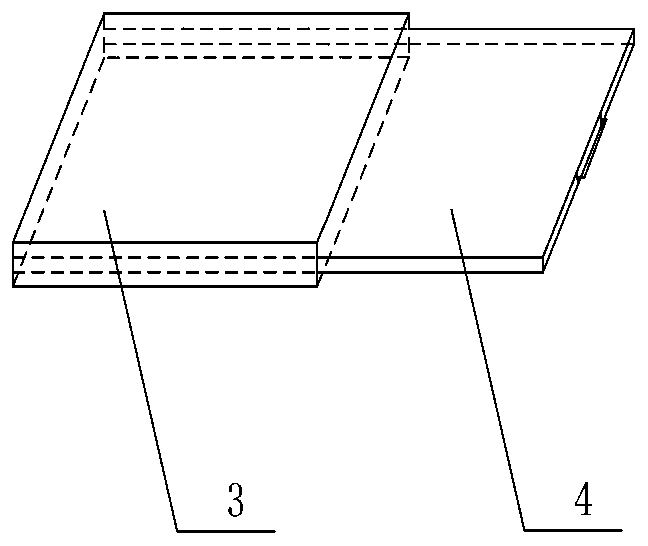

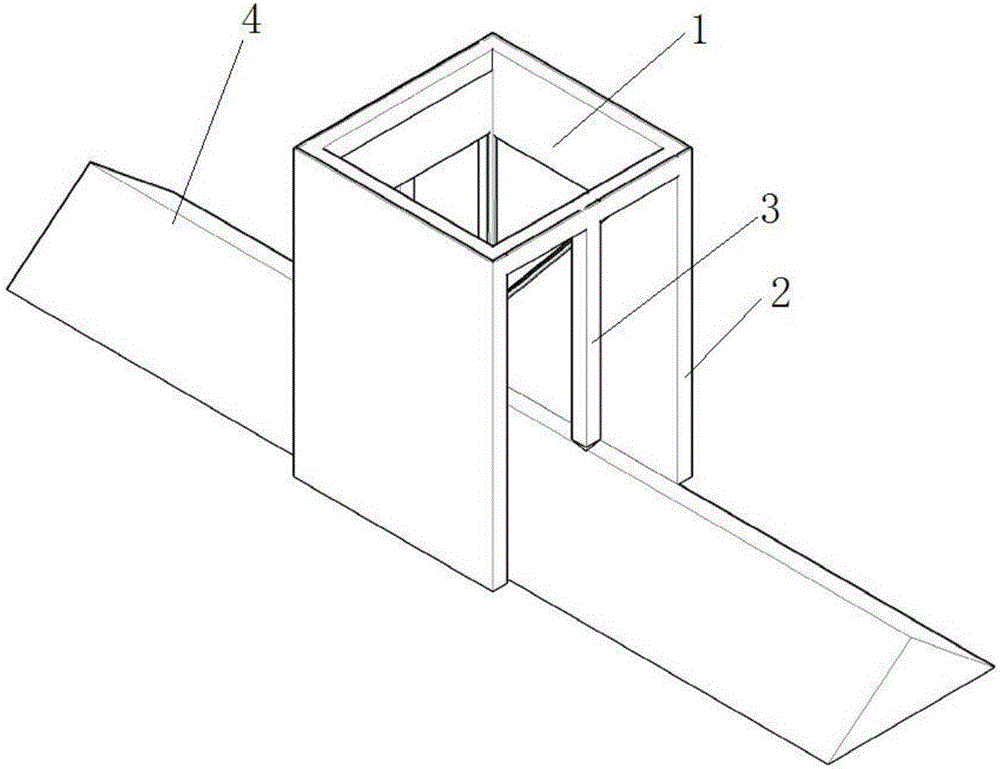

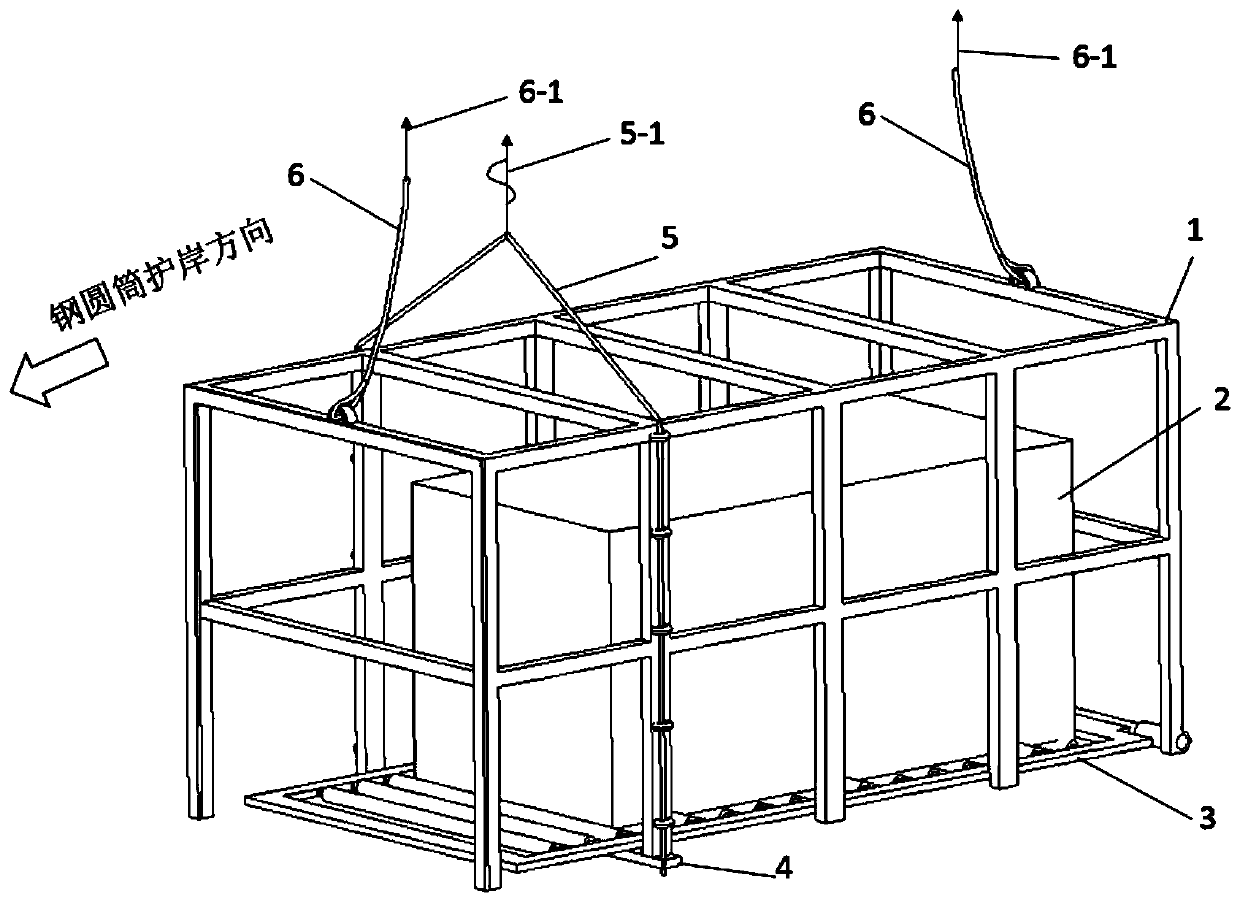

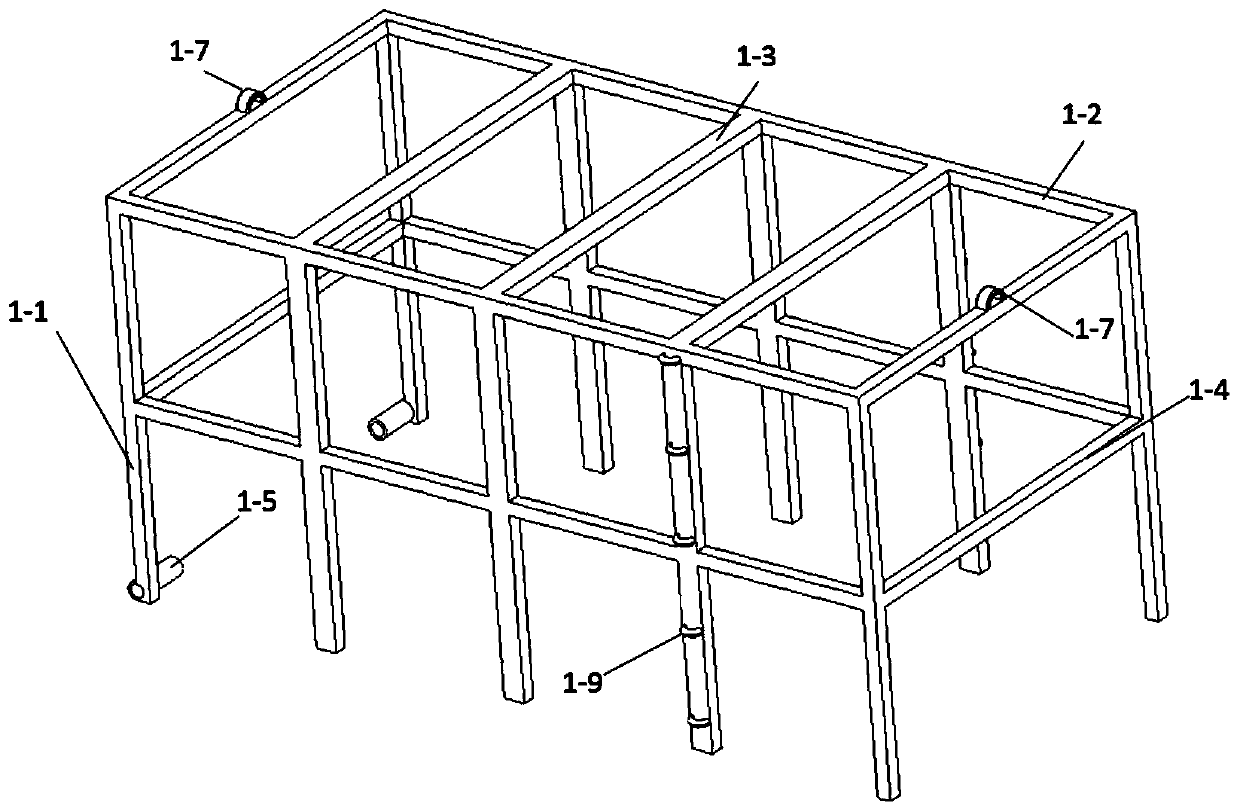

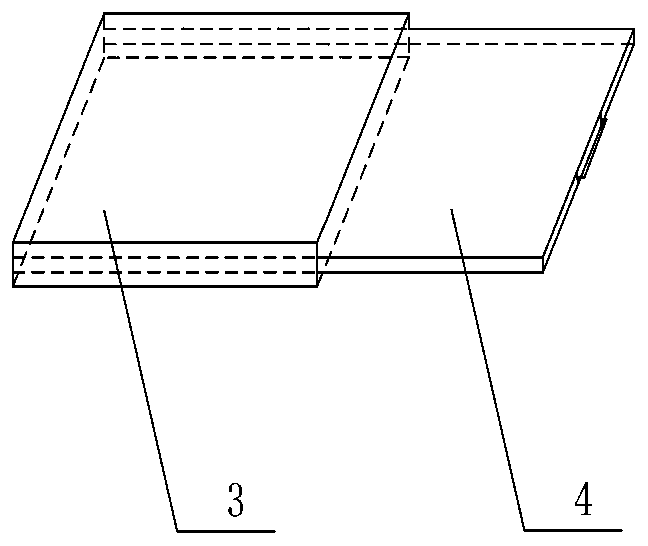

Facing stone cage net bag bump-free dump filling construction method

ActiveCN107761738AReduce underwater unhooking operationsEnsure construction safetyFoundation engineeringEngineeringCrane Equipment

The invention discloses a facing stone cage net bag bump-free dump filling construction method. The method comprises the steps that a stone cage net bag dump filling device is prepared; the stone cagenet bag dump filling device is placed on a barge deck, end steel slings located on the front side of an upper frame body are lifted to lifting hooks of crane equipment; the lifting hooks are lifted to pull up the upper frame body, a stone cage net bag is placed on an openable rolling bottom plate, and the upper frame body is placed down to be folded with the openable rolling bottom plate; the twoend steel slings are connected with the end lifting hooks, the steel slings are connected with the lifting hooks connected with an automatic hook disengagement device above the upper frame body, thelifting hooks connected with the automatic hook disengagement device and the two end lifting hooks are connected to the lifting hooks of the crane equipment through a three-leg chain; the stone cage net bag dump filling device is lifted and placed into water, the lifting hooks connected with the automatic hook disengagement device are disengaged, and the stone cage net bag slides down towards thesteel cylinder revetment direction. By means of the method, the stone cage net bag can accurately fall down to the position tightly attached to the steel cylinder revetment structure.

Owner:中建六局华南建设有限公司

Mechanical strength test apparatus

ActiveCN108037000AEnsuring Mechanical Strength Test CapabilitiesConvenience falls onInvestigating material hardnessTest efficiencyTested time

The invention discloses a mechanical strength test apparatus. A pedestal is provided with a frame body which is hinged to the upper end of a swinging rod. An impact hammer is fixed to the lower end ofthe swinging rod. A first ratchet wheel is arranged at the outer side of an arc-shaped swinging track of the impact hammer and is fixed to the frame body. A positioning apparatus is in slide connection with the first ratchet wheel and is used for fixing an initial swing position of the impact hammer. A first pawl matched with the first ratchet wheel is hinged to the positioning apparatus, so thatthe positioning apparatus is stably located at a required height on the first pawl by cooperation of the first ratchet wheel and first pawl. The positioning apparatus is connected to a connection rodwhich is detachable from the impact hammer. A to-be-tested piece mounting position for fixing a to-be-tested piece is arranged on a position, at the right side of the first ratchet wheel, of the frame body. The test apparatus has simple structure and has safe and reliable test process, can save manpower and test time during the test process, and can increase test efficiency.

Owner:钧风电控科技泰州有限责任公司

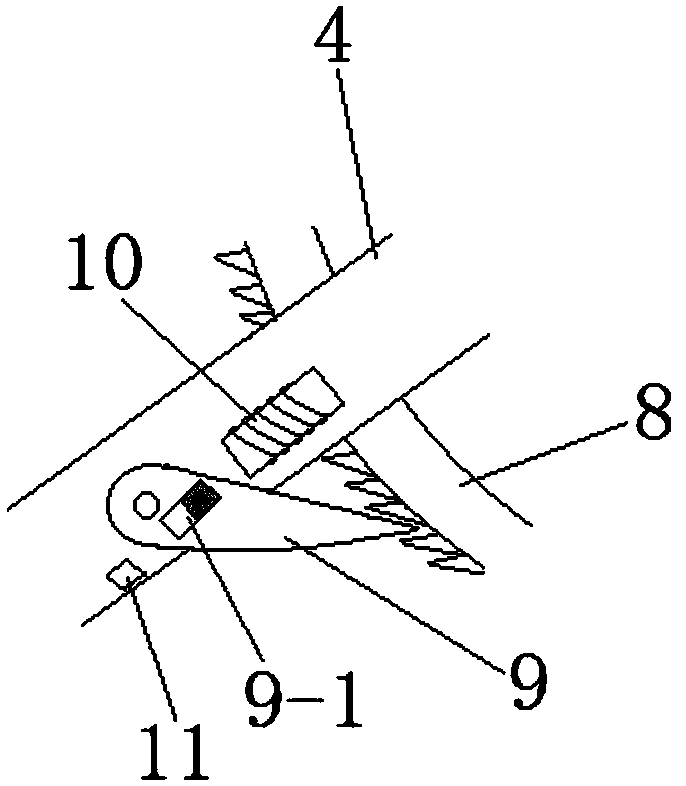

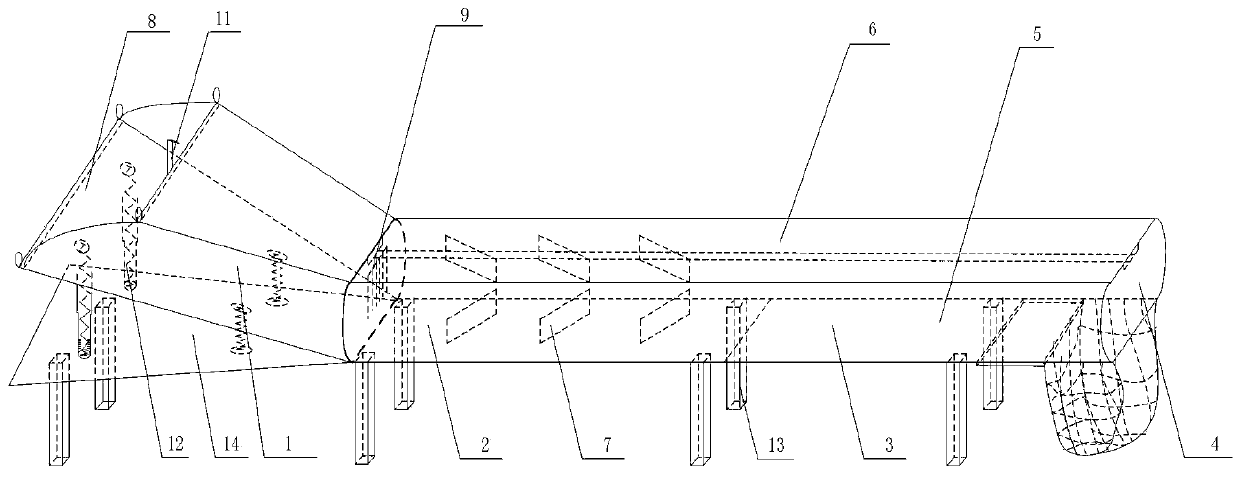

Corn miss-seeding reseeding device and control system

ActiveCN111788908ARealize real-time monitoringAccurately fall onOperating means/releasing devices for valvesSeed depositing seeder partsSeederControl system

The invention discloses a corn miss-seeding reseeding device and a control system. The corn miss-seeding reseeding device comprises seed metering devices, wherein each seed metering device consists ofa first seat shell, a seed metering plate, a first seed filling cavity cover, a first seed protection plate, a first main shaft, a first outer clamp, a first rolling bearing, a first bearing end cover and a second bearing end cover; each first seat shell is mounted below a seeder; each first main shaft is connected with the center of the corresponding seed metering plate through an outer spline;each seed metering plate is axially limited by the corresponding first outer clamp; each first seed filling cavity cover is in fastening connection with one side of the corresponding first seat shell;each first seed protection plate is in circumferential sliding connection with an inner wall of the corresponding first seat shell; one end of each first main shaft is in rotary connection with the center of the corresponding first seed filling cavity cover through the corresponding first rolling bearing; the other end of each first main shaft is in rotary connection with the center of a housingthrough the corresponding first rolling bearing; the corn miss-seeding reseeding device further comprises a reseeding device; one reseeding device is directly arranged on the adjacent seed metering devices; one reseeding device is used for carrying out reseeding operation on two rows of seed metering devices; the corn miss-seeding reseeding device is simple and compact in structure and high in reseeding accuracy and instantaneity; and the miss-seeding rate of a corn precision seeder is reduced, and the seeding quality and the production efficiency are improved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

An oil cylinder lifting land power catwalk

ActiveCN104265207BImprove work efficiencyThe drill effect is obviousDrilling rodsDrilling casingsOil drillingPulley

The invention discloses a hoisting land power catwalk of a cylinder and belongs to the technical field of oil drilling equipment. The hoisting land power catwalk comprises a ramp, a pedestal, a rotating arm and a V-shaped drilling tool support beam, the upper end of the ramp is provided with a ramp guide pulley which is positioned at the connection part of the ramp and the drilling platform; the bottom of the V-shaped drilling tool support beam is provided with a support beam guide rail combined with the ramp guide pulley, and the support beam guide rail can be moved with respect to the ramp guide pulley. The hoisting land power catwalk is characterized in that the support beam guide rail at the V-shaped drilling tool support beam bottom is combined with the ramp guide pulley on the upper end of the ramp to directly convey the drilling rod near the well mouth, thereby improving drill-feeding working efficiency, in particular, the structure has the more obvious drill-feeding effect in the high drilling platform.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Automotive upholstery production device

ActiveCN103753641AIncrease flexibilityIncrease punching frequencyMetal working apparatusPunchingEngineering

The invention discloses an automotive upholstery production device. The device is characterized by comprising a rack and a punching unit which is arranged on the rack movably. According to the device, a punching guide rail is added on the rack, so that offset of a device head on the rack during moving is prevented, the device head can fall in the preset hole position on a to-be-punched upholstery support accurately, the punching stability and the punching accuracy are improved, the punching quality is improved, and the punching efficiency is enhanced.

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

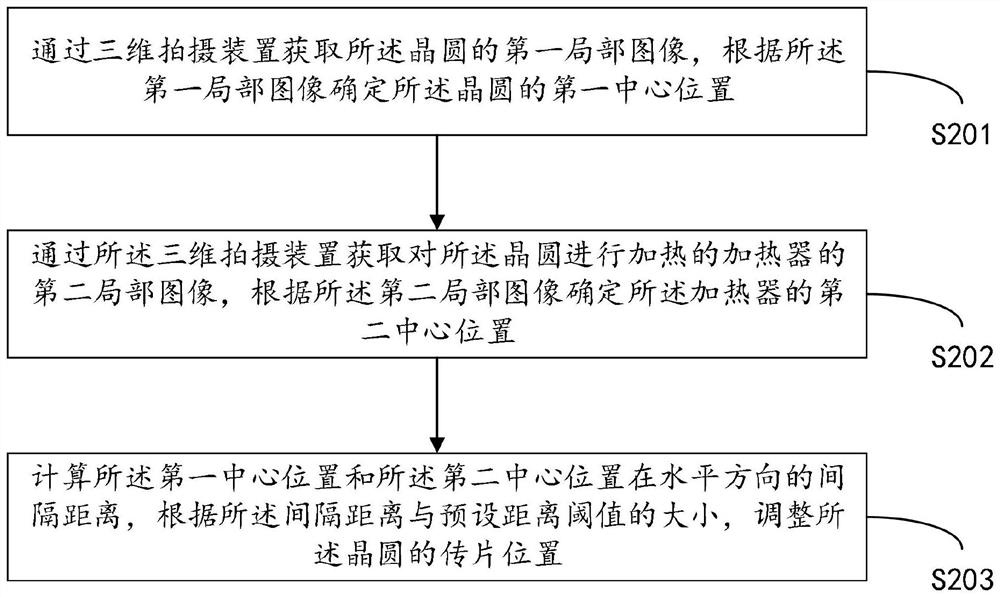

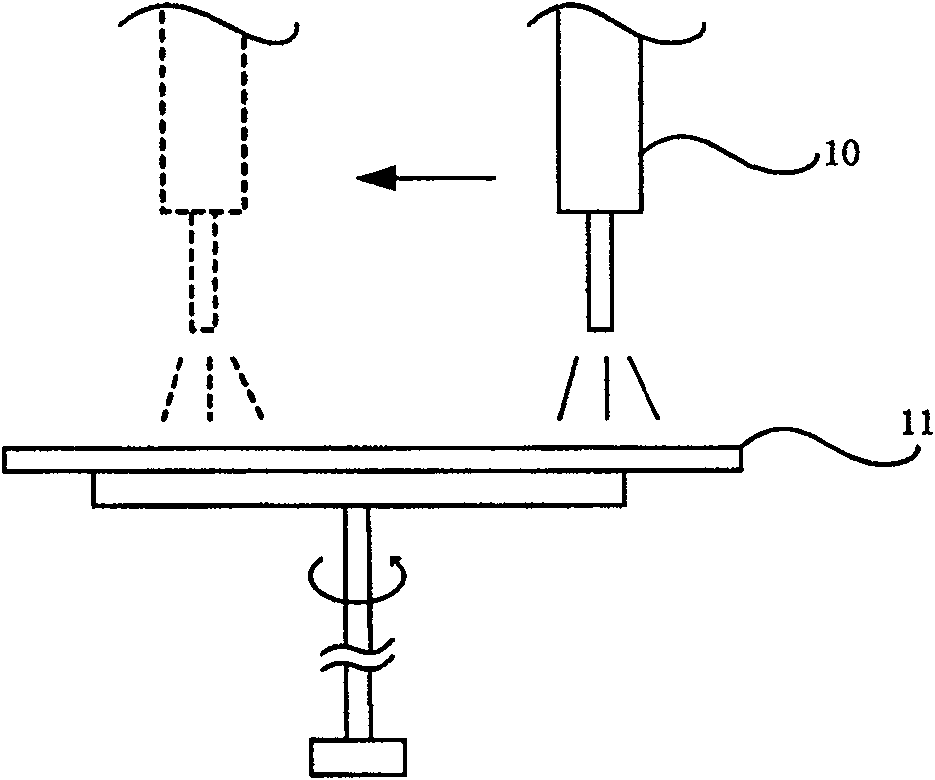

Wafer transfer position adjusting method and device

PendingCN114203597AAccurately fall onImprove the heating effectImage enhancementImage analysisWaferEngineering

The invention provides a wafer transfer position adjusting method and device, which are applied to the heating process of a wafer, and the adjusting method comprises the steps: obtaining a first local image of the wafer through a three-dimensional shooting device, and determining a first central position of the wafer according to the first local image; acquiring a second local image of a heater for heating the wafer through the three-dimensional shooting device, and determining a second central position of the heater according to the second local image; and calculating the spacing distance between the first central position and the second central position in the horizontal direction, and adjusting the wafer transfer position of the wafer according to the spacing distance and a preset distance threshold value. And the in-chip uniformity of the wafer processing technology is improved.

Owner:PIOTECH CO LTD

Building roof dropping cargo receiving device capable of fulfilling buffering function

ActiveCN109823761ARealize automatic receivingAvoid damageAircraft componentsLaunching weaponsEngineeringLow altitude

Owner:DALIAN NATIONALITIES UNIVERSITY

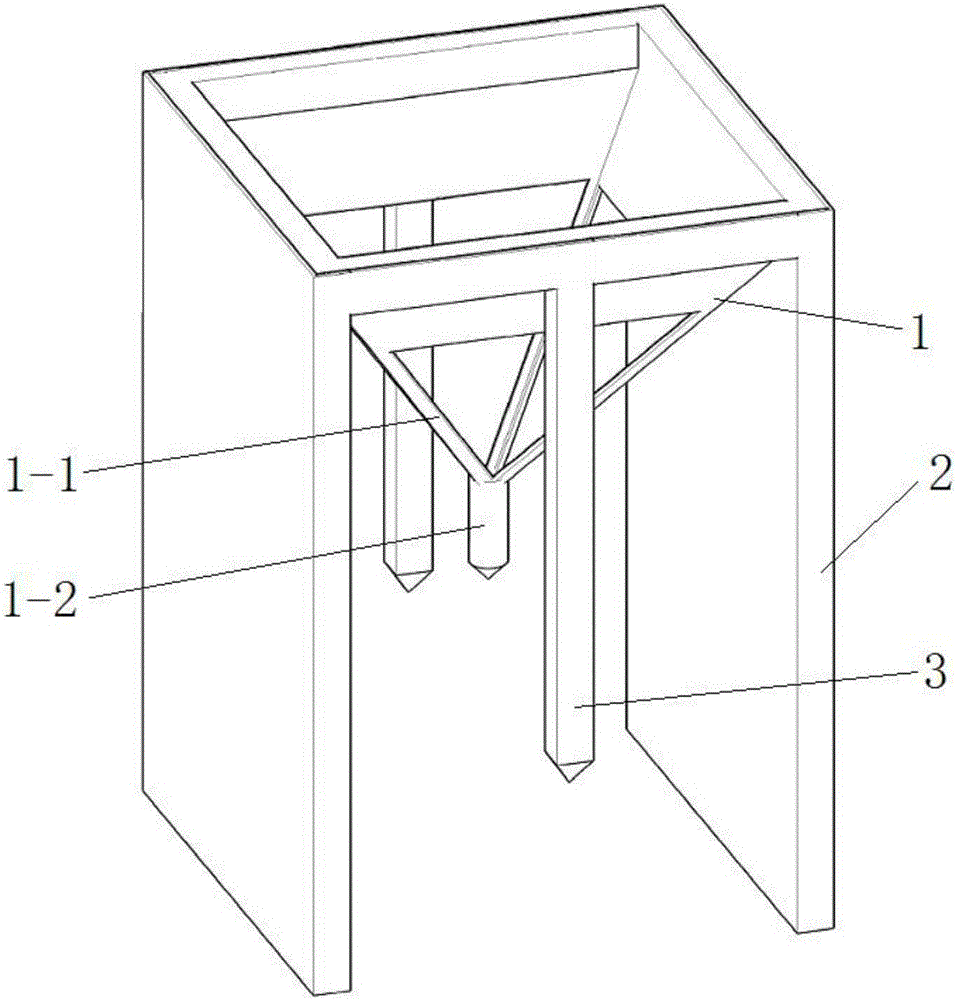

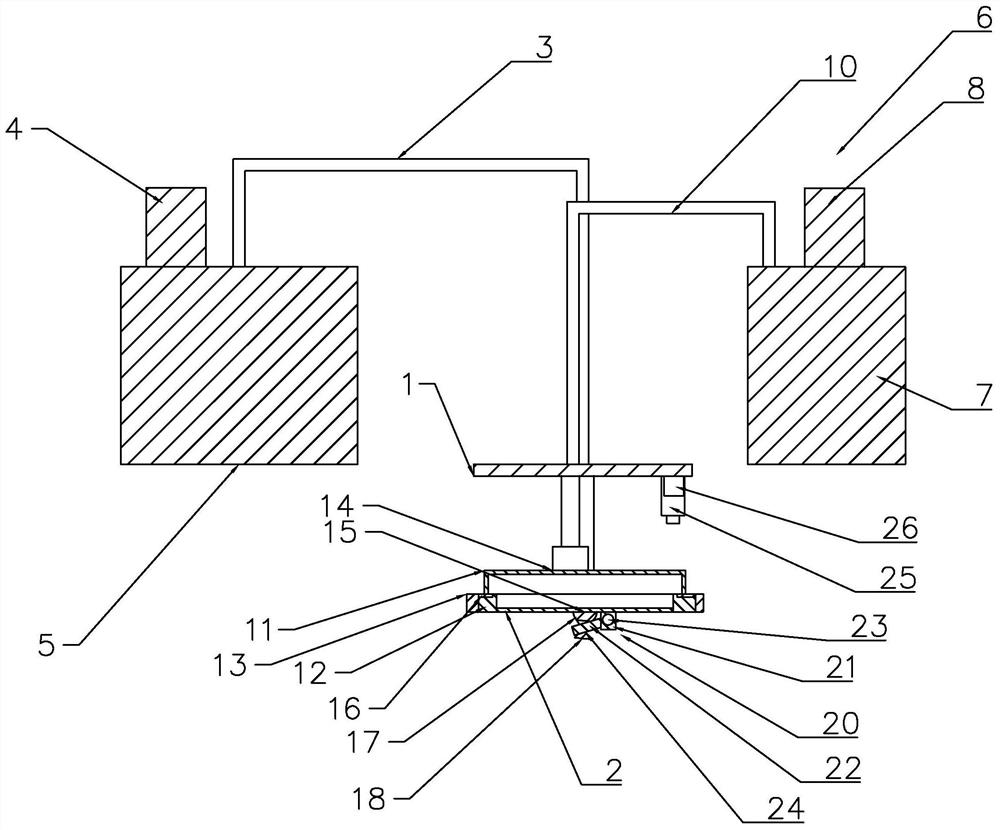

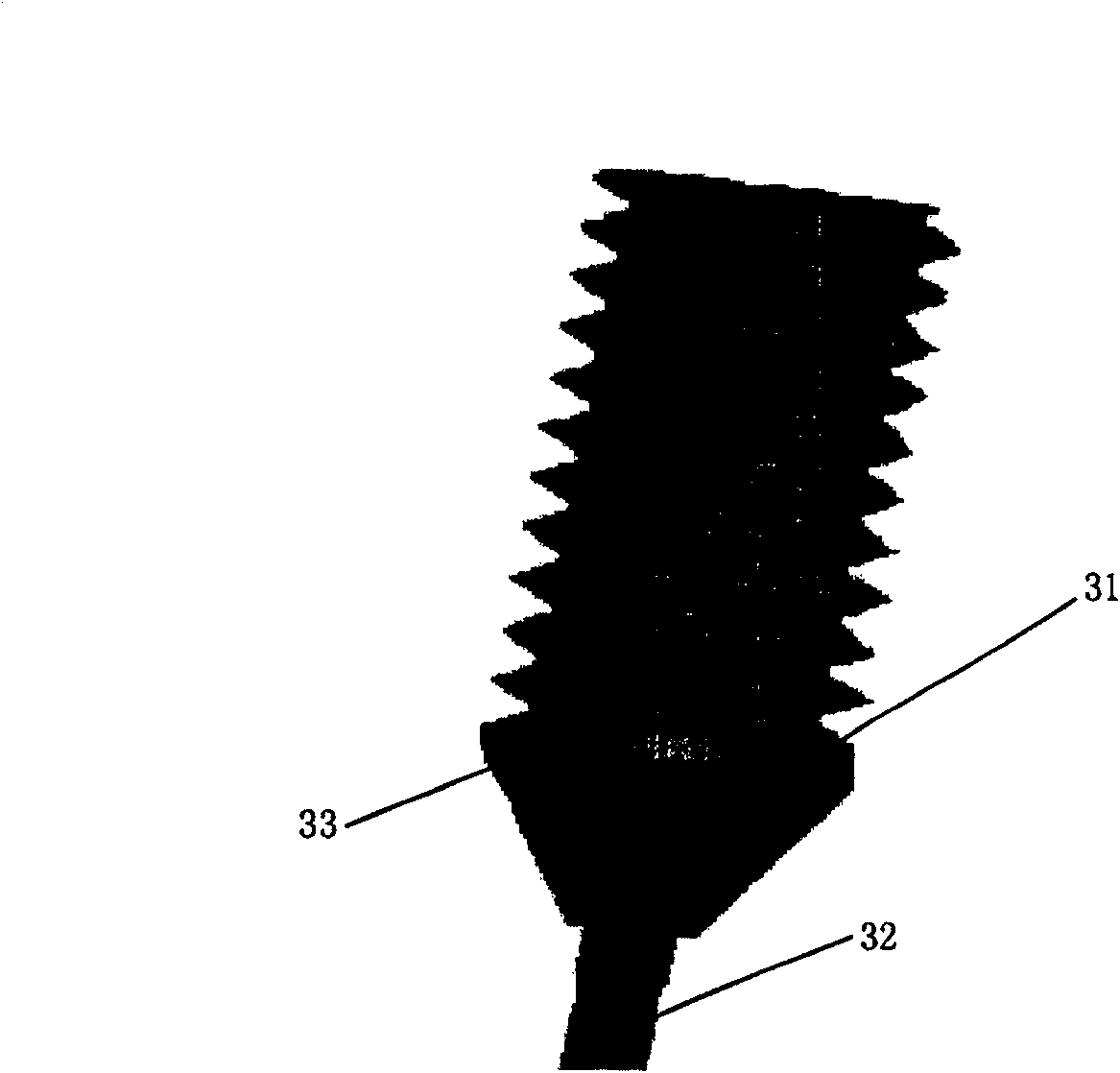

Dropping funnel for solid dangerous goods burning speed test

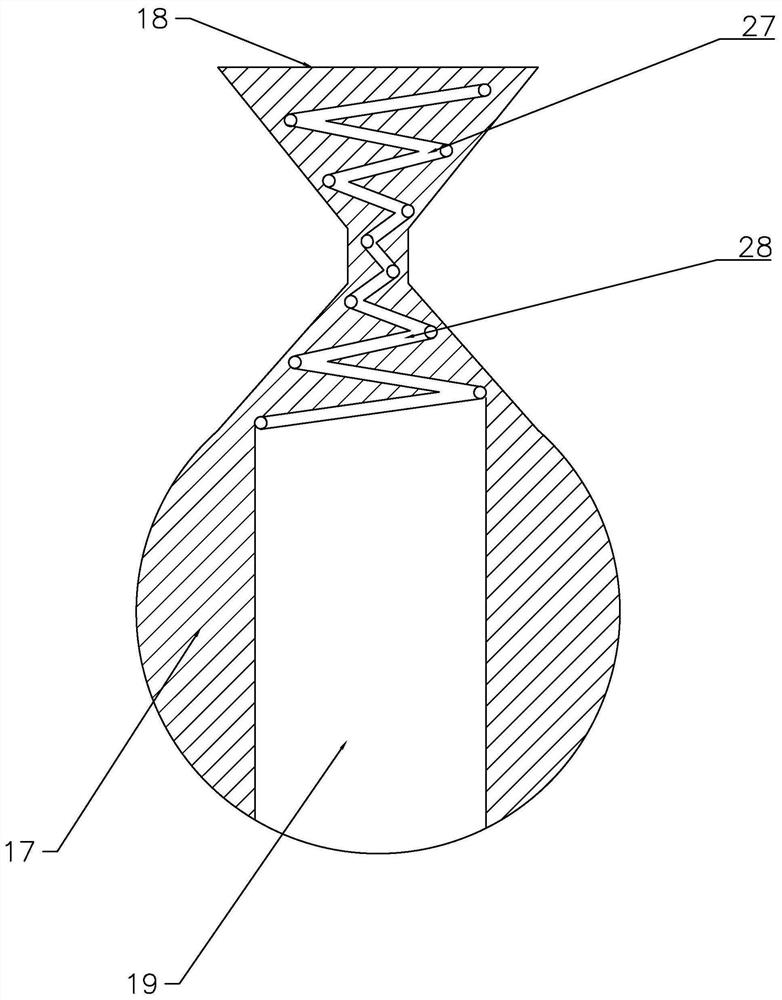

InactiveCN105842383AAccurately fall onImprove accuracyChemical analysis using combustionInverted pyramidSpeed test

The invention discloses a dropping funnel for a solid dangerous goods burning speed test; the dropping funnel is composed of a supporting foot stand, an inverted pyramid type liquid collecting tank and sighting bars; a tower tip of the inverted pyramid type liquid collecting tank consists of four prisms and is connected with a guide post; the tower bottom of the inverted pyramid type liquid collecting tank is fixedly connected with the supporting foot stand; two sighting bars are fixed at the side edges of the tower bottom, and the bottom ends of the sighting bars are tips; the tip of the guide post is located at a connection line of the tips of the two sighting bars. The funnel can ensure that a wetting agent is accurately dropped to a stacked ridge of a measured substance according to test requirements, a strong guarantee is provided for implementation of the United Nations dangerous goods flammable solid burning speed test strictly according to requirements; the funnel is simple in structure, low in cost and capable of direct production through 3D printing.

Owner:广西出入境检验检疫局危险品检测技术中心 +1

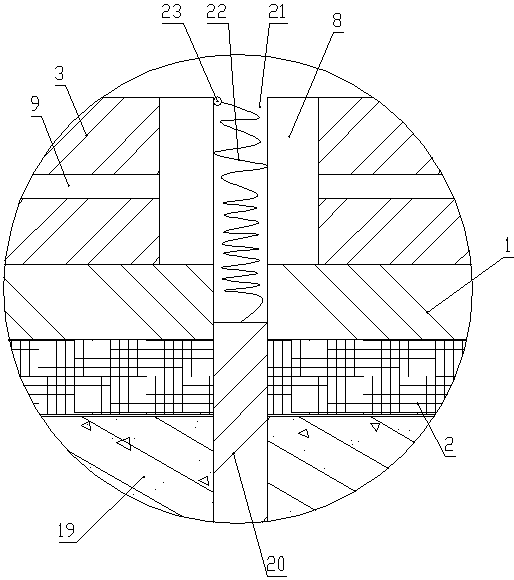

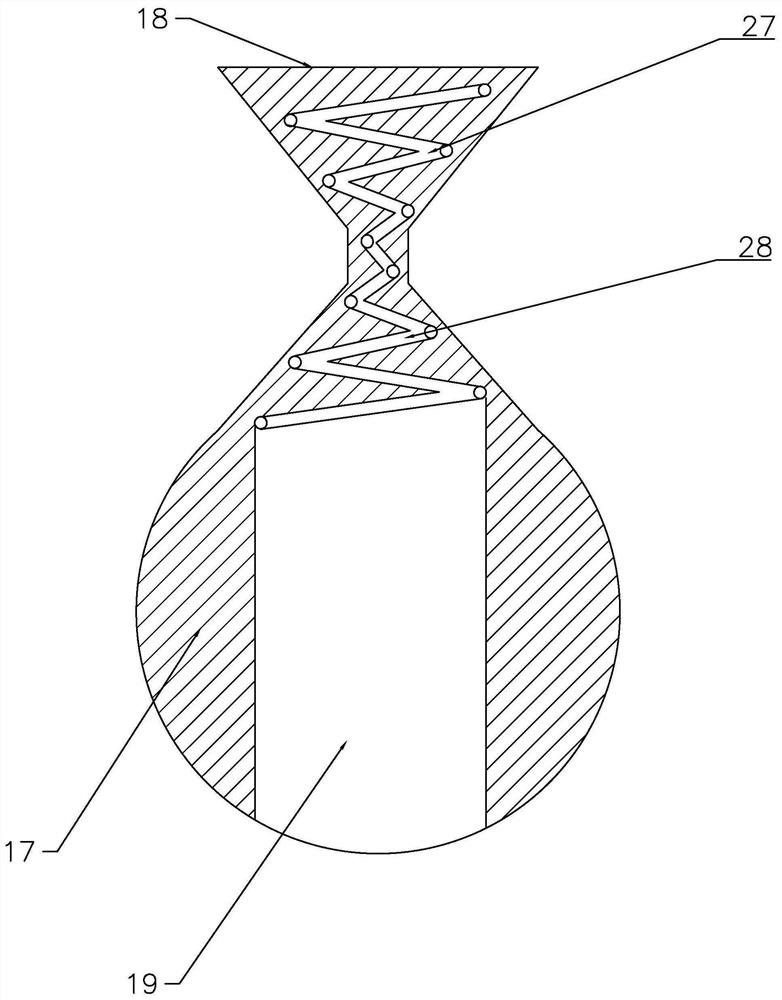

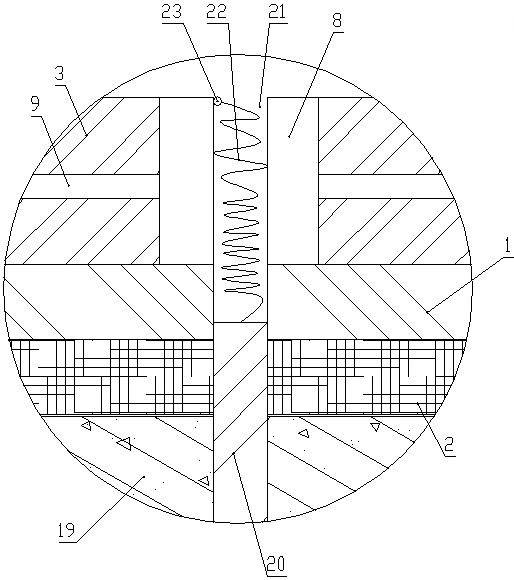

Bottom-fixed ADCP probe sink-float system, mounting method thereof and maintenance debugging method

The invention discloses a bottom-fixed ADCP probe sink-float system, which comprises a sink-float mechanism, a trapezoidal plate, and a control mechanism. The sink-float mechanism comprises a circularsupporting plate which is connected with an air bag and an integrated circuit board. The outer edge of the supporting plate is connected with a cable main tube and a cantilever tube. The cantilever tube is connected with the trapezoidal plate. The trapezoidal plate is connected with an ADCP probe through a cross-shaped hoop bracket. The air bag is connected with a ventilation pipe. Connecting wires of the ventilation pipe and a pressure sensor extend into the cable main tube and extend along the cable main tube to the river bank to be connected with the control mechanism. The control mechanism comprises an electric control device, a display screen, a venting solenoid valve, and an air pump. The invention further discloses a mounting method of bottom-fixed ADCP probe sink-float system anda maintenance debugging method. The invention floats components up to the water surface for maintenance and debugging, so that the maintenance and debugging work does not need to wade in the water andis no longer affected by the flood season, and therefore, an operator will be protected from the personal danger caused by the wading operation, thereby improving the accuracy of the flow measurementdata.

Owner:徐志国

A kind of corn missed sowing and reseeding device and control method

ActiveCN111788908BRealize real-time monitoringAccurately fall onOperating means/releasing devices for valvesSeed depositing seeder partsSeederRolling-element bearing

The invention discloses a corn missed sowing reseeding device and a control method thereof, comprising a seed metering device, the seed metering device is composed of a seat shell 1, a seed metering tray, a first seed filling chamber cover, a seed protection plate 1, a main shaft 1, and an outer card 1. Rolling bearing 1, bearing end cover 1 and bearing end cover 2. Seat shell 1 is installed under the seeder. Main shaft 1 is connected to the center of the seeding disc through an external spline, and the axial direction of the seeding disc is limited by the outer card 1. , the first seed-filling chamber cover is fastened to one side of the seat shell, the seed protection plate is connected to the inner wall of the seat shell by sliding in the circumferential direction, the main shaft-one end is rotationally connected to the center of the first seed-filling chamber cover through a rolling bearing, and the main shaft The other end is rotationally connected to the center of the housing through a rolling bearing, and also includes a re-seeding device, and a re-seeding device is directly provided on the adjacent seed metering device, and a re-seeding device is used to re-seed two rows of seed metering devices. The structure is simple and compact, and the replanting accuracy and real-time performance are high, which reduces the missed seeding rate of the corn precision seeder, and improves the seeding quality and production efficiency.

Owner:ANHUI AGRICULTURAL UNIVERSITY

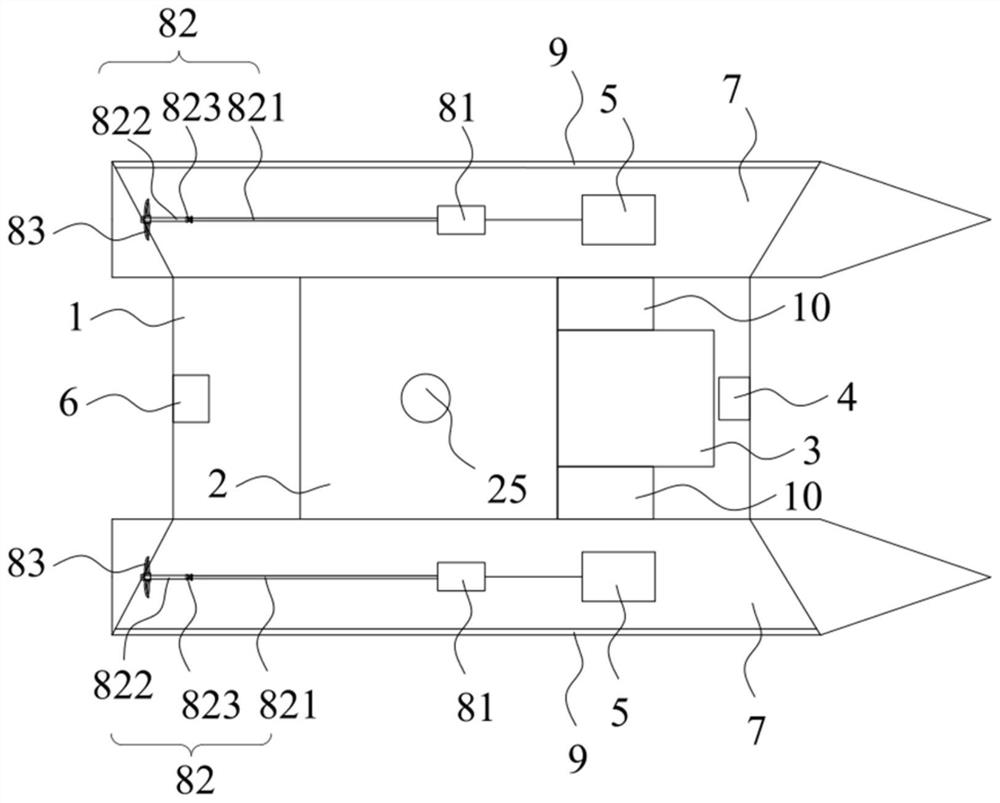

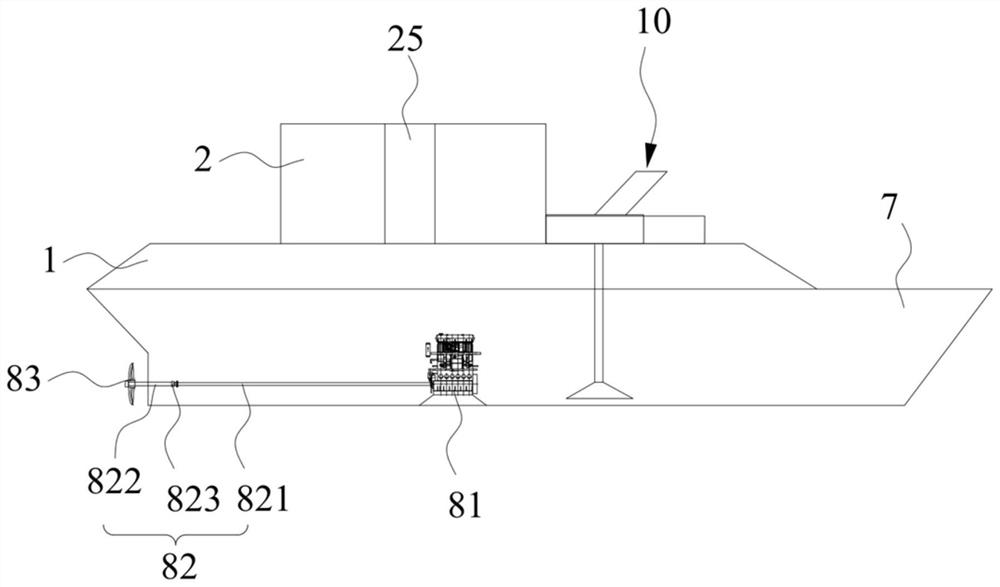

Fire-fighting intelligent ship

InactiveCN112124501AImprove the speed and efficiency of fire suppressionSecurityWaterborne vesselsFire rescueFirefightingAutomatic control

The invention discloses a fire-fighting intelligent ship, and relates to the technical field of rescue ships. The fire-fighting intelligent ship comprises a main ship body, a high-pressure fire extinguishing bomb device, a rescue ring launching device, a fire source monitoring and tracking device, a power supply and a controller, wherein the main ship body is provided with a deck house; the high-pressure fire extinguishing bomb device is rotationally arranged in the deck house and used for ejecting a fire extinguishing bomb, the rescue ring launching device is arranged on the main ship body and used for launching a rescue ring, the fire source monitoring and tracking device is arranged in the deck house and used for monitoring and tracking a fire source, and the high-pressure fire extinguishing bomb device, the rescue ring launching device and the fire source monitoring and tracking device are all electrically connected with the power supply; and the controller is electrically connected with the power source, and the high-pressure fire extinguishing bomb device, the rescue ring launching device and the fire source monitoring and tracking device are all connected with the controller. The fire source can be monitored and tracked through the fire source monitoring and tracking device so that dangerous situations can be rapidly found out, meanwhile, the devices are controlled through the controller, the purpose of automatic control can be achieved, and the fire extinguishing speed and efficiency are improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

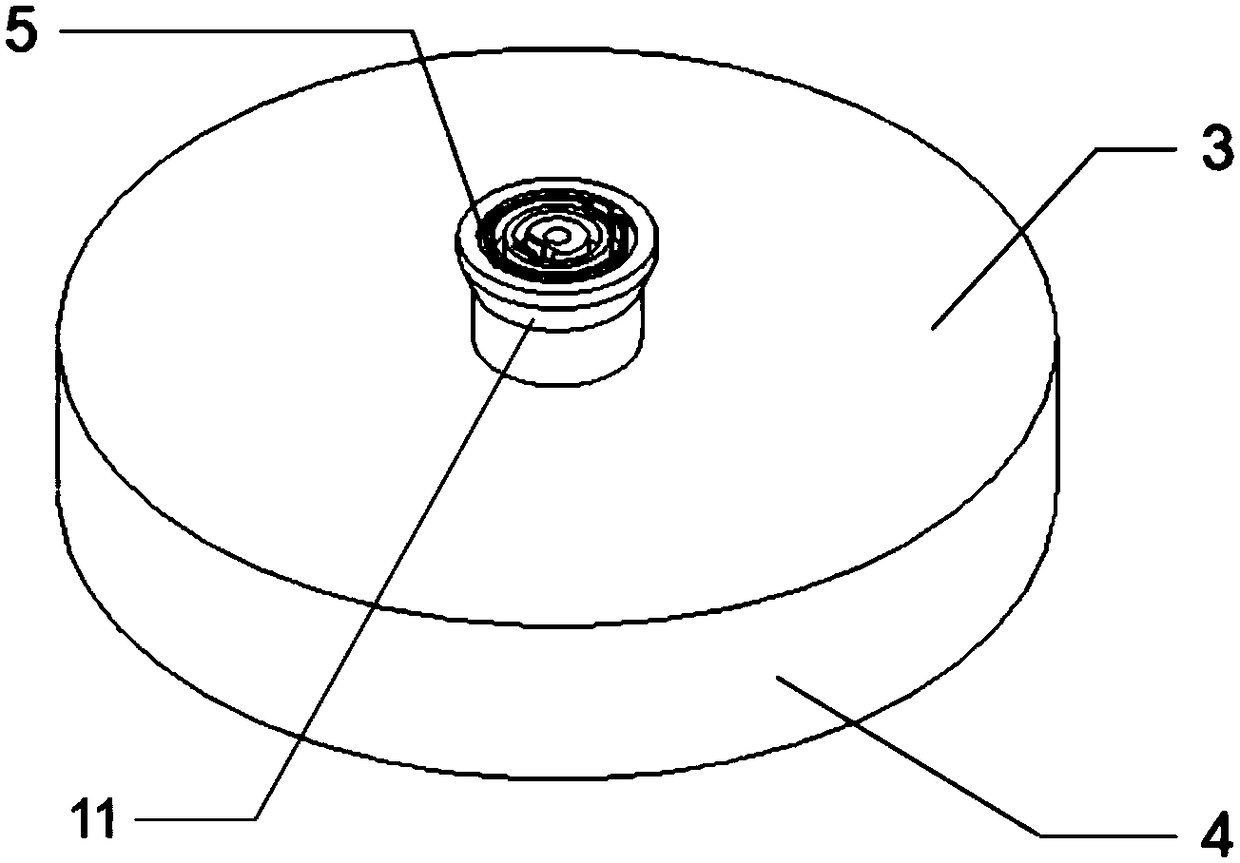

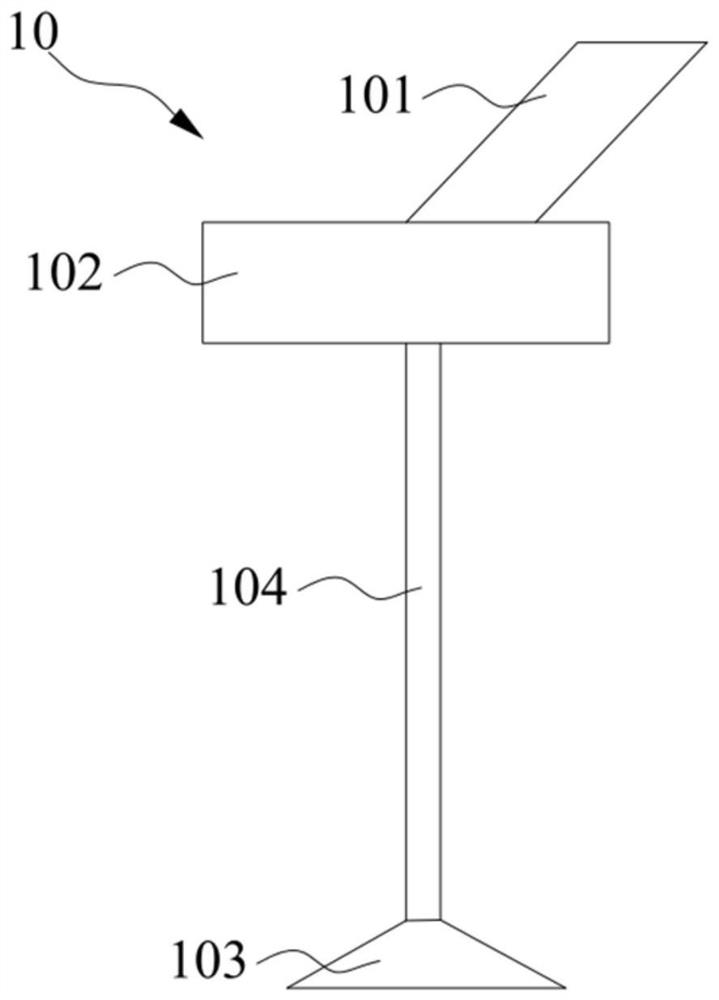

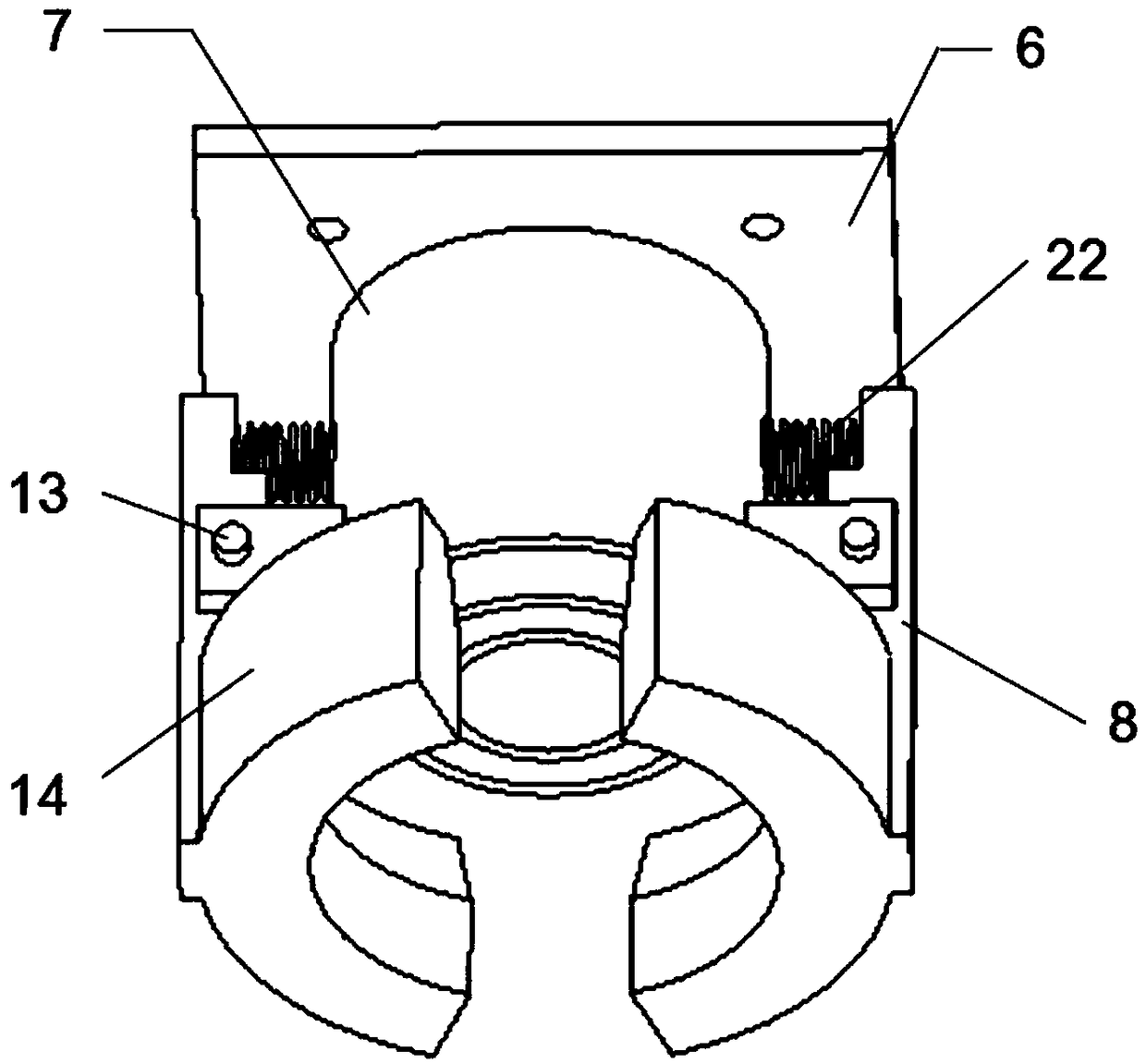

Detachable battery

ActiveCN108448040AReduced precision requirementsImprove fault toleranceCurrent conducting connectionsEngineeringElectrical and Electronics engineering

The invention discloses a detachable battery, and belongs to the technical field of machinery. The detachable battery comprises a detachable battery apparatus (1) and a battery connecting apparatus (2); the detachable battery apparatus (1) comprises a battery (3), a battery cabin (4) and a first connector (5); and the battery connecting apparatus comprises a connecting plate (6), a second connector (7) and a clamping apparatus (8). The detachable battery provided by the invention has significant applications on the aspects of power supply of an unmanned aerial vehicle, an unmanned car and a robot.

Owner:JIANGNAN UNIV

Construction method of non-collision throwing and filling of face protection gabion net bag

ActiveCN107761738BCause damageReduce underwater unhooking operationsFoundation engineeringEngineeringRevetment

The invention discloses a facing stone cage net bag bump-free dump filling construction method. The method comprises the steps that a stone cage net bag dump filling device is prepared; the stone cagenet bag dump filling device is placed on a barge deck, end steel slings located on the front side of an upper frame body are lifted to lifting hooks of crane equipment; the lifting hooks are lifted to pull up the upper frame body, a stone cage net bag is placed on an openable rolling bottom plate, and the upper frame body is placed down to be folded with the openable rolling bottom plate; the twoend steel slings are connected with the end lifting hooks, the steel slings are connected with the lifting hooks connected with an automatic hook disengagement device above the upper frame body, thelifting hooks connected with the automatic hook disengagement device and the two end lifting hooks are connected to the lifting hooks of the crane equipment through a three-leg chain; the stone cage net bag dump filling device is lifted and placed into water, the lifting hooks connected with the automatic hook disengagement device are disengaged, and the stone cage net bag slides down towards thesteel cylinder revetment direction. By means of the method, the stone cage net bag can accurately fall down to the position tightly attached to the steel cylinder revetment structure.

Owner:中建六局华南建设有限公司

Bufferable roof dropped cargo receiving method

ActiveCN109823762ARealize automatic receivingAvoid damageAircraft componentsChutesLow altitudeEngineering

The invention discloses a bufferable roof dropped cargo receiving method and belongs to the field of unmanned aerial vehicle cargo transport. The bufferable roof dropped cargo receiving method aims atachieving the effect of being independent of control of operators and can achieve automatic receiving of unmanned aerial vehicle cargo. At the moment of several minutes before a fixed wing unmanned aerial vehicle arrives at a receiving device, LED lamps at the four corners of the receiving device are on; and an extending-and-contracting plate at a cargo picking area at the tail of the device slides into the tail of a sliding speed reduction area, and a highly-elastic rubber net in the cargo picking area is opened. The unmanned aerial vehicle is adjusted from high-altitude flight to horizontalflight away from the receiving device by a certain vertical distance height; and the bufferable roof dropped cargo receiving method achieves the effect that the dropped cargo can be received at the low altitude in a roof area capable of containing the device.

Owner:DALIAN NATIONALITIES UNIVERSITY

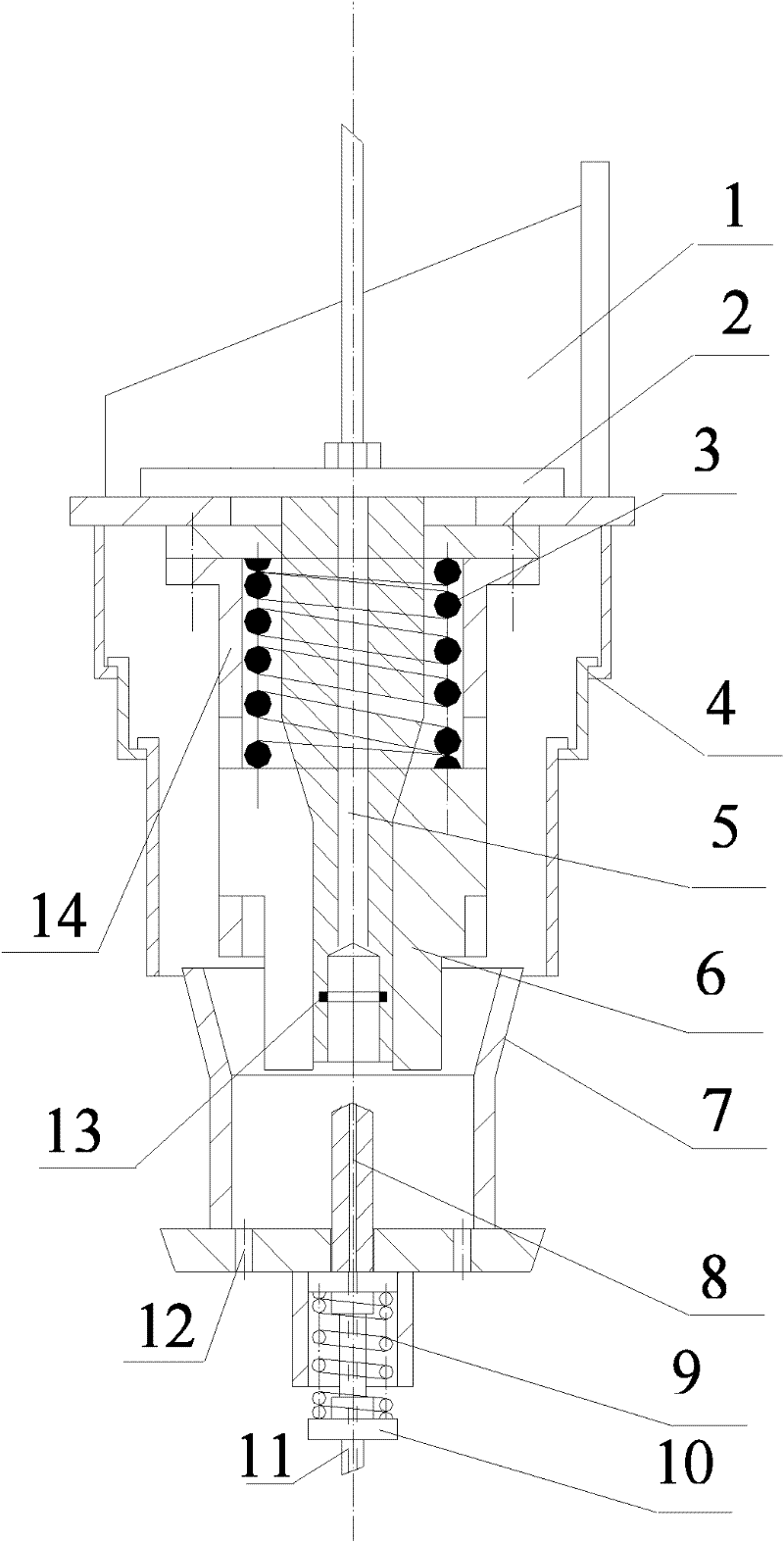

A mechanical strength testing device

ActiveCN108037000BEnsuring Mechanical Strength Test CapabilitiesConvenience falls onInvestigating material hardnessRatchetEngineering

The invention discloses a mechanical strength test apparatus. A pedestal is provided with a frame body which is hinged to the upper end of a swinging rod. An impact hammer is fixed to the lower end ofthe swinging rod. A first ratchet wheel is arranged at the outer side of an arc-shaped swinging track of the impact hammer and is fixed to the frame body. A positioning apparatus is in slide connection with the first ratchet wheel and is used for fixing an initial swing position of the impact hammer. A first pawl matched with the first ratchet wheel is hinged to the positioning apparatus, so thatthe positioning apparatus is stably located at a required height on the first pawl by cooperation of the first ratchet wheel and first pawl. The positioning apparatus is connected to a connection rodwhich is detachable from the impact hammer. A to-be-tested piece mounting position for fixing a to-be-tested piece is arranged on a position, at the right side of the first ratchet wheel, of the frame body. The test apparatus has simple structure and has safe and reliable test process, can save manpower and test time during the test process, and can increase test efficiency.

Owner:钧风电控科技泰州有限责任公司

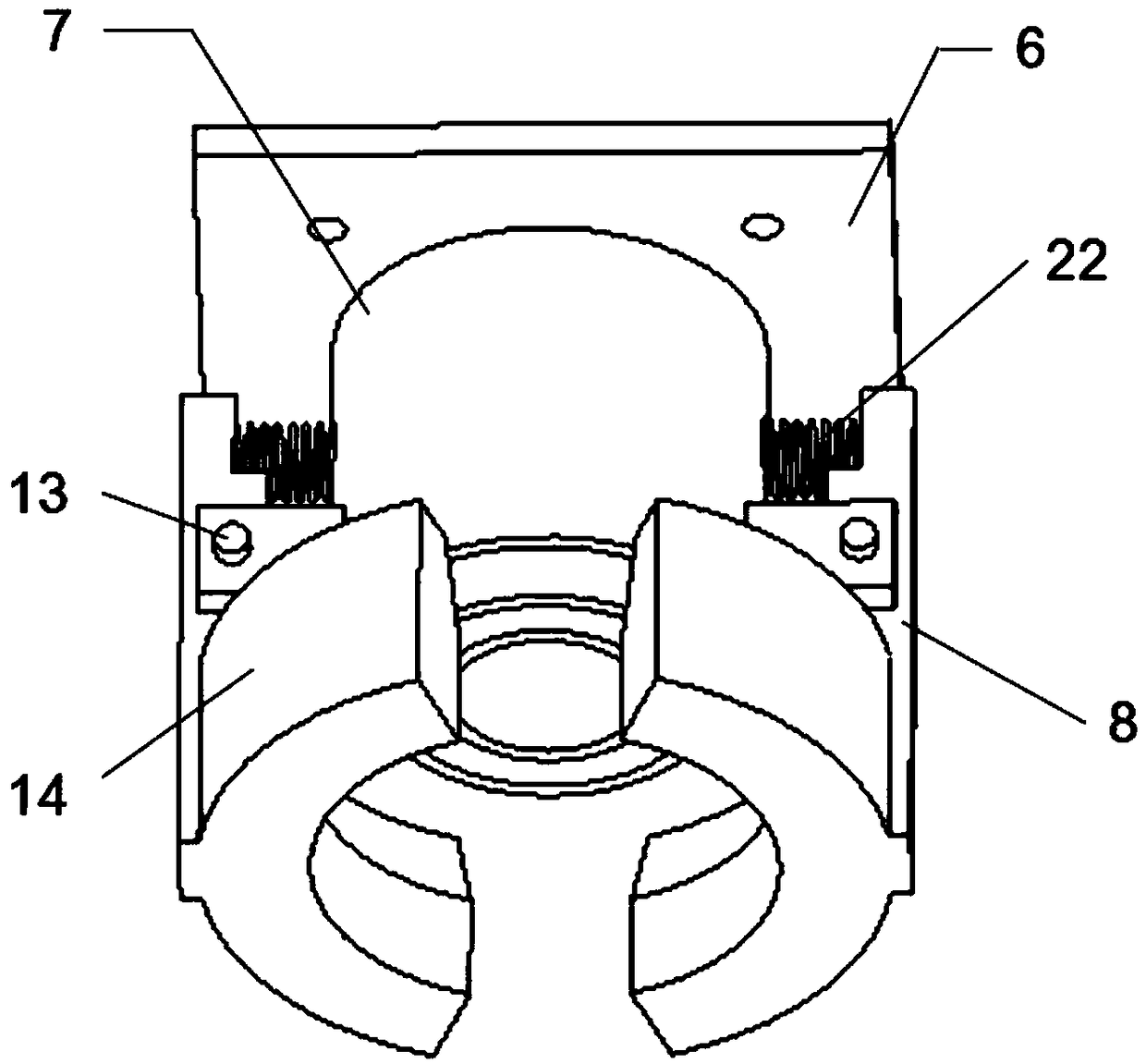

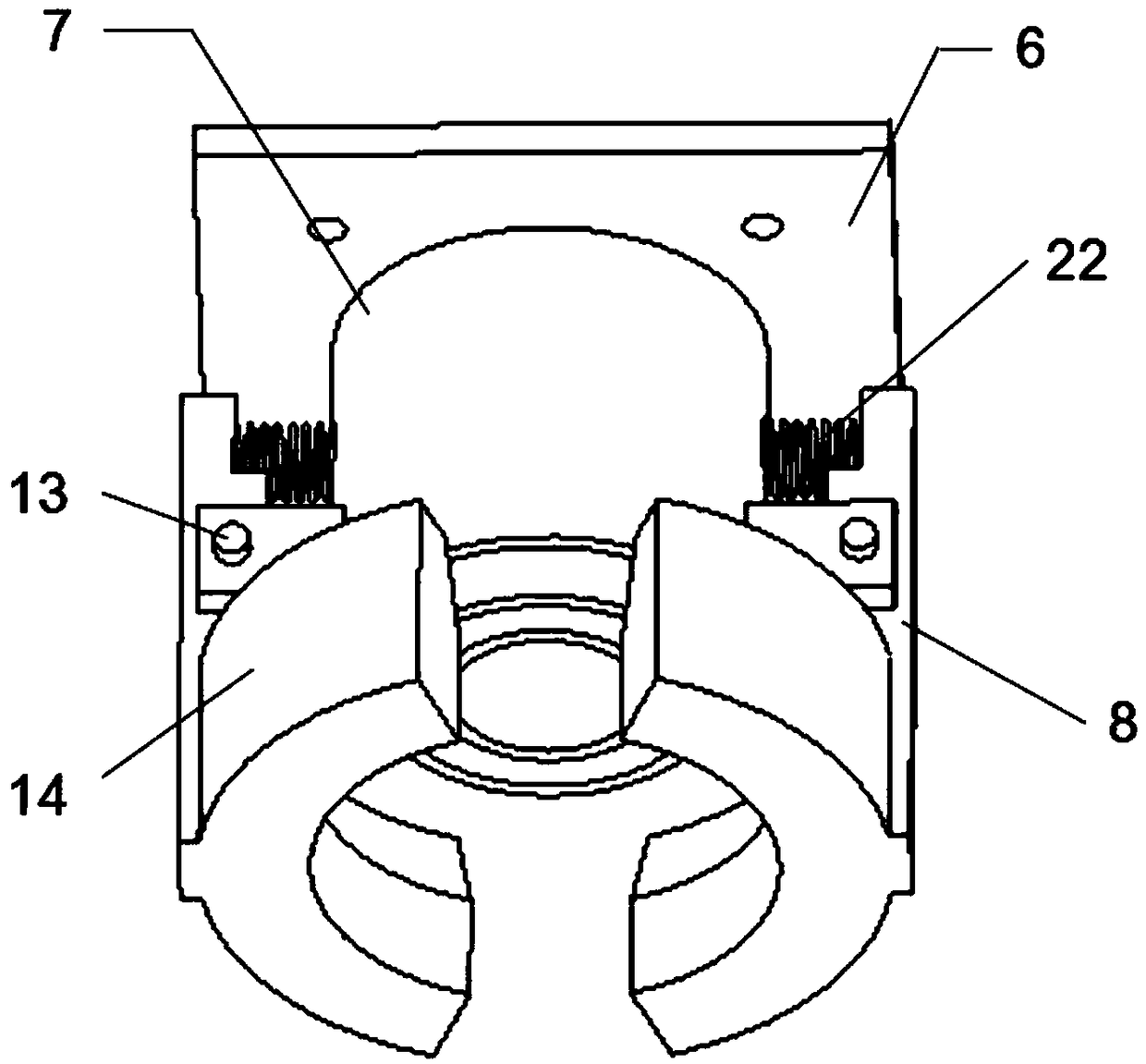

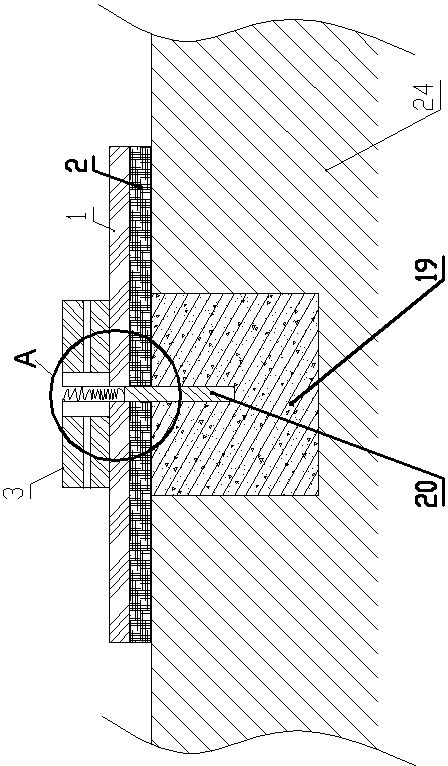

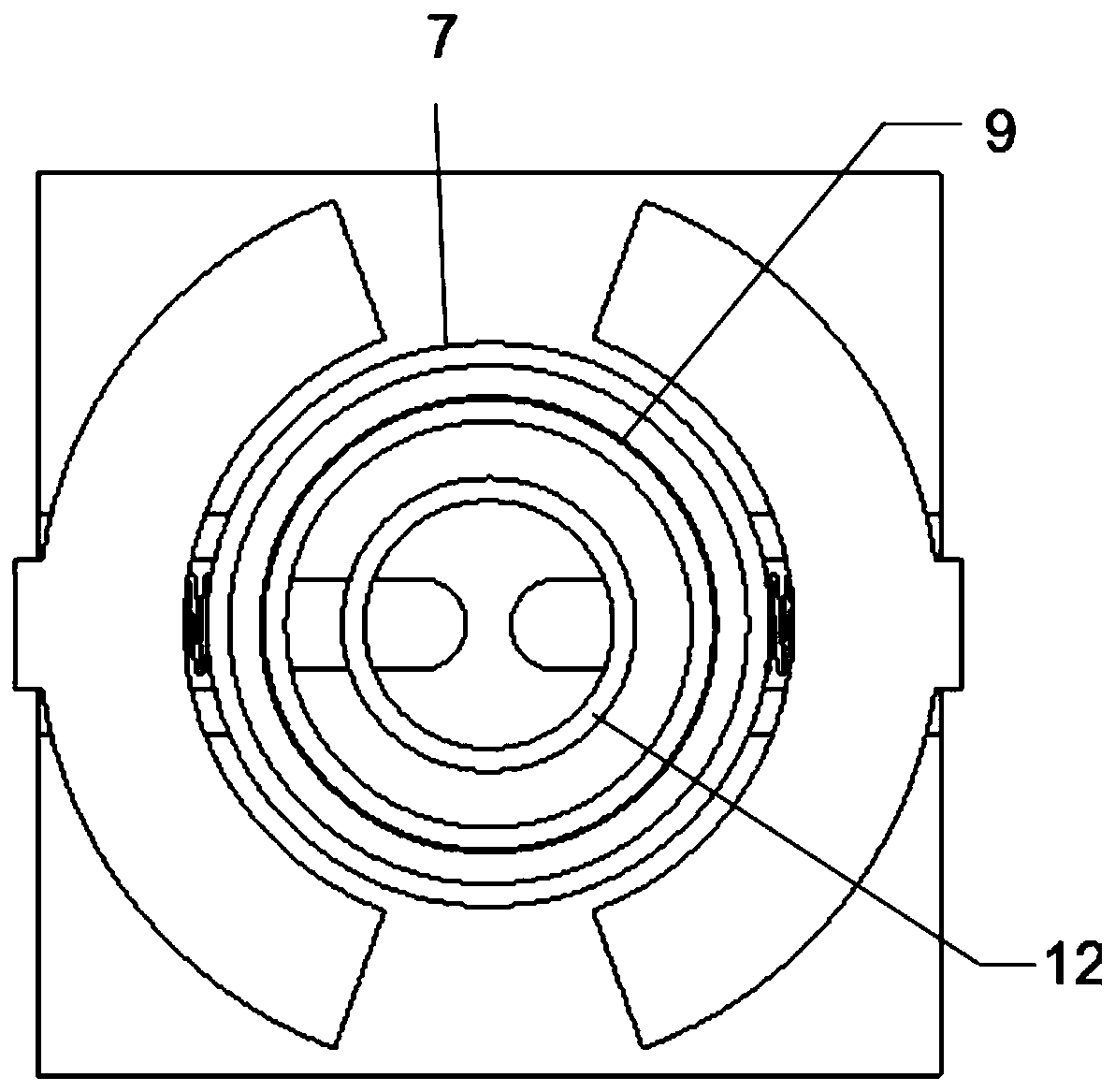

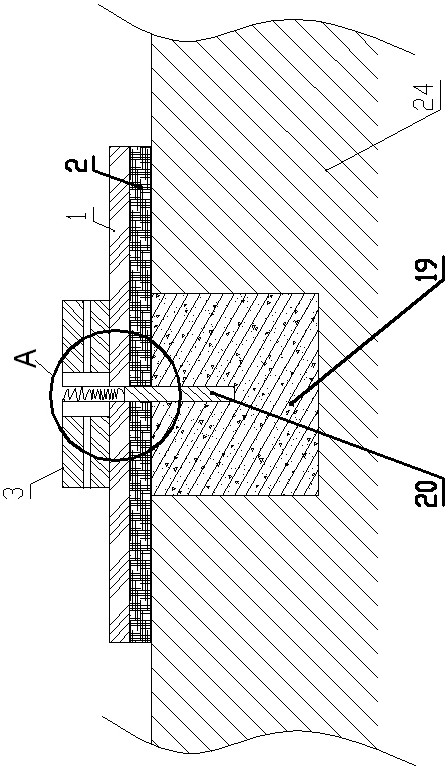

Automatic centering argon blowing device connector

The invention discloses an automatic centering argon blowing device connector, which comprises a support, a socket movably connected with the support, and a plug component arranged below the socket, wherein the plug component comprises a guide sleeve of which the upper end is provided with an opening, a plug arranged in the guide sleeve and matched with the socket, and an elastic piece arranged below the plug and pressed against the plug; a three-claw positioning device is arranged at the periphery of the socket; and air holes for making argon pass through are respectively formed on the plug and the socket. Due to the plug and the socket which are matched mutually, and the three-claw positioning device arranged at the periphery of the socket, the automatic centering argon blowing device connector enables an argon blowing device at the bottom of a steel ladle to automatically and accurately fall down on a steel ladle transportation truck; in the absence of a limiting device on the steel ladle transportation truck or the steel ladle, a crane driver can operate conveniently; therefore, the connecting time for the argon blowing device at the bottom of the steel ladle is shortened greatly, the energy is saved, and the refining production efficiency is improved.

Owner:吉林建龙钢铁有限责任公司

Bufferable rooftop airdrop cargo receiving device

ActiveCN109823761BRealize automatic receivingAvoid damageAircraft componentsChutesMarine engineeringUncrewed vehicle

Owner:DALIAN NATIONALITIES UNIVERSITY

A dual-fluid water mist high-efficiency fire extinguishing device

A two-fluid fine water mist high-efficiency fire extinguishing device, comprising an equipment base, a fine water mist nozzle connected to the equipment base, a water supply pipe connected to the fine water mist nozzle, a pump set connected to the water supply pipe, a pump set connected to the pump set A water storage tank, an air supply device connected to the fine water mist nozzle, the gas supply device includes an air storage tank, a pressure pump connected to the air storage tank, an air outlet head connected to the fine water mist nozzle, an air outlet head and a pressure pump The connecting pipe between them, the air outlet head includes a fixed base, a rotating base and a rotating motor for driving the rotating base to rotate, the fixed base is fixedly connected to the fine water mist nozzle, the fixed base, the rotating base The seat and the fine water mist nozzle are coaxially arranged, the top of the fixed base is provided with an air inlet, one end of the connecting pipe is fixedly connected to the air inlet, the rotating base is provided with an air outlet, and the rotating base A sealing ring is provided between the seat and the fixed base, and both the rotating base and the fixed base are hollowed out.

Owner:ZHEJIANG YOUAN GAOKE FIRE FIGHTING SYST

A method for receiving air-dropped goods on the roof that can be buffered

ActiveCN109823762BRealize automatic receivingAvoid damageAircraft componentsLaunching weaponsLevel flightMarine engineering

The invention discloses a bufferable roof dropped cargo receiving method and belongs to the field of unmanned aerial vehicle cargo transport. The bufferable roof dropped cargo receiving method aims atachieving the effect of being independent of control of operators and can achieve automatic receiving of unmanned aerial vehicle cargo. At the moment of several minutes before a fixed wing unmanned aerial vehicle arrives at a receiving device, LED lamps at the four corners of the receiving device are on; and an extending-and-contracting plate at a cargo picking area at the tail of the device slides into the tail of a sliding speed reduction area, and a highly-elastic rubber net in the cargo picking area is opened. The unmanned aerial vehicle is adjusted from high-altitude flight to horizontalflight away from the receiving device by a certain vertical distance height; and the bufferable roof dropped cargo receiving method achieves the effect that the dropped cargo can be received at the low altitude in a roof area capable of containing the device.

Owner:DALIAN NATIONALITIES UNIVERSITY

A detachable battery swap charging device

ActiveCN108515866BImprove fault toleranceReduced precision requirementsCharging stationsElectric propulsion mountingUncrewed vehicleMechanical engineering

Owner:JIANGNAN UNIV

Photoresist coating device and its method

InactiveCN100561346CAccurately fall onPrecise positioningLiquid surface applicatorsPhotomechanical coating apparatusWaferingControl system

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

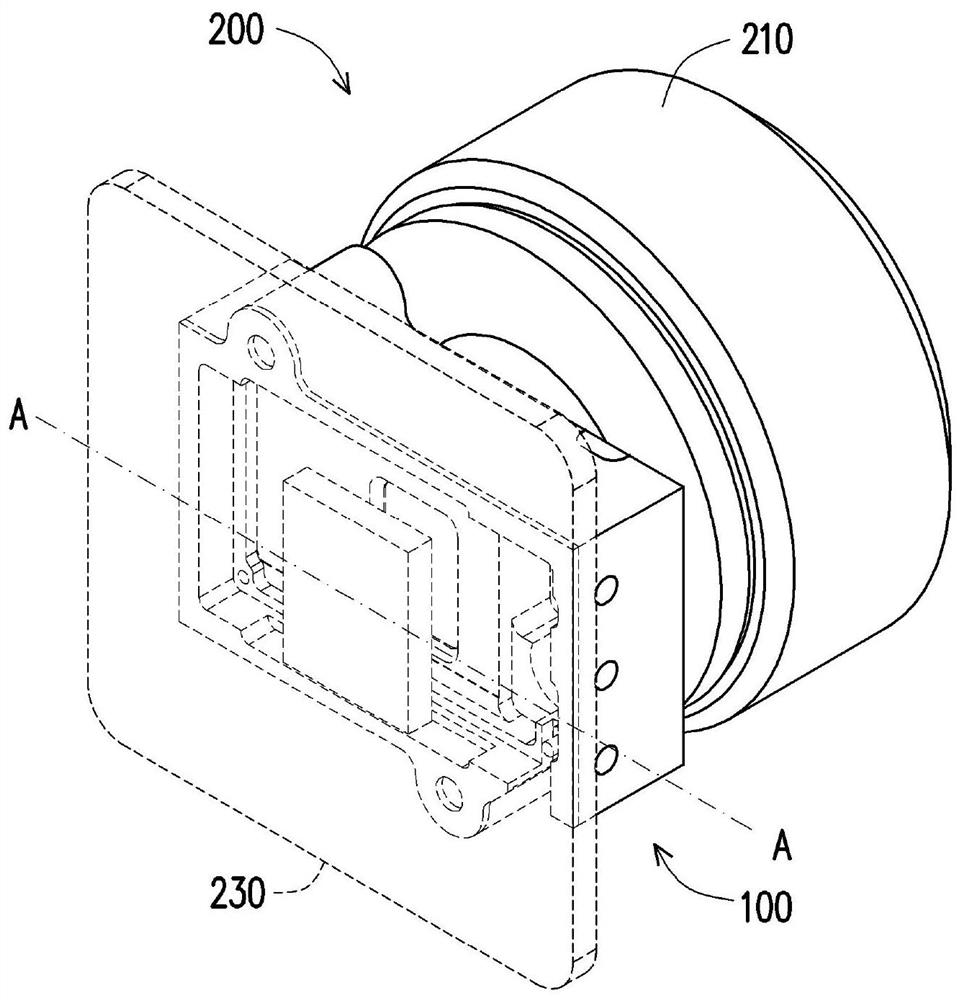

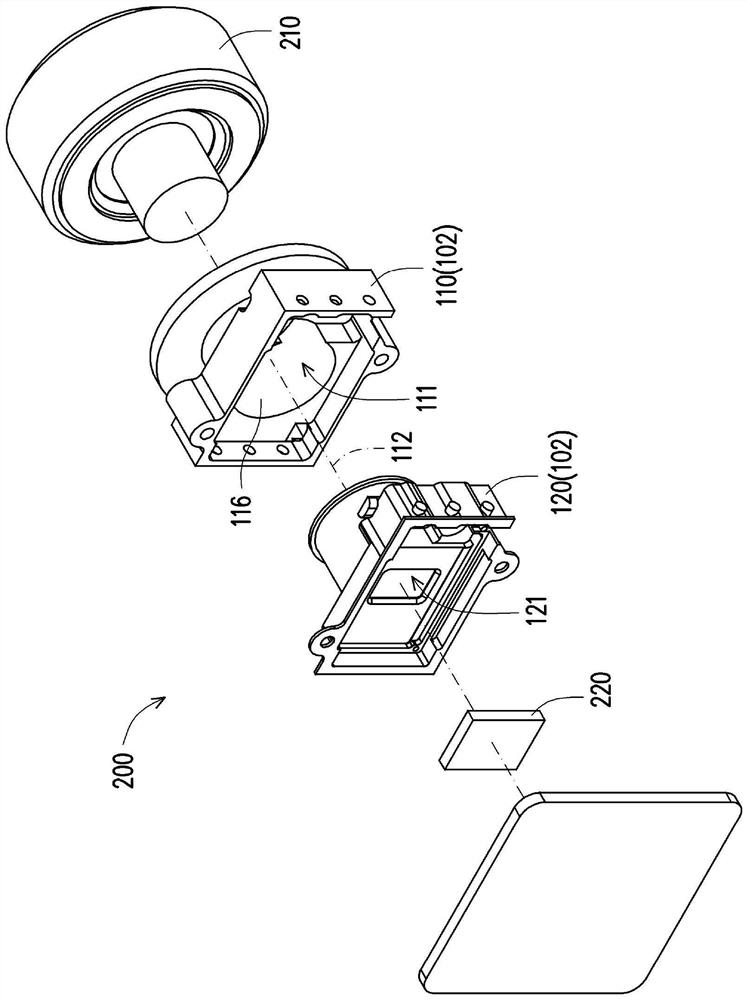

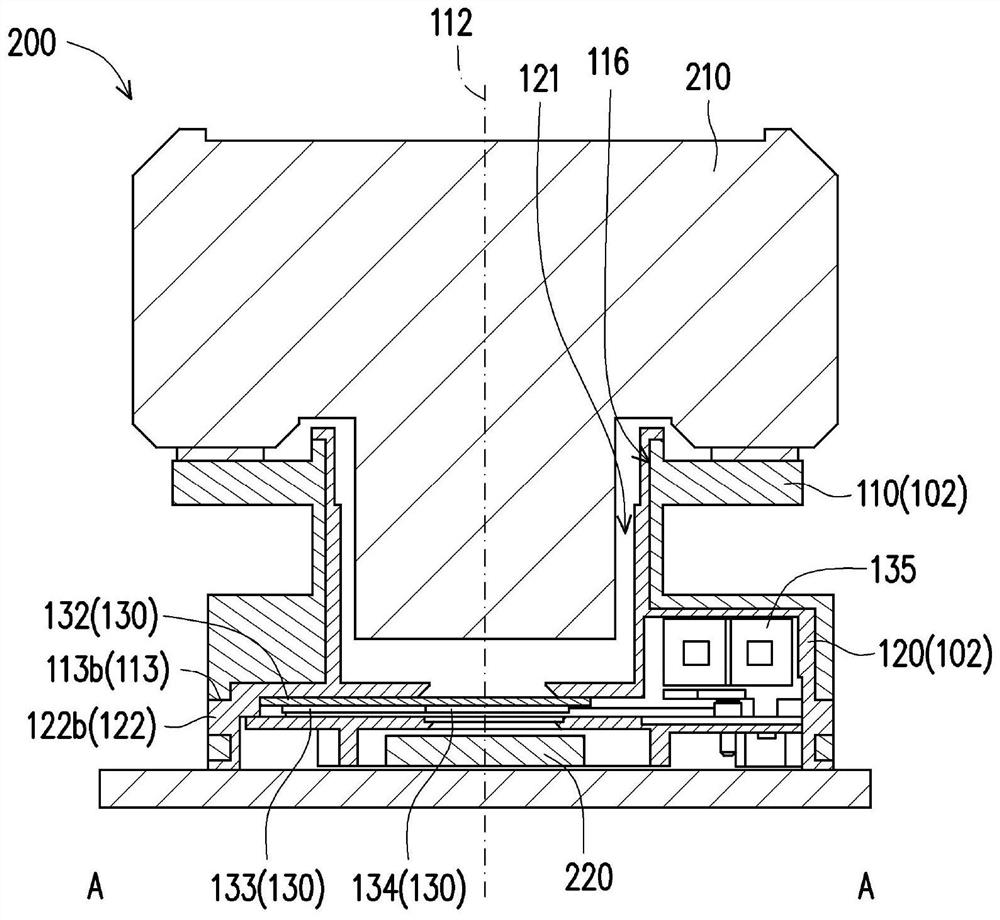

Filter Switcher Module Integrated with Lens

ActiveCN108267825BLow focus offsetSmall coefficient of thermal expansionMountingsThermal dilatationEngineering

The invention provides an optical filter switcher module integrated with a lens, which includes a housing component and an optical filter switcher. The shell assembly includes a first shell and a second shell. The first shell has a first through hole, and the first through hole extends along the axis. The second shell is arranged in the first shell along the axis and partially embedded in the first shell. The second housing has a second through hole corresponding to the first through hole. The coefficient of thermal expansion of the first housing in the direction along the axis is smaller than the coefficient of thermal expansion of the second housing in the direction along the axis. The filter switcher is configured on the second housing and partly corresponds to the position of the second through hole.

Owner:LITE ON TECH CORP

A kind of drug screener for western medicine

ActiveCN111389718BSolve wasteTo achieve the purpose of screening and grinding integrationSievingScreeningPharmacyWestern medicine

The invention discloses a drug screening device for western medicine, which comprises a base, a limited-slip kit is arranged on the front and rear sides of the top of the base, a hollow box is fixedly connected to the right side of the top of the base, and the limited-slip Both sides of the bottom of the kit are fixedly connected with bearing columns, and the bottom of the left bearing column is fixedly connected with the base. The invention is driven by the driving mechanism, and under the cooperative use of the groove box and the sieve hole 1, the preliminary screening of the medicine is carried out, and then the medicine with a larger radius is rolled and screened by the setting of the rolling mechanism, and finally qualified The medicament is transported to the inner cavity of the base, and the purpose of integrating screening and grinding can be achieved. The western pharmacy medicament screener solves the problem of the existing process of screening medicaments. Secondary processing, the process is time-consuming and labor-intensive, and the screening efficiency is low, and the problem of waste of chemicals may be caused during the screening process.

Owner:于永波

Bottom-adhered adcp probe sinking and floating system and its installation method, maintenance and debugging method

ActiveCN109341670BImprove efficiencyFrom personal dangerOpen water surveyMarine engineeringSolenoid valve

The invention discloses a bottom-attached ADCP probe sinking and floating system, which includes a floating and sinking mechanism, a trapezoidal plate and a control mechanism; the floating and sinking mechanism includes a circular support plate, the support plate is connected with an air bag, and the support plate is connected with a line summary plate; The edge is connected with the cable main pipe and the cantilever pipe, and the cantilever pipe is connected with the trapezoidal plate; the trapezoidal plate is connected with the ADCP probe through the cross-shaped hoop bracket; Extend along the cable main pipe to the river bank and connect with the control mechanism; the control mechanism includes an electric control device, a display screen, a deflation solenoid valve and an air pump. The invention also discloses an installation method and a maintenance and debugging method of the sinking and floating system of the bottom-attached ADCP probe. The invention floats each component to the water surface for maintenance and debugging. The maintenance and debugging work does not require wading and is no longer affected by flood seasons. Personnel are protected from personal dangers caused by wading operations, and the accuracy of flow measurement data is improved.

Owner:徐志国

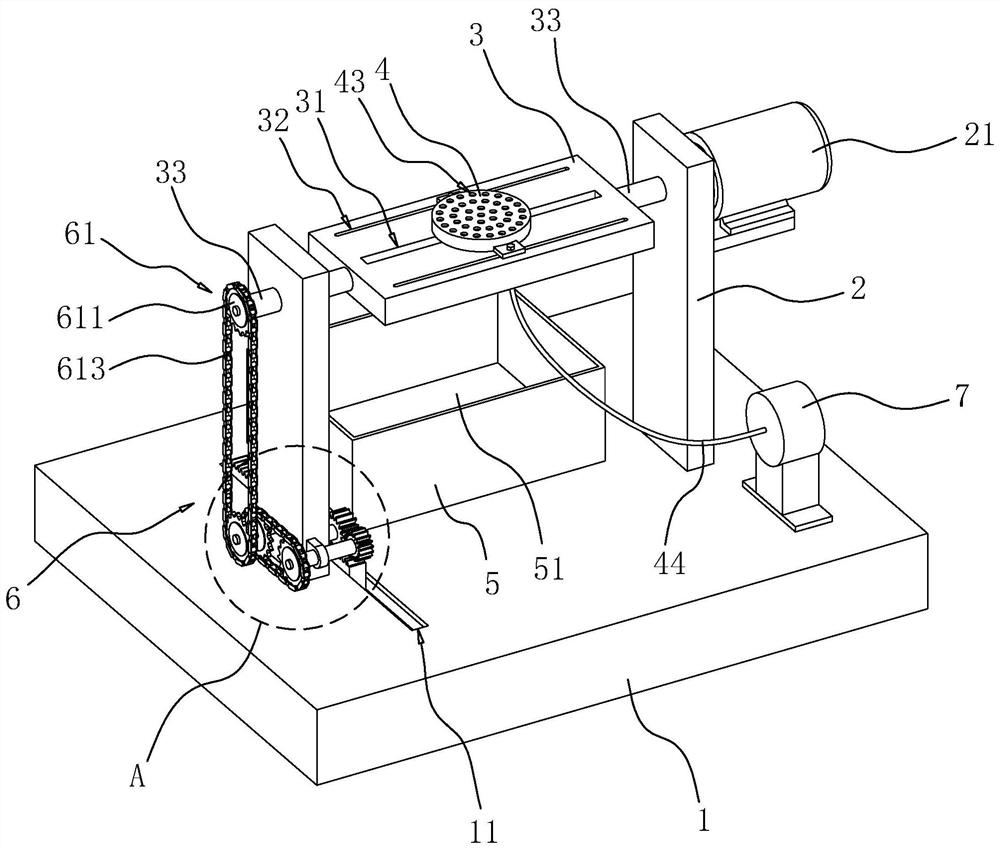

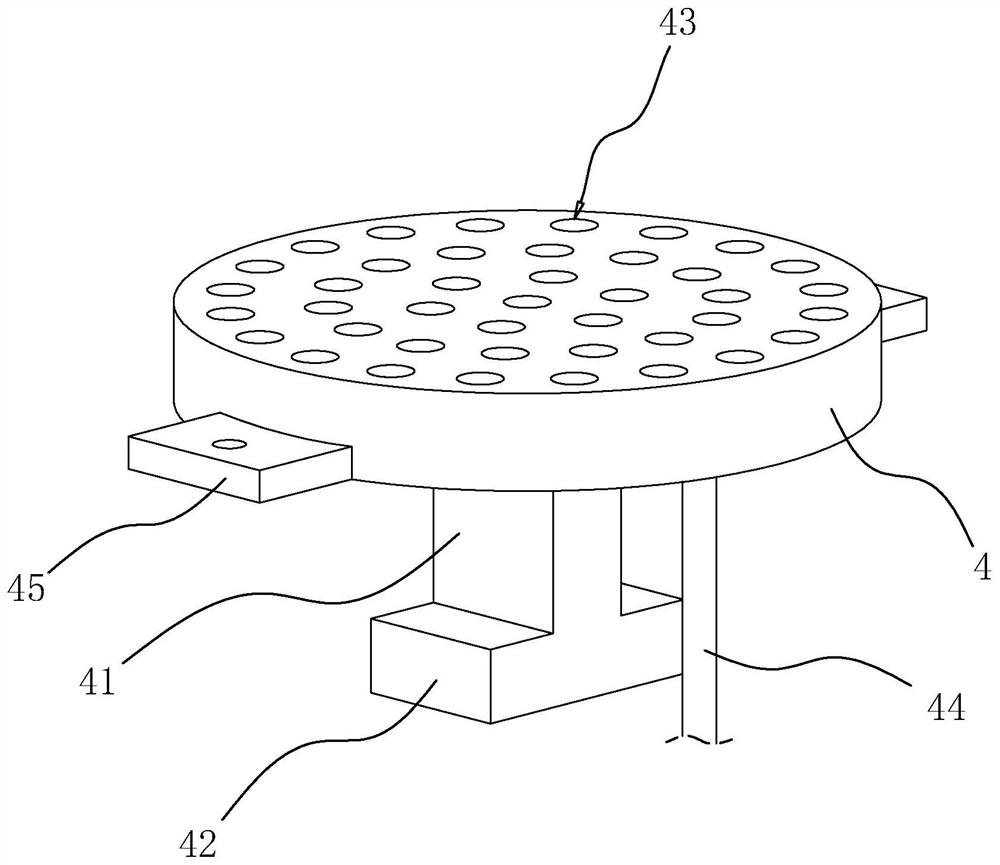

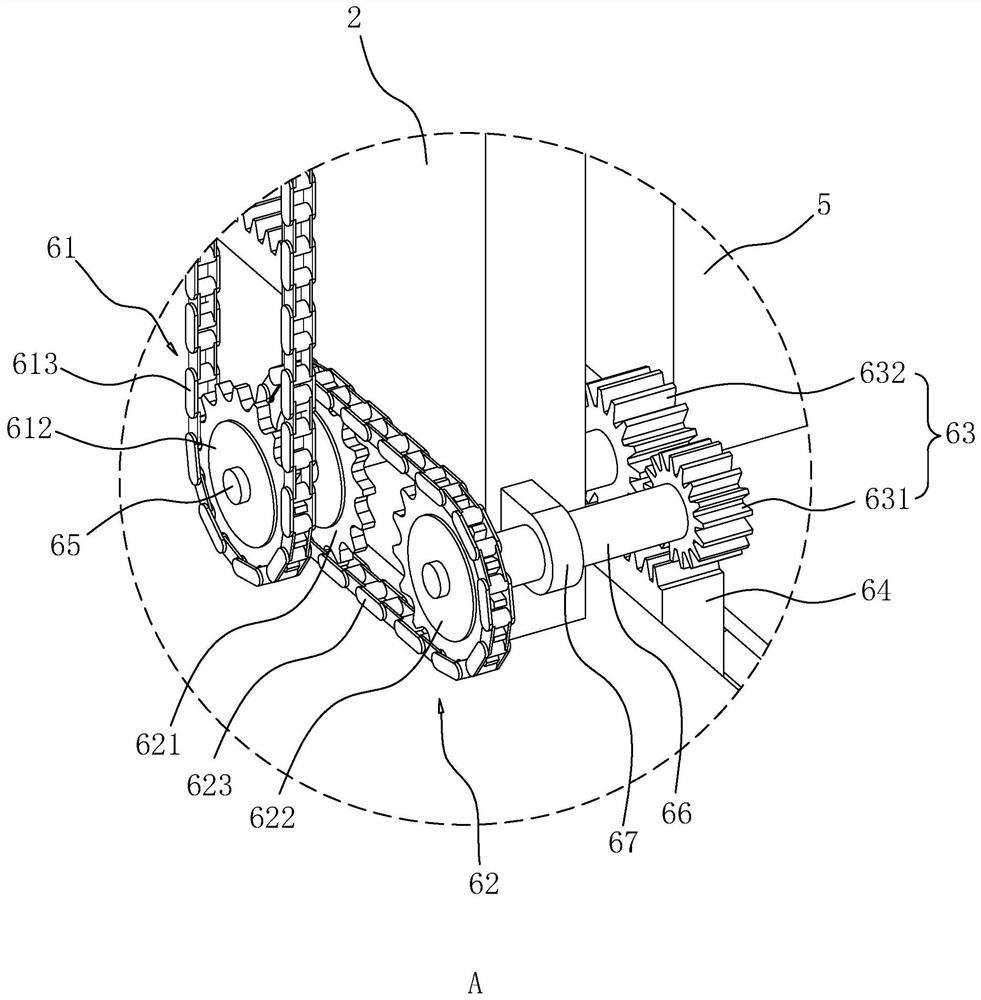

Electrical component test frame and operation process thereof

PendingCN113092830AAccurately fall onReduce bobbingStatic indicating devicesElectrical testingElectric machineTest frame

The invention relates to an electrical component test frame and an operation process of the test frame and belongs to the technical field of electrical tests. The test device comprises a test seat, two supporting plates fixedly connected to the testing seat, a testing bottom plate rotationally installed between the two supporting plates, a testing disc installed on an upper side of the testing bottom plate and a testing box installed on the testing seat and located between the two supporting plates, wherein the side walls, close to the two supporting plates, of the testing bottom plate are fixedly connected with rotating rollers respectively, and the rotating rollers penetrate through the close supporting plates respectively and are rotationally connected with the supporting plates; one supporting plate is fixedly connected with a driving motor which is fixedly connected with the rotating roller; and a transmission mechanism which is connected with the rotating roller and drives the testing box to slide along the upper surface of the testing seat is mounted on the other supporting plate. The test device has the effect of reducing the possibility that the electric appliance element cannot accurately fall into the test box after being thrown out.

Owner:深圳市众铭安科技有限公司

Efficient two-fluid water mist fire extinguishing device

An efficient two-fluid water mist fire extinguishing device comprises an equipment base, a fine water mist spray head connected to the equipment base, a water supply pipe connected to the fine water mist spray head, a pump set connected to the water supply pipe, a water storage barrel connected to the pump set and an air supply device connected to the fine water mist spray head. The air supply device comprises an air storage barrel, a pressure pump connected to the air storage barrel, an air outlet head connected to the water mist spray head and a connecting pipe connected between the air outlet head and the pressure pump; the air outlet head comprises a fixed base, a rotating base and a rotating motor used for driving the rotating base to rotate, the fixed base is fixedly connected to the water mist spray head, the fixed base, the rotating base and the water mist spray head are coaxially arranged, an air inlet is formed in the top of the fixed base, one end of the connecting pipe is fixedly connected to the air inlet, an air spraying opening is formed in the rotating base, a sealing ring is arranged between the rotating base and the fixed base, and the interiors of the rotating base and the fixed base are hollowed out.

Owner:ZHEJIANG YOUAN GAOKE FIRE FIGHTING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com